Iron-based amorphous alloy strip, preparation method thereof and single-roller rapid quenching device for iron-based amorphous alloy strip

A technology for iron-based amorphous alloys and strips, applied in the field of iron-based amorphous alloy strips, can solve problems such as unsatisfactory customer stability, increased customer complaint rate, and fluctuations in basic performance of amorphous strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method for obtaining a continuous and stable iron-based amorphous alloy strip texture, comprising the following steps:

[0035] The iron-based amorphous alloy molten steel in the molten state is sprayed on the cooling roller through the nozzle for rapid cooling to obtain the iron-based amorphous alloy strip;

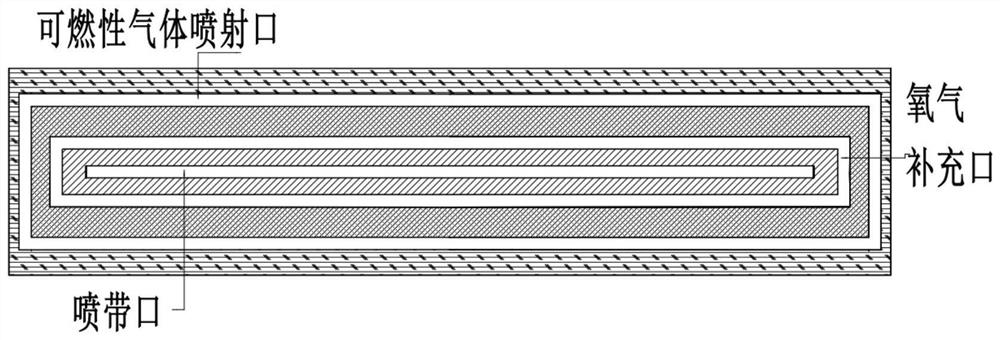

[0036] The strip spray nozzle includes a strip spray port arranged in the center, an oxygen replenishment port arranged on the periphery of the strip spray port, and a combustible gas injection port arranged on the periphery of the oxygen supplement port;

[0037] The 360° direction of the spray nozzle is provided with an annular fire spray head;

