Miller cycle diesel oil-natural gas dual fuel engine and control method thereof

A dual-fuel engine, Miller cycle technology, applied in engine control, combustion engine, fuel injection control and other directions, can solve the problems of natural gas engine limitation, short cruising range, etc., to reduce heat load, improve expansion ratio, flexible and simple way Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described below with reference to the drawings.

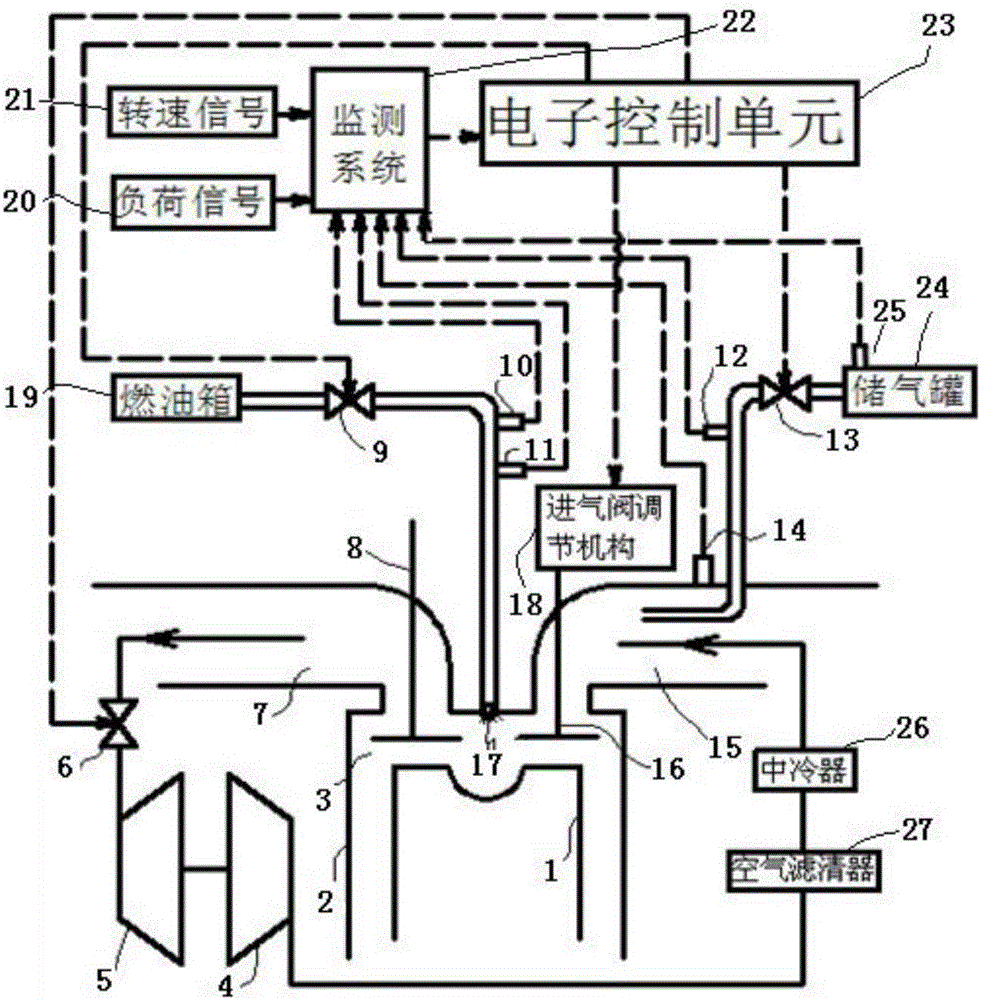

[0022] The main structure of the main body of the diesel-natural gas dual fuel engine of the present invention includes 1. piston; 2. cylinder; 3. combustion chamber; 4. compressor; 5. turbine; 6. wastegate valve; 7. exhaust port; Gas valve; 9. Diesel control valve; 10. Fuel pressure sensor; 11. Fuel temperature sensor; 12. Gas mass flow sensor; 13. Gas supply valve; 14. Air intake pressure sensor; 15. Air inlet; 16. Inlet Air valve; 17. Fuel injector; 18. Air intake valve adjustment mechanism; 19. Fuel tank; 20. Load signal; 21. Speed signal; 22. Engine monitoring system; 23. Electronic control unit; 24. Gas storage tank; 25. Gas pressure sensor; 26. Intercooler; 27. Air filter.

[0023] In the cylinder 2 of the engine, a reciprocating piston 1 is provided, and a combustion chamber 3 is formed between the upper surface of the piston 1 and the inner surface of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com