Punching die structure of side face side wall hole

A punching and mold technology, applied in the direction of punching tools, manufacturing tools, metal processing equipment, etc., can solve the problems of uneven side walls of square holes, many square hole processing procedures, and high processing costs, so as to achieve reasonable punching technology and mold Reasonable and ingenious structural design, high punching quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention are further described below in conjunction with the accompanying drawings, but are not limited to the following embodiments. Because those skilled in the art can refer to this punching die structure design punching process method and idea to make various modifications and improvements to other specific embodiments, modify or supplement or use similar methods to replace.

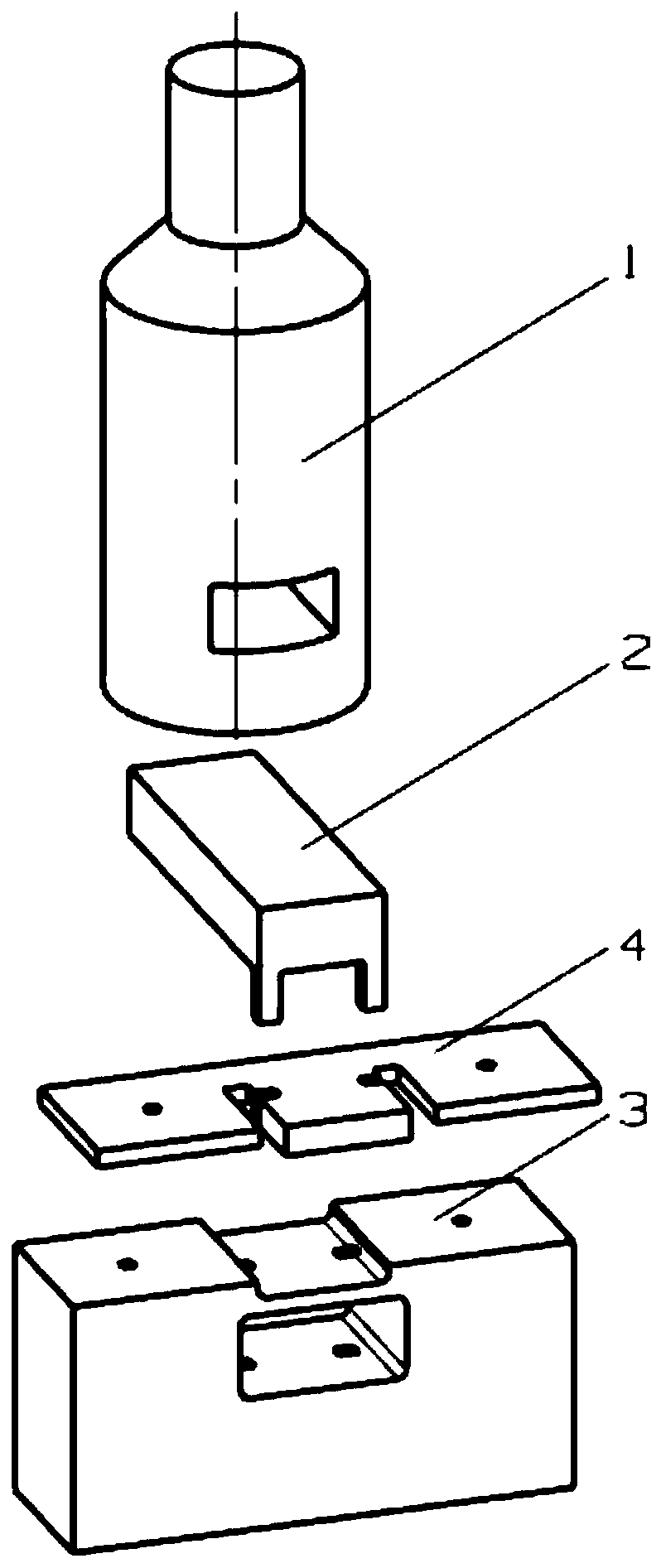

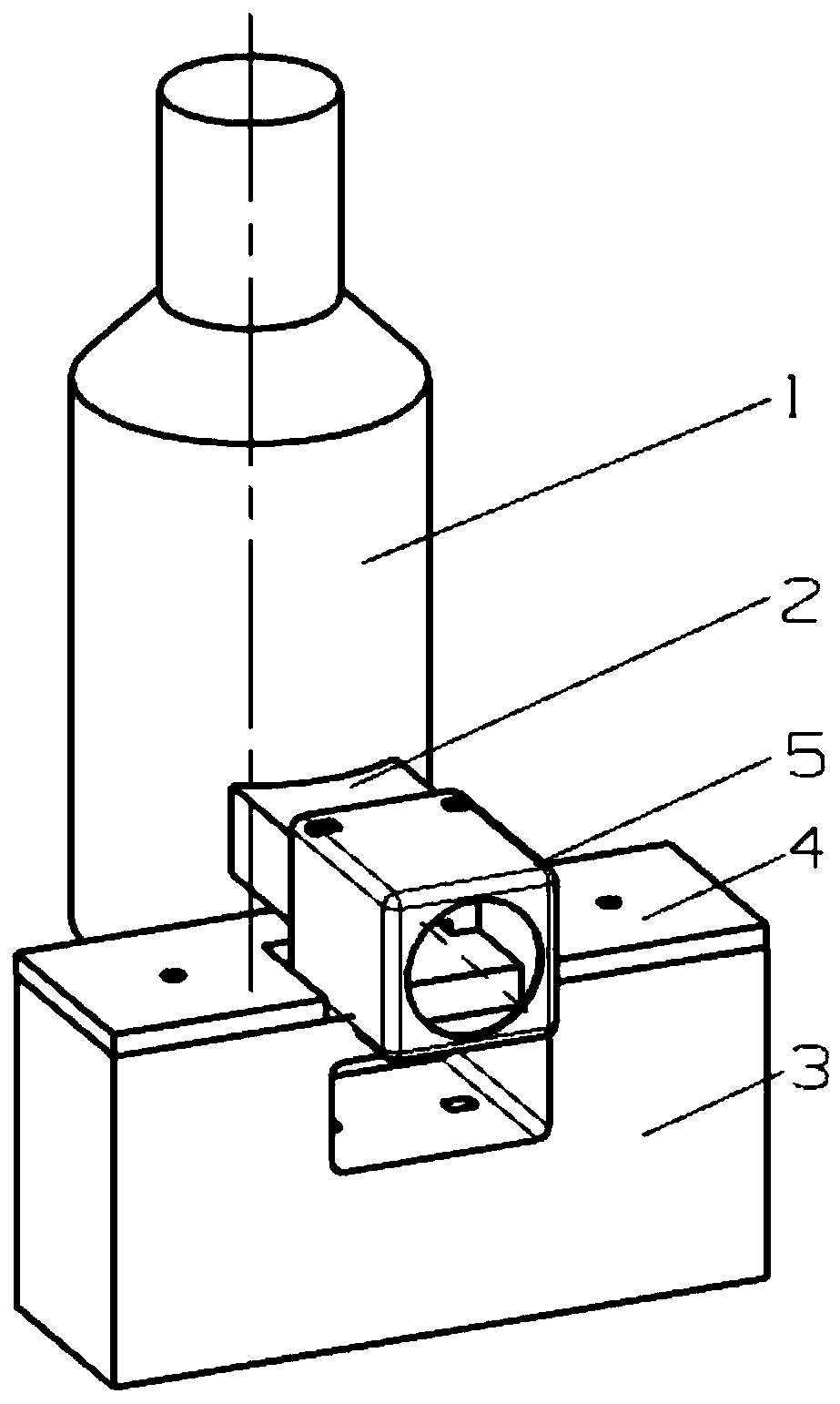

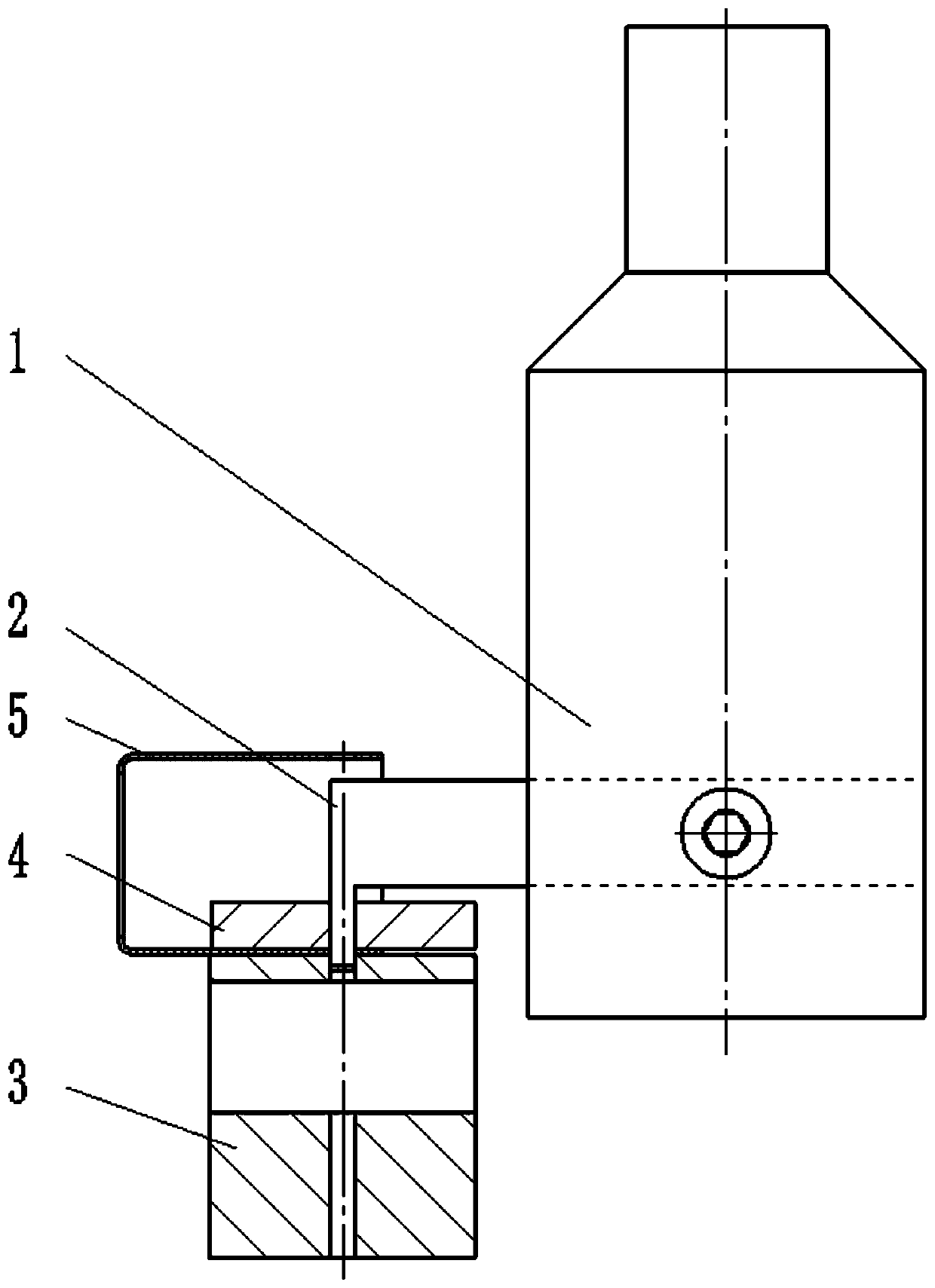

[0026] like figure 1 As shown, a punching die structure with side wall holes, the punching technology principle is that the punch and die are reversed, and the die is designed on the outer surface of the shell part, and the size of the die is no longer limited by the internal space of the shell parts , can be fully extended along the outer wall of the side of the shell. When working, the punch is placed inside the shell part, and the punch punches from the inner cavity to the outside. blade. This structure at least punch fixed block, punch, die, bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com