A test device and method for steel-soil interface shear characteristics considering the thickness of the shear band

A characteristic test and shear band technology, which is applied in the direction of using a stable shear force to test the strength of materials, etc., can solve problems such as damage to the contact surface of steel and soil, and achieve the effect of ensuring high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

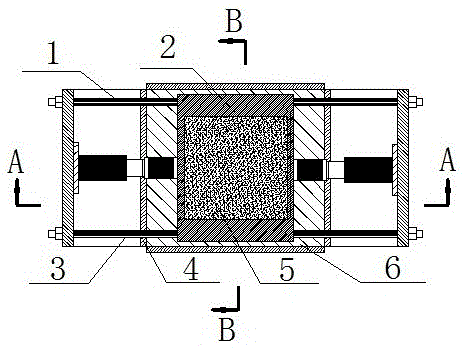

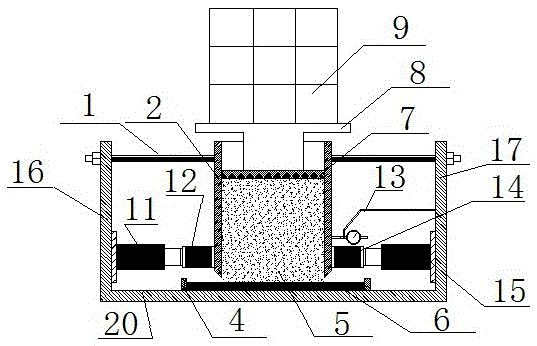

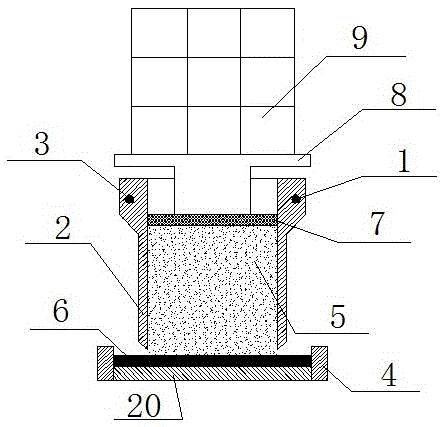

[0033] A test device for steel-soil interface shear characteristics considering the thickness of the shear zone, comprising a shear box 2, a bottom plate 20 and a pad 18. The bottom plate 20 has a horizontal upper surface carrying the steel plate 6 to be tested, and the shear box 2 has a hollow cavity for accommodating the soil sample 5 to be tested. It also includes a guide rail I1 and a guide rail II3 fixed above the bottom plate 20 and parallel to each other. The guide rail I1 and the guide rail II3 pass through the upper end of the shear box 2 , and the lower end of the shear box 2 is suspended, that is, the guide rail I1 and the guide rail II3 bear the weight of the shear box 2 . When the steel plate 6 to be tested is placed on the bottom plate 20 , there is a gap between the lower end of the shear box 2 and the upper surface of the steel plate 6 to be tested. The spacer 18 is filled in the gap.

[0034] In this embodiment, there are various ways to fix the guide rail I...

Embodiment 2

[0041] The method that adopts the device described in embodiment 1 to test may further comprise the steps:

[0042] 1) Fix the steel plate 6 to be tested on the horizontal upper surface of the bottom plate 20 . In this embodiment, several side limiting plates 4 can be installed on the upper surface of the bottom plate 20 (generally conveniently installed at both ends of the steel plate 6 to be tested) to prevent the steel plate 6 to be tested from sliding along the direction of the guide rail during the test. Further, the thickness of the side limiting plate 4 is greater than the thickness of the steel plate 6 to be tested, the purpose is to limit the movement of the spacer 18 during the sample preparation process. That is, the pad strip 18 is supported on the side limiting plate by a rigid rod, so as to avoid the wedge-shaped pad being extruded by the sample during the sample preparation process;

[0043] 2) Place the spacer 18 on the upper surface of the steel plate 6 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com