Ultrahigh-supercharging turbo-charging Miller cycle engine

A Miller cycle and turbocharging technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as increased thermal power and decreased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

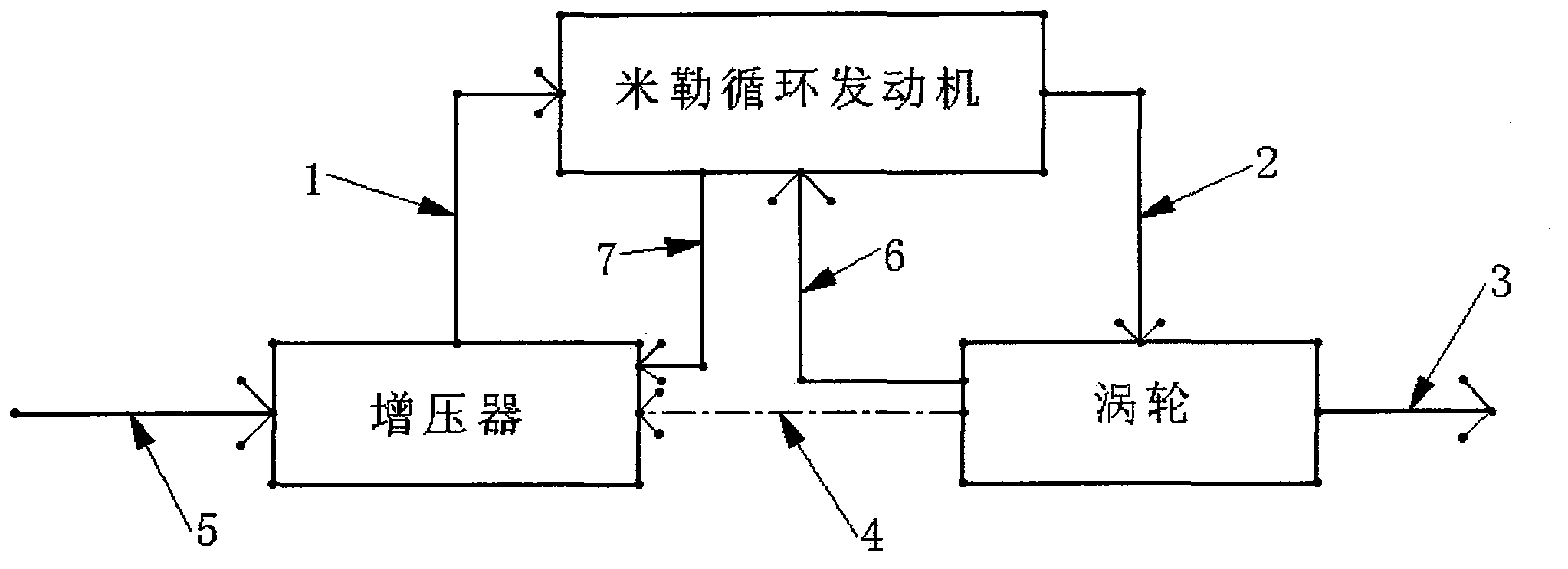

[0009] The supercharged turbocharged Miller cycle engine of the present invention can refer to figure 1 . The air enters the supercharger through the intake pipe 5, and the supercharged air enters the Miller cycle engine through the recent manifold 1, and the exhaust gas discharged by the Miller cycle engine at the same pressure as the intake manifold 1 enters the turbine through the exhaust manifold 2 , the exhaust gas after doing work is discharged through the exhaust pipe 3. The mechanical work absorbed by the turbine can be provided via shaft 4 directly to the supercharger, or via shaft 6 to the crankshaft of a Miller cycle engine. When using a supercharger, the Miller cycle engine can drive the supercharger via shaft 7. The Miller cycle engine cannot be directly boosted by a supercharger, otherwise its cycle will become a supercharged Otto cycle, and a large amount of energy will be wasted, which will not improve efficiency. The turbine here is not an ordinary turbine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com