Foaming method for thermal insulation layer of polyurethane foaming thermal insulation pipe

A polyurethane and thermal insulation pipe technology, which is applied in the foaming field of the thermal insulation layer of polyurethane foam thermal insulation pipes, can solve the problems of easy occurrence of voids in the thermal insulation layer and low operating efficiency, and achieve the effects of avoiding voids, uniform distribution, and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

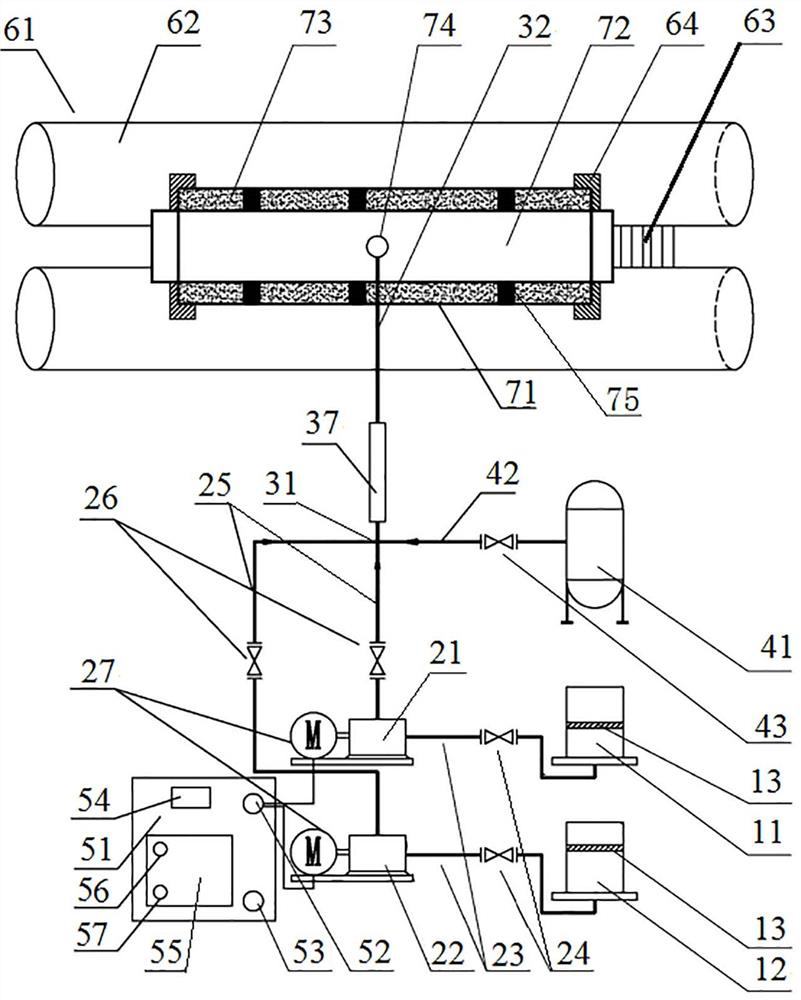

[0039]The foaming method of the insulation layer of the polyurethane foam insulation pipe in this embodiment is used for foaming the insulation layer 73 of the polyurethane foam insulation pipe for heating in the oil field, between the inner pipe 72 and the outer pipe 71 of the polyurethane foam insulation pipe of the pipeline The intertube annulus is injected with foam material. In this embodiment, the outer diameter of the polyurethane foam insulation pipe is φ219 mm, and the material of the insulation layer 73 is polyisocyanate and combined polyether. The inner pipe 72 can be a steel pipe or an anti-corrosion pipe, and the outer pipe 71 is a polyethylene protective pipe.

[0040] The foaming method of the insulation layer of the polyurethane foam insulation pipe is as follows: figure 1 and figure 2 The foaming device for the insulation layer of the polyurethane foam insulation pipe shown, the foaming device for the insulation layer includes six subsystems, namely the mat...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, a transparent pipe section 37 is provided between the outlet of the injection pipe 32 and the gas injection joint 36 . In this embodiment, the injection pipe 32 is a whole pipe, which is directly connected to the gas injection joint 36 .

Embodiment 3

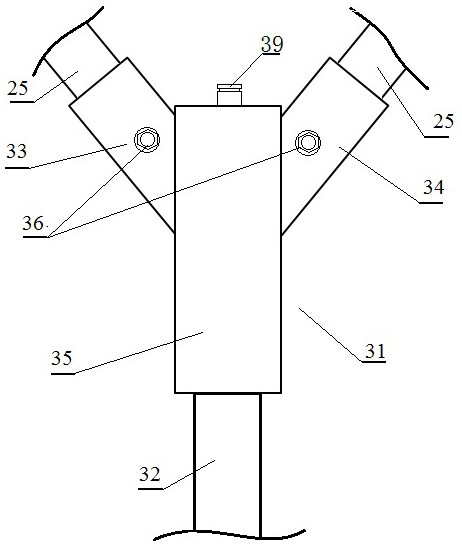

[0061] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the manifold joint 31 includes a first feed port 33 connected to the first feed pump 21, a feed port 33 connected to the second feed pump 22, The second feed end 34 and the discharge end 35 connected with the injection pipe 32 form a Y-shaped structure. In this embodiment, however, the first feed end 33 and the second feed end 34 are arranged in line, forming a T-shaped structure with the discharge end 35 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com