System and method for operating an internal combustion engine

a technology of internal combustion engine and system, which is applied in the direction of combustion engine, valve arrangement, machine/engine, etc., can solve the problems of affecting engine performance, efficiency, exhaust pollutants, other engine characteristics, and diesel engines operating in such environmental conditions are subject to greater loads, and the effect of reducing the number of cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

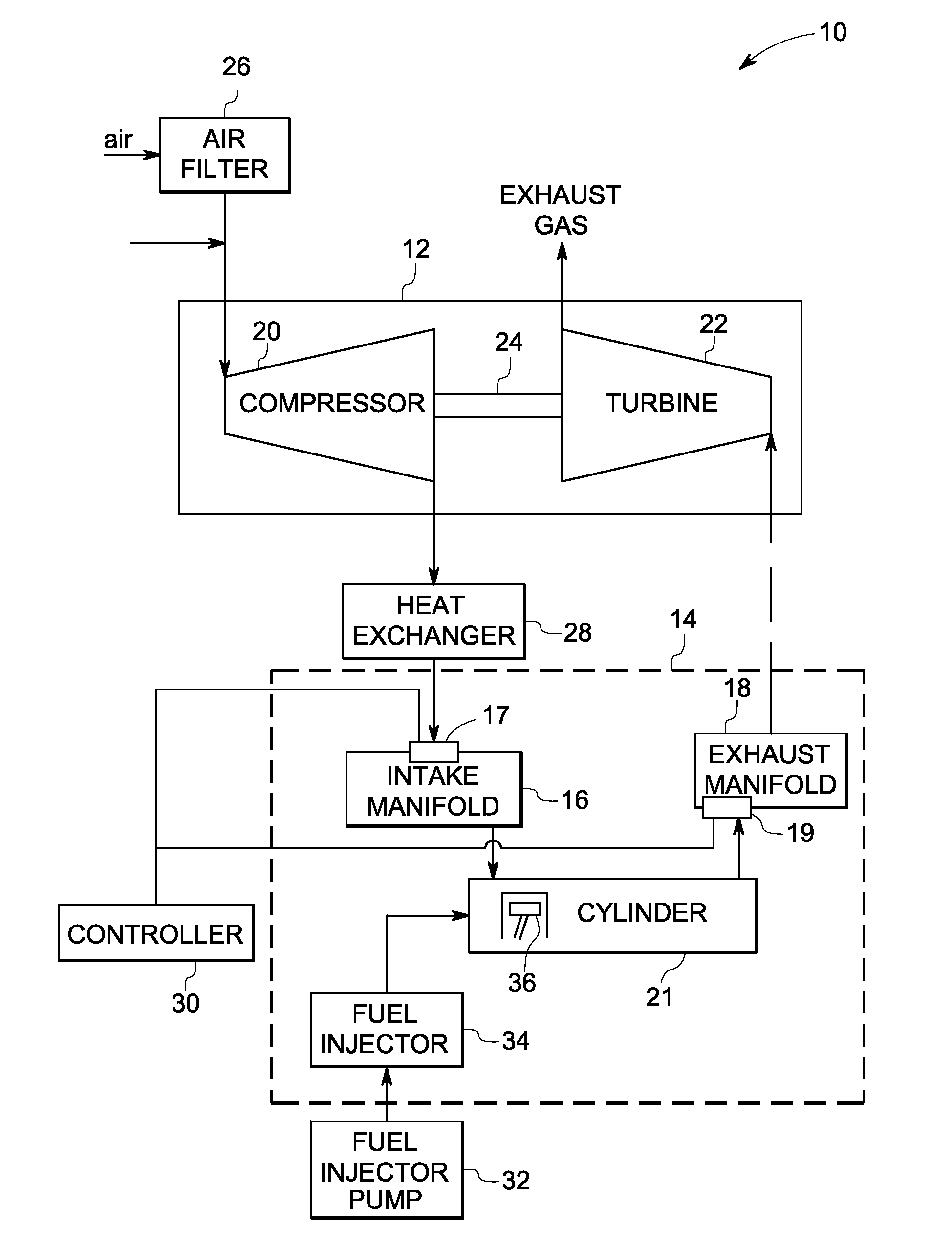

