Novel LED lamp strip and liquid crystal module provided with same

A technology for LED light strips and liquid crystal modules, which is applied to the parts of lighting devices, lighting and heating equipment, instruments, etc., can solve the problem of vignetting quality, the LED light-emitting area cannot be completely covered, and it cannot meet the requirements of narrow borders and no borders. and other problems to achieve the effect of meeting the design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

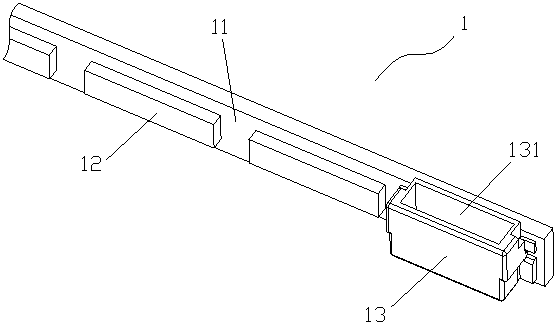

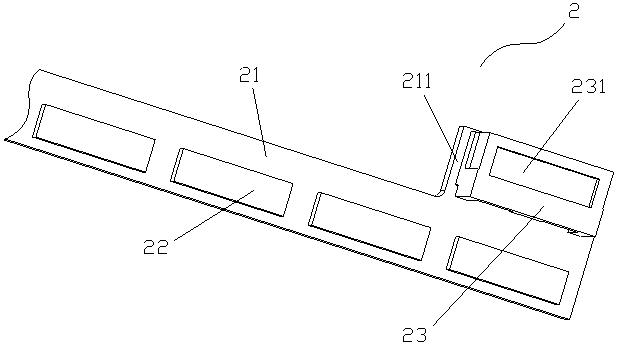

[0017] Such as image 3 As shown, a new type of LED light bar includes a strip-shaped PCB board 21, and the surface of the PCB board 21 is packaged with a plurality of equally spaced LEDs 22 along its length direction. The terminal side of the PCB board 21 A connecting portion 211 extends from the portion along its width direction. The connecting portion 211 of the PCB 21 is provided with a connecting terminal 23 on its surface.

[0018] In this embodiment, in order to improve the heat dissipation effect, the PCB board 21 is an aluminum substrate; the size of the connecting terminal 23 is 7.9 mm.

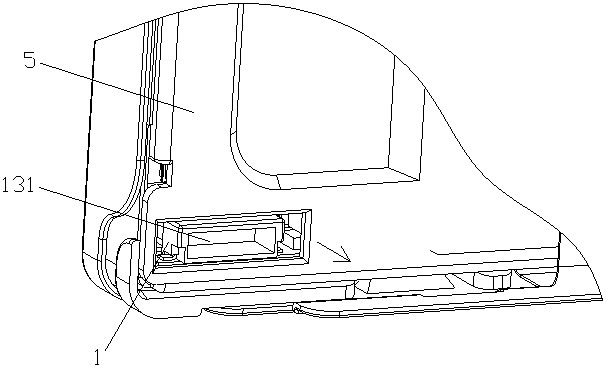

[0019] Such as Figure 3~5 As shown, a liquid crystal module applying the above-mentioned new type of LED light bar, including a back plate 3, a new type of LED light bar 2 and a light guide plate 4, the light guide plate 4 is arranged on the back plate 3, and the new type of LED light bar The light bar 2 is arranged on the side of the light guide plate 4, and a visible area A of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com