Large piston-reciprocating low-speed engine

An engine and piston technology, applied in the field of high-power piston reciprocating low-speed engines, can solve the problems of manufacturing, installation, maintenance and repair difficulties, increase the cost of engine manufacturing and use, occupy equipment load and installation space, and save manufacturing and maintenance The cost of repair, the difficulty of overcoming manufacturing and assembly, and the effect of reducing equipment load and installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

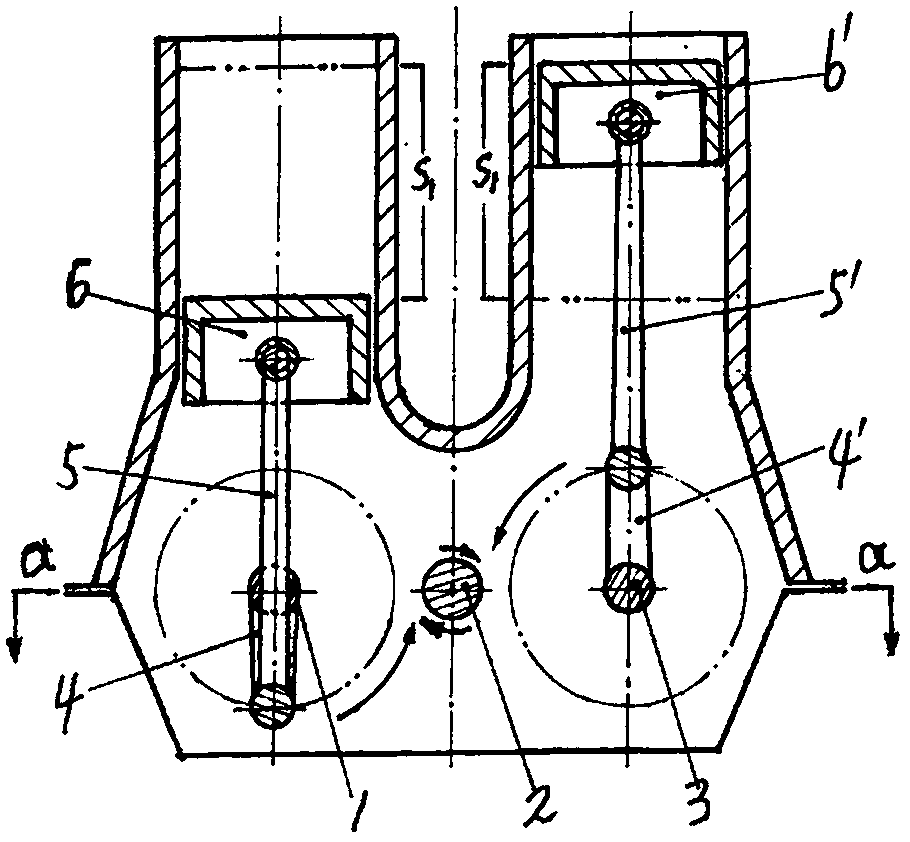

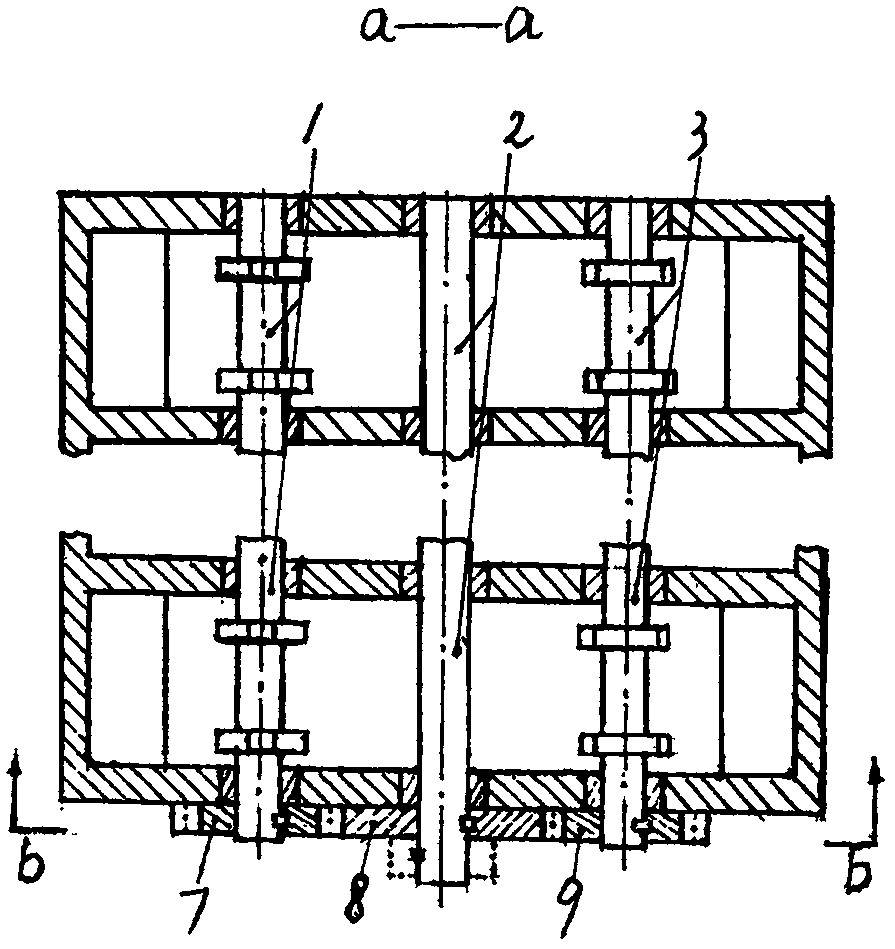

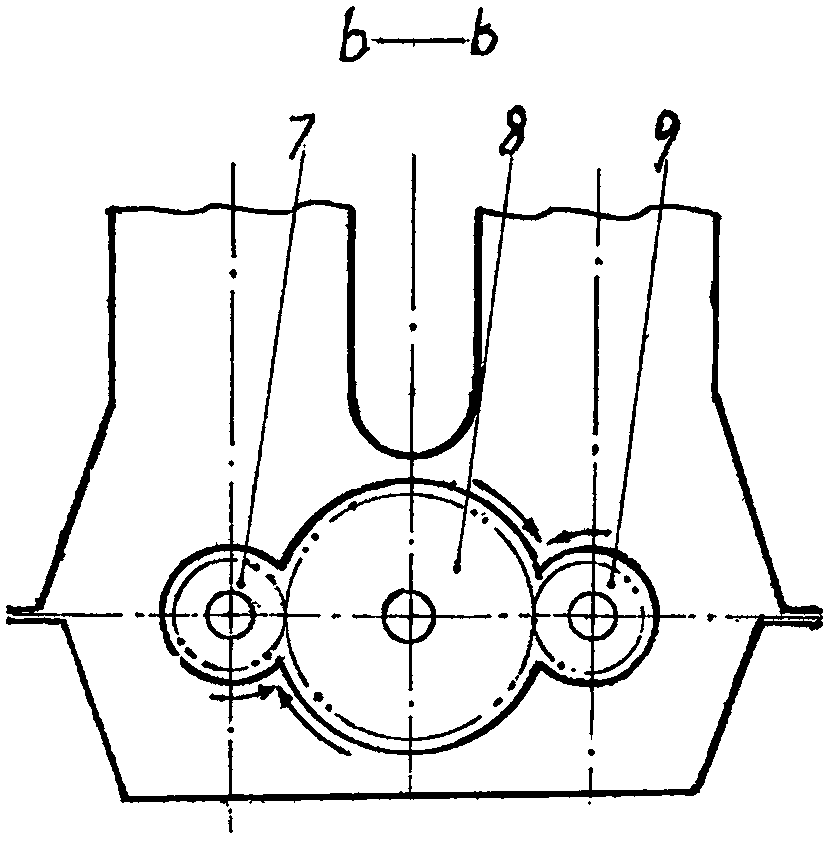

[0028] figure 1 Show: the left and right sides of this design are parallel and vertically parallel to the starting cylinder of two L-type engines in a row, and its piston (6, 6 ') diameter is the same as that of the comparison engine ( Figure 5Shown) the diameter of the piston (10) is the same, and the piston stroke is slightly larger than 1 / 3 of the piston stroke of the engine; The rotational speed is 1 / 3 of the nominal rotational speed of the two crankshafts), that is, the reciprocating frequency of the pistons is 3 times the reciprocating frequency of the pistons of the comparison engine; therefore figure 1 Shows the nominal power vs. Figure 5 The nominal power per cylinder of the comparison engine shown is the same.

[0029] Figure 4 Engine single cylinder shown: diameter and stroke S of its piston (6) 1 and figure 1 If the single cylinders in the parallel twin cylinders shown are the same, the volumes of the two single cylinders are also the same; Figure 4 and ...

specific Embodiment approach 2

[0032] The technical parameters described in the above embodiments are only examples, and the engine piston diameter, stroke, crankshaft nominal speed, output shaft The parameters such as the calibrated speed and the ratio of the diameter of the pitch circle of the crankshaft gear to the diameter of the pitch circle of the output shaft gear are modified. For example, changing the ratio of the diameter of the pitch circle of the crankshaft gear to the diameter of the pitch circle of the output shaft gear, so that the rated speed of the output shaft is greater than or lower than the rated speed of the comparison engine, so as to meet the requirement that the rated speed of the engine output is greater than or lower than the rated speed of the comparison engine; Change the piston diameter or stroke of the engine cylinder to meet the requirements of the rated power of the engine's single cylinder.

specific Embodiment approach 3

[0033] If it is difficult to have a suitable comparison engine for the designed engine, or when its technical parameters and operating parameters are quite different from the comparison engine, various technical parameters and operating parameters can be independently designed according to the technical scheme and principles of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com