Method for measuring absolute position of rotor in motor servo system

A servo system and absolute position technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of no recovery ability, unable to give absolute zero position, etc., to improve cost performance, reduce signal processing circuits and coarse-fine coupling operations, and simplify machinery structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

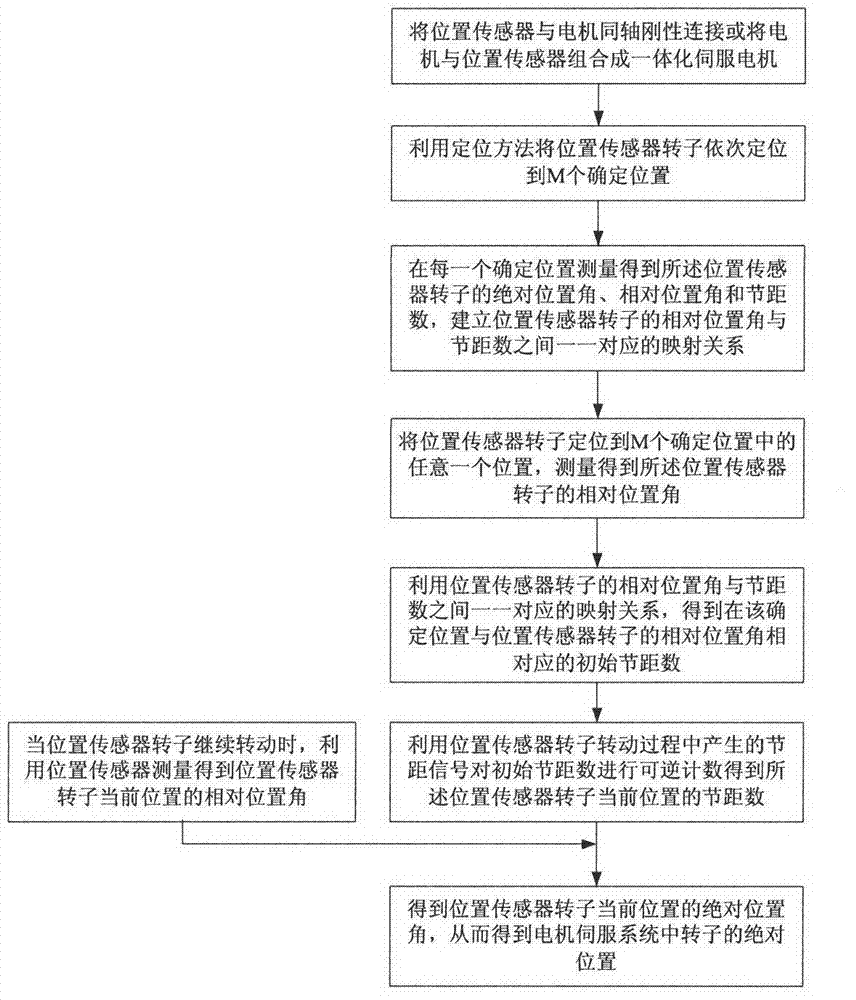

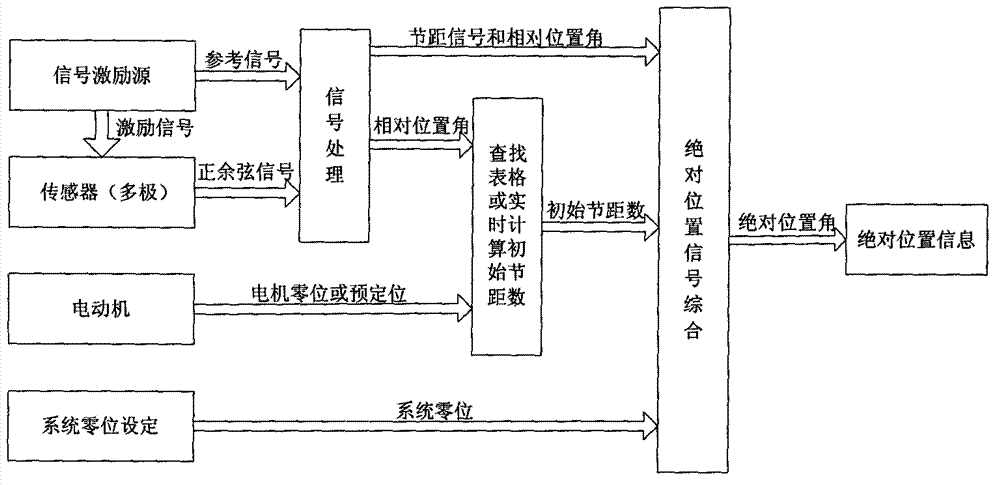

[0077] The present invention can be realized with another kind of method, and its concrete realization steps (1), (3), (4) are identical with above-mentioned invention realization steps, and the realization method of step (2) is as follows:

[0078] First, the relative position angle α of any one of the M determined positions is known 1 and pitch number P 1 The one-to-one mapping relationship;

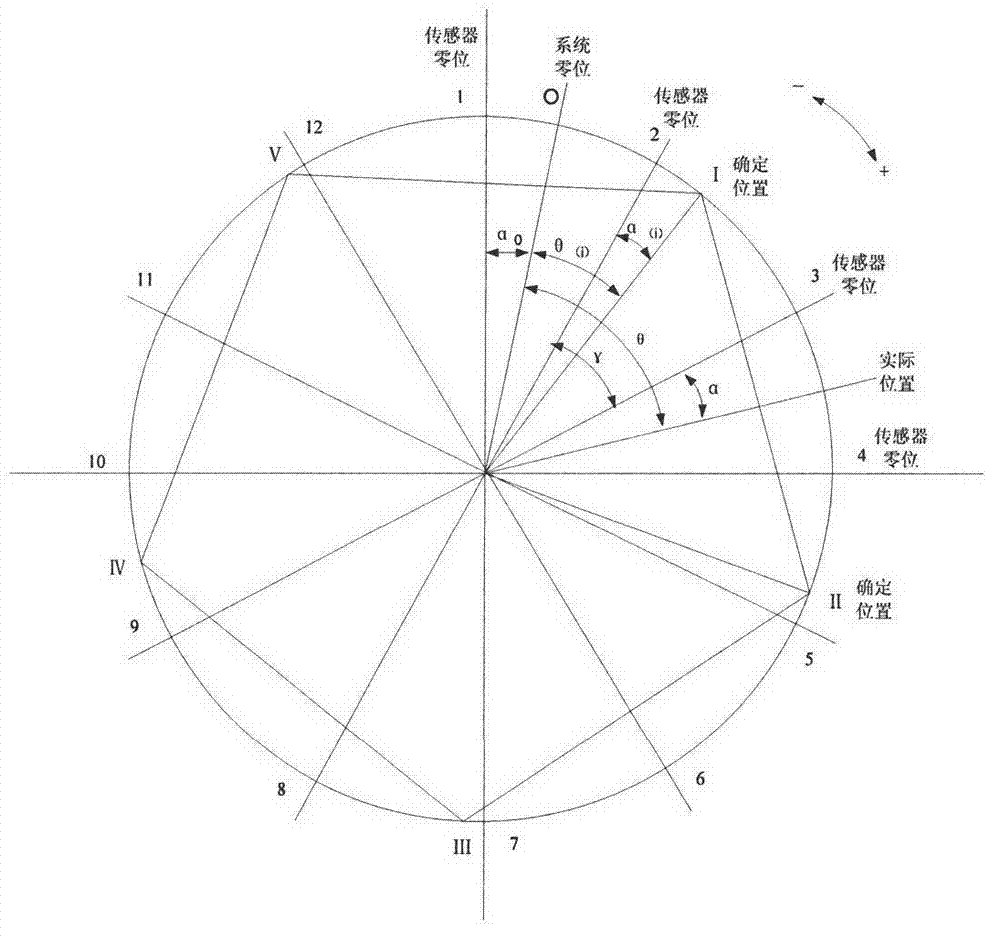

[0079] Then, using the relation: α (i) = α 1 +(β×m-γ×P (i) ), i∈[1,M]

[0080] The one-to-one mapping relationship between the relative position angle and the pitch number of the remaining M-1 determined positions is calculated. in:

[0081] 0≤m≤M, 0≤P (i) ≤N, 0≤α 1 ≤360° / N, 0≤α (i) ≤360° / N;

[0082] N is the number of pole pairs of the position sensor;

[0083] γ is the pitch angle of the position sensor;

[0084] M is the cycle number of the stable position when the motor rotor rotates one revolution;

[0085] β is the periodic angle between two adjacent stable positions...

Embodiment 2

[0088] The present invention can also be realized with a third method, and its concrete realization steps (1), (4) are identical with the implementation steps of the present invention, and the realization method of step (2) is as follows:

[0089] Measure the relative position angle α of any one of the M determined positions 1 and pitch number P 1 The one-to-one mapping relationship;

[0090] The implementation method of step (3) is as follows:

[0091] First, using the same positioning method as step (2), position the position sensor rotor to any one of the M determined positions in step (2), and measure the relative position angle of the position sensor rotor;

[0092] Then, using the relation: α (i) = α 1 +(β×m-γ×P 0 ), i ∈ [1, M]

[0093] Calculate the relative position angle α of the determined position (i) and initial pitch number P 0 One-to-one mapping relationship. in:

[0094] 0≤m≤M, 0≤P 0 ≤N, 0≤α 1 ≤360° / N, 0≤α 0 ≤360° / N;

[0095] N is the number of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com