Building formwork assembly and aluminum alloy window frame installation method

A technology of building formwork and installation method, which is applied to the on-site preparation of building components, construction, and window/door frames, etc., can solve the problems of low dimensional accuracy of aluminum alloy window frames, low construction progress, poor waterproof performance, etc. The effect of installation and construction cost, improvement of project construction progress, and high installation flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

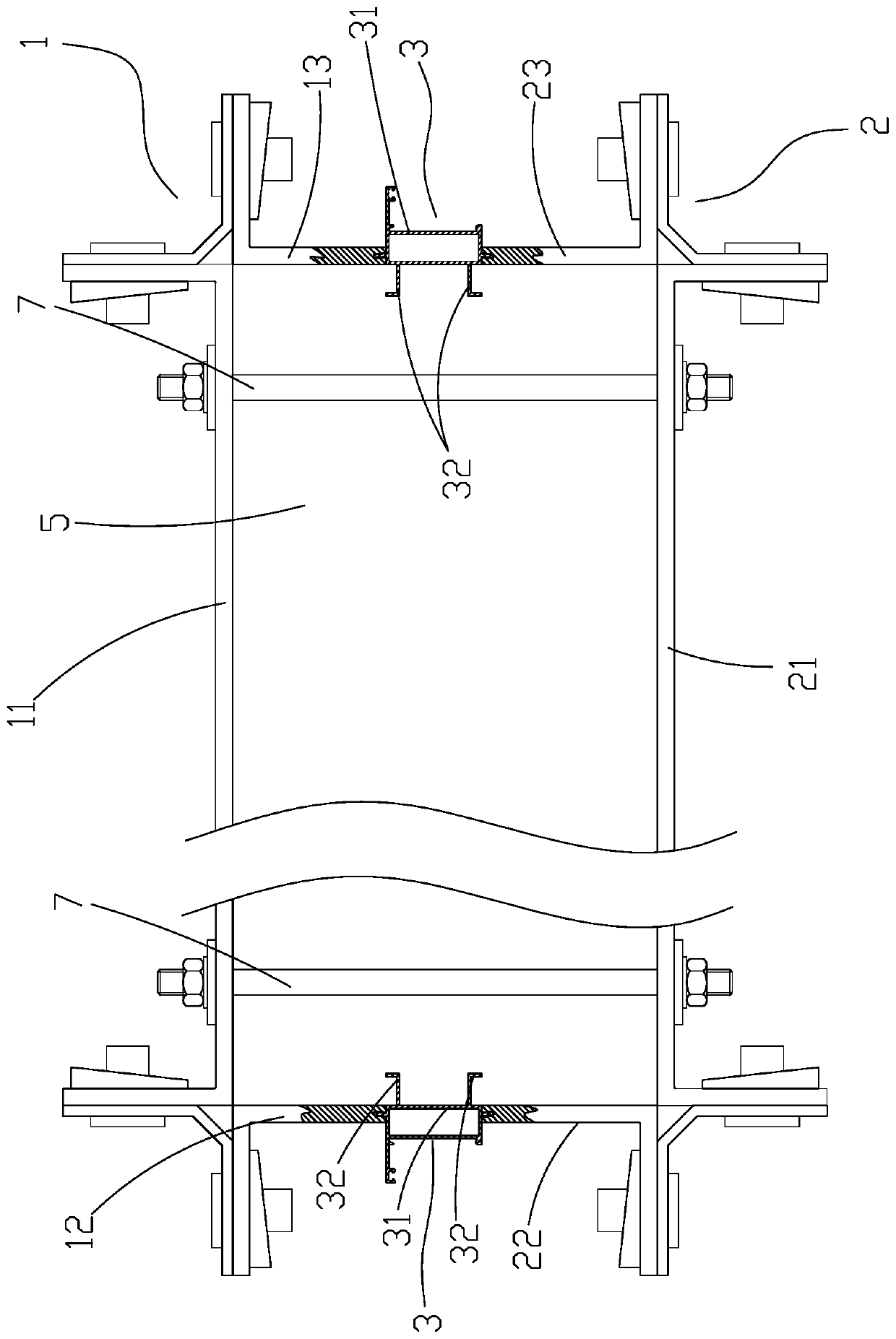

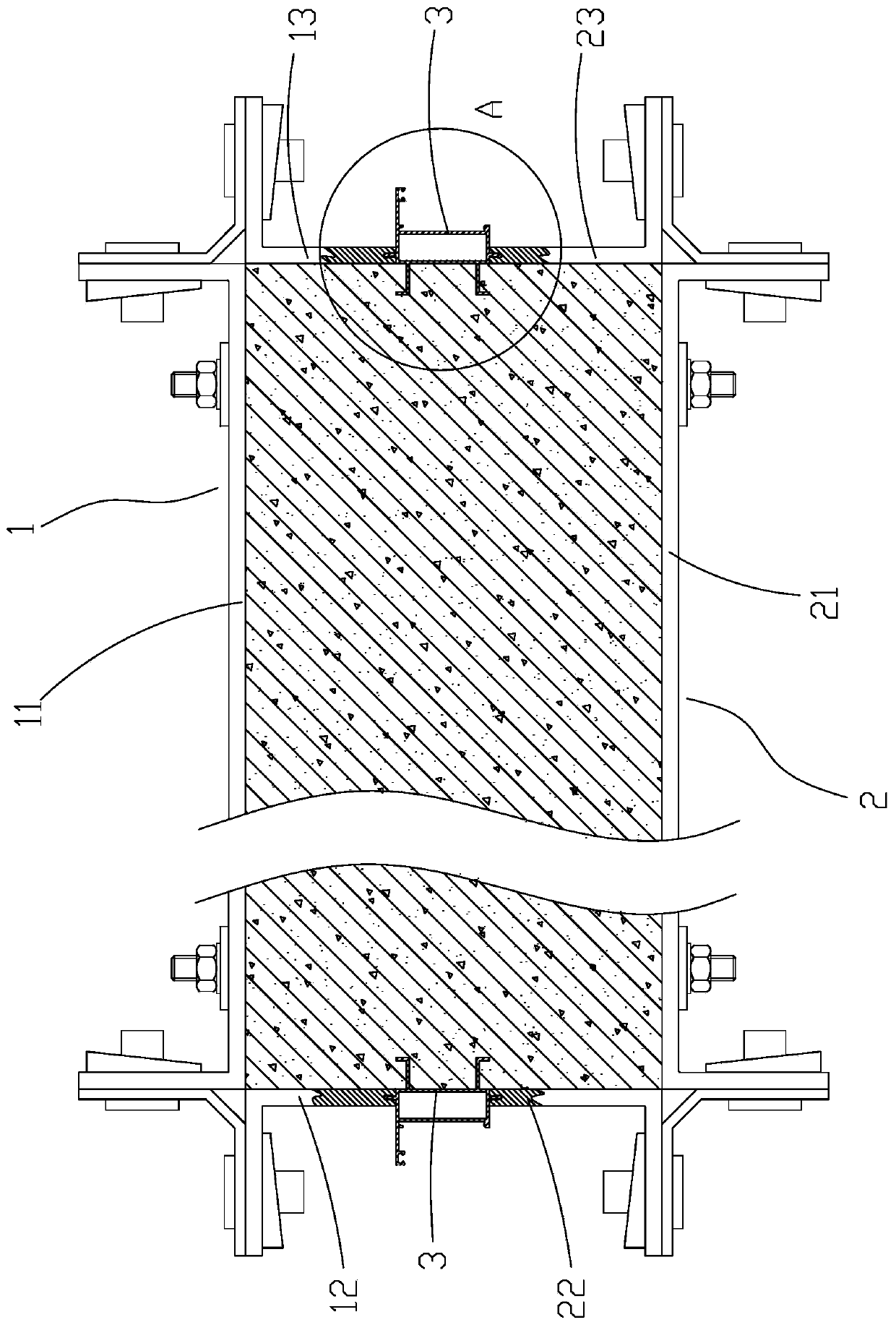

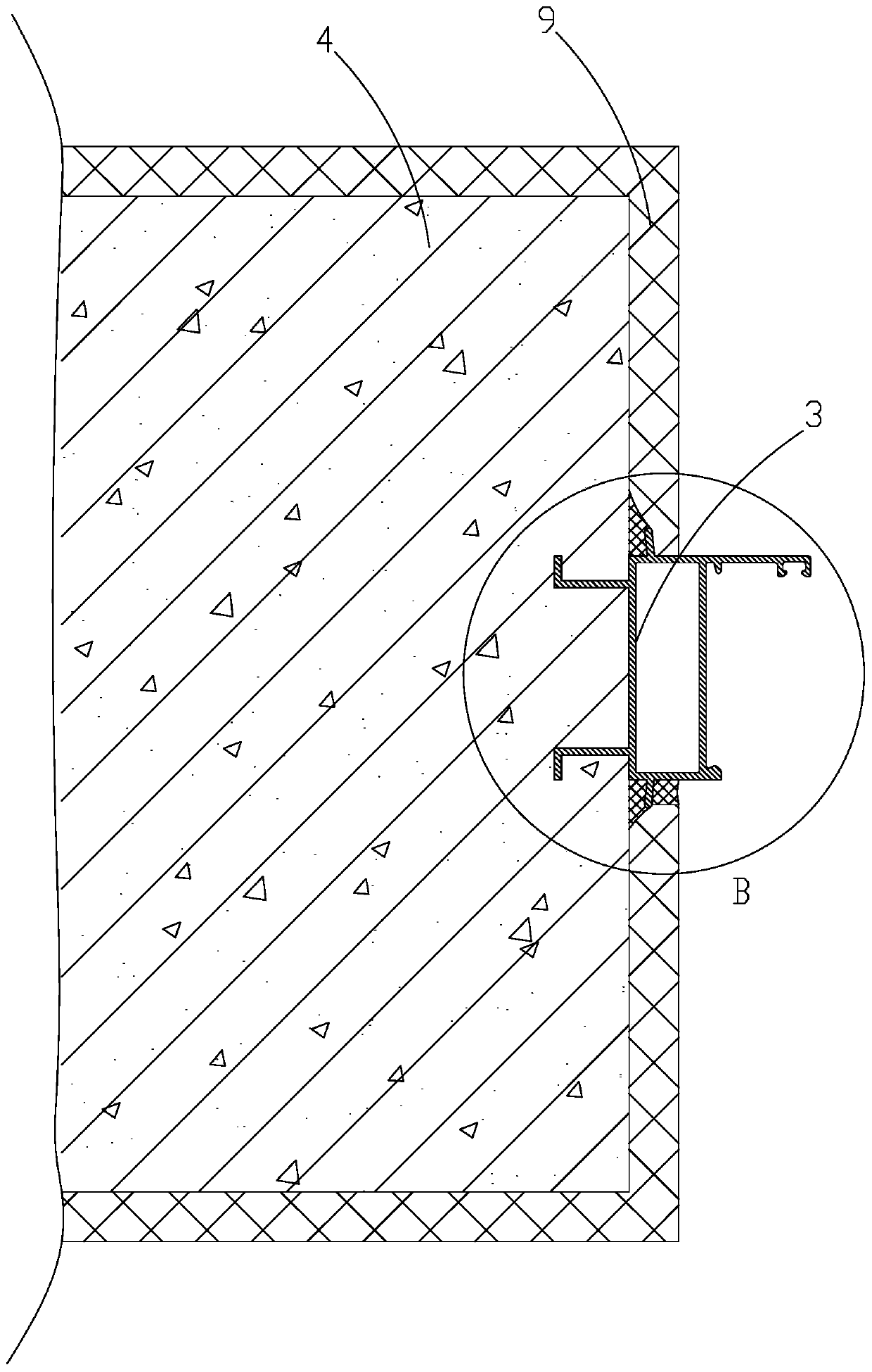

[0032] Such as Figure 1 to Figure 5 As shown, a building formwork assembly includes a front formwork assembly 1 and a rear formwork assembly 2, and the front formwork assembly 1 and the rear formwork assembly 2 are provided with a The separated aluminum alloy window frame 3, the front mold assembly 1, the rear mold assembly 2 and the aluminum alloy window frame 3 enclose a mold cavity 5 for pouring the concrete wall 4, and the aluminum alloy window frame 3 It includes a frame body 31 , and the frame body 31 is provided with embedding ribs 32 that extend into the mold cavity 5 and can be embedded in the concrete wall body 4 . The aluminum alloy window frame 3 becomes a part of the building formwork assembly. During the pouring process of the concrete wall 4, the embedded ribs 32 on the aluminum alloy window frame 3 are poured into the concrete wall 4, so that the aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com