Preparation equipment and process of high-strength magnesia carbon brick for refining ladle

A high-strength, magnesia-carbon brick technology, used in manufacturing tools, supply devices, forming conveyors, etc., can solve problems such as low efficiency and different densities of refractory bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

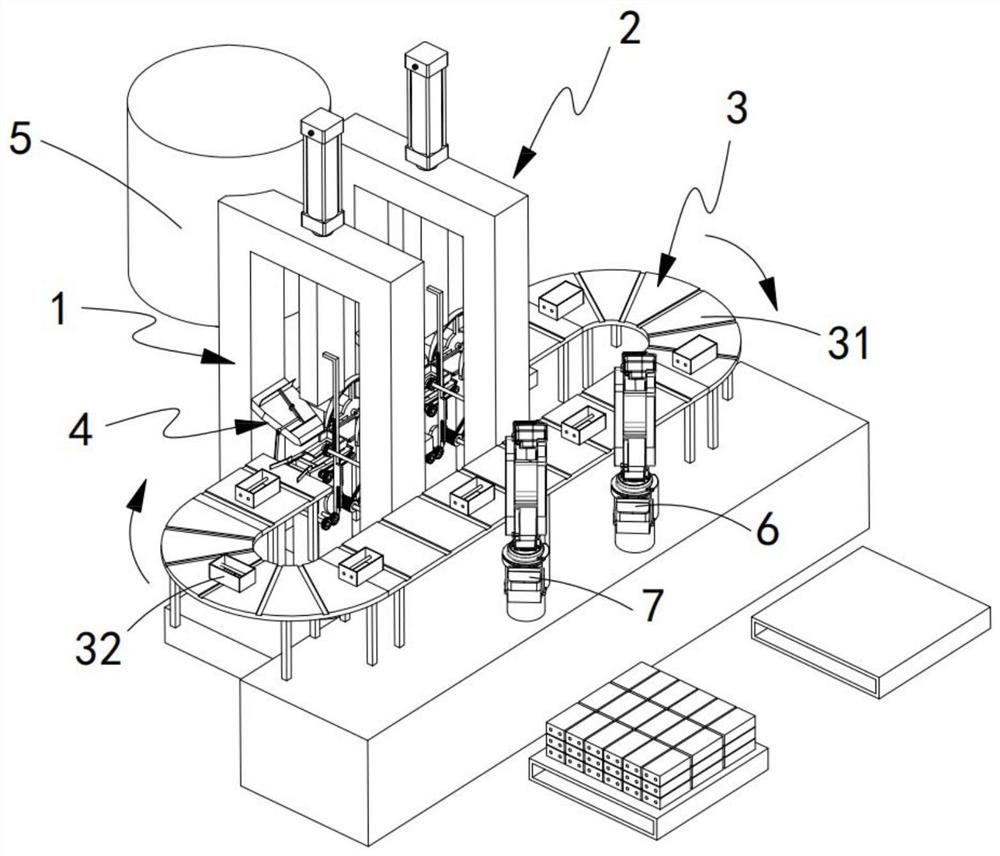

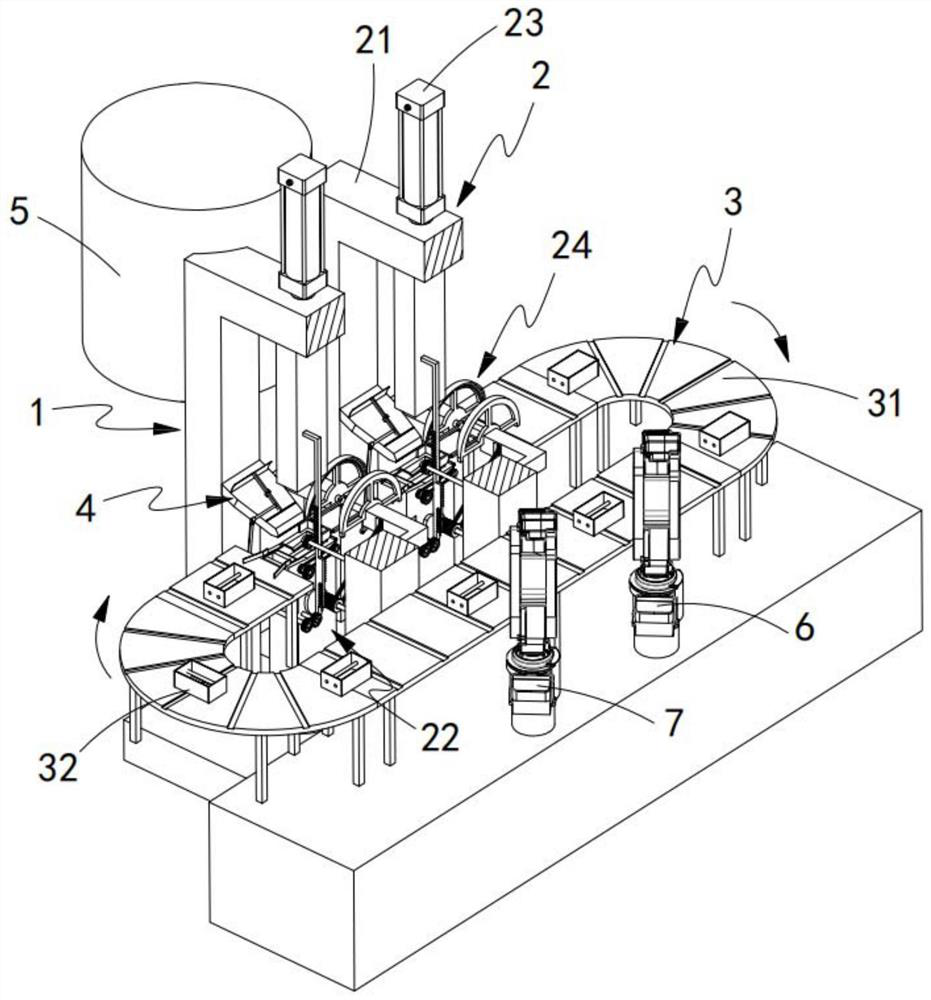

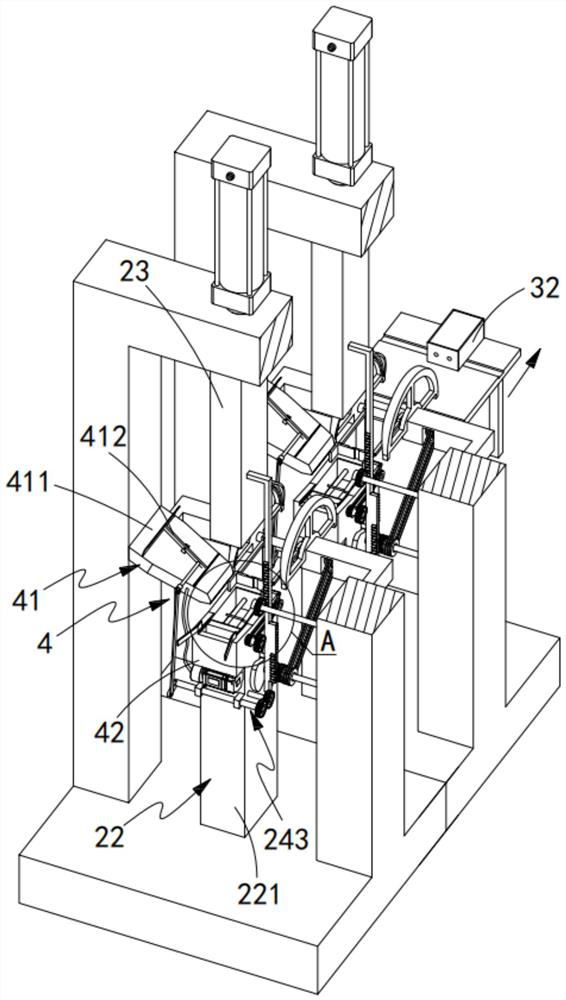

[0067] Such as Figure 1 to Figure 6 As shown, a high-strength magnesia-carbon brick preparation equipment for refining ladles includes: a first pressing device 1, a second pressing device 2 arranged on one side of the first pressing device 1, a mold circulation device 3 and a powder adding device 4;

[0068] Both the first pressing device 1 and the second pressing device 2 include a frame 21, a cavity assembly 22, a die assembly 23 and a transmission assembly 24, and the cavity assembly 22 is vertically arranged on the frame 21 The bottom includes an outer column 221 integrally connected to the frame 21 and a thimble 222 constrained in the outer column 221 and can only slide along the length direction of the outer column 221, and the thimble 222 is located on the outer column 221. At the bottom of the column 221, the thimble 222 and the outer column 221 form a mold cavity 223, and the die assembly 23 is arranged on the top of the frame 21 facing the cavity assembly 22;

[0...

Embodiment 2

[0103] Such as figure 1 , 2 As shown in and 15, a preparation process for high-strength magnesia-carbon bricks for refining ladles comprises the following steps:

[0104] Step 1, the upper mold 32, the mold circulation device 3 transports the mold 32 to the mold cavity assembly 22 in the first pressing device 1, and the mold 32 is introduced into the mold cavity assembly 22 by the mold introduction assembly;

[0105] Step 2, adding powder, the die assembly 23 continues to rise to drive the powder adding device 4 to open the mold cavity 223 to add powder;

[0106] Step 3, primary pressing, the die assembly 23 descends to perform the first pressing on the powder;

[0107] Step 4, secondary pressing, the die assembly 23 rises, drives the rack frame 2411 to drive the cleaning wheel set 25 to move, and the cleaning wheel set 25 drives the gripper 2424 to move to clean and collect the excess powder on the outer column 221 mouth to the auxiliary adding assembly 42 , when the die a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com