A quenching method for aerodynamic thermoforming of complex components of ultra-high-strength steel

An ultra-high-strength steel and ultra-high-strength technology, applied in quenching devices, forming tools, heat treatment furnaces, etc., can solve the problems of high design cost of cooling system, high cost of cooling pipeline design, and large thermal shock damage of molds, etc., to achieve Reduce the difficulty of forming technology and manufacturing cost, the effect of low technical implementation difficulty and high mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

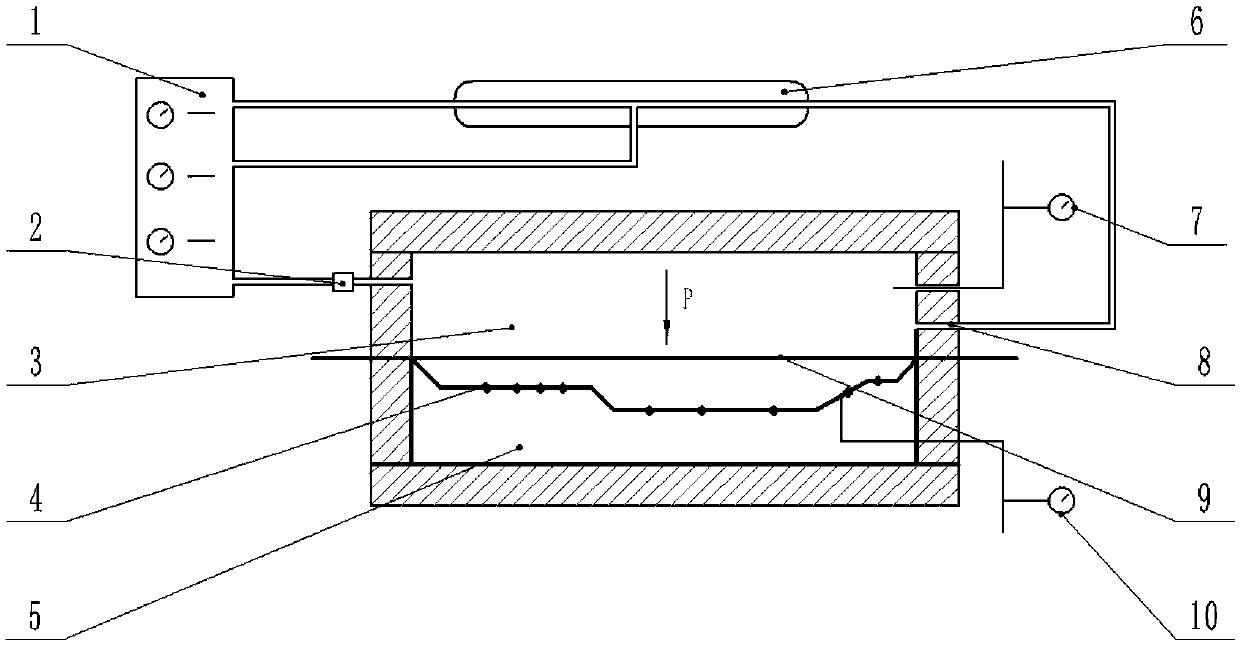

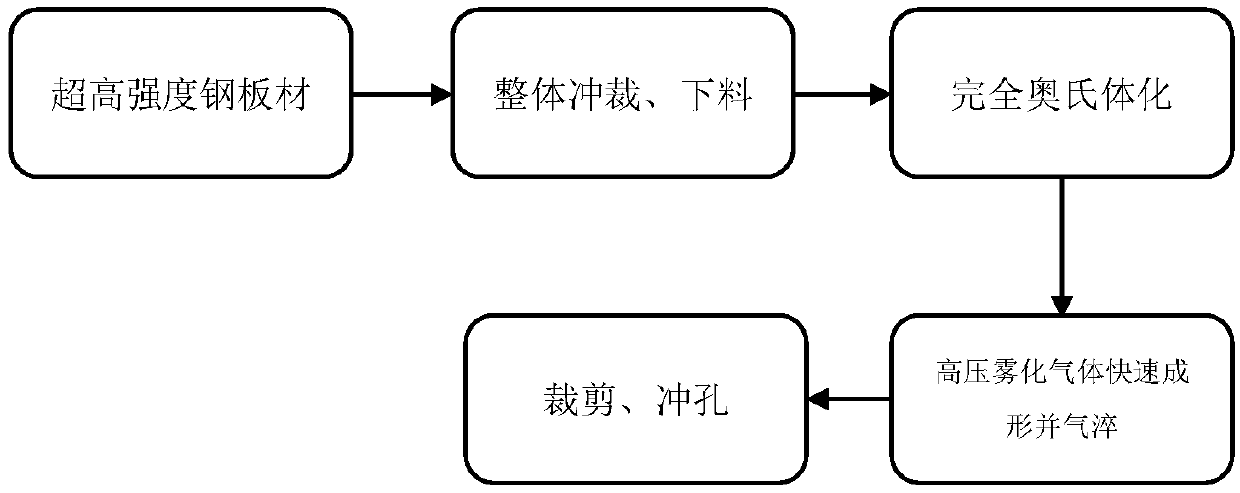

[0033] Embodiment one: with reference to attached figure 1 , 2 , As shown in 3, a pneumatically controlled ultra-high-strength steel hot stamping forming method includes the following steps:

