Early closing miller cycle internal combustion engine

a technology of internal combustion engine and miller cycle, which is applied in the direction of machines/engines, non-mechanical valves, output power, etc., can solve the problems of large impact due to momentum of valves, decreased flexibility of valve design, and likely decrease of durability of valves, so as to reduce flexibility of valve design and reduce the effect of valve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Selected embodiments of the present invention will now be explained with reference to the drawings. It will be apparent to those skilled in the art from this disclosure that the following description of the embodiments of the present invention is provided for illustration only, and not for the purpose of limiting the invention as defined by the appended claims and their equivalents.

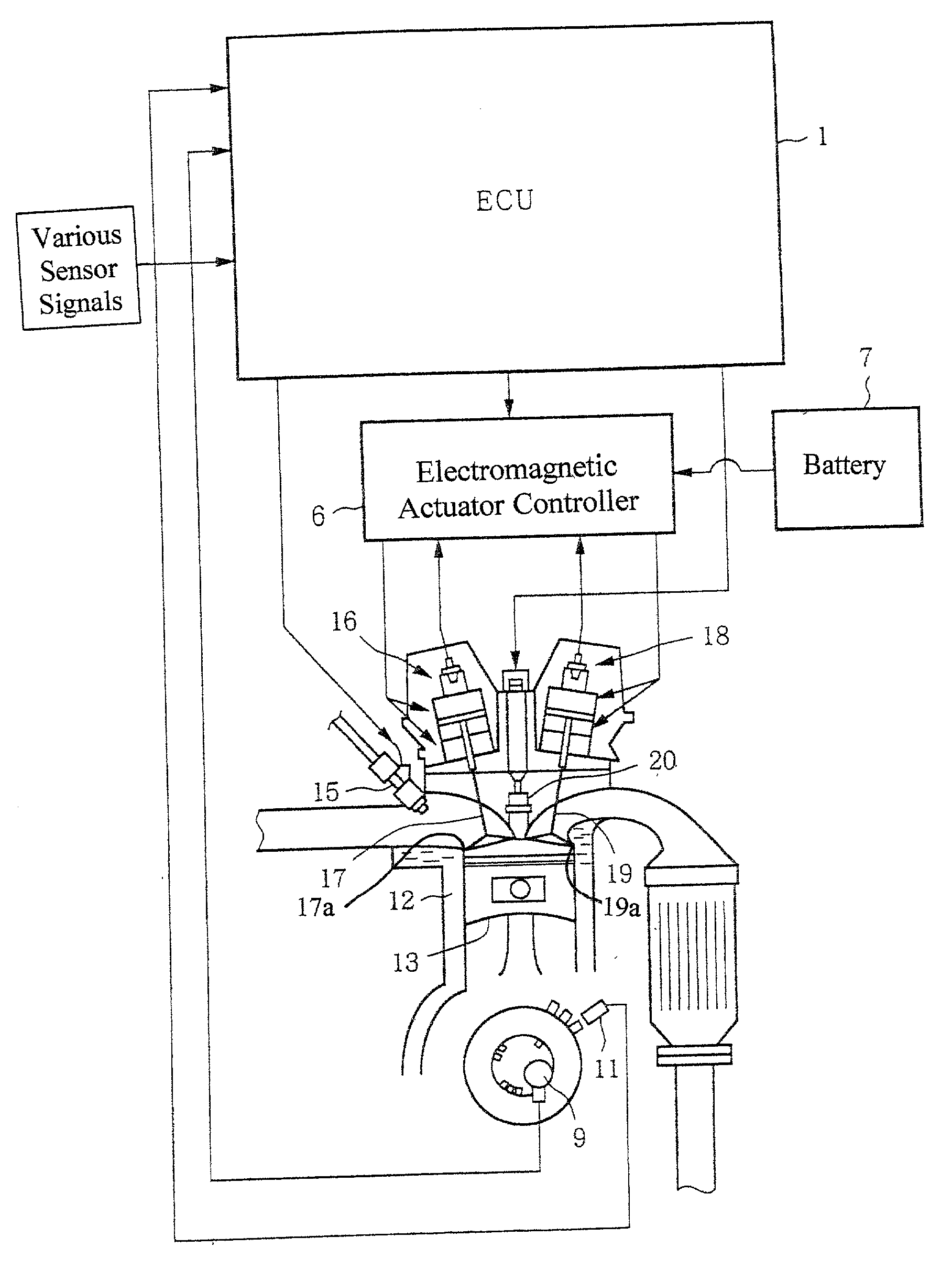

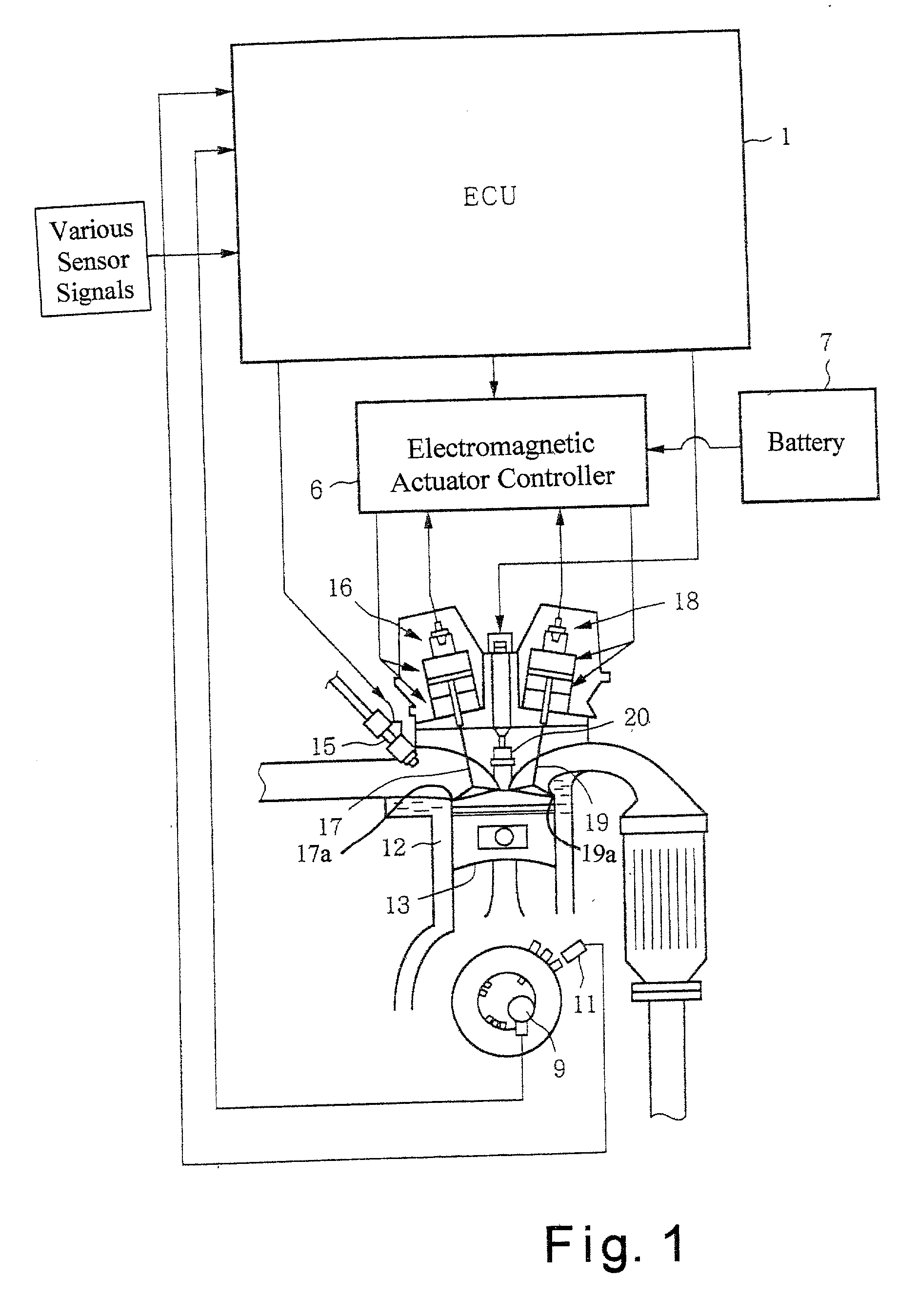

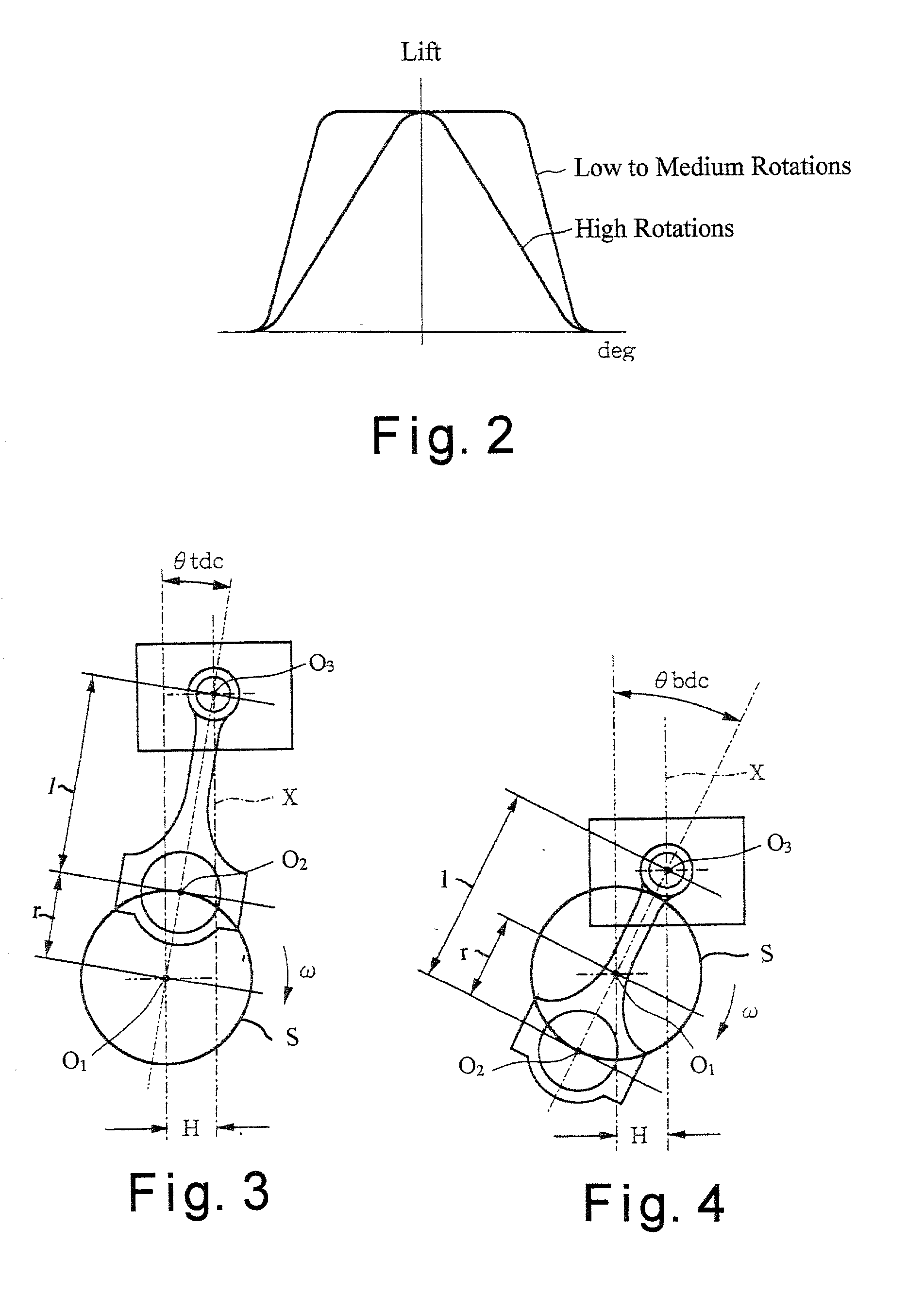

[0024] Referring initially to FIG. 1, an early closing Miller cycle internal combustion engine is diagrammatically illustrated to explain a first embodiment of the present invention. Basically, the early closing Miller cycle internal combustion engine embodiment of the present invention has an engine control unit 1 that controls an electromagnetic actuator controller 6 to open and close a plurality of intake valves 17 (only one shown) and a plurality of exhaust valve 19 (only one shown) by an intake valve driving actuator 16 and an exhaust valve driving actuator 18, respectively, such that the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com