Detecting method for double-curvature skin part of airplane

A technology for skin parts and hyperbolicity, which is applied in the field of aircraft manufacturing, can solve the problems of inability to determine the degree of mold sticking, affecting the accuracy of aircraft shape and other problems, so as to improve reliability and measurement accuracy, easy to implement and popularize, and simple to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

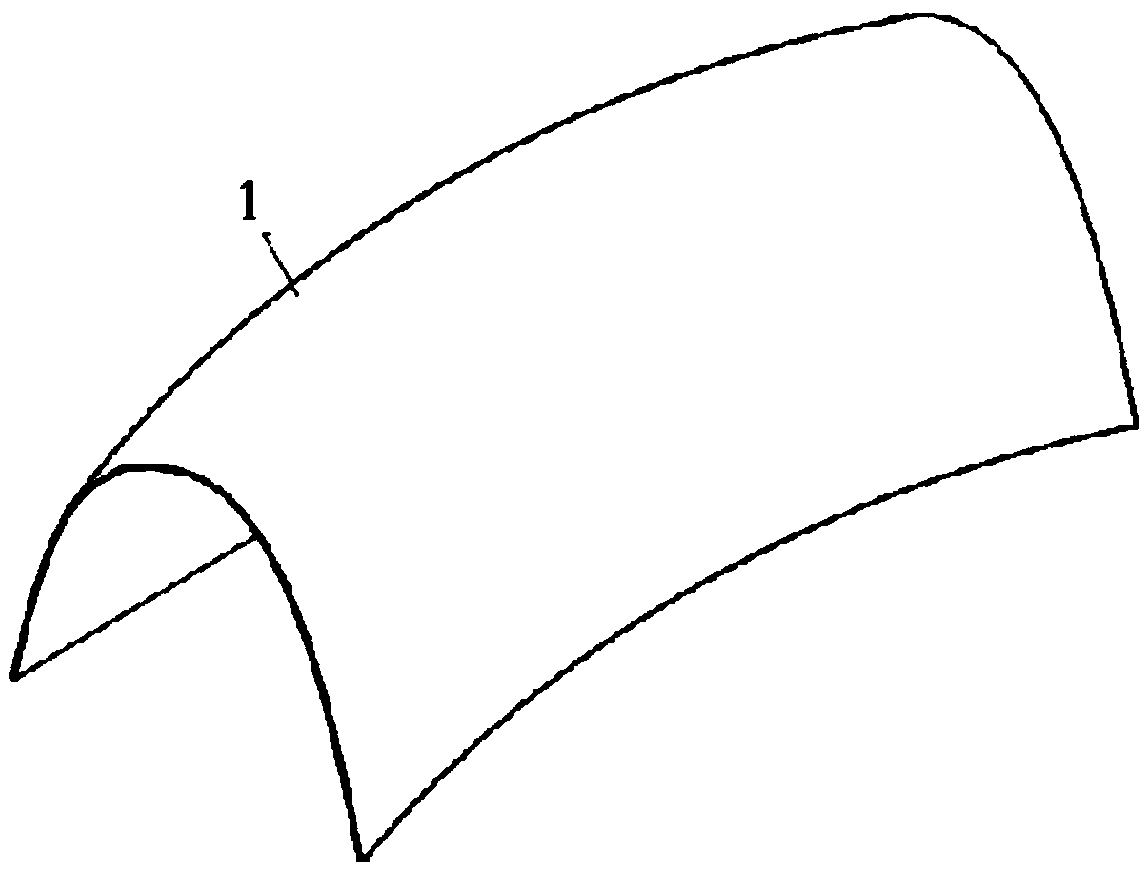

[0016] See attached figure 1 , in actual production, during the processing of the double curvature skin part 1 of the aircraft, due to the extremely uneven deformation of the sheet metal, it is easy to have the problem of inconsistent molding gap between the edge and the non-visible area in the middle; the current conventional detection method can only detect the edge Contour fit degree, there are detection blind spots in most of the space areas, and it is easy to appear stressful assembly and affect the accuracy of aircraft shape.

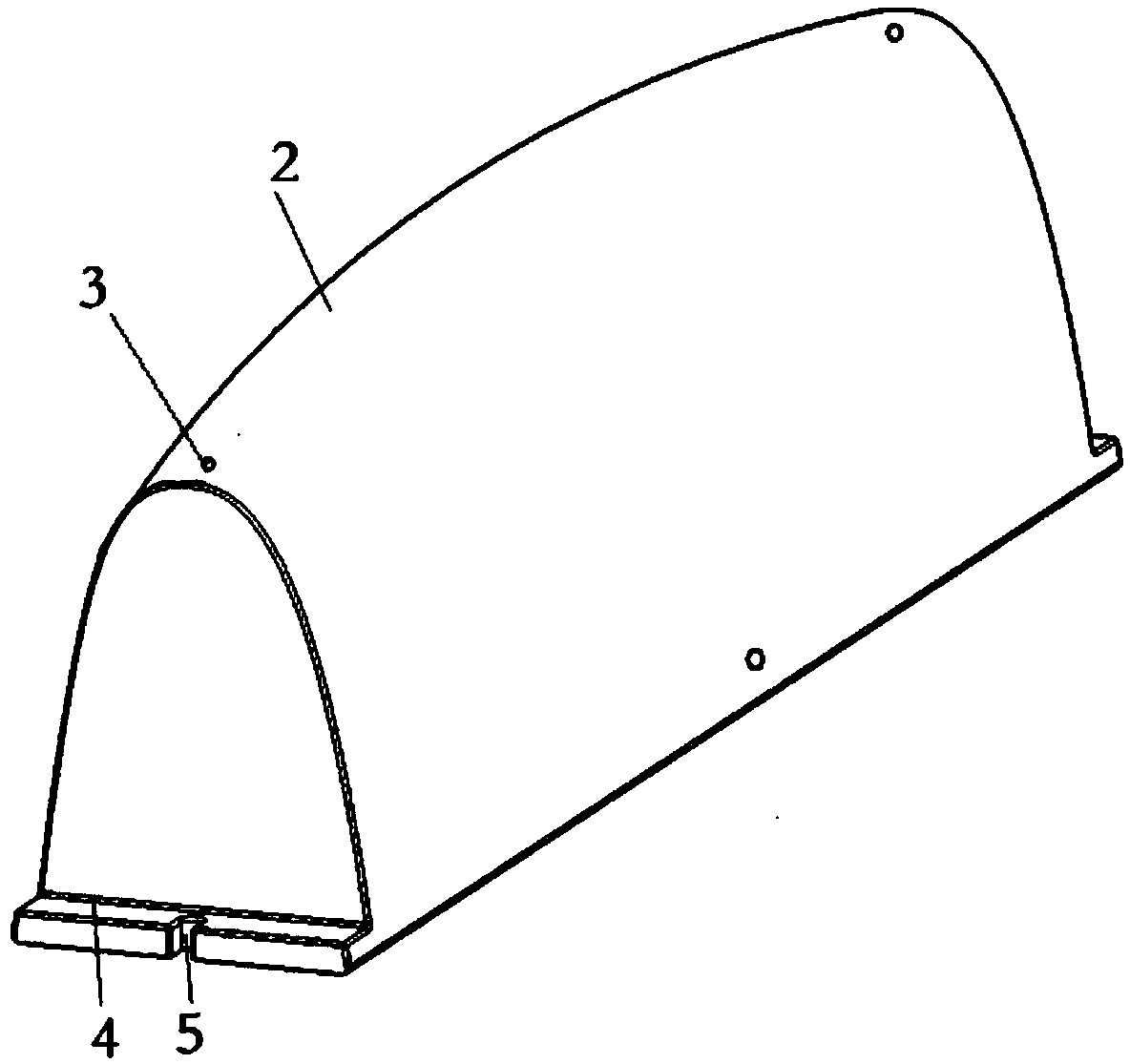

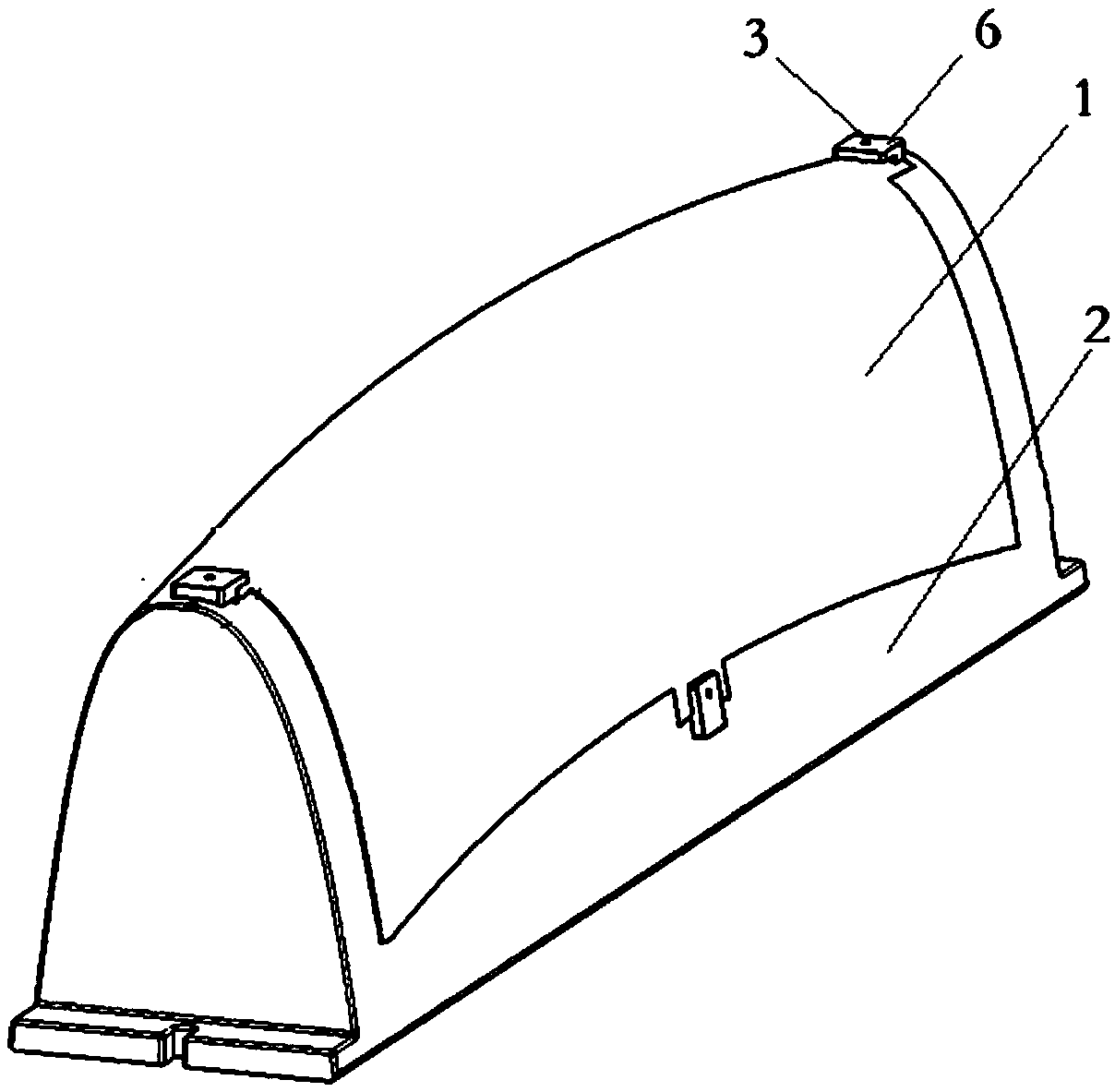

[0017] The detection method of aircraft hyperbolic skin part 1 that the application proposes, the theoretical model of known hyperbolic skin part, 1) has a detection mold tire 2, is provided with the convex shape that matches with skin theory model on it The convex surface is the detection reference surface, and there are at least two reference holes 3 on it. The reference holes 3 correspond to the positioning holes on the hyperbolic skin part 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com