Patents

Literature

121 results about "Composite grid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

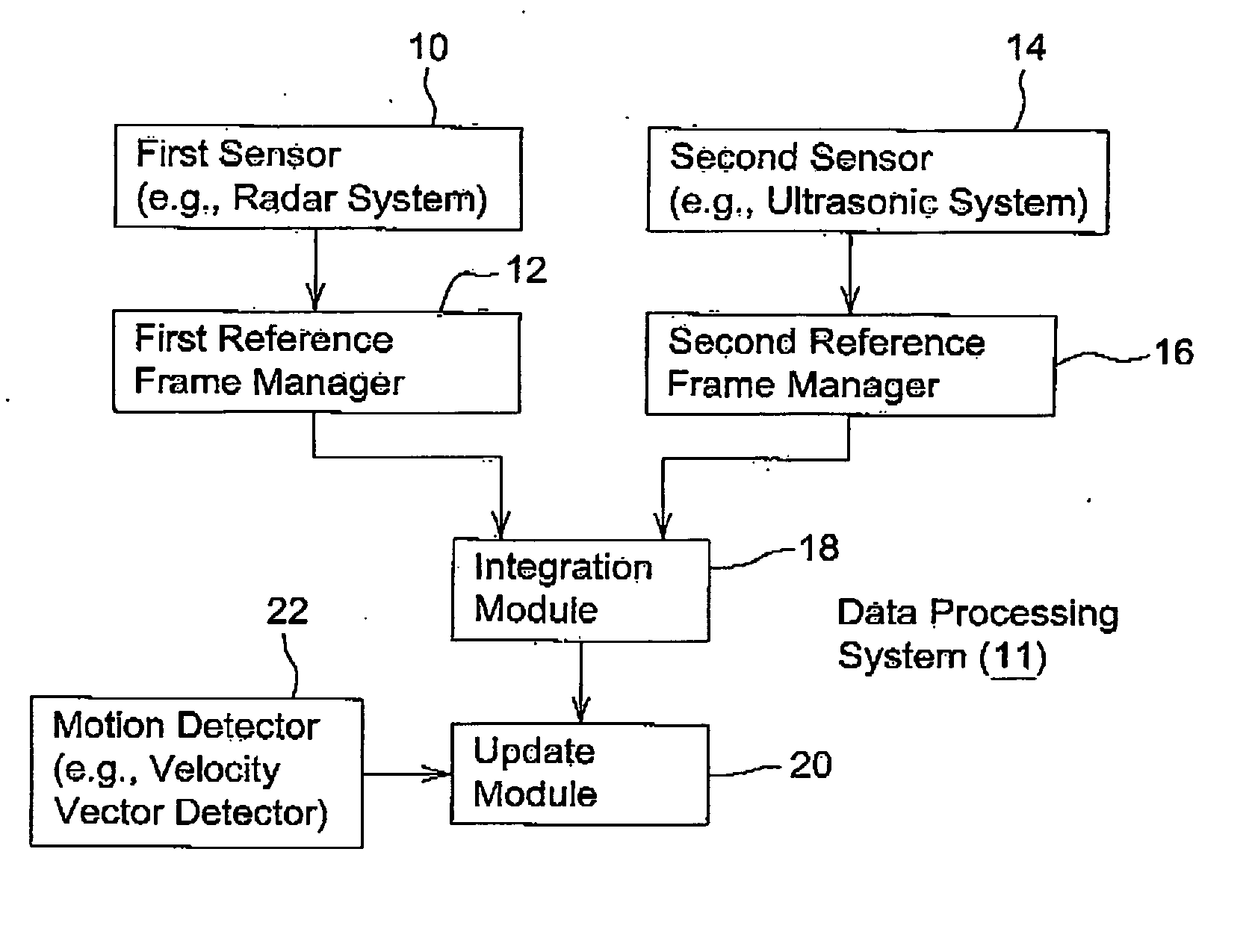

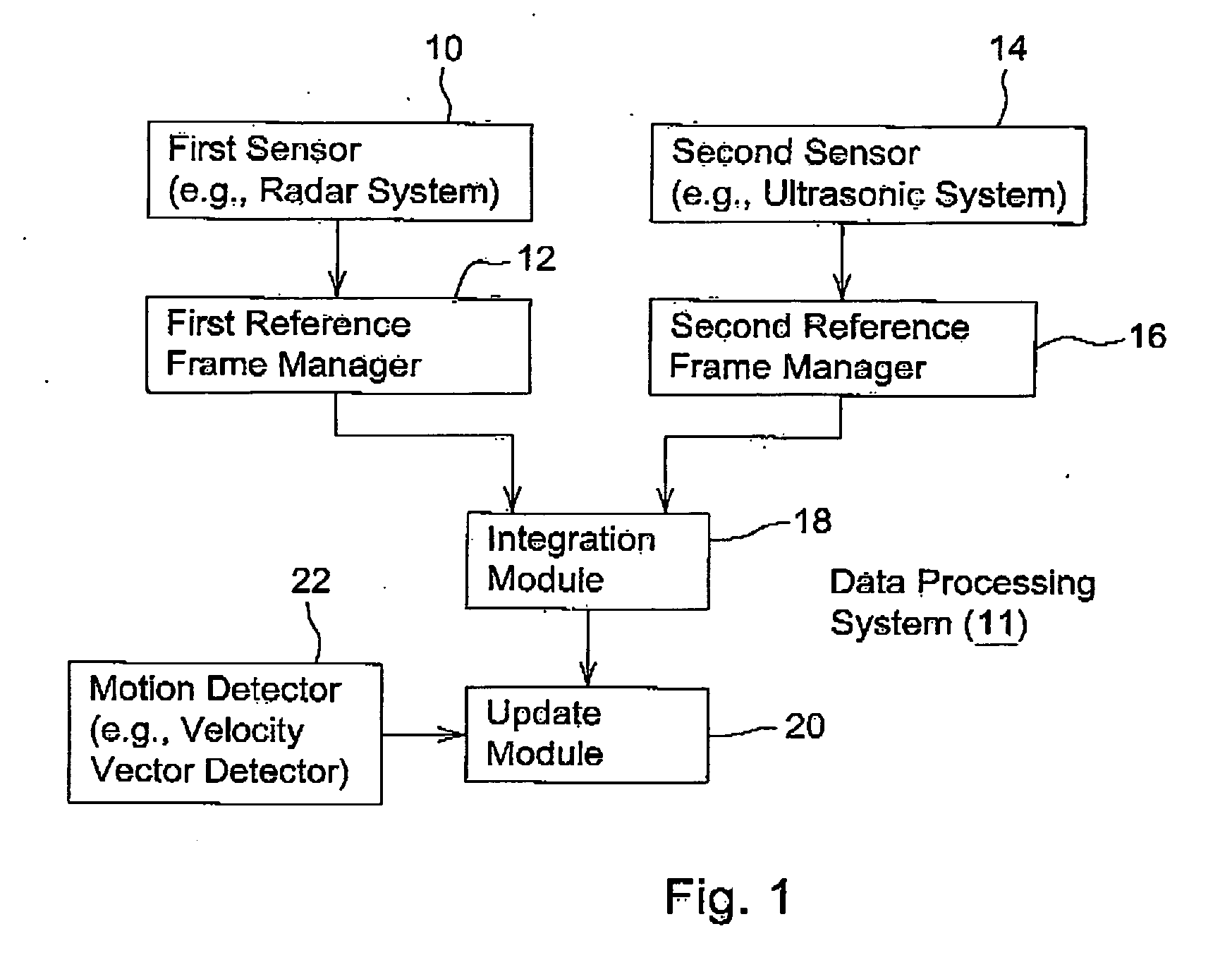

Method and system for sensor signal fusion

ActiveUS7266477B2Reliable determinationDigital data processing detailsAnti-collision systemsTerrainComposite grid

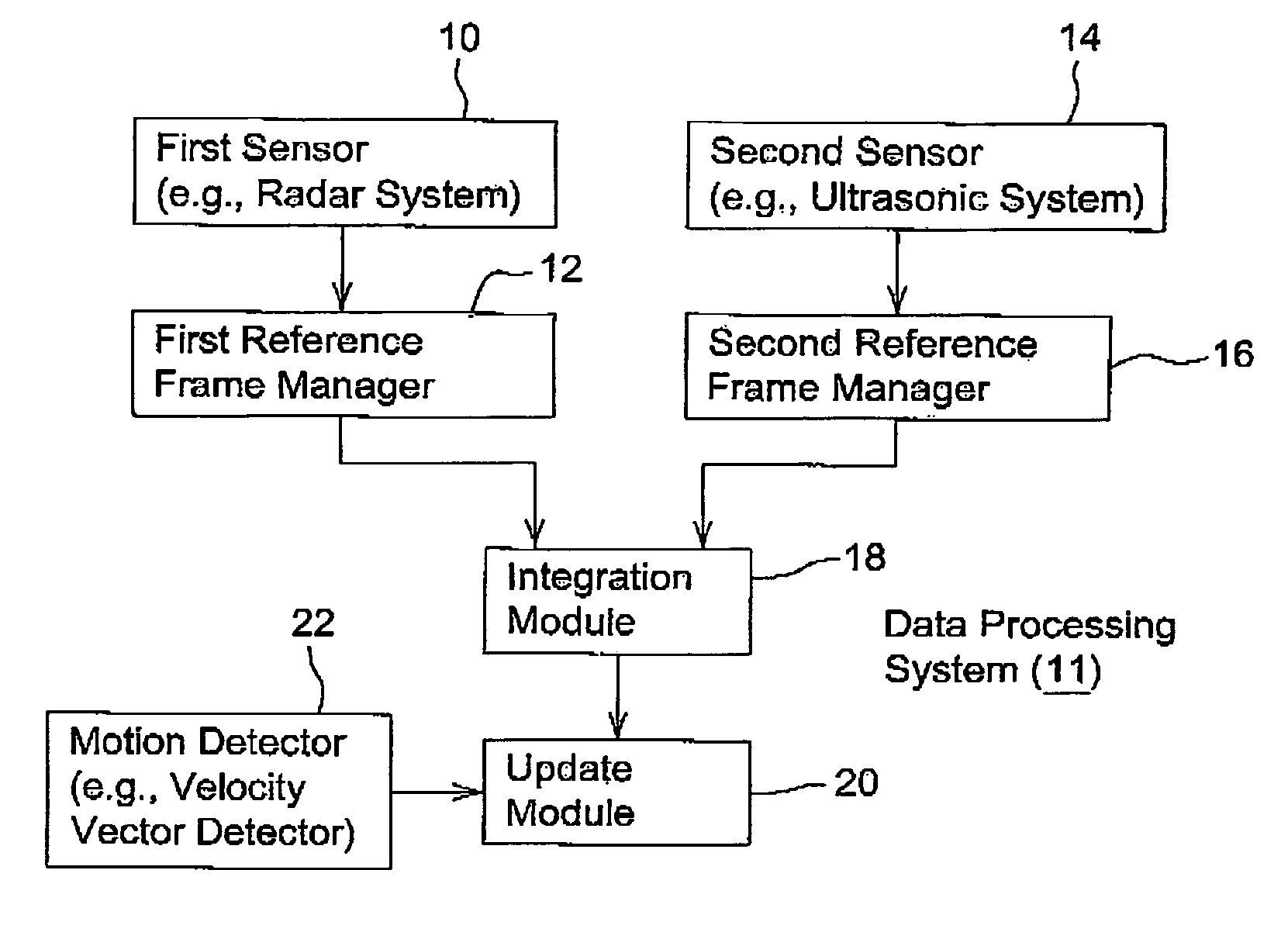

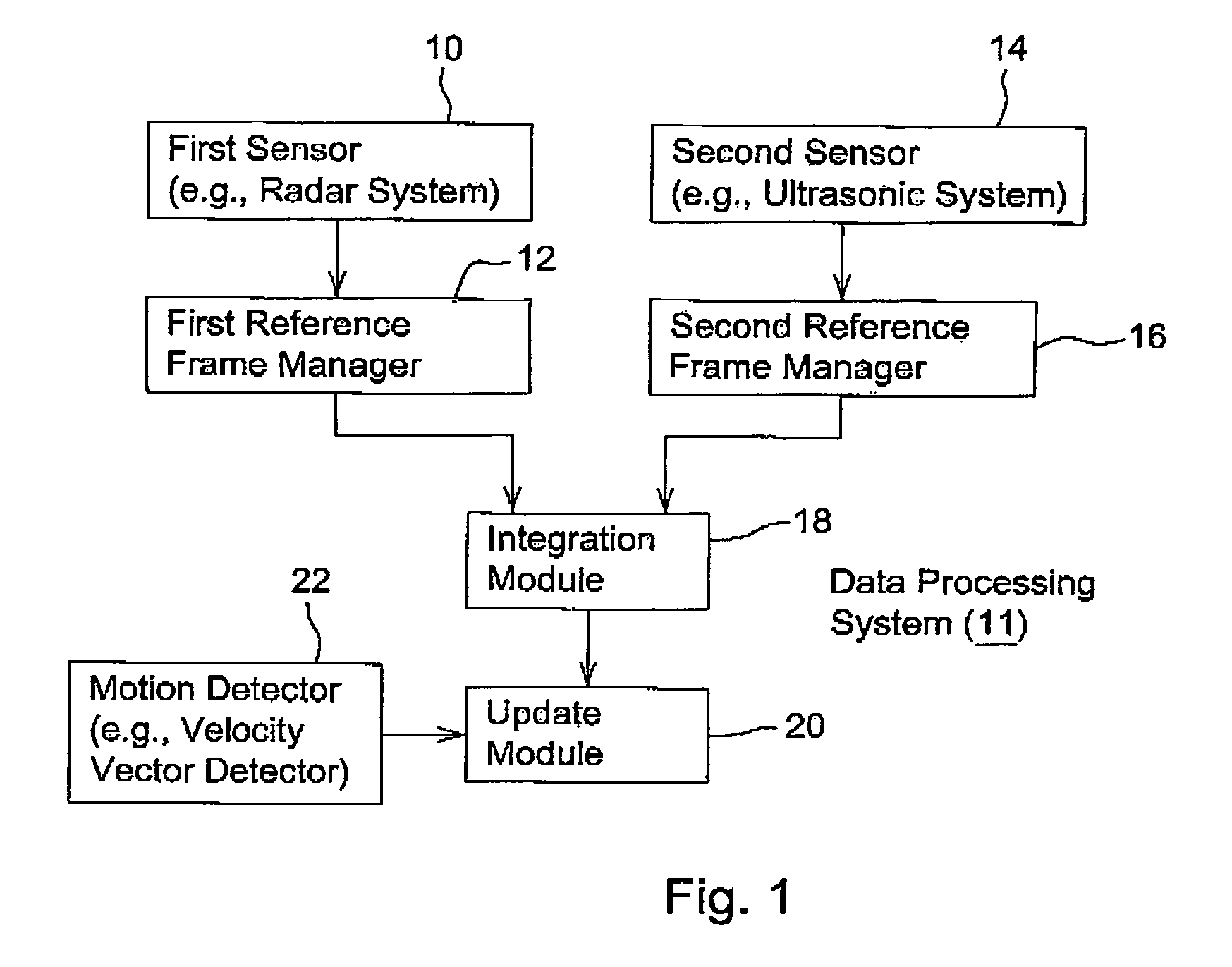

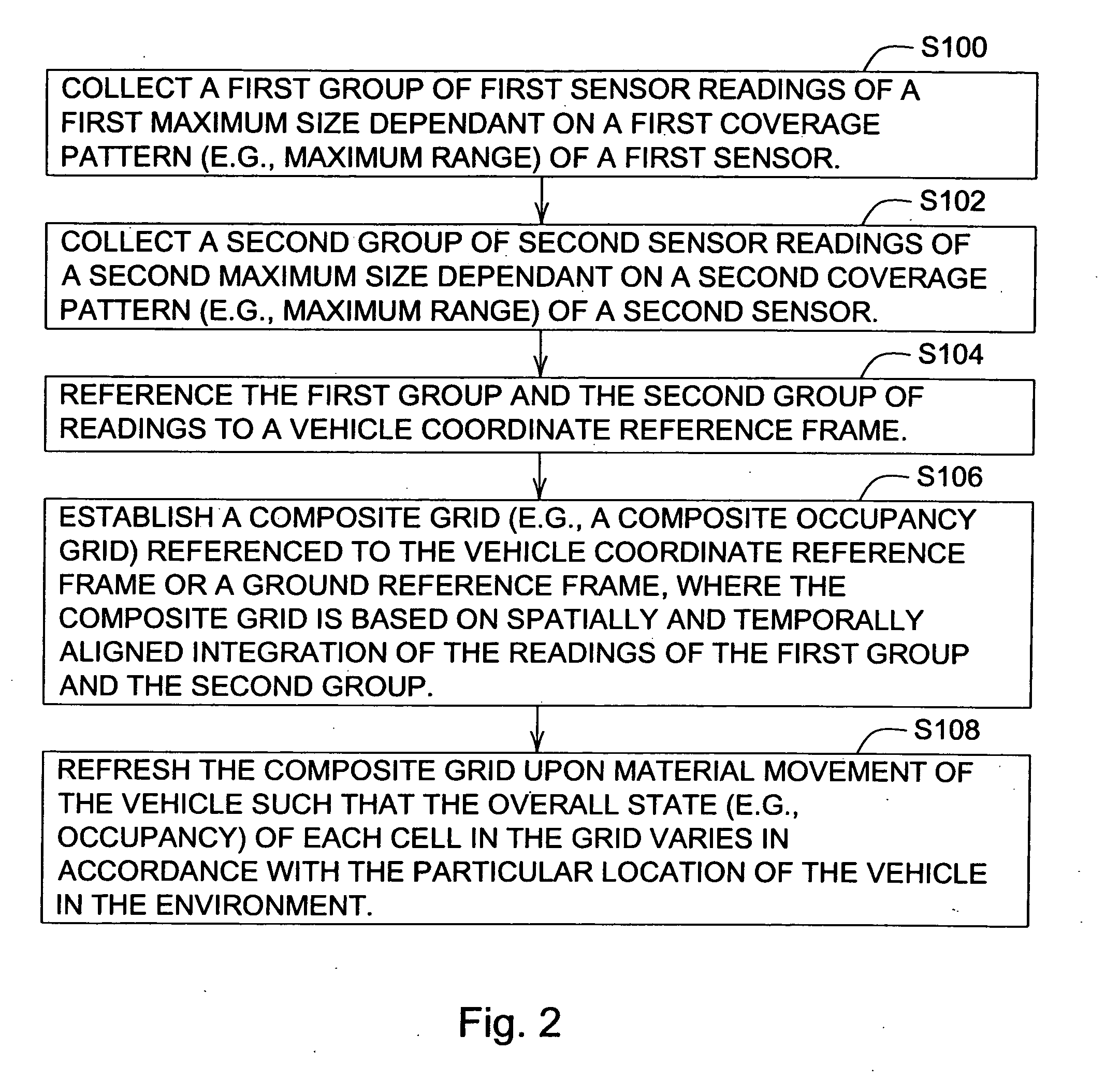

The first sensor collects a first group of first sensor readings of first fixed size dependent on a range of a first sensor and safeguarding requirements of a vehicle. A second sensor collects a second group of second sensor readings of second fixed size dependent on a range of a second sensor and the safeguarding requirements. A reference frame manager references the first group and the second group of readings to a vehicle coordinate reference frame. An integration module establishes a composite grid referenced to the ground based on a spatially aligned integration of the readings of the first group and the second group. A update module refreshes the composite grid upon material movement of the vehicle such that the global occupancy of each cell in the composite grid varies in accordance with the particular location of the vehicle on the terrain.

Owner:DEERE & CO

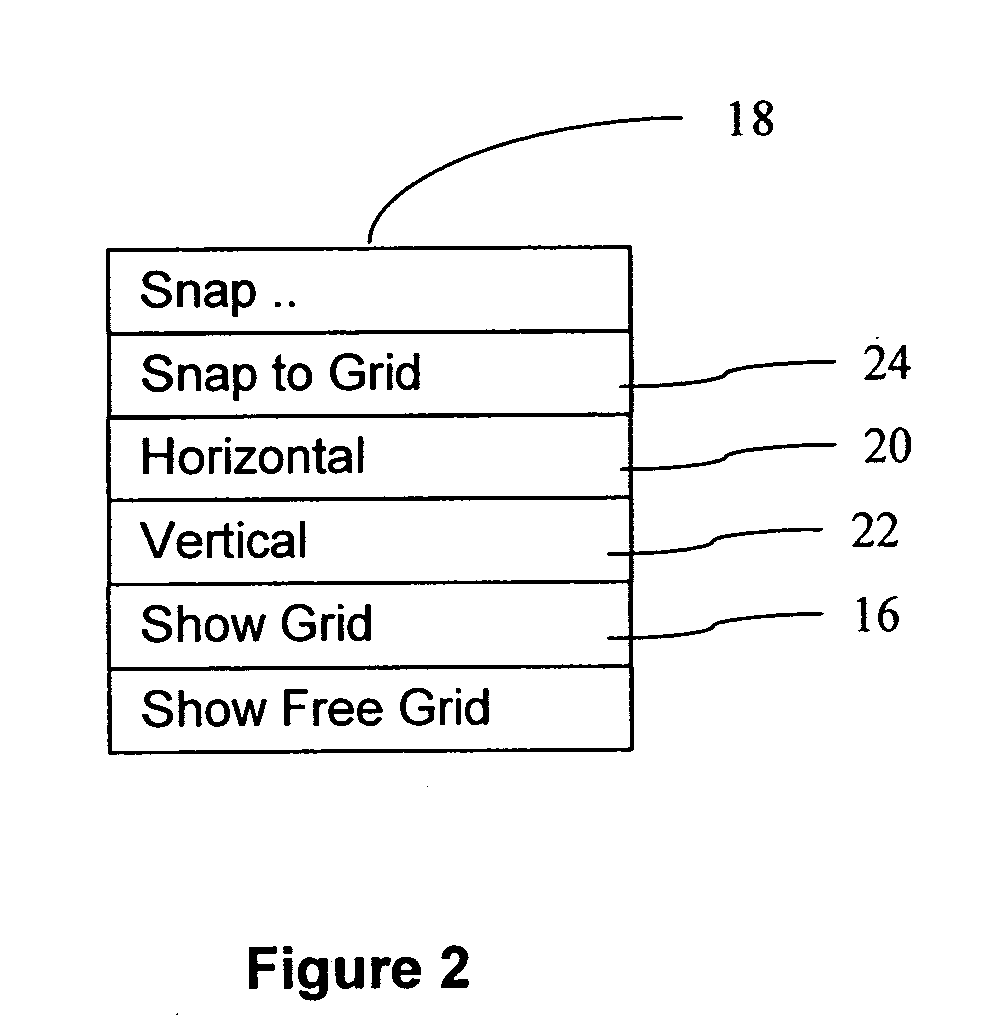

Method for creating and using user-friendly grids

InactiveUS20050068290A1Cathode-ray tube indicatorsInput/output processes for data processingGraphicsGraphical user interface

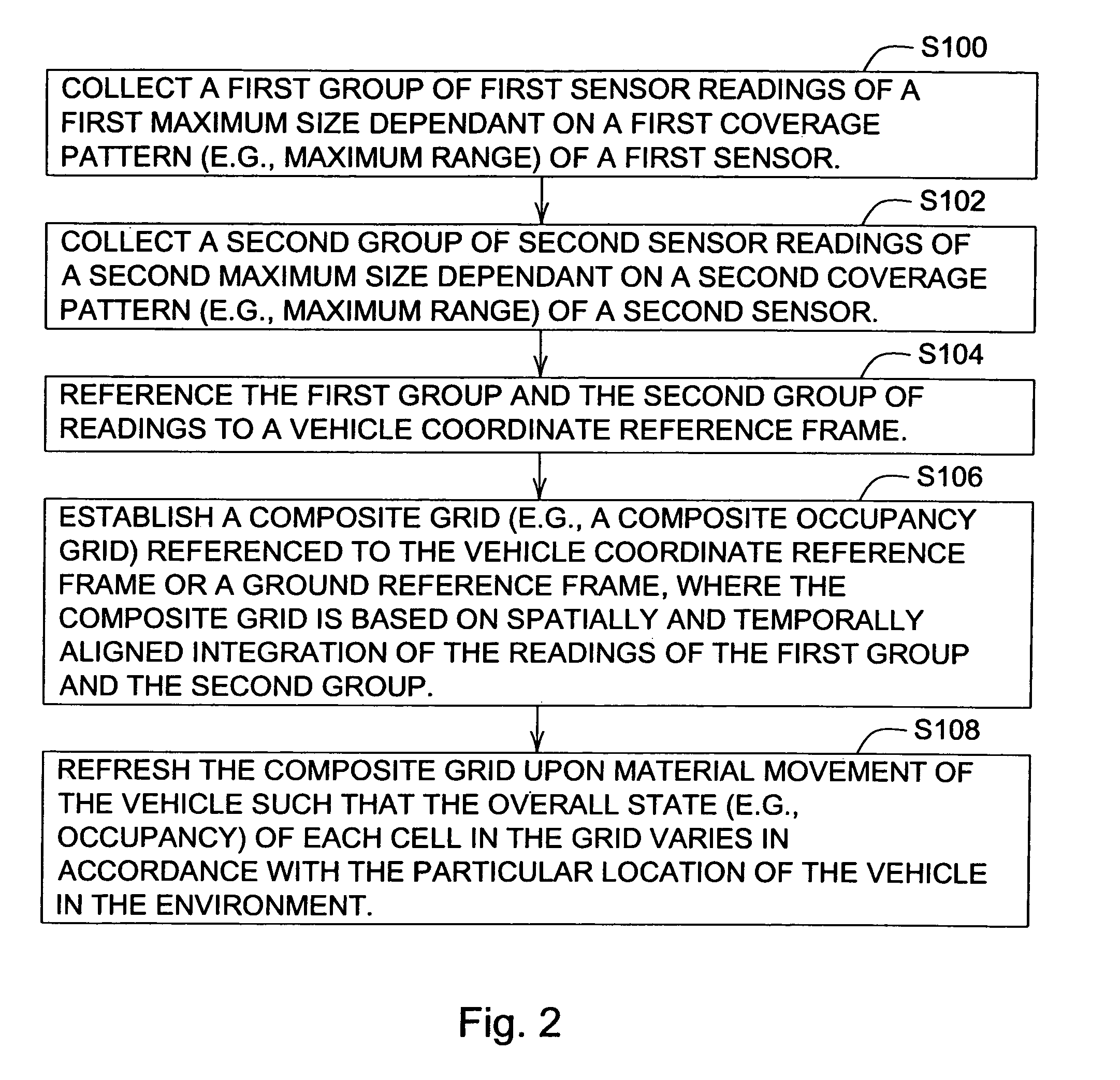

A graphic user interface and method for creating and using grids includes displaying one or more grids as graphic objects having many of the properties associated with common graphic objects. As a result, the grids may be independently moved and / or resized in a manner similar to the moving and / or resizing of other graphic objects. In addition, the grids may be snapped to other grids in a manner similar to then snapping of other graphic objects to a grid. Thus, an complex composite grid can be formed by snapping multiple grids together.

Owner:NBOR CORP

Method and system for sensor signal fusion

ActiveUS20070005306A1Reliable determinationAmplifier modifications to reduce noise influenceDigital computer detailsTerrainComposite grid

The first sensor collects a first group of first sensor readings of first fixed size dependent on a range of a first sensor and safeguarding requirements of a vehicle. A second sensor collects a second group of second sensor readings of second fixed size dependent on a range of a second sensor and the safeguarding requirements. A reference frame manager references the first group and the second group of readings to a vehicle coordinate reference frame. An integration module establishes a composite grid referenced to the ground based on a spatially aligned integration of the readings of the first group and the second group. A update module refreshes the composite grid upon material movement of the vehicle such that the global occupancy of each cell in the composite grid varies in accordance with the particular location of the vehicle on the terrain.

Owner:DEERE & CO

Weak coverage area detection method and system

ActiveCN106973406ARealize detectionImprove detection accuracyWireless communicationGeographic siteTelecommunications

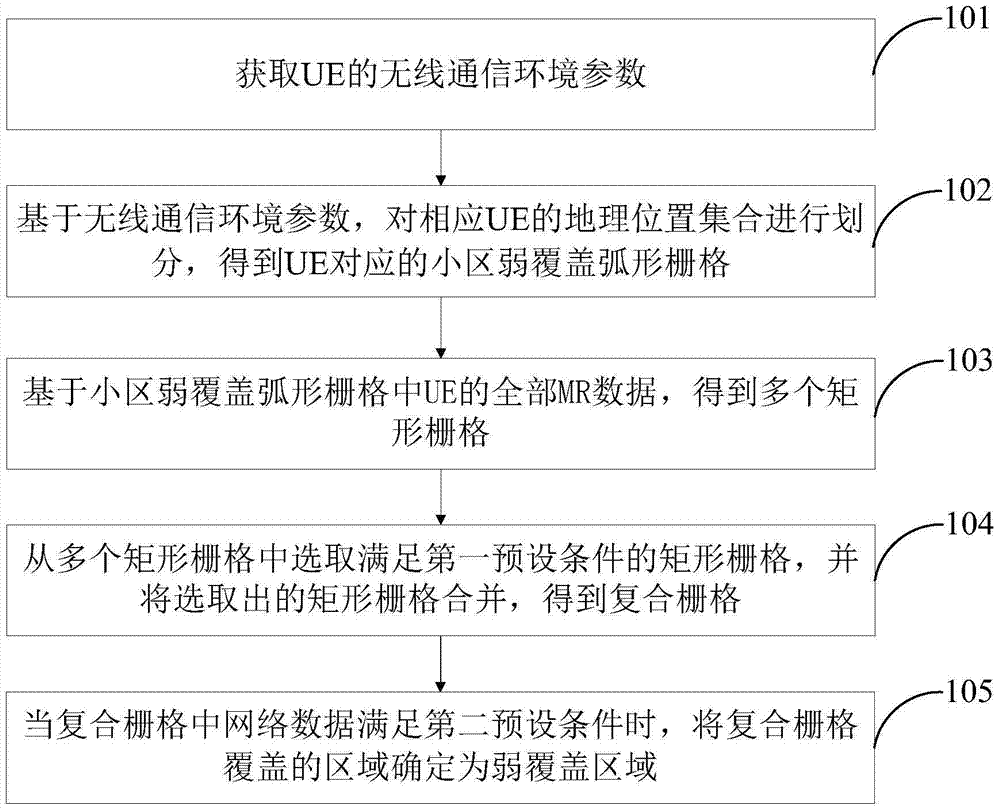

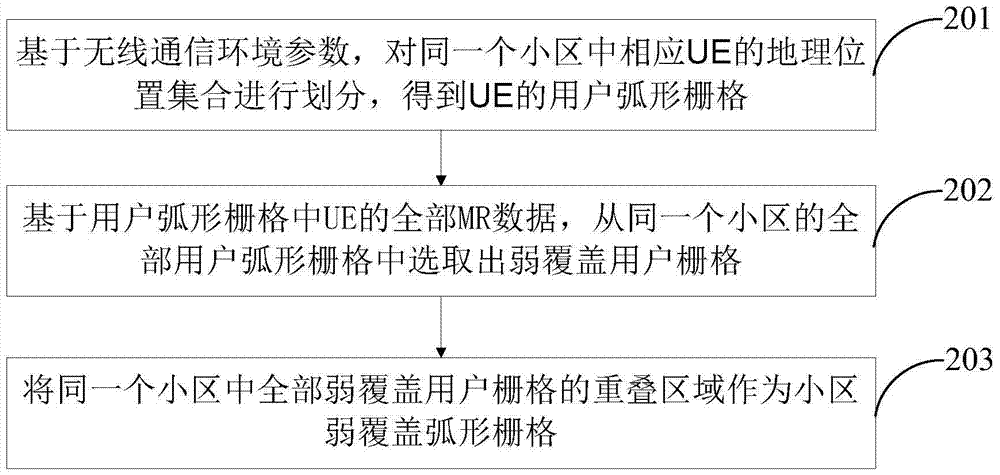

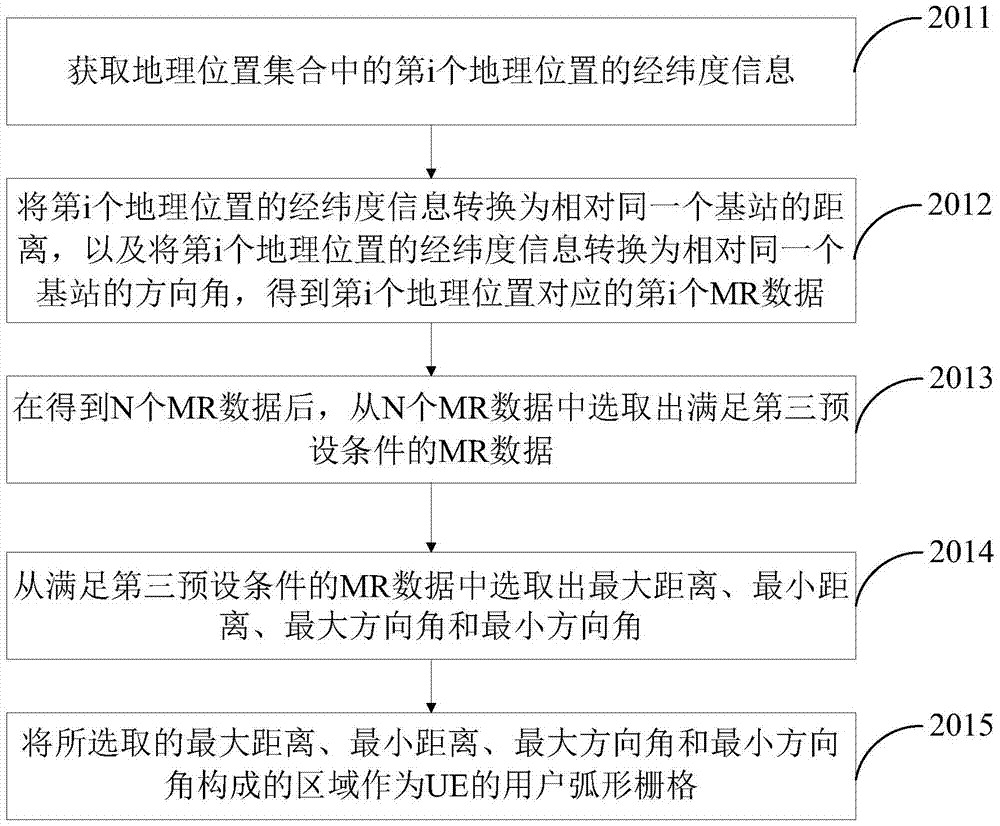

The invention provides a weak coverage area detection method and system. The method comprises the following steps: after acquiring wireless communication environment parameters of UE, dividing a geographical location set of the UE based on the wireless communication environment parameters to obtain cell weak coverage curved grids corresponding to the UE; obtaining multiple rectangular grids based on all MR data of the UE in the cell weak coverage curved grids; selecting the rectangular grids that meet first preset conditions from the multiple rectangular grids, and combining the selected rectangular grids to obtain a composite grid; and when the UE parameters calculated by the composite grid meet second preset conditions, determining an area covered by the composite grid as a weak coverage area. Thereby, the weak coverage area can be detected based on the wireless communication environment parameters of the UE, and the wireless communication environment parameters of the UE are the data actively reported by the UE without the agreement of holders, and thus the promotion difficulty of the detection method provided by the invention can be reduced.

Owner:BOCO INTER TELECOM

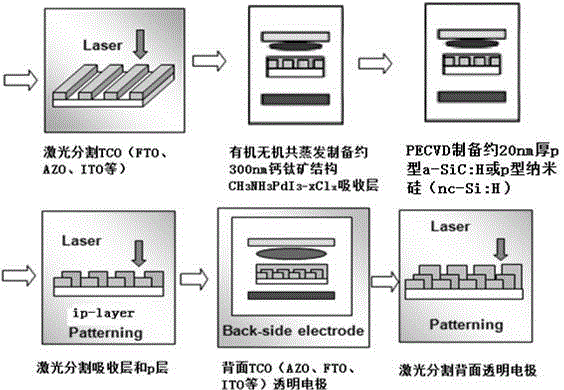

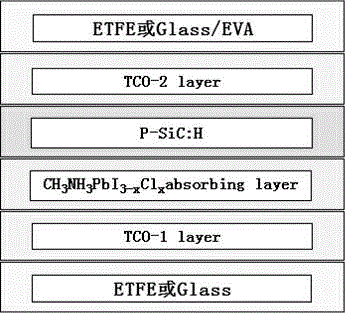

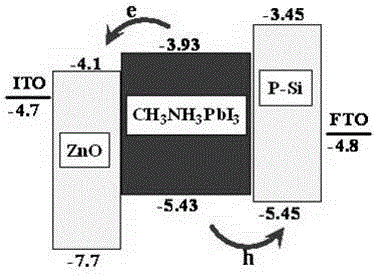

Novel two-sided thin film solar cell and industrial manufacturing method thereof

InactiveCN104157789ALow costReduce usageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringComposite grid

The invention belongs to the field of high-efficiency and low-cost thin film solar cells and particularly provides a novel two-sided thin film solar cell and an industrial manufacturing method thereof. Firstly, laser segmentation is conducted on TCO-1 (front electrode and electron transport materials (ETM)), an ABX3 (A=CH3NH3, B=Pd, Sn and the like, and X=I, Cl, Br and the like) perovskite absorbing layer (the thickness ranges from 200 nm to 400 nm, the band gap width is 1.5 eV and the electron affinity is 3.93 eV) is deposited on TCO-1 conducting glass (the band gap width is larger than 3.2 eV and the electron affinity is about 4.8 eV) obtained after laser segmentation in a dual-source coevaporation mode, samples are transferred into PECVD equipment, a gradient doped p / p<+> type hydrogenated silicon-based thin film (the thickness ranges from 5 nm to 30 nm, the band gap width ranges from 1.8 eV to 2.0 eV, and the electron affinity is 3.45 eV) is deposited, and a back-side electric field is established; after secondary laser segmentation is immediately conducted on the samples, the samples are transferred into vacuum equipment, TCO-2 (ITO or ZnO or the like) is deposited, and finally third laser segmentation is conducted on the samples obtained after the procedures so as to establish composite grid line electrodes. Finally, the high-efficiency and low-cost novel two-sided light-catching solar cell is obtained.

Owner:YUNNAN NORMAL UNIV

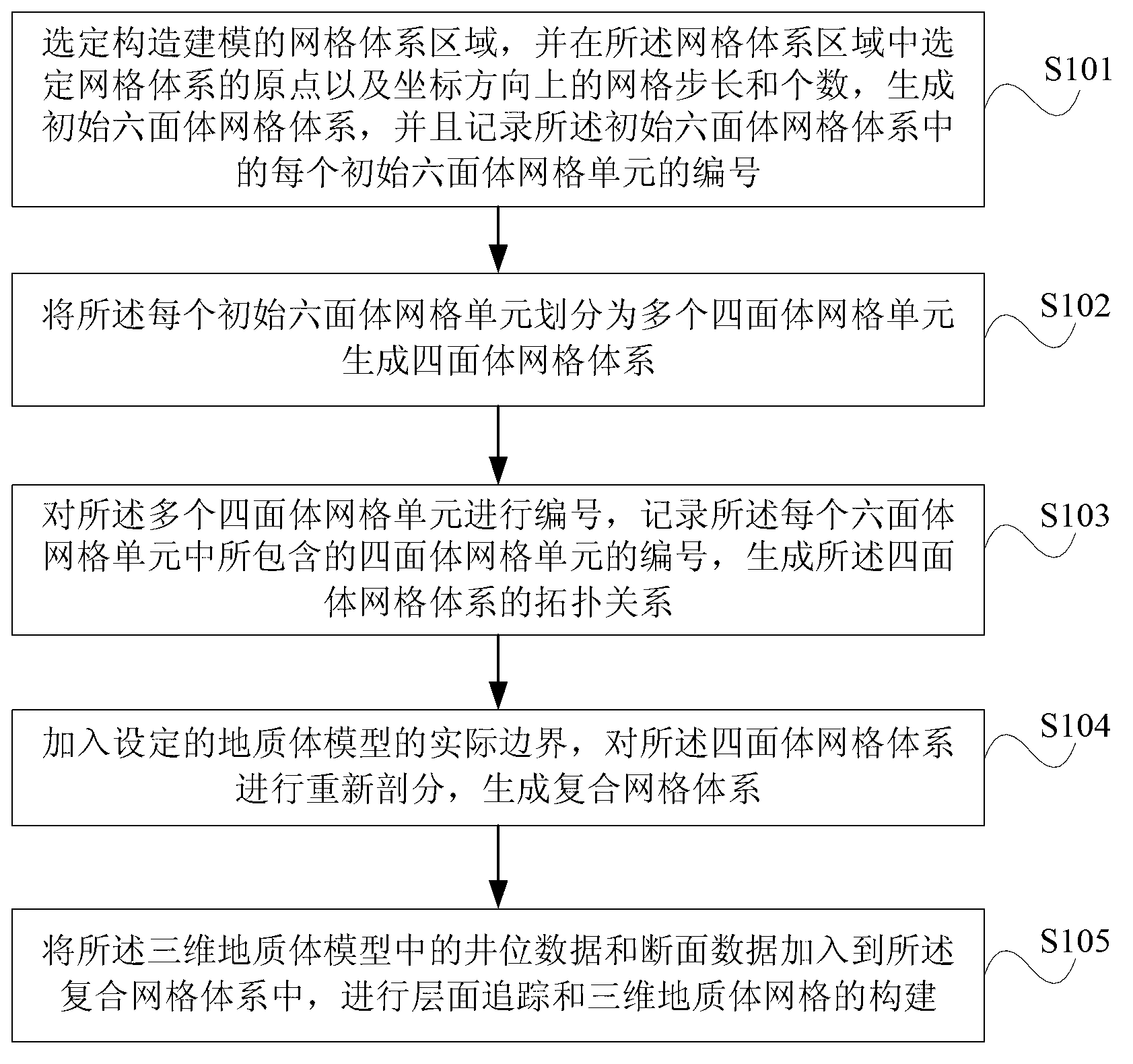

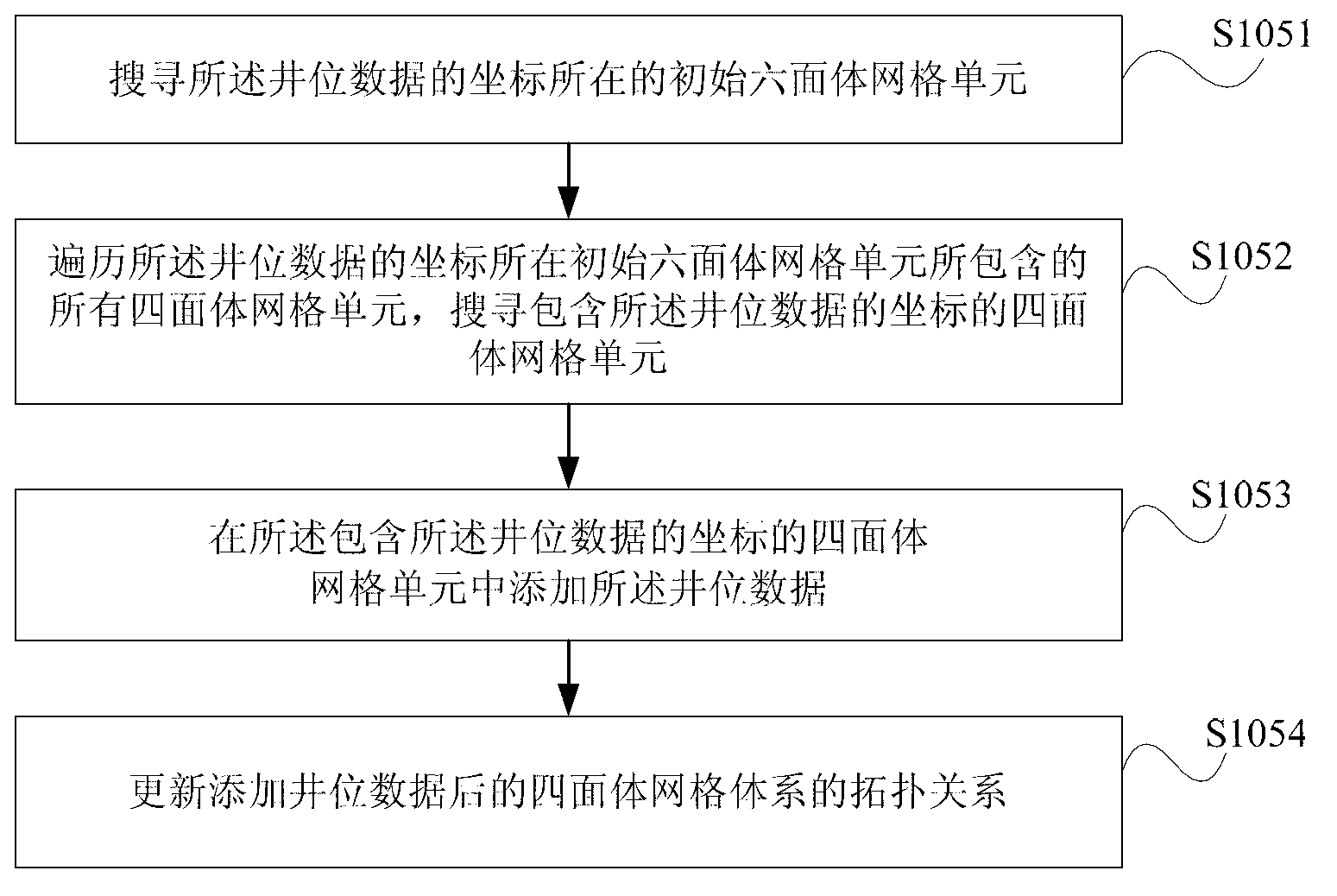

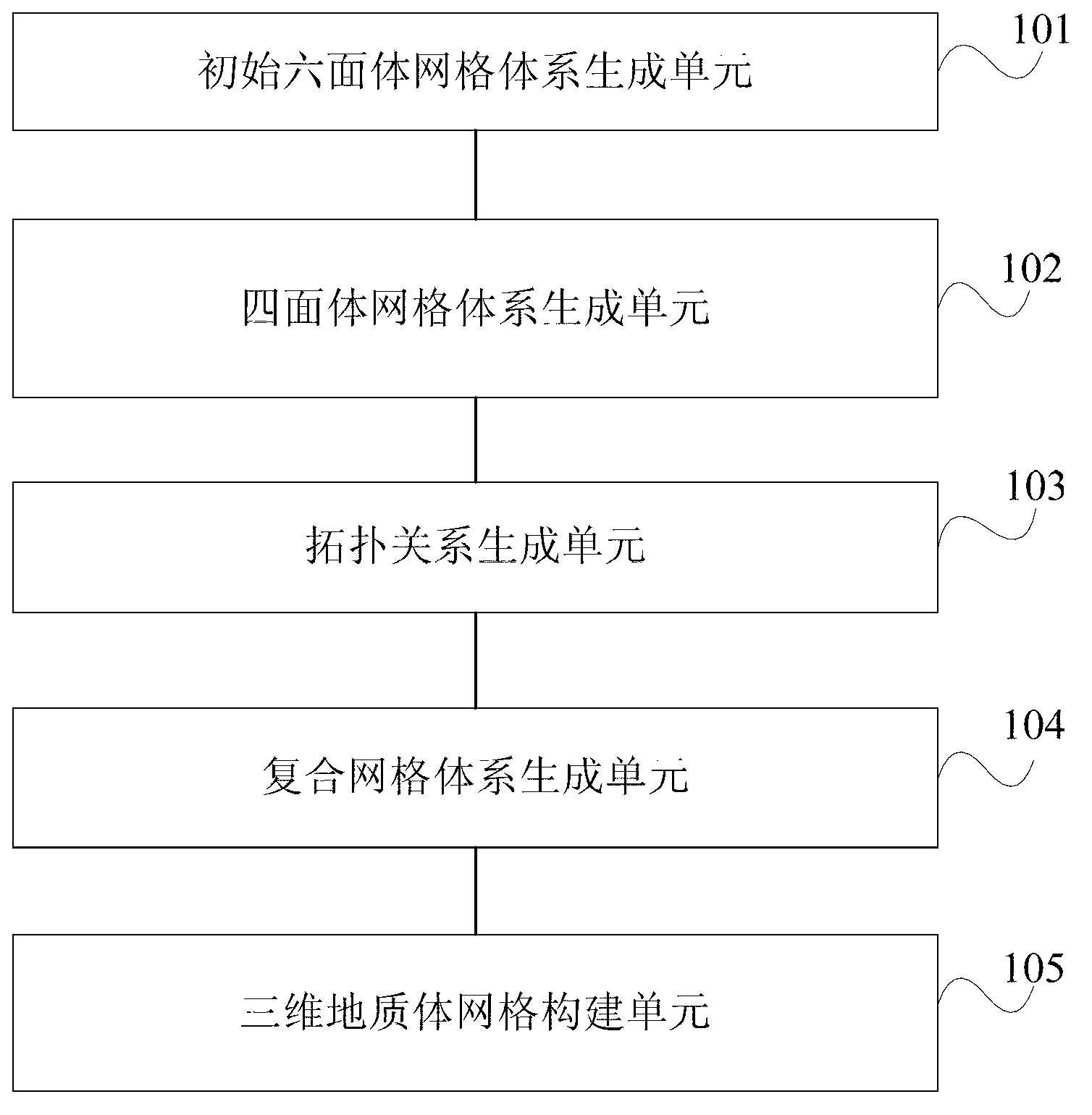

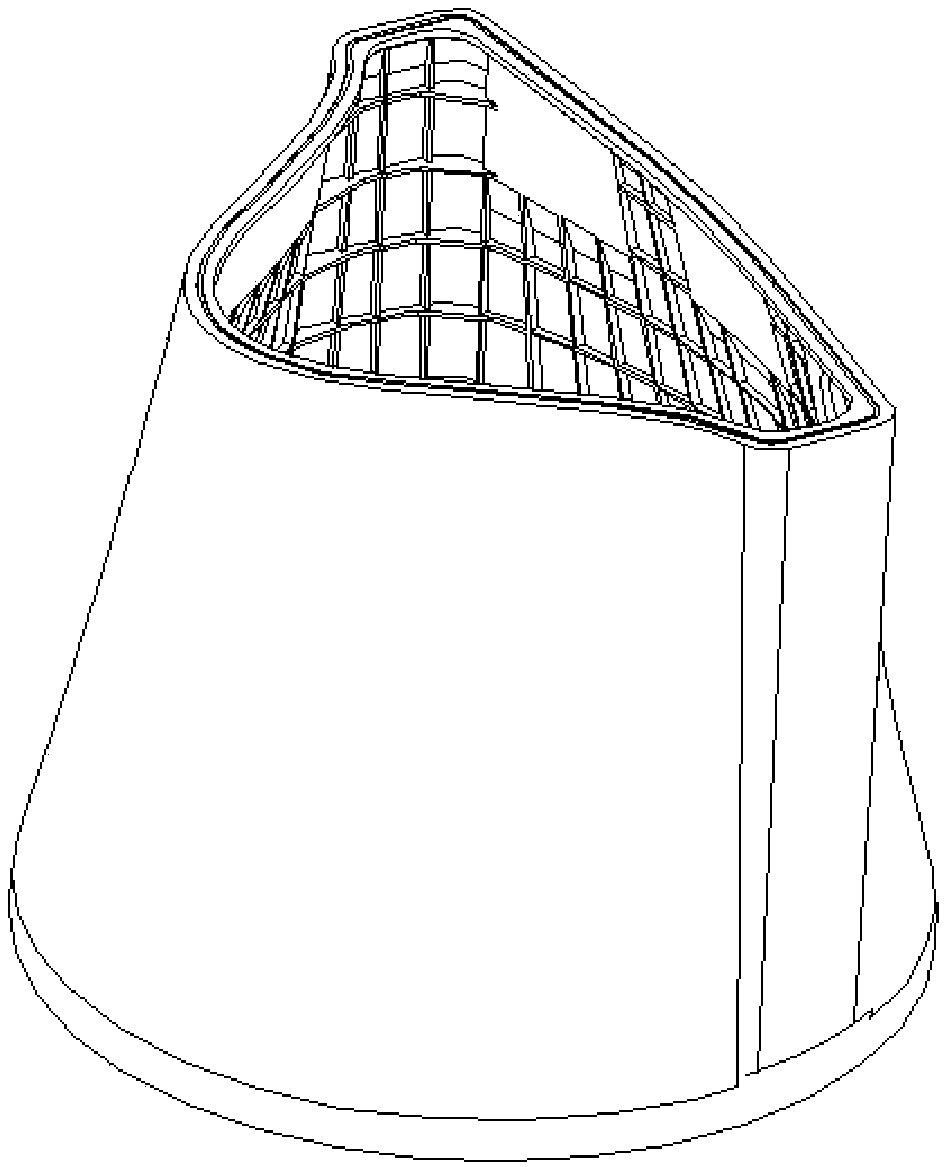

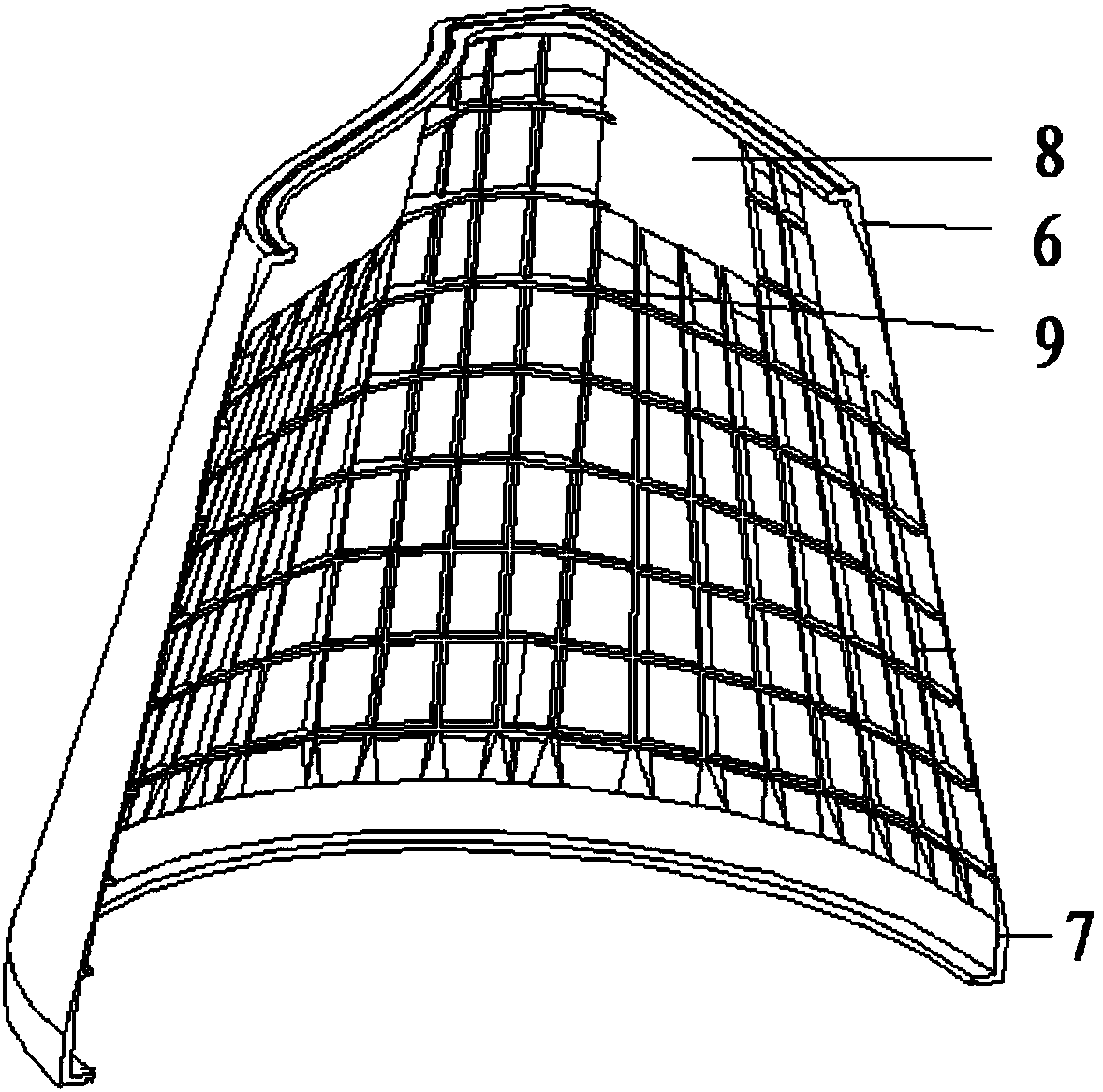

Three-dimensional geological structure modeling method and system based on composite grid

The invention embodiment discloses a three-dimensional geological structure modeling method and system based on a composite grid. The three-dimensional geological structure modeling method includes selecting a grid system area of structure modeling, selecting an origin of the grid system and the grid step size and number on the coordinate direction, and generating an initial hexahedral grid system; dividing each initial hexahedral grid unit into multiple tetrahedral grid units, and generating a tetrahedral grid system; numbering the multiple tetrahedral grid units, recording the number of the multiple tetrahedral grid units contained in each initial hexahedral grid unit, and generating topology relationship of the tetrahedral grid system; adding an actual boundary of a set geological body model, redividing the tetrahedral grid system, and generating a composite grid system; and adding well location data and cross section data of the three-dimensional geological body model into the composite grid system, and performing layer tracking and three-dimensional geological grid construction.

Owner:BEIJING GOLDENSUN PETROLEUM TECH

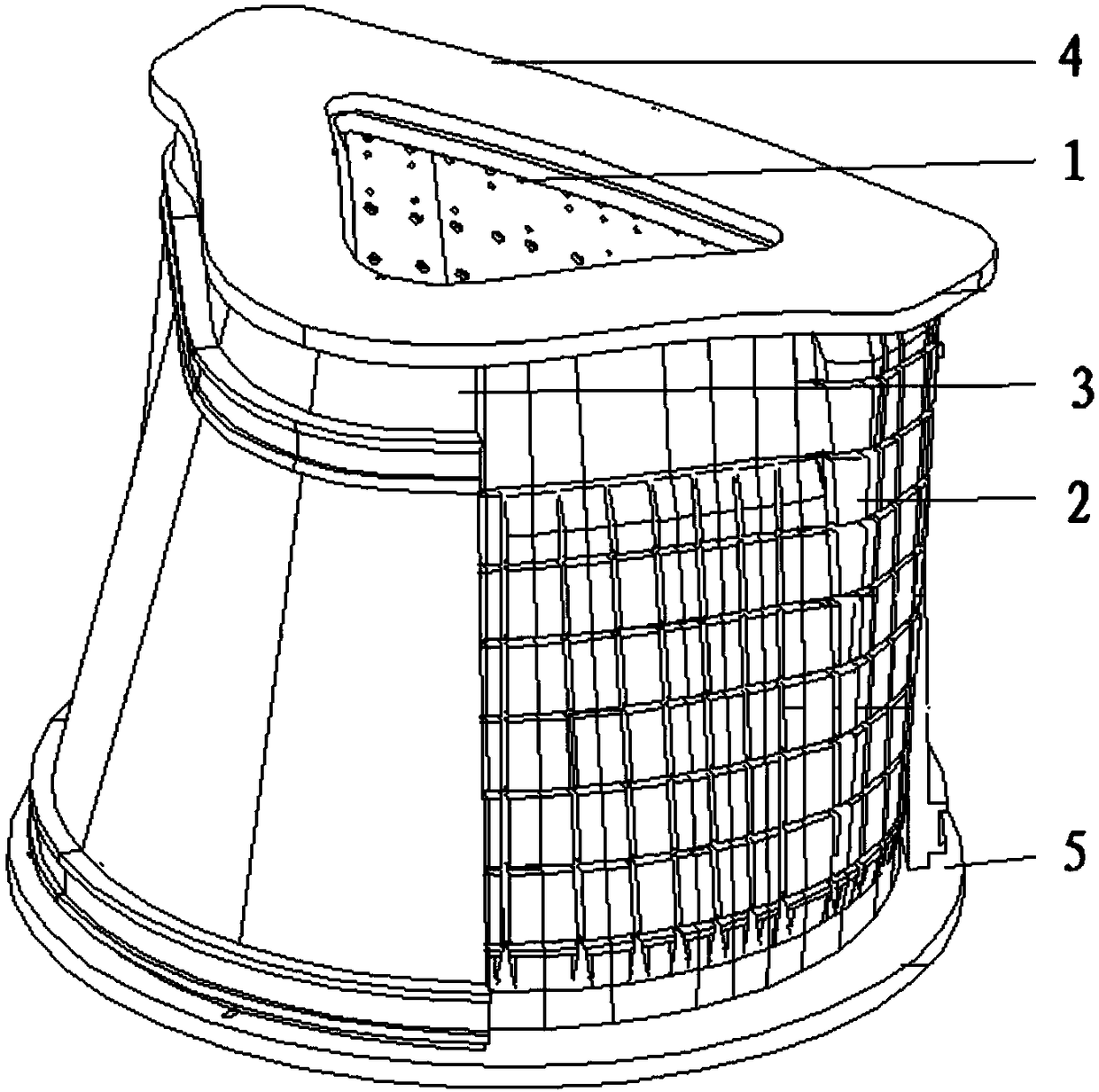

Forming method of heterogeneous composite grid skin cabin

The invention provides a forming method of a heterogeneous composite grid skin cabin, and relates to technical field of a composite forming process. The forming method comprises the following step (1)of making a forming mould of the heterogeneous composite grid carbon fiber prepreg cabin; the step (2) of spreading carbon cloth prepreg at a hoop rib deep-groove area; the step (3) of winding carbonfiber prepreg filaments, and filling the hoop rib deep-groove area; the step (4) of winding the carbon fiber prepreg filaments, and spreading the carbon fiber prepreg; the step (5) of making vacuum suction treatment for first time; the step (6) of spreading the carbon fiber prepreg, and making vacuum suction treatment for second time; the step (7) of winding the carbon fiber prepreg filaments, spreading the carbon fiber prepreg, and making vacuum curing treatment; and the step (8) of removing the mould, and obtaining the heterogeneous grid carbon fiber prepreg cabin. According to the formingmethod provided by the invention, the problems of demoulding of a male die disc, locating and pressurization of a female die disc and so forth are solved, and the internal quality and profile accuracyrequirements of products are ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

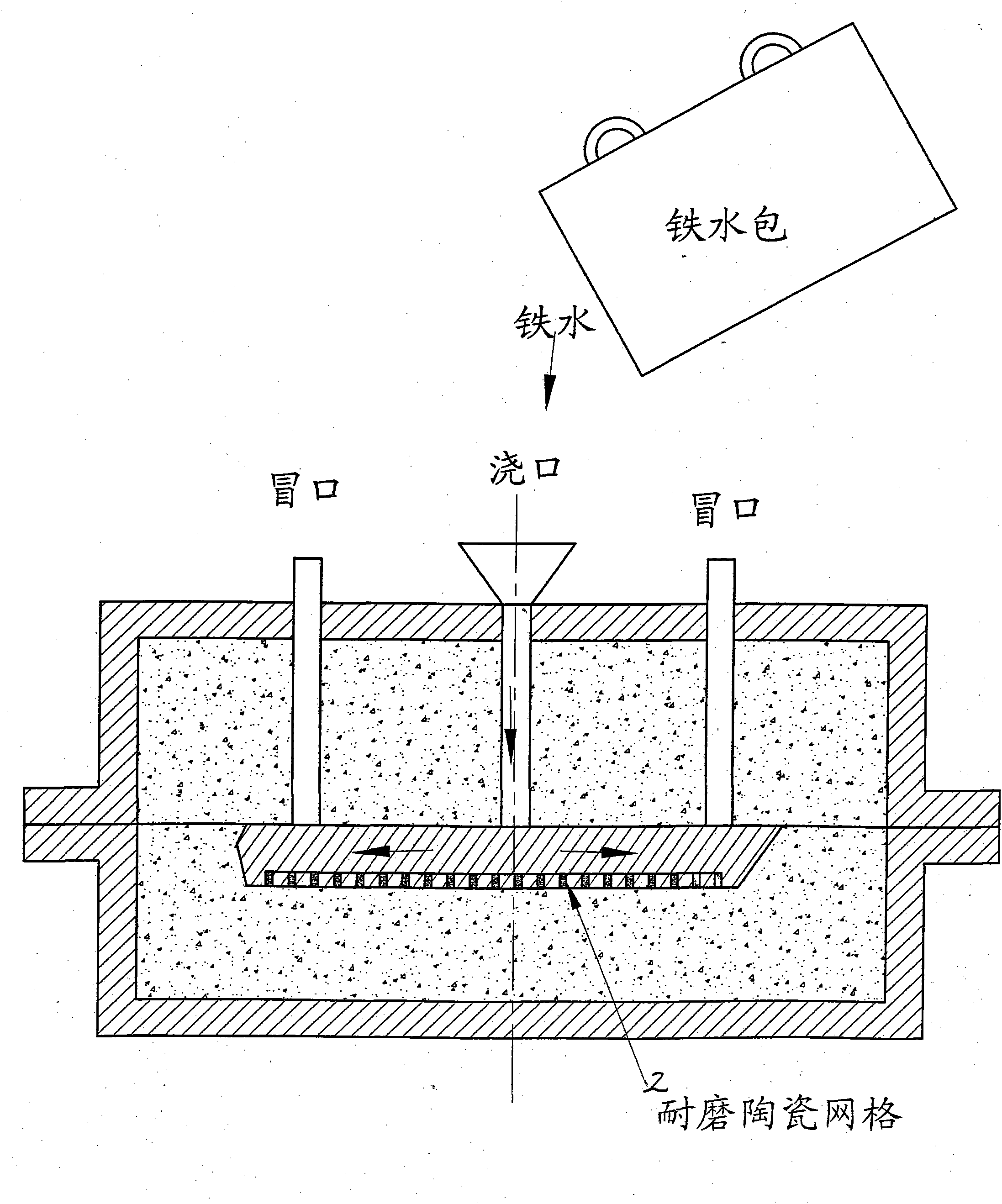

Manufacture technology for compositing high-chromium alloy ceramic grain composite on surface of wear-proof machine part

The invention discloses a manufacture technology for compositing a high-chromium alloy ceramic grain composite on the surface of a wear-proof machine part, which comprises the following steps of: preparing a high-chromium alloy ceramic grain composite grid; fixing the high-chromium alloy ceramic grain composite grid on the shaped surface; and casting the machine part, so that the high-chromium alloy ceramic grain composite grid is fixed on the surface of the machine part. The manufacture technology organically combines the wear-proof resistance of the ceramic grain material with the mechanical performance of the high chromium alloy, can manufacture the composite material with good rigidity, impact resistance and wear resistance, can manufacture the composite material with the shape of grid, can manufacture the composite with various shapes and sizes such as taper, arc, arc and the like, secondly casts the super-hard netty composite to form into the wear-proof product as required, and can effectively meet the requirement of the work condition of crushing resistance and wearing resistance of the equipment.

Owner:钱兵

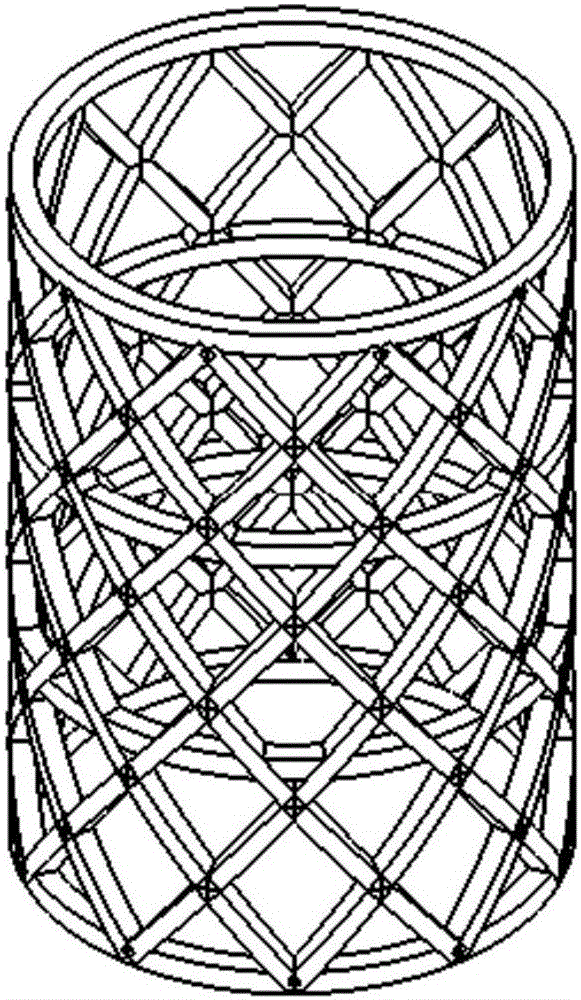

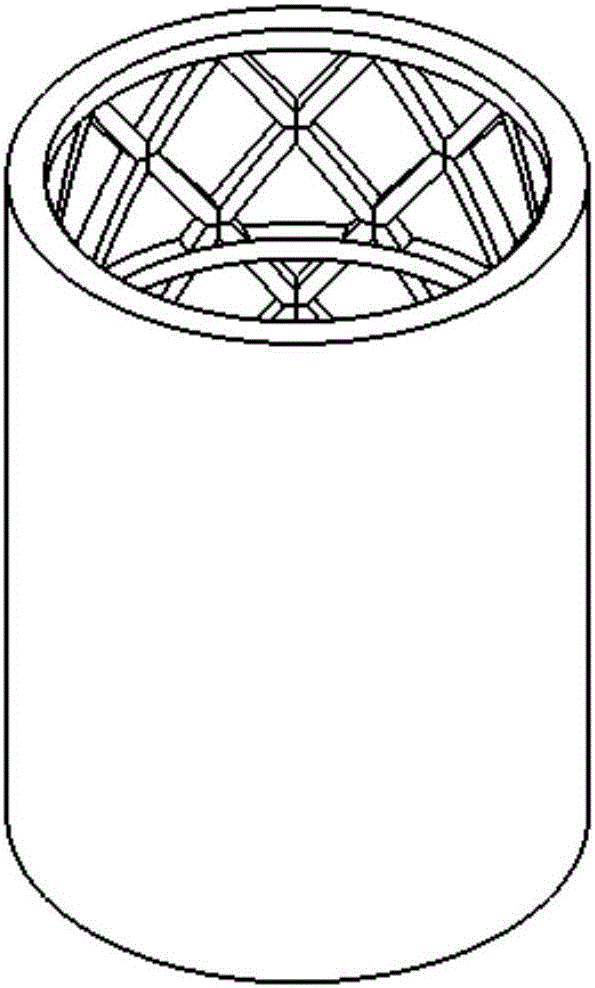

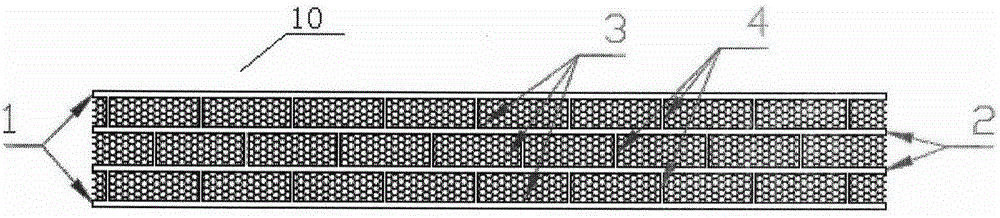

Preparation method for cylindrical composite grid structure

The invention provides a preparation method for a cylindrical composite grid structure. The preparation method comprises the steps of foam shaping, foam surface grooving, foam grooving concave surface processing, grid wet winding, rotary curing, demolding and the like, so that integral winding, co-curing and one-time forming of the composite grid structure are achieved. According to the preparation method for the cylindrical composite grid structure, grid structure wet winding integral forming and grid unitization processing are adopted; grid structure wet continuous winding is conducted; the cost is reduced; and the production efficiency is improved.

Owner:HENGSHEN

A compound bar, bar source self-separating VDMOS, 1GBT power unit and its making technology

InactiveCN101017849AQuick ShieldSimple manufacturing processSemiconductor/solid-state device manufacturingSemiconductor devicesState of artManufacturing technology

The invention relates to VDMOS and IGBT power device with composite grid and self-isolated grid-source. Wherein, it sets a thermal-oxidized SiO2 grid between source and multicrystal Si grid, and adds a Si3N4 layer to form a composite grid together with last grid to increase grid yield. Compared with prior art, this invention increase can fast shield grid window and generate only -very-thin oxidation layer to simplify manufacture technology, and needs low cost.

Owner:上海富华微电子有限公司 +1

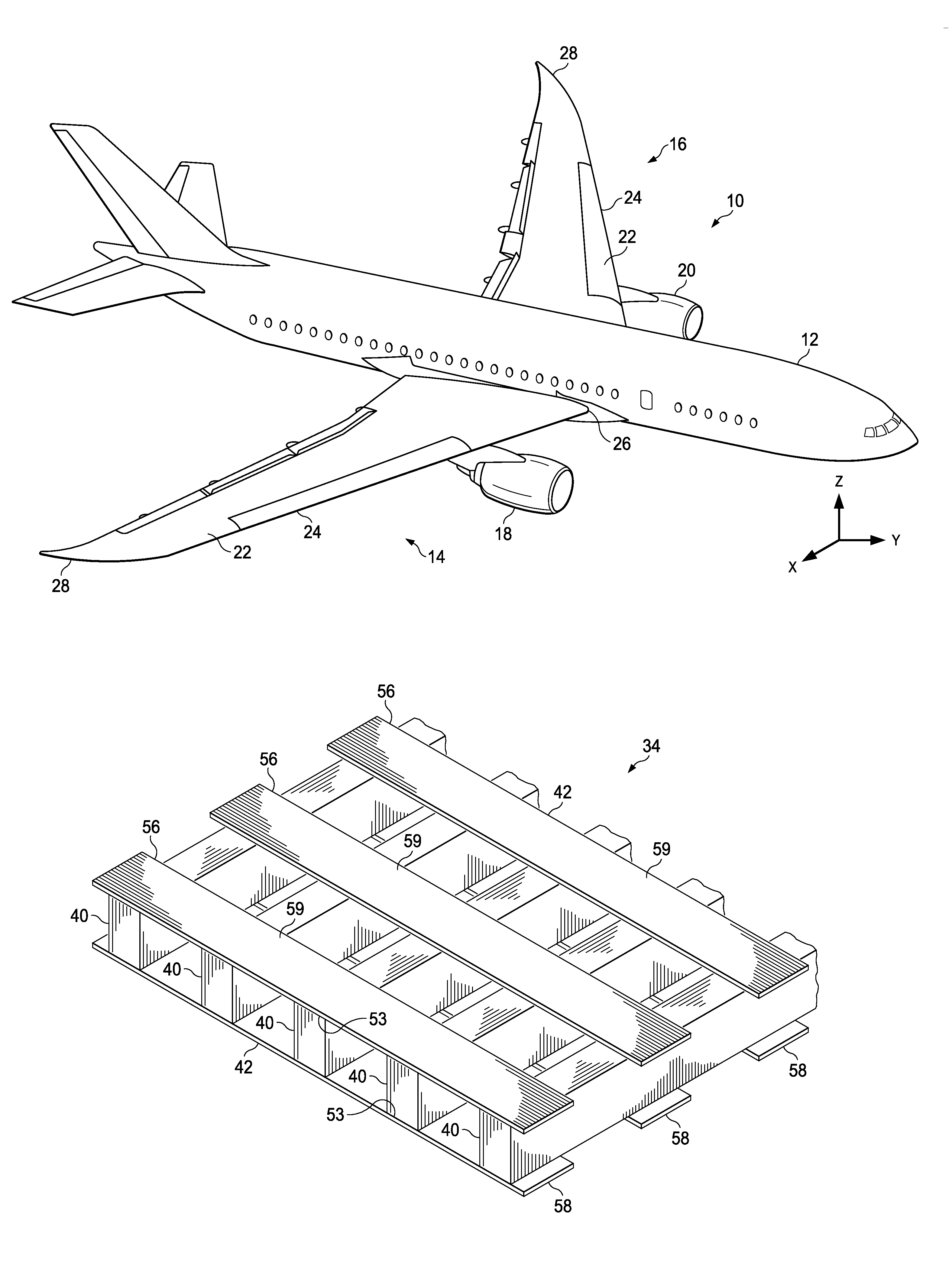

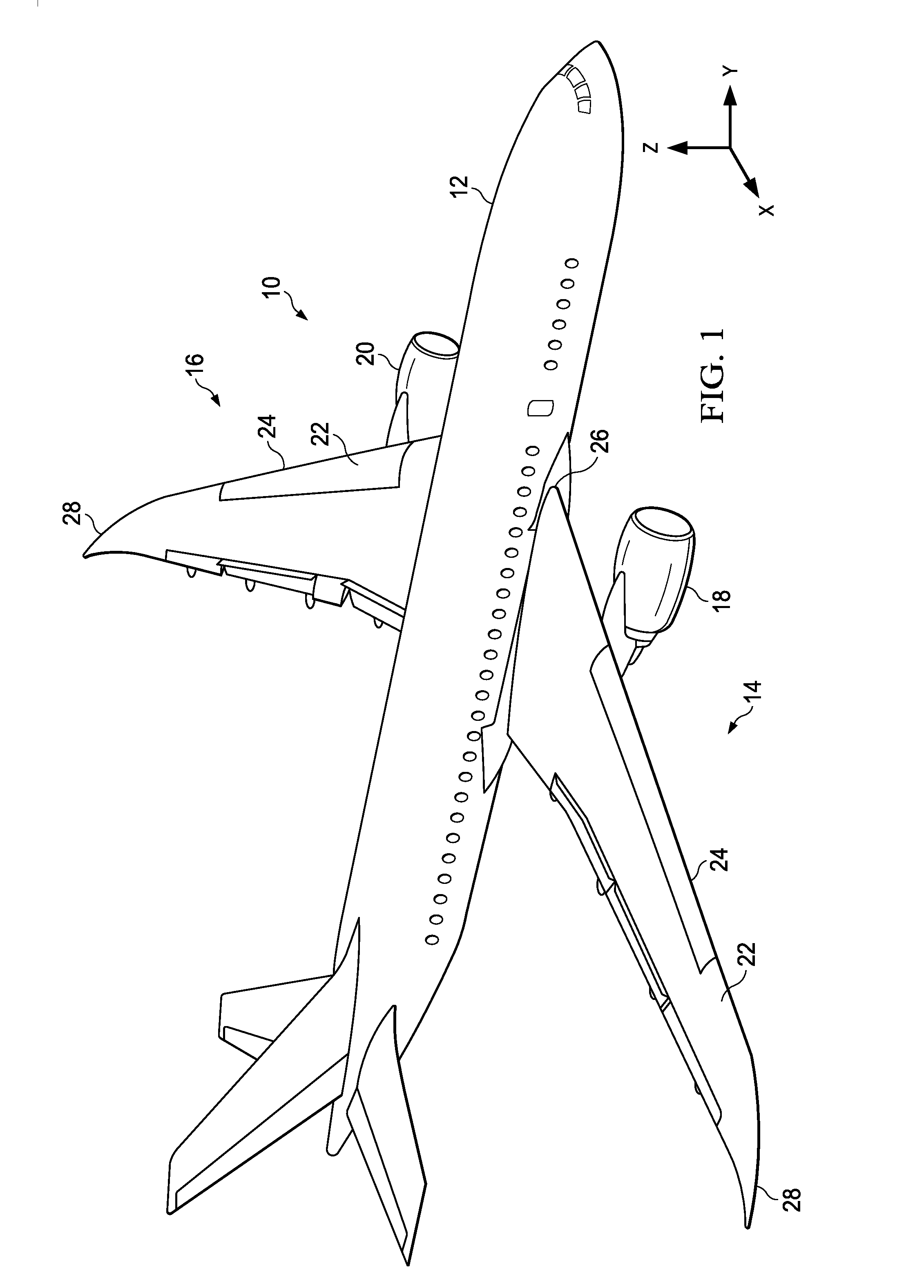

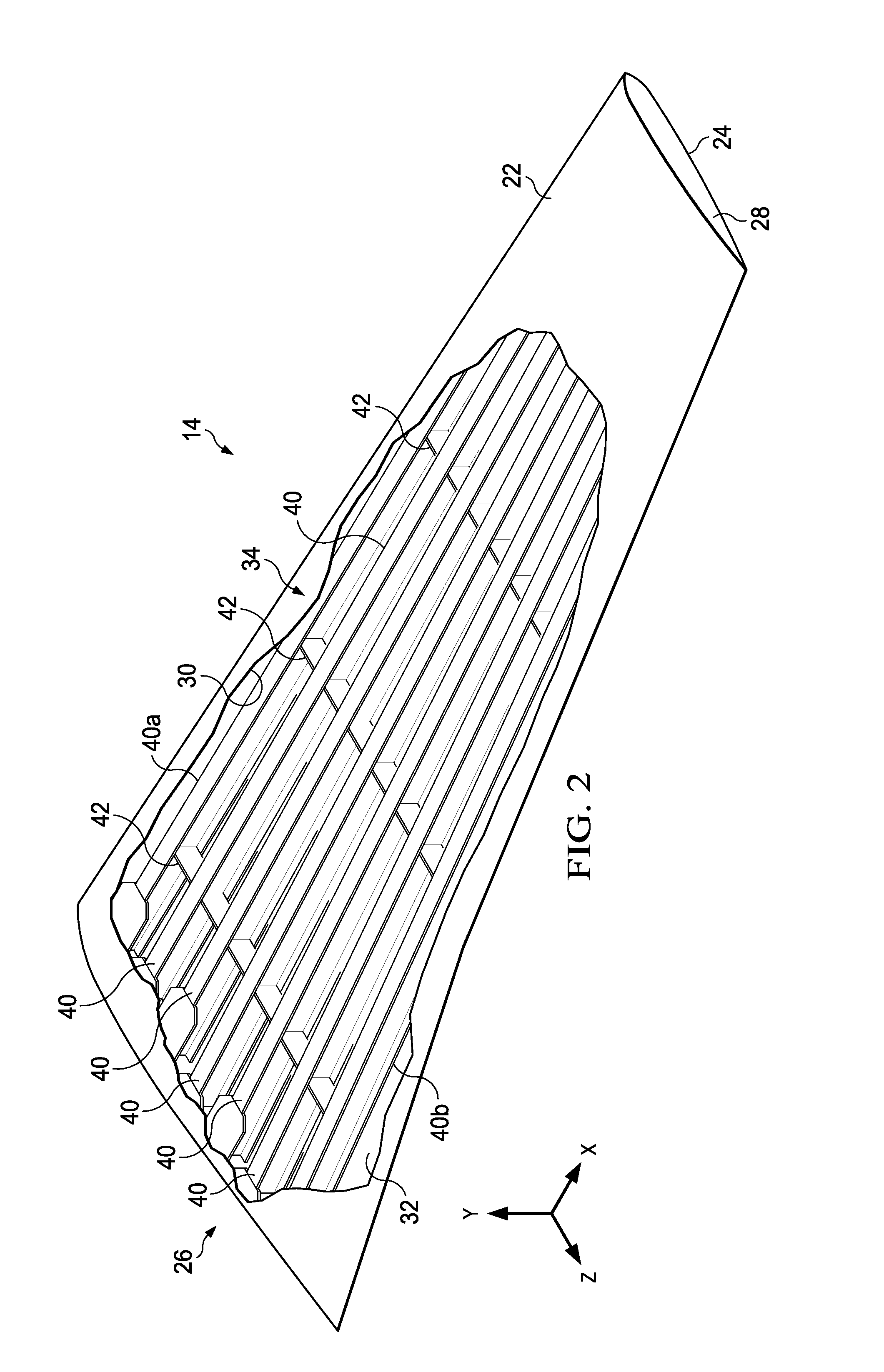

Bonded composite aircraft wing

InactiveUS8851422B2Different fracture toughnessDamage capabilityAircraft stabilisationSpars/stringersComposite laminatesComposite grid

A unitized composite aircraft wing includes upper and lower composite laminate wing skins that have differing stiffnesses and are bonded to a composite grid structure. The grid structure includes grid spars extending in a span-wise direction, and cross beams extending in a chord-wise direction of the wing. The grid spars include caps bonded to the upper and lower wing skins.

Owner:THE BOEING CO

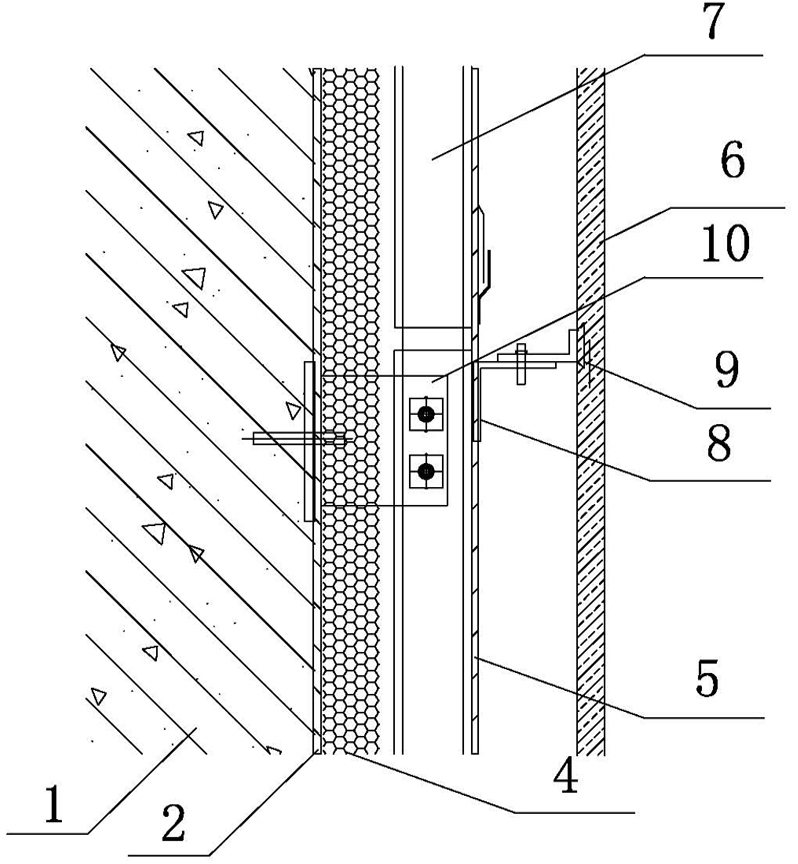

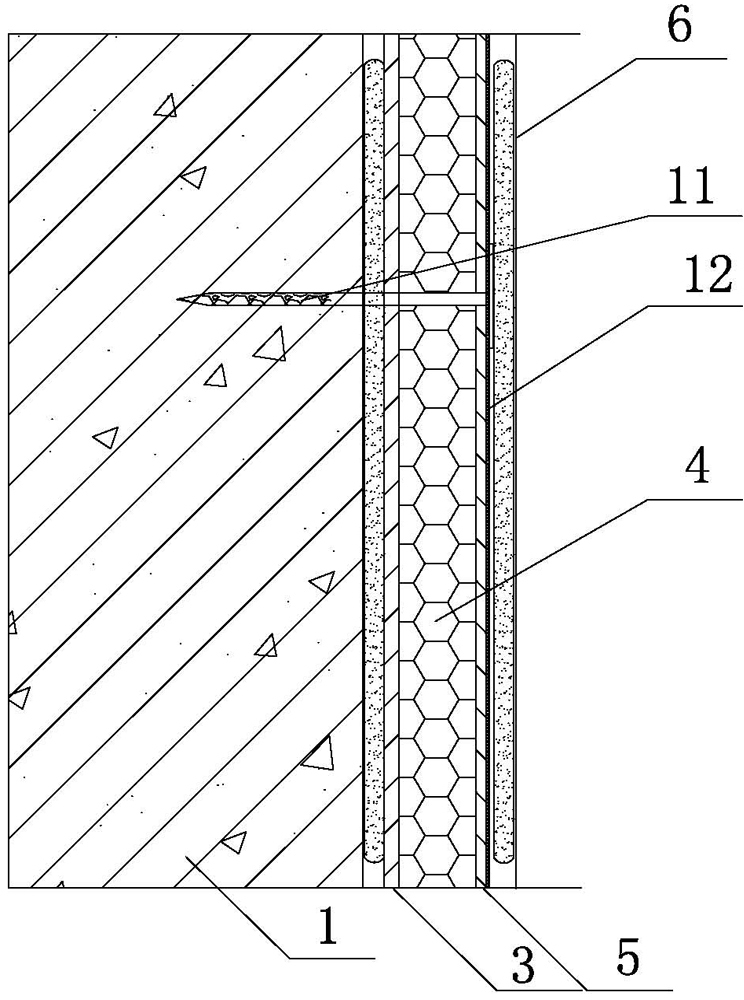

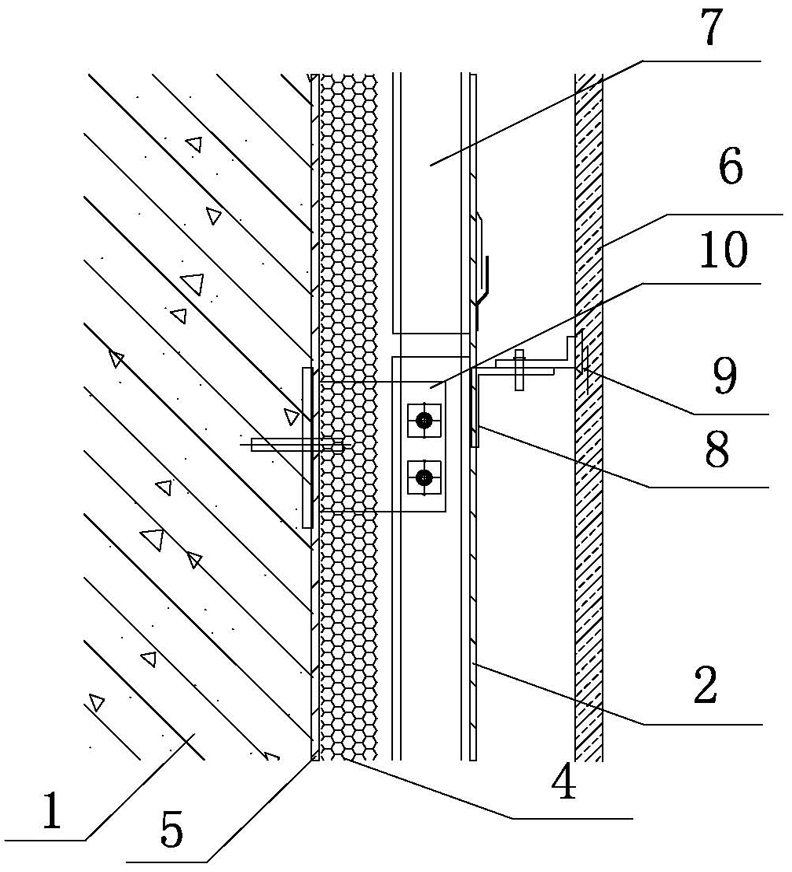

Dew formation-preventing building envelope structure for different thermal areas

InactiveCN102071750AImprove waterproof performanceGood vapor permeabilityWallsClimate change adaptationBrickBuilding energy

The invention relates to a building envelope structure, in particular to a dew formation-preventing building envelope structure for different thermal areas. The structure comprises a heat preservation layer, wherein a composite grid reinforcing rib waterproof vapor-permeable film coiled material is arranged on one side of the heat preservation layer; and a metal-plated waterproof vapor-isolating film coiled material or a surface non-woven cloth composite waterproof vapor-isolating film coiled material is arranged on the other side of the heat preservation layer. The composite grid reinforcing rib waterproof vapor-permeable film has high waterproof property and vapor permeability, and the metal-plated waterproof vapor-isolating film coiled material and the surface non-woven cloth composite waterproof vapor-isolating film coiled material have high waterproof property and vapor isolating property, so that dews are difficult to form on the building envelope structure. A surface metal-plated layer has good moistureproof and reflecting functions and the reflectivity of over 90 percent, effectively reduces building energy consumption and is suitable for curtain wall structures; and the surface composite non-woven cloth is characterized by high compatibility with cement mortar and other binders, and is more suitable for solid facing bricks or coating outer walls.

Owner:董阳军

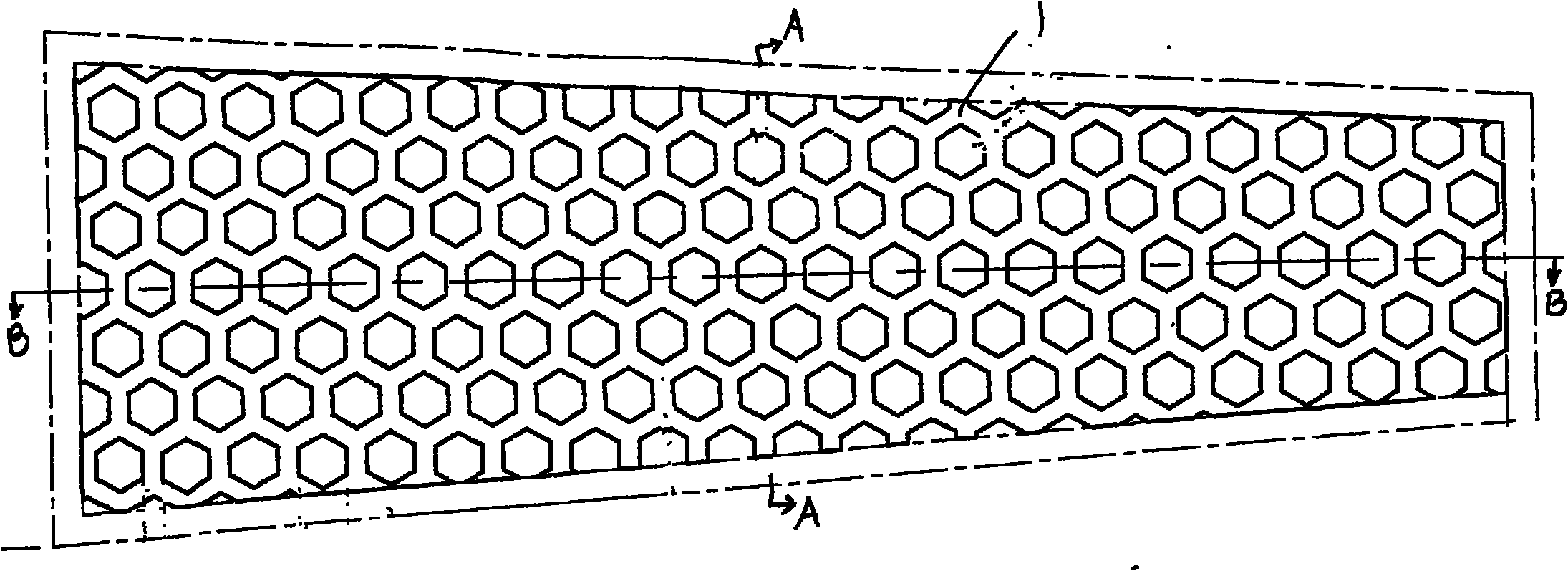

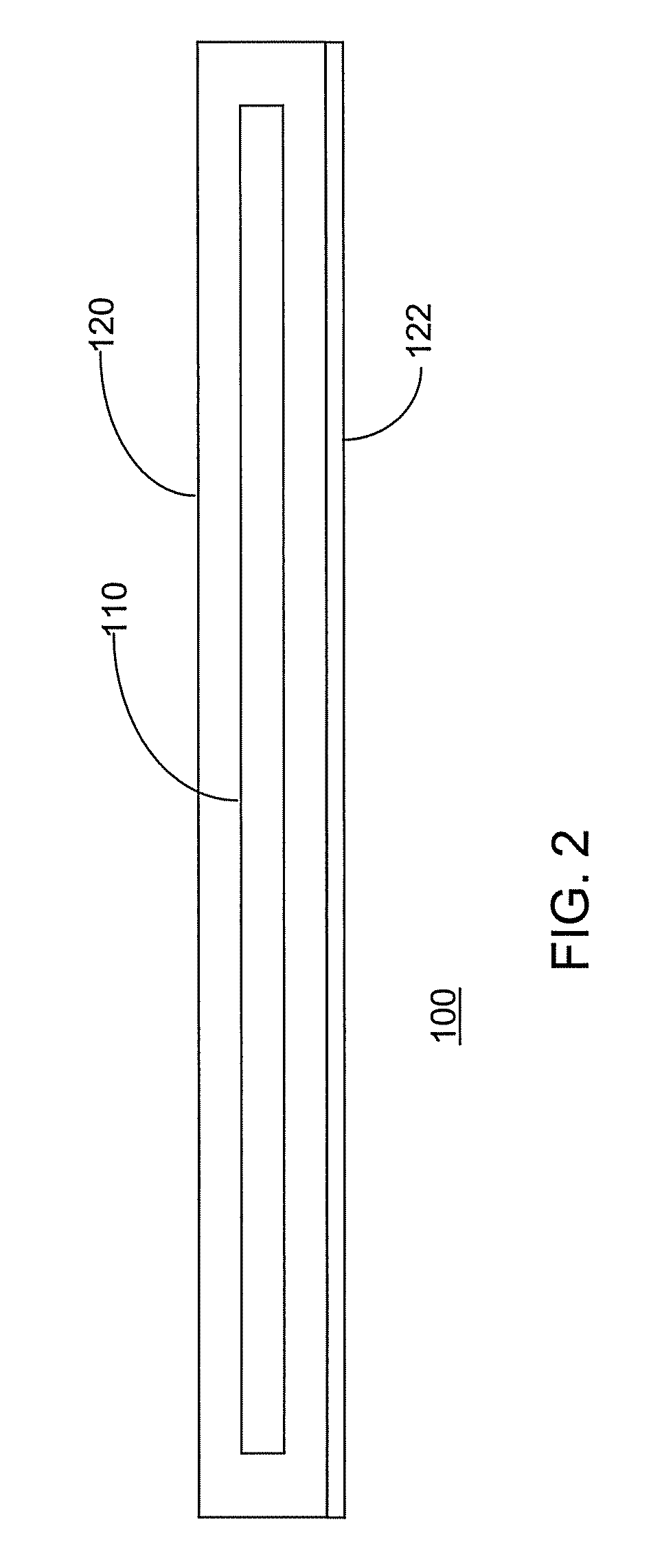

Composite grid with tack film for asphaltic paving, method of paving, and process for making a composite grid with tack film for asphaltic paving

A composite material comprises: an open grid comprising at least two sets of strands. Each set of strands has openings between adjacent strands. The sets are oriented at a substantial angle to one another. A tack film is laminated to the open grid. The tack film has first and second major surfaces, such that a material of the tack film at its first and second major surfaces includes about 50% or more of resinous non-asphaltic component and about 50% or less of asphaltic component.

Owner:SAINT GOBAIN TECHN FABRICS AMERICA INC

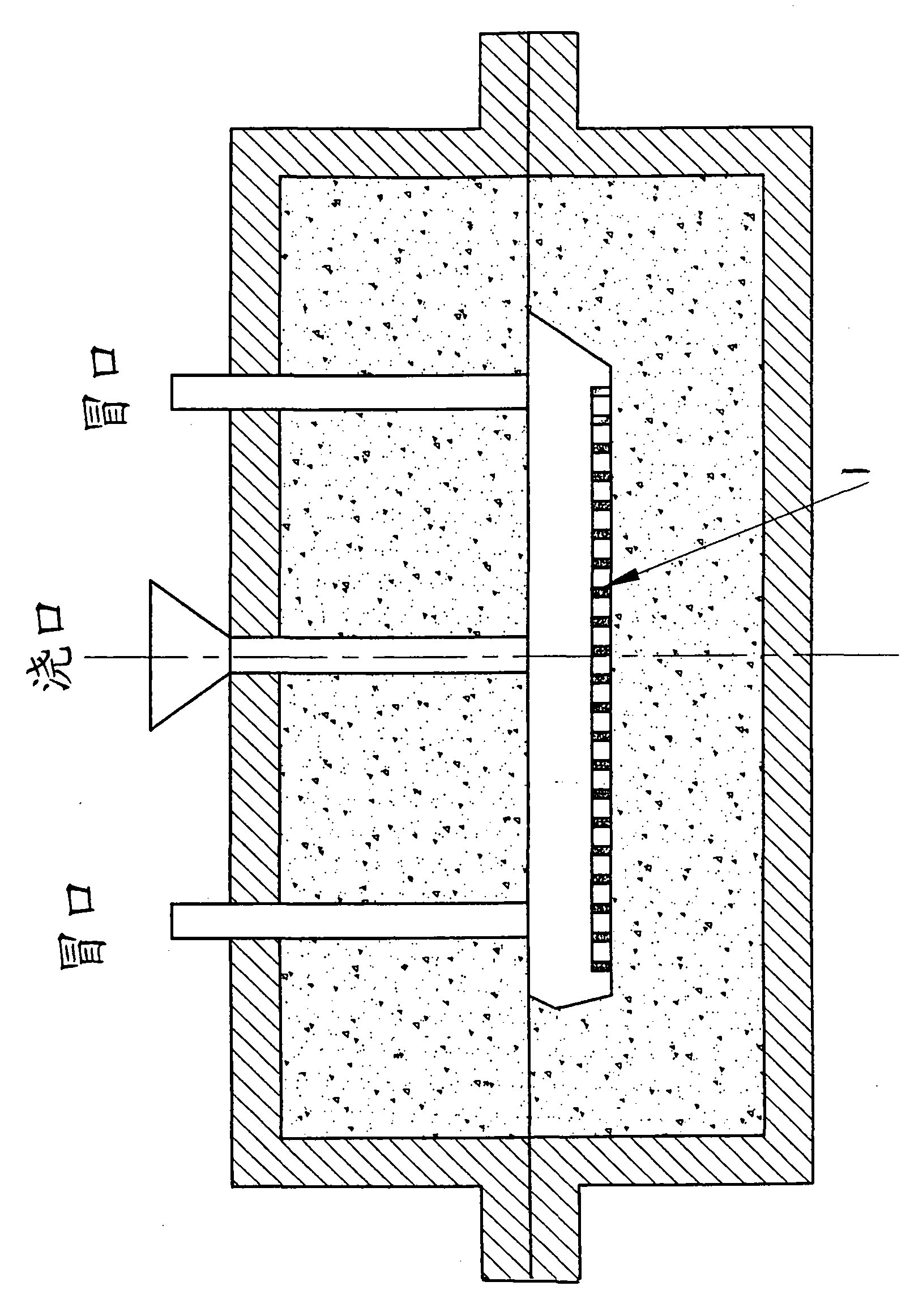

Production process of high-chromium alloy ceramic particle composite grids

InactiveCN101844208AAchieve anti-wear effectImprove or extend operating lifeFoundry mouldsFoundry coresWear resistantShock resistance

The invention discloses a production process of high-chromium alloy ceramic particle composite grids, which comprises the following steps of: melting high-chromium alloy, and then, putting the melted high-chromium alloy into steel ladle; adding sintered and crushed aluminum oxide and / or zirconium oxide particles of which the particle diameters are 80-100 meshes into the steel ladle and stirring and mixing, and then, injecting the mixed liquid into grid sand molds; and cooling and taking out grids to obtain high-chromium alloy ceramic particle composite grids. In the invention, the wear resistance of the ceramic particle materials and the mechanical properties of the high-chromium alloy are organically combined; the produced composite materials have high hardness, shock resistance and wear resistance, are latticed, can be prepared into tapered, cambered and circular grids in various shape sizes, and can also be prepared into grids in other shapes; and the super-hard latticed composites are cast for the second time to form required wear resistant products to achieve the anti-wear effect of mechanical equipment.

Owner:钱兵

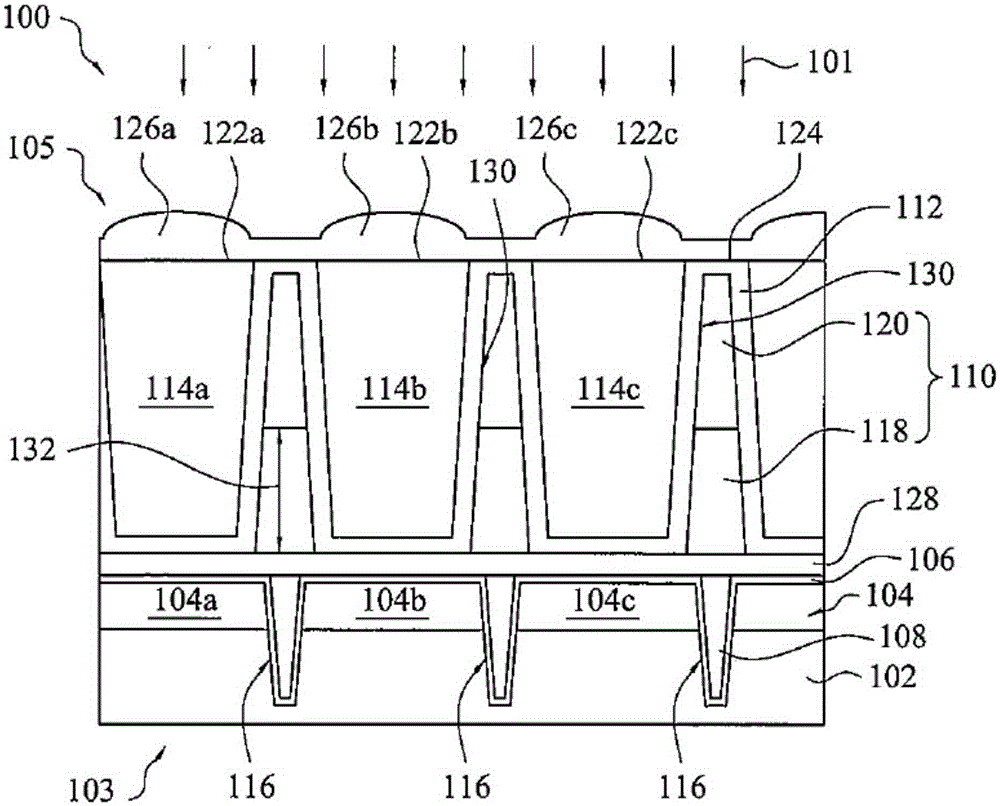

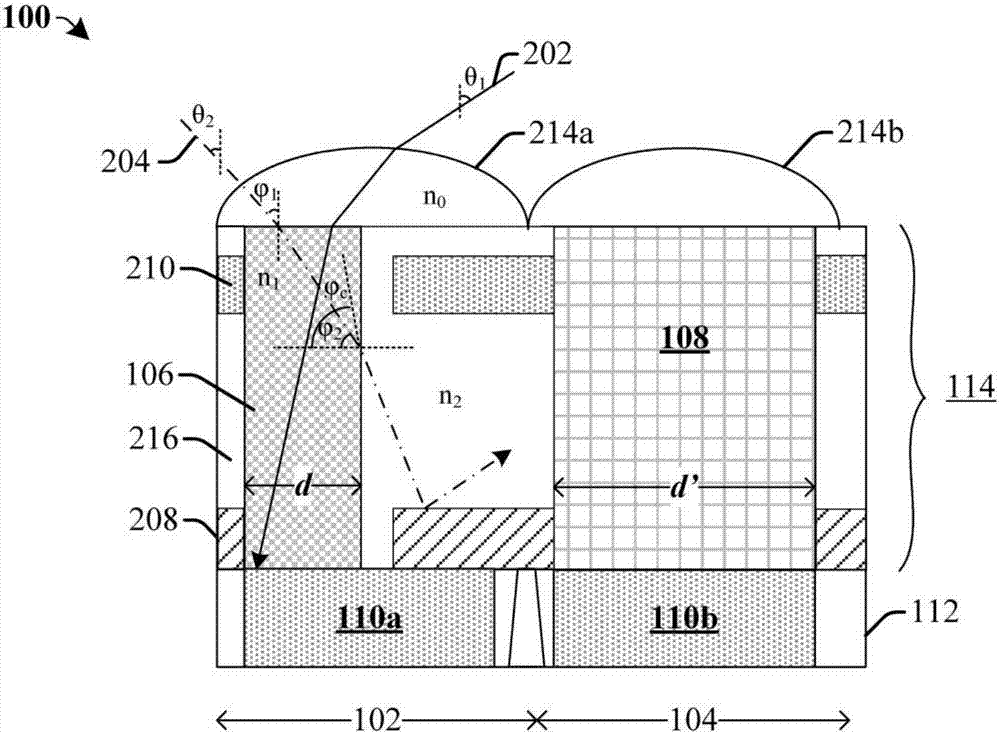

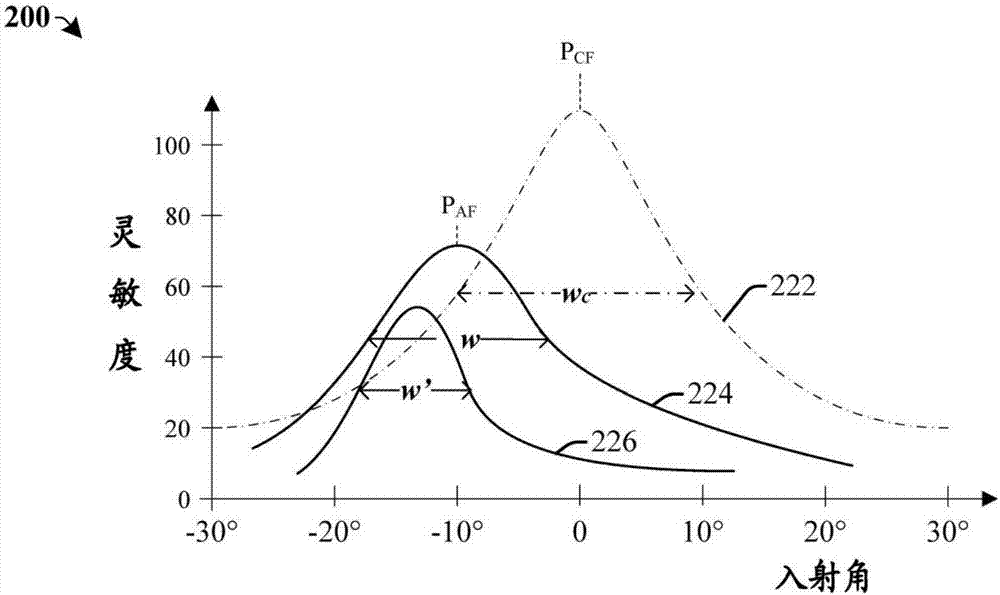

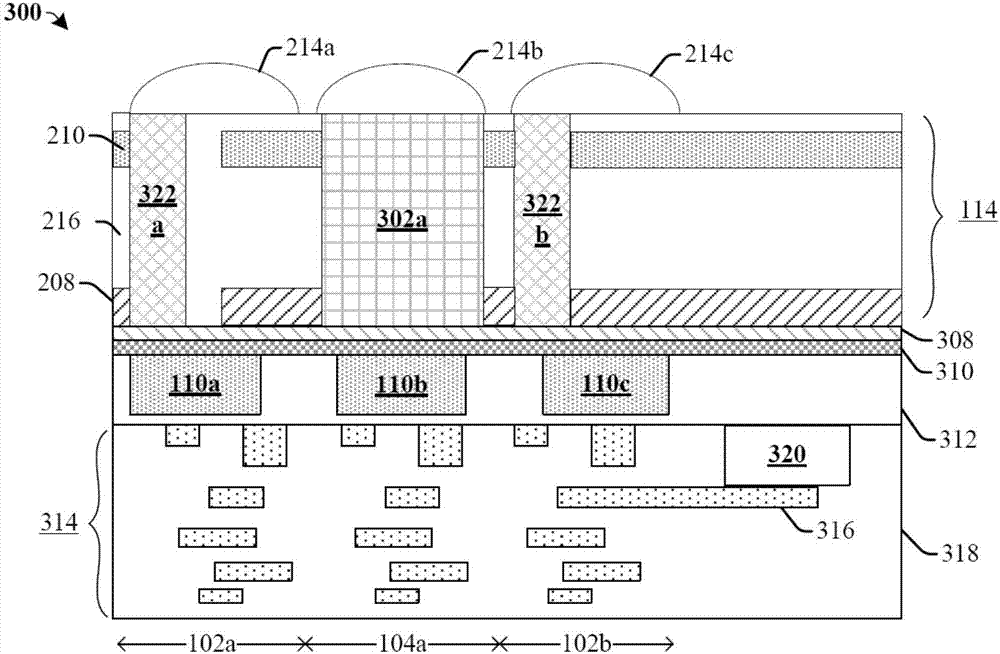

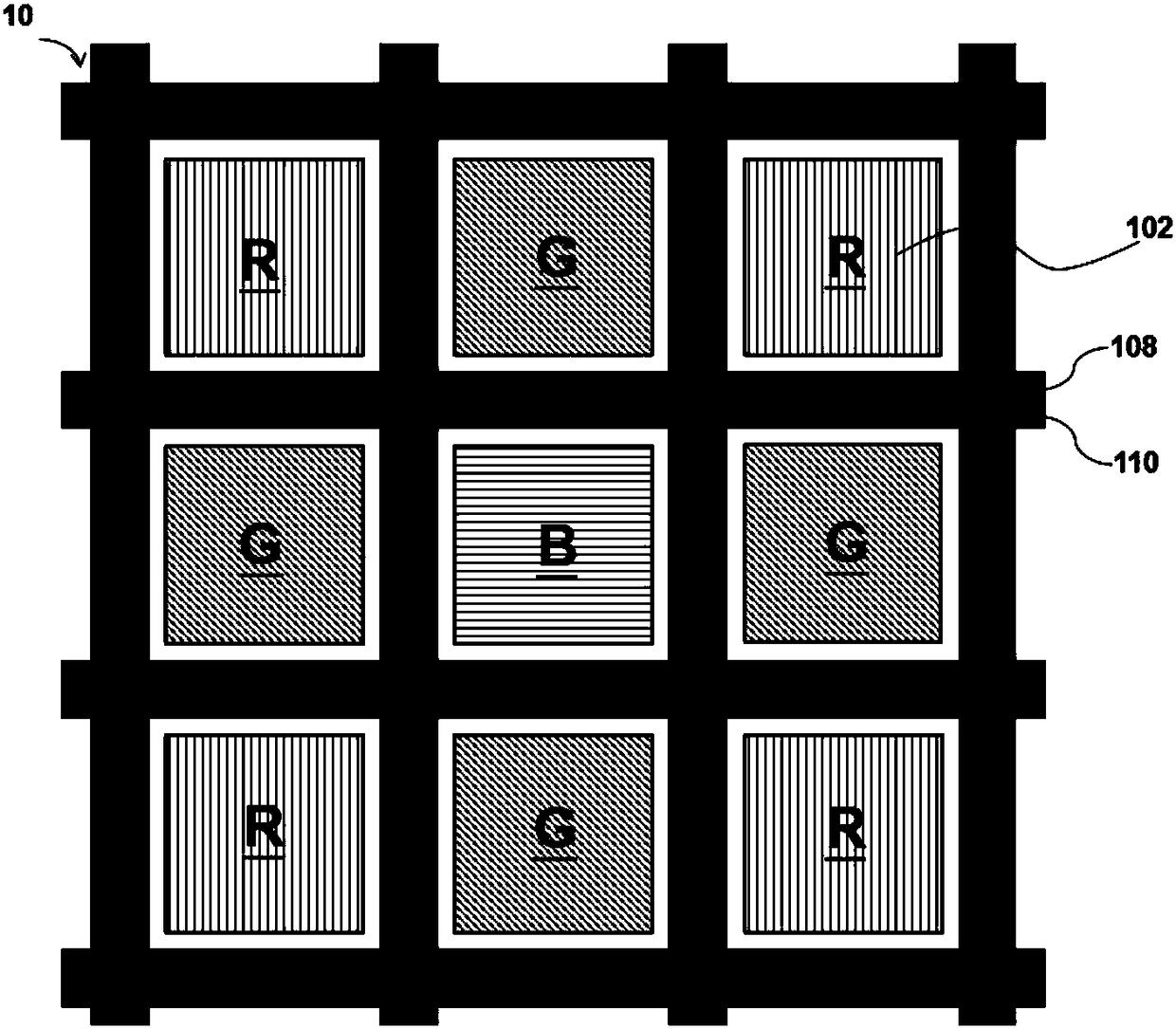

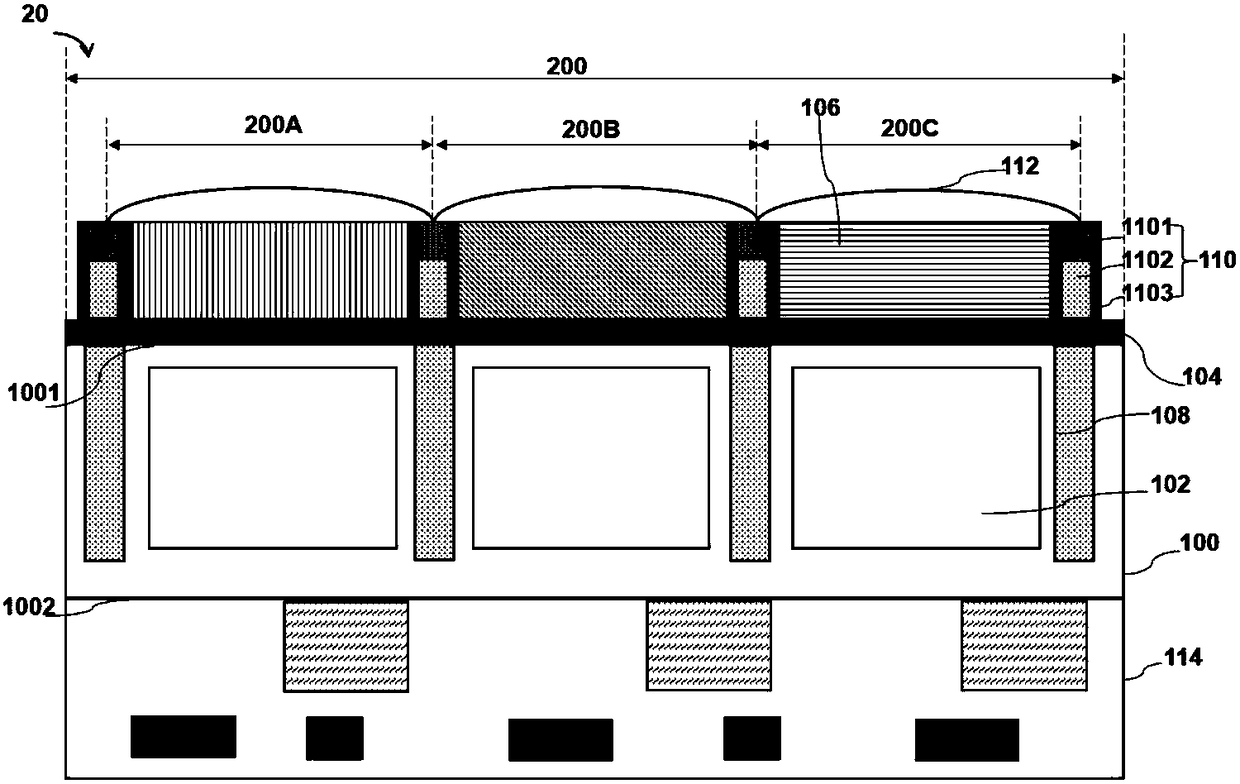

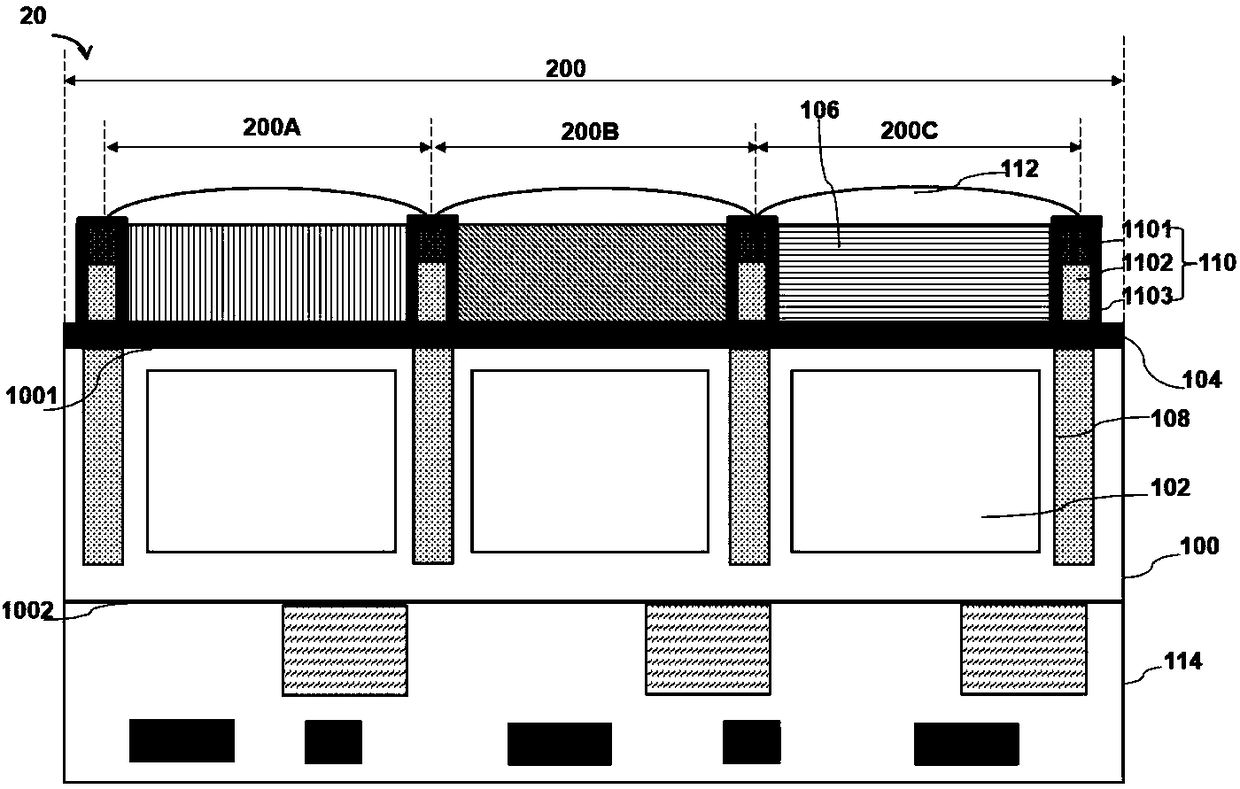

