Heat-dissipation switch cabinet

A heat dissipation switch and heat dissipation fan technology, which is applied in the field of switch cabinets, can solve the problems of increased manpower, power consumption, and high heat generated by cable contacts, and achieve the effects of improving heat dissipation efficiency, prolonging service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

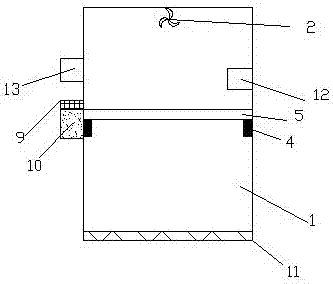

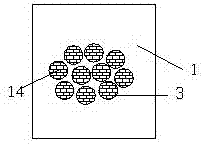

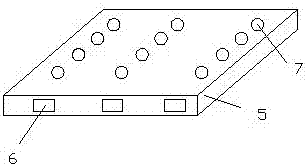

[0031] see figure 1 , figure 2 , image 3 and Figure 4 , this embodiment relates to a heat dissipation switch cabinet, including a cabinet body 1, a heat dissipation fan 2 is provided on the top of the inner wall of the cabinet body 1, and a plurality of ventilation holes 3 are correspondingly provided on the upper bottom surface of the cabinet body 1 and the heat dissipation fan 2, so that The middle part of the inner wall side of the cabinet body 1 is symmetrically provided with a horizontal slide rail 4, the horizontal slide rail 4 is provided with a baffle plate 5, and the inside of the baffle plate 5 is provided with a plurality of strip-shaped cavities 6, and the cavities 6 communicate with each other. The upper bottom surface and the lower bottom surface of the cavity 6 are provided with a number of cooling holes 7, the cavity 6 is provided with pipelines 8, and the pipelines 8 are connected to each other, and the outer wall of the cabinet body 1 is provided with a ...

Embodiment 2

[0039] see image 3 , Figure 4 , Figure 5 and Figure 6 , this embodiment relates to a heat dissipation switch cabinet, including a cabinet body 1, a heat dissipation fan 2 is provided on the top of the inner wall of the cabinet body 1, and a plurality of ventilation holes 3 are correspondingly provided on the upper bottom surface of the cabinet body 1 and the heat dissipation fan 2, so that The middle part of the inner wall side of the cabinet body 1 is symmetrically provided with a horizontal slide rail 4, the horizontal slide rail 4 is provided with a baffle plate 5, and the inside of the baffle plate 5 is provided with a plurality of strip-shaped cavities 6, and the cavities 6 communicate with each other. The upper bottom surface and the lower bottom surface of the cavity 6 are provided with a number of cooling holes 7, the cavity 6 is provided with pipelines 8, and the pipelines 8 are connected to each other, and the outer wall of the cabinet body 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com