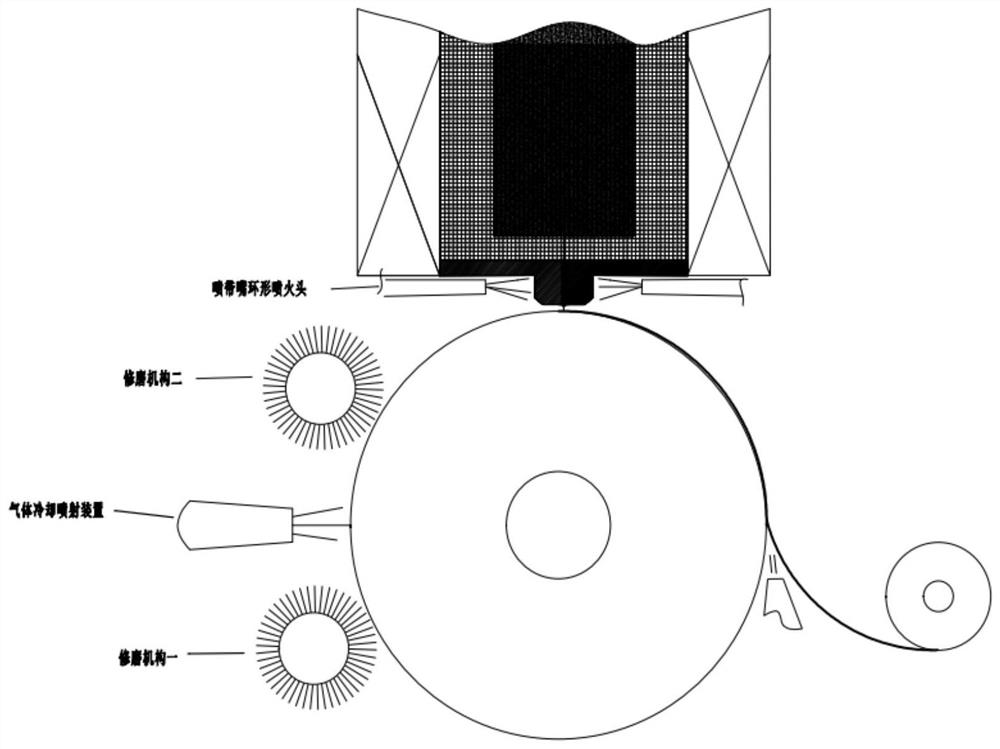

[0038] A first grinding wheel, a gas cooling injection device and a second grinding wheel are arranged in the rotation direction of the cooling roller, and the gas cooling injection device is arranged between the first grinding wheel and the second grinding wheel; the fi...

Embodiment 1

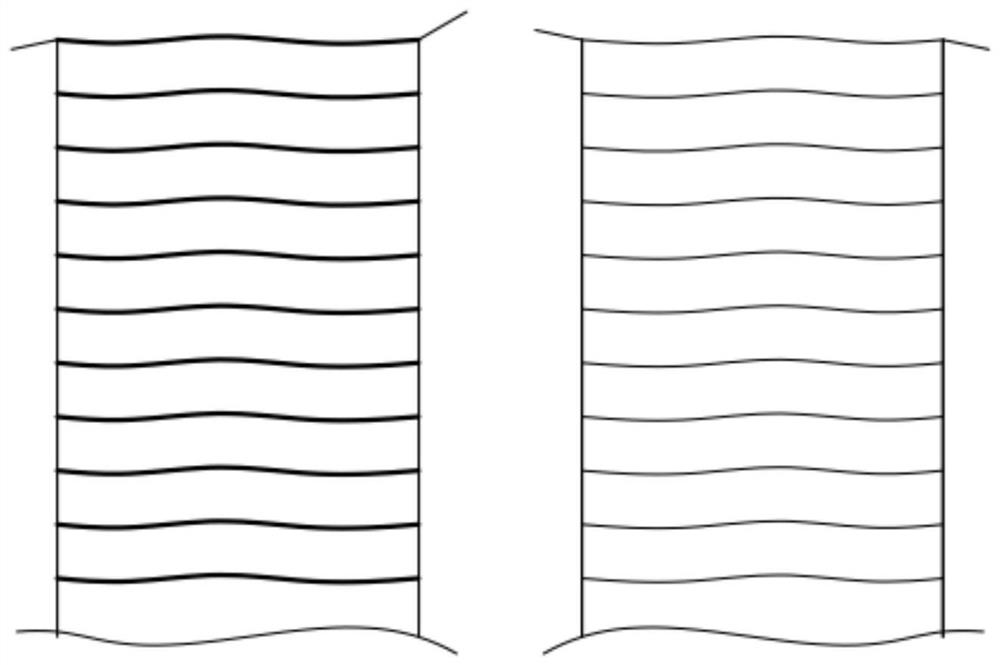

[0059] In terms of atomic percentage, the chemical composition is Fe a Si b B c C d m f The molten steel in the molten state of the iron-based amorphous alloy is rapidly cooled on the cooling roll through the spray nozzle under different process conditions, that is, the molten steel in the molten state is rapidly quenched by a single roll to obtain an iron-based amorphous alloy with a width specification of 142mm and a thickness of 27μm. Crystalline alloy strip; Wherein process condition 1 is the example process condition of the present invention, and process condition 2 is conventional process condition;

[0060] Process condition 1: In the process of single-roll rapid quenching, a ring-shaped flame nozzle with nozzle nozzle is installed within the 360° range of the nozzle nozzle, and the temperature of the nozzle nozzle is fully controlled, and each nozzle has an independent switch; at the same time The spray nozzles are arranged in a circular air gap, the outermost is t...

Embodiment 2

[0079] In order to verify the influence of the method of the present invention on the texture, further experimental verification is carried out by means of cross experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com