Fluororubber plate cementing, pressurizing and curing method and device

A fluororubber sheet, pressurized curing technology, applied in the field of non-metallic materials, can solve the problems of existence of cavities, inability to vacuumize and cure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

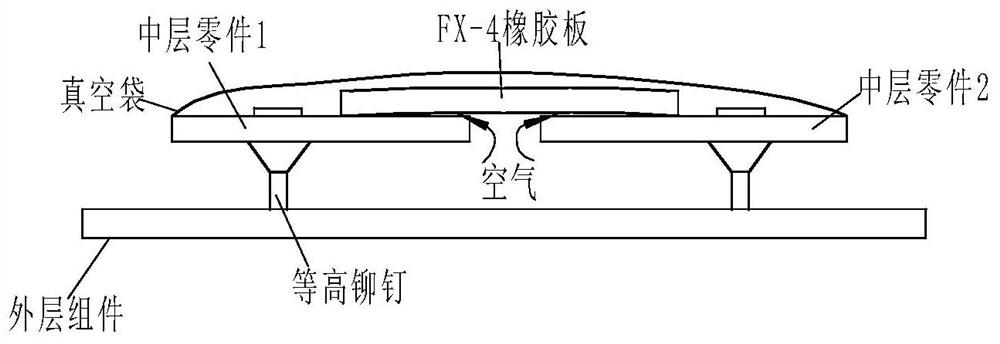

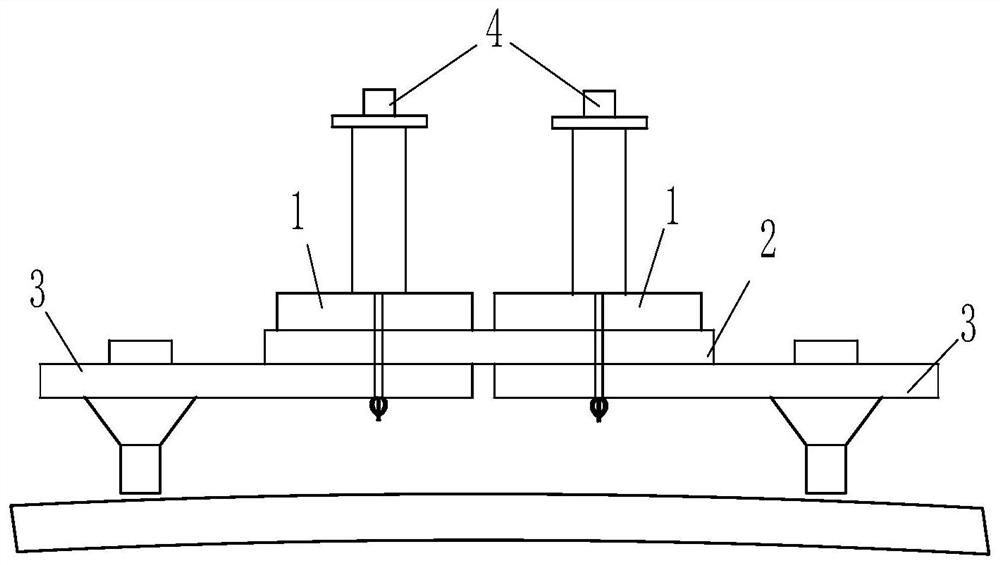

[0033] The method and device for gluing and pressurizing fluororubber panels provided by the present invention will be explained below in conjunction with the accompanying drawings.

[0034] refer to figure 1 and figure 2 , the invention solves the technical difficulty that the fluororubber board cannot be pressurized and solidified after being glued in the production process, and lays a good technical foundation for product production.

[0035] The main content of the present invention includes: in the process of product processing, by designing and manufacturing the first pressing plate and the second pressing plate that are consistent with the curvature changes of the bonding surfaces of the first part and the second part to be bonded, and the first pressing plate A row of process holes is preset on the second platen. In the bonding process, first, the fluororubber plate is bonded to the bonding surface of the first part and the second part. Then the first pressing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com