[0034] 1) Punching: Select 2mm thick 22MnB5 uncoated ultra-high strength steel plate, and punch it to 1500mmx500mm;

[0035] 2) Austenitization: use electric heating to heat the sheet to 920°C under a high-pressure nitrogen protective atmosphere, and keep it warm for 180s to completely austenitize the sheet;

[0036] 3) High-pressure gas forming: The fully austenitized 22MnB5 sheet is quickly transferred to a high-pressure atomized gas forming device, and the transfer time is controlled within 20s. Slowly increase the mold clamping force to 300kN after closing the mold, and control the slab not to feed during the stamping process;

[0037] Place the fully austenitized steel plate in the high-pressure gas forming device through the rapid transfer device, open the air inlet 2 and the gas ...

Embodiment 2

[0044] Embodiment two: with reference to attached figure 1 , 2 , 4, a pneumatically controlled ultra-high strength steel hot stamping forming method, comprising the following steps:

[0045] 1) Punching: Select 1.2mm thick 30CrNi3MoV ultra-high-strength steel plate with aluminum-silicon coating, and punch it to 1100mmx800mm;

[0046] 2) Austenitization: Under the protective atmosphere of high-pressure nitrogen / helium gas mixture (volume ratio 3:1), the sheet is heated to 930°C by electric heating, and the sheet is completely austenitized by keeping it warm for 180s;

[0047] 3) High-pressure gas forming: The fully austenitized 30CrNi3MoV sheet is quickly transferred to the high-pressure atomized gas forming device, and the transfer time is controlled within 15s. Slowly increase the mold clamping force to 300kN after closing the mold, so that the slab can be fed during the stamping process;

[0048] Control the slab at the stage where the temperature is not lower than 800°C,...

Embodiment 3

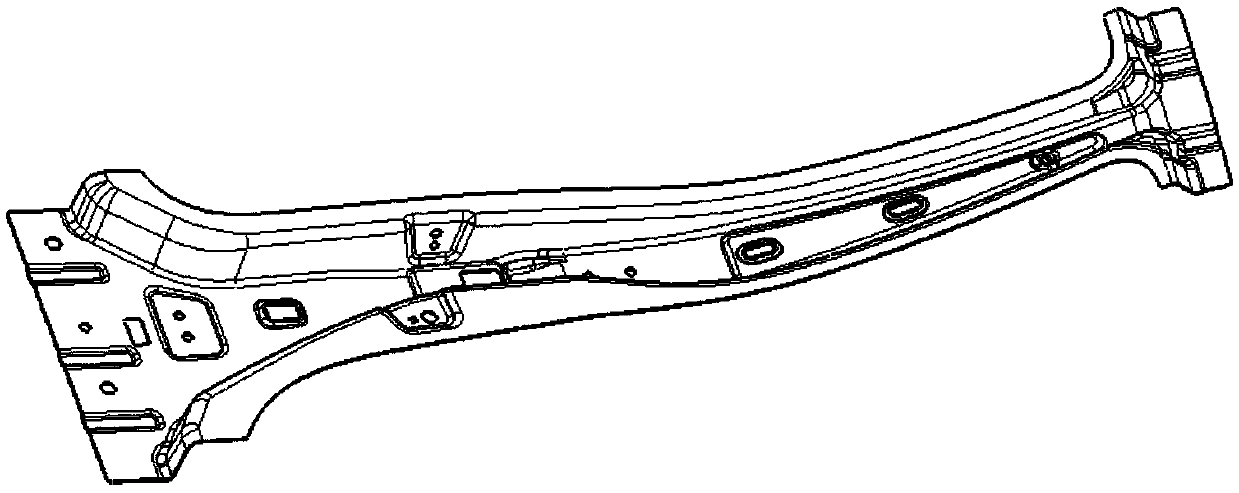

[0051] Embodiment three: with reference to attached figure 1 , 2 , 5, a pneumatically controlled ultra-high strength steel hot stamping forming method, comprising the following steps:

[0052] 1) Punching: Select 1.5mm thick 43CrNiSiMoV ultra-high strength steel plate with pure zinc coating, and punch it to 1300mm×500mm;

[0053] 2) Austenitization: use electric heating to heat the sheet to 940°C under a high-pressure helium protective atmosphere, and keep it warm for 160s to completely austenitize the sheet;

[0054] 3) High-pressure gas forming: The fully austenitized 43CrNiSiMoV sheet is quickly transferred to the high-pressure atomized gas forming device, and the transfer time is controlled within 17s. Slowly increase the mold clamping force to 300kN after closing the mold, so that the slab can be refilled during the stamping process;

[0055] Control the slab to fill the upper half of the cavity with high-pressure helium when the temperature is not lower than 800°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com