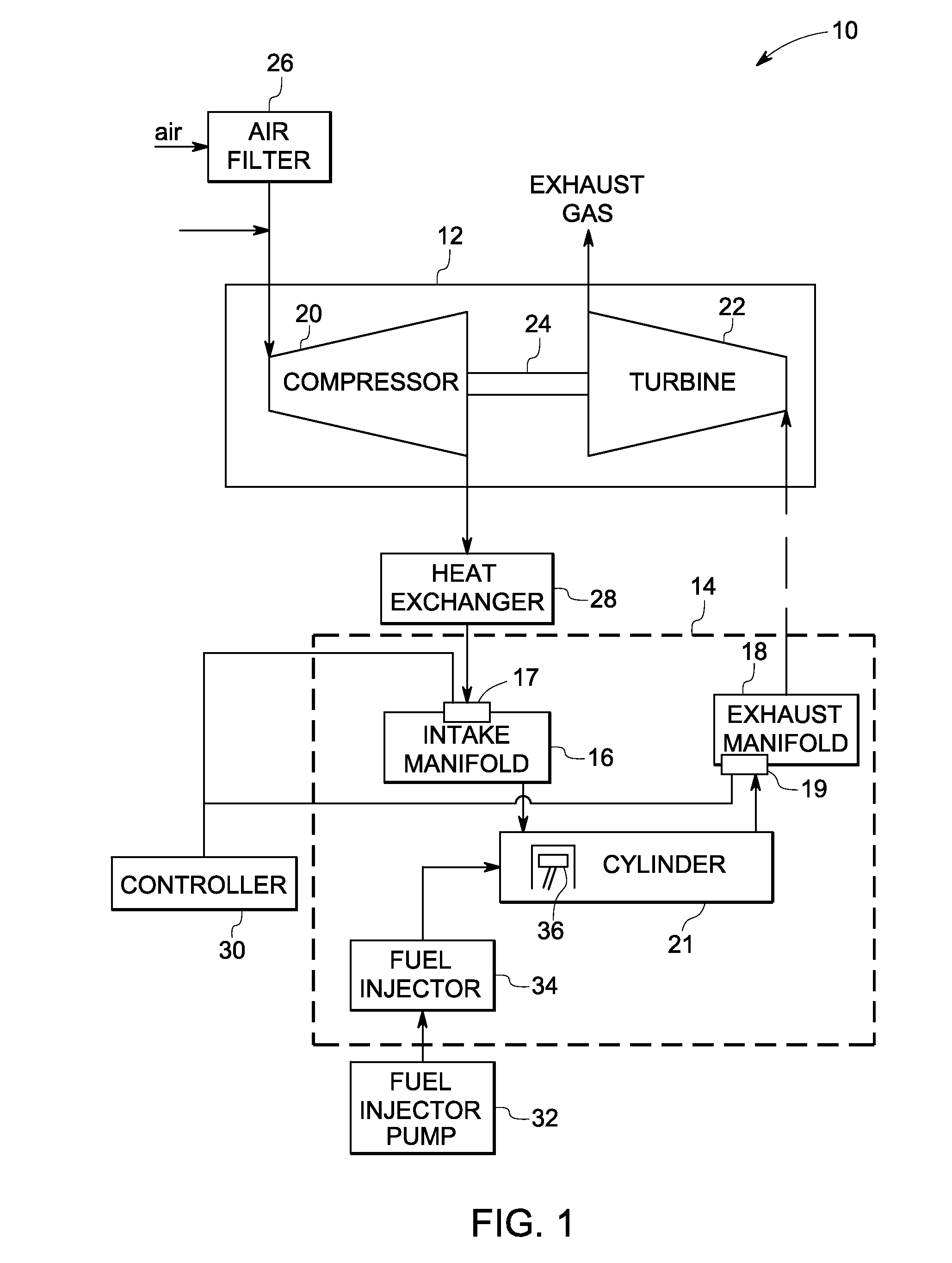

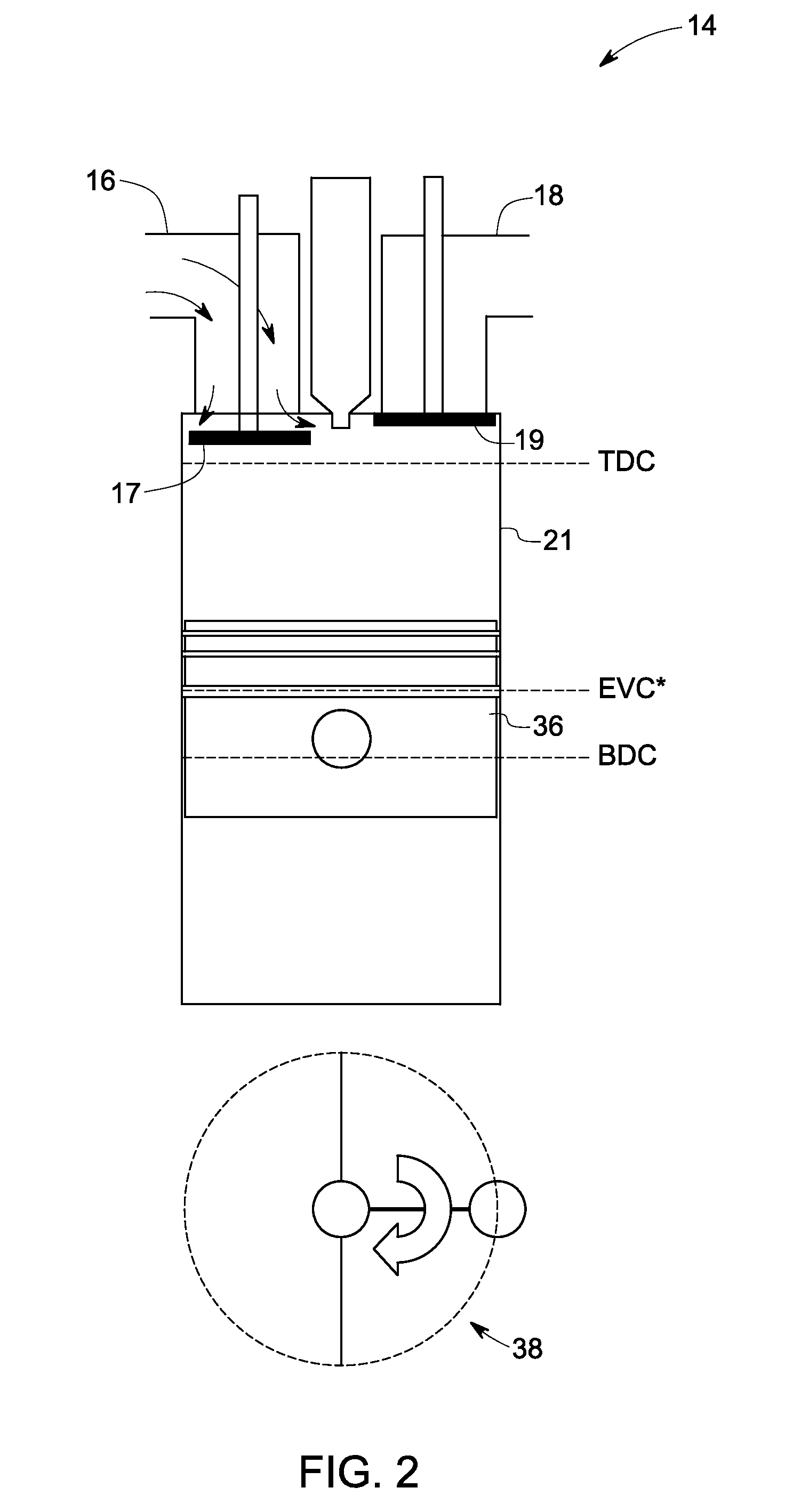

[0015]In accordance with certain embodiments of the present invention, a method of operating an internal combustion engine in accordance with a Miller cycle is disclosed. The method includes moving a piston from a top dead center position towards a bottom dead center position in an engine cylinder and closing an intake valve of the internal combustion engine when a piston is about the bottom dead center position in the engine cylinder. The method includes opening an exhaust valve for a predetermined time period when the piston is about the bottom dead center position of the engine cylinder after closing the intake valve during a compression stroke of the piston so as to exhaust a predetermined quantity of fresh charge from the engine cylinder via the exhaust valve. In accordance with a specific embodiment of the present invention an internal combustion engine operated in accordance with a Miller cycle is disclosed. As discussed herein below, the exhaust valve of the engine is re-ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com