Cam-driven hydraulic fully variably valve mechanism of internal combustion engine

A technology of valve mechanism and internal combustion engine, which is applied in the direction of internal combustion piston engine, valve driving device, engine components, etc. It can solve the problems of large volume, inability to flexibly control valve lift and valve timing, complex structure, etc., and achieve large fluid flow inertia , improve fuel economy, improve the effect of cold start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

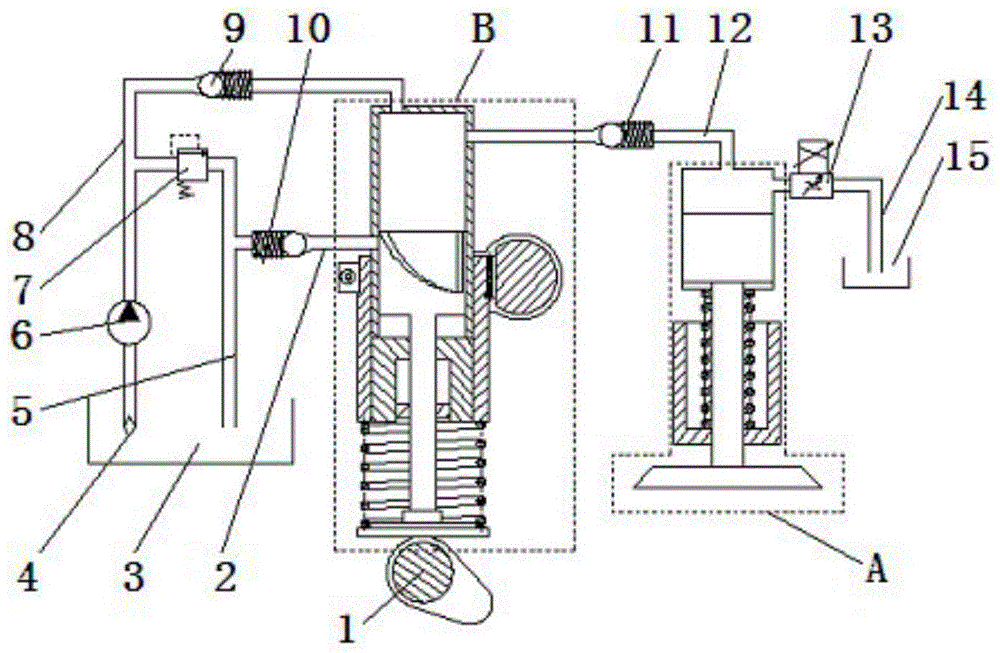

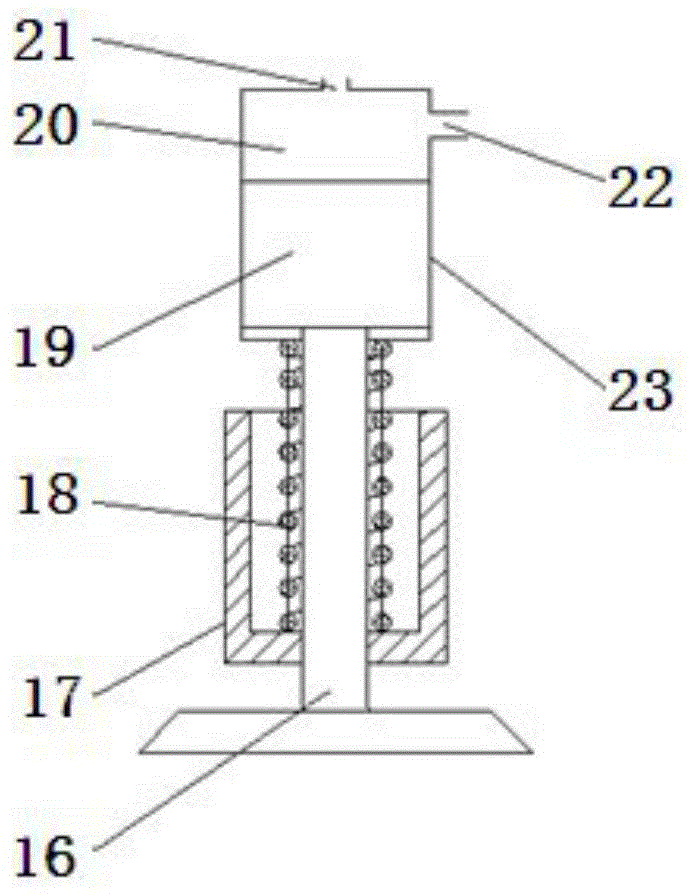

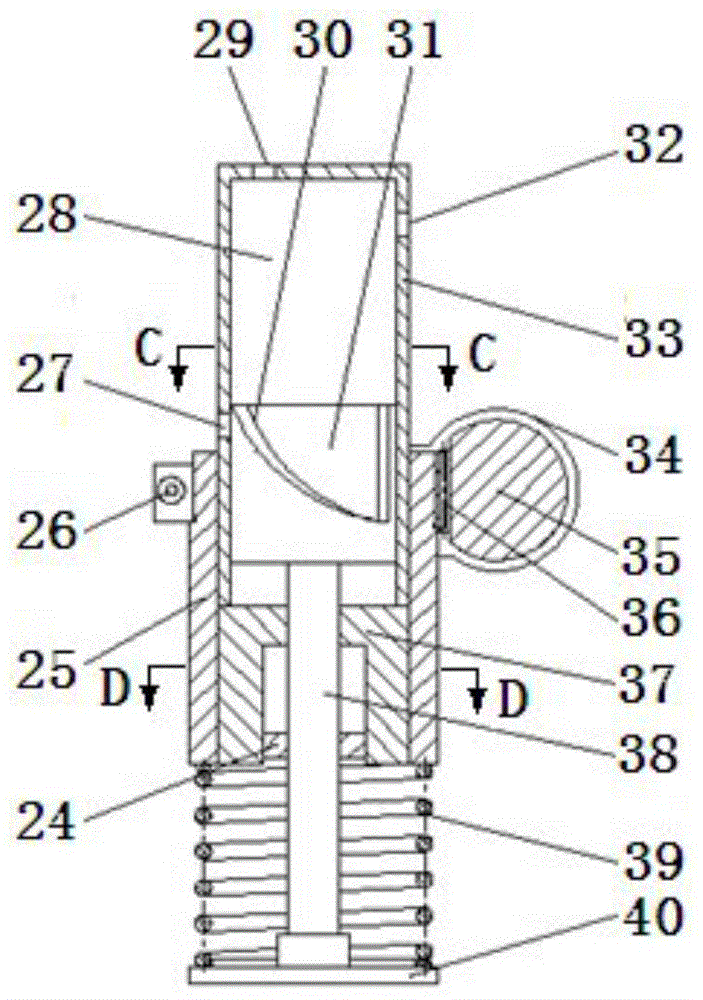

[0025] The present invention consists of hydraulic piston valve group A, tappet group B, cam 1, oil pipe I2, oil tank I3, filter 4, oil pipe II5, oil pump 6, overflow valve 7, oil pipe III8, one-way valve I9, one-way Valve II10, one-way valve III11, oil pipe IV12, electro-hydraulic proportional valve 13, oil pipe V14 and oil tank II15, the hydraulic piston valve group A is composed of valve 16, valve spring seat I17, valve spring I18, valve piston 19, piston Cavity 20 and piston sleeve 23 are formed, and described tappet group B is made up of tongue 24, oil amount adjustment sleeve 25, ring gear clamping screw 26, tappet cavity 28, spiral groove 30, tappet piston 31, tappet Cover 33, oil quantity adjustment tooth bar sleeve 34, oil quantity adjustment tooth bar 35, ring gear 36, tongue groove 37, piston rod 38, spring II 39, spring seat II 40 form.

[0026] Refer to attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com