Hybrid power four-wheel drive configuration method for electrifying internal combustion power vehicle

A technology of hybrid power and configuration method, which is applied to the layout of multiple different prime movers of hybrid vehicles and general power devices, power devices, etc., and can solve the problems of increasing weight, shortening maintenance cycles, rare earth shortage resource consumption and mining and processing environmental issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

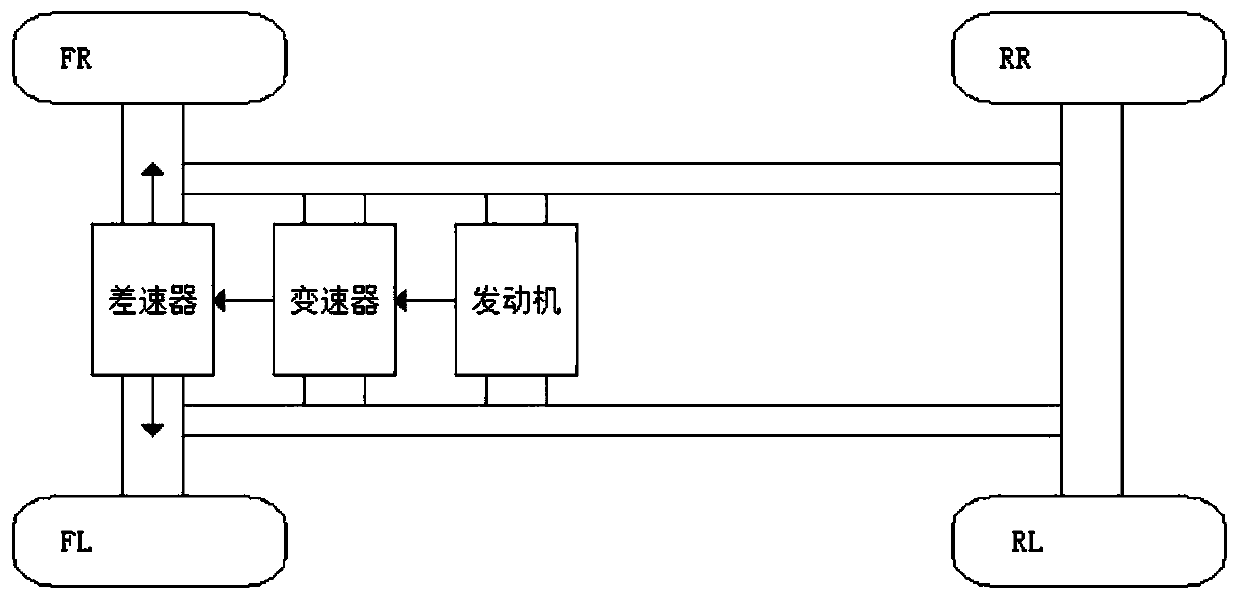

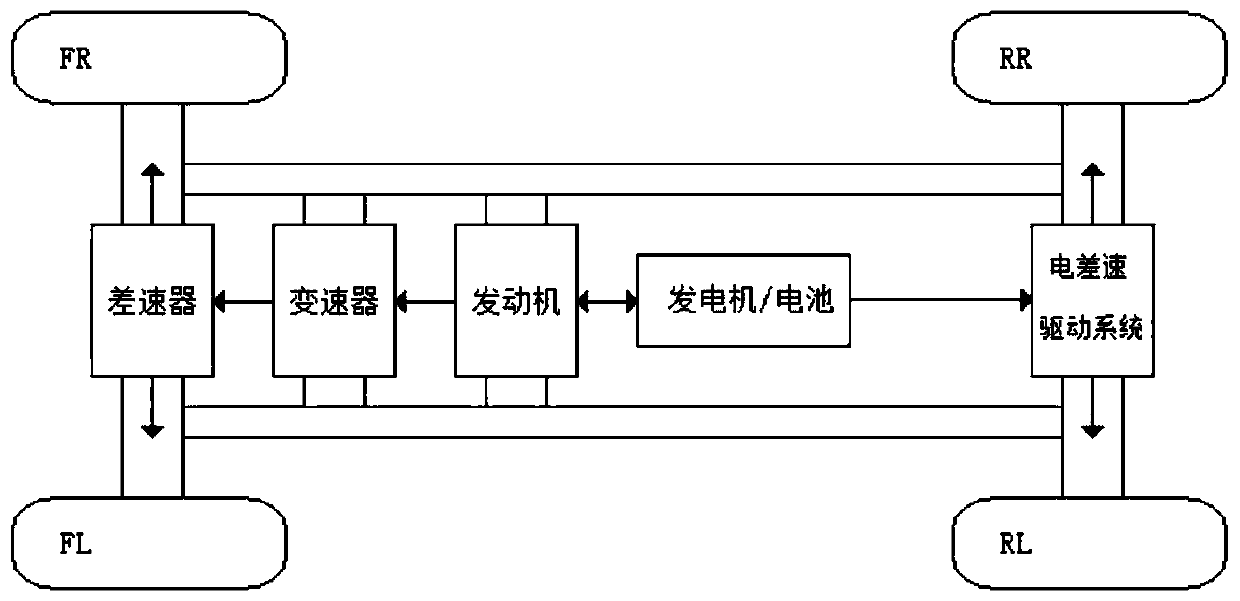

[0119] This embodiment provides a hybrid four-wheel drive configuration method for electrifying fuel vehicles, such as image 3 As shown, the internal combustion power part includes an engine, a transmission, and a mechanical differential. The power configuration of the internal combustion power part is that the two front wheels are driven by internal combustion power; its technical feature is that an electric differential drive system is set. The rear wheels provide power, and this power configuration separates the internal combustion power part and the electric drive part, which belong to the front axle drive and rear axle drive, and can also be set as independent drives, that is, only the internal combustion power part of the front drive can be used , Turn off the electric drive part of the rear drive, so that the electric drive part is called a slipping state, and the braking power generation function of the rear drive part can also be used to store it in the battery. It i...

Embodiment 2

[0127] This embodiment provides a hybrid four-wheel drive configuration method. The hybrid four-wheel drive is equipped with an electric differential drive system, which includes an electronically controlled quasi-differential lock control system that cancels the mechanical differential. The quasi-differential control system is configured with two three-phase AC motors for the first A motor and a second motor, such as Figure 8 As shown, the three-phase windings that the first motor has are the first winding (1), the second winding (2) and the third winding (3), and the first and last terminals of the first winding (1) are respectively 11 and 12, The first and last two terminals of the second winding (2) are respectively 21 and 22, the first and last two terminals of the third winding (3) are respectively 31 and 32, and the three-phase winding that the second motor has is the fourth winding (4), The fifth winding (5) and the sixth winding (6), the first and last two terminals...

Embodiment 3

[0142] Provides a hybrid four-wheel drive configuration method, Figure 12 A differential speed control system for two motors is shown.

[0143]In this method, the three control switches K1, K2 and K3 included in the quasi-differential lock control circuit (2000) of Embodiment 2 are also provided with respective signal input terminals, and the quasi-differential lock control circuit also includes a conduction rate modulation circuit (1000), the conduction rate modulation circuit (1000) has three signal output terminals correspondingly connected with the signal input terminals of switches Ka, Kb and Kc, and is used to respectively control three switches Ka, Kb and Kc through the conduction rate modulation circuit The conduction rate Cy (Conductivity) of each of the two control terminals of Kc. Wherein, corresponding to each control switch, isolating circuits 2001, 2002 and 2003 are arranged, so as to obtain a better signal matching relationship between the conduction ratio mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com