Gas intake and distribution system based on electric hydraulic control mode

An electro-hydraulic control and control mechanism technology, applied in engine control, valve details, valve drive devices, etc., can solve problems such as small variable range of gas distribution phase, complex transmission mechanism, energy consumption, etc., to avoid insufficient response speed, The effect of flexible lift control and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

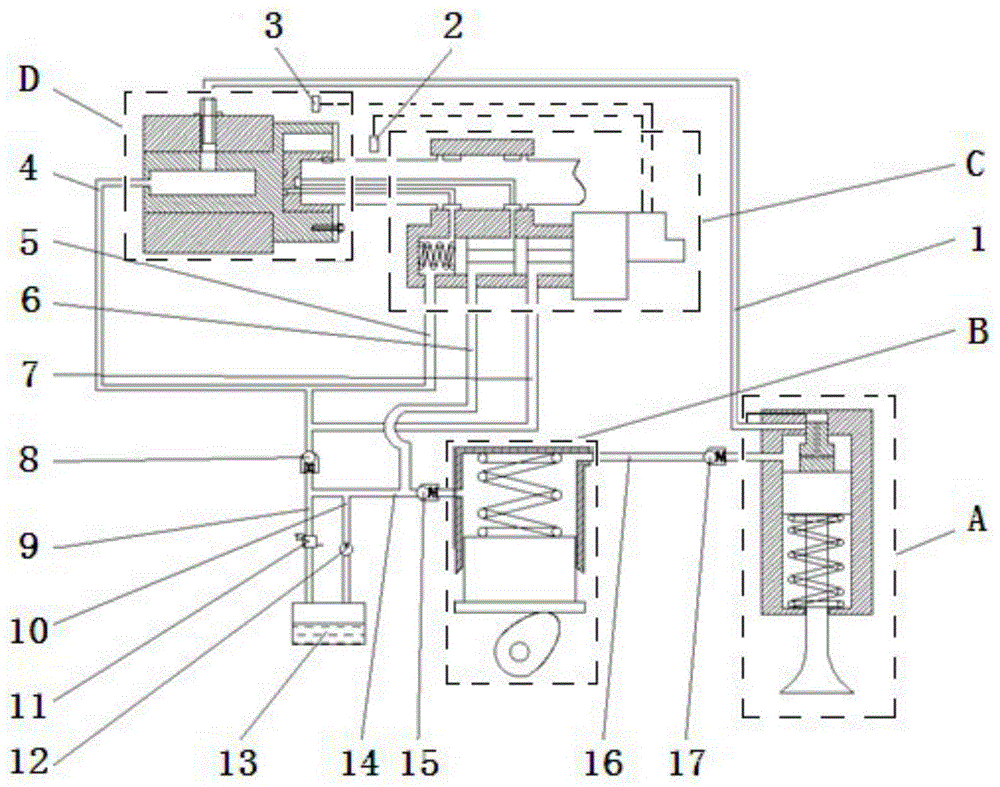

[0028] The concrete work process of the present invention is illustrated below in conjunction with accompanying drawing:

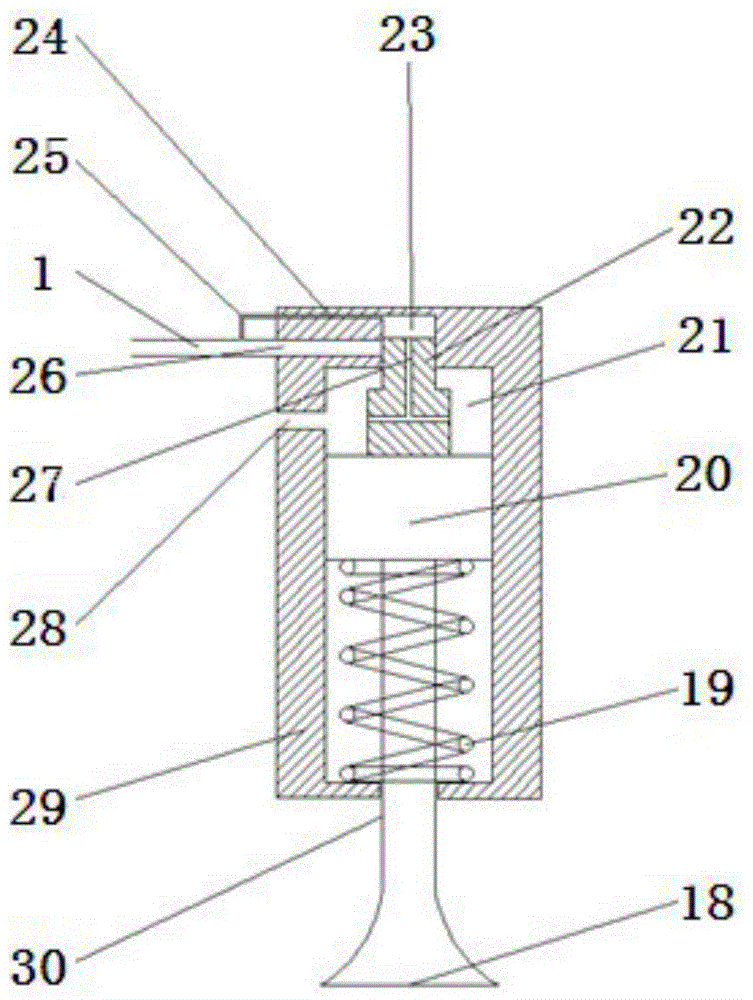

[0029] figure 2 It is a structural diagram of the valve drive mechanism A, including valve 18, valve spring 19, valve piston 20, piston chamber 21, valve buffer block 22, buffer chamber 23, buffer oil return hole 24, buffer oil inlet pipe 25, oil return hole I26, buffer block Oil hole 27, oil inlet hole I28, valve housing 29, and valve hole 30 are composed, wherein the bottom of valve housing 29 is provided with valve hole 30, and the upper left wall of valve housing 29 is provided with buffer oil return hole 24, The oil return hole I26 and the oil inlet hole I28, the valve housing 29 is provided with a buffer chamber 23; one end of the buffer oil inlet pipe 25 communicates with the buffer chamber 23 through the buffer oil return hole 24, and the other end of the buffer oil inlet pipe 25 communicates with the oil return pipe I1; The upper part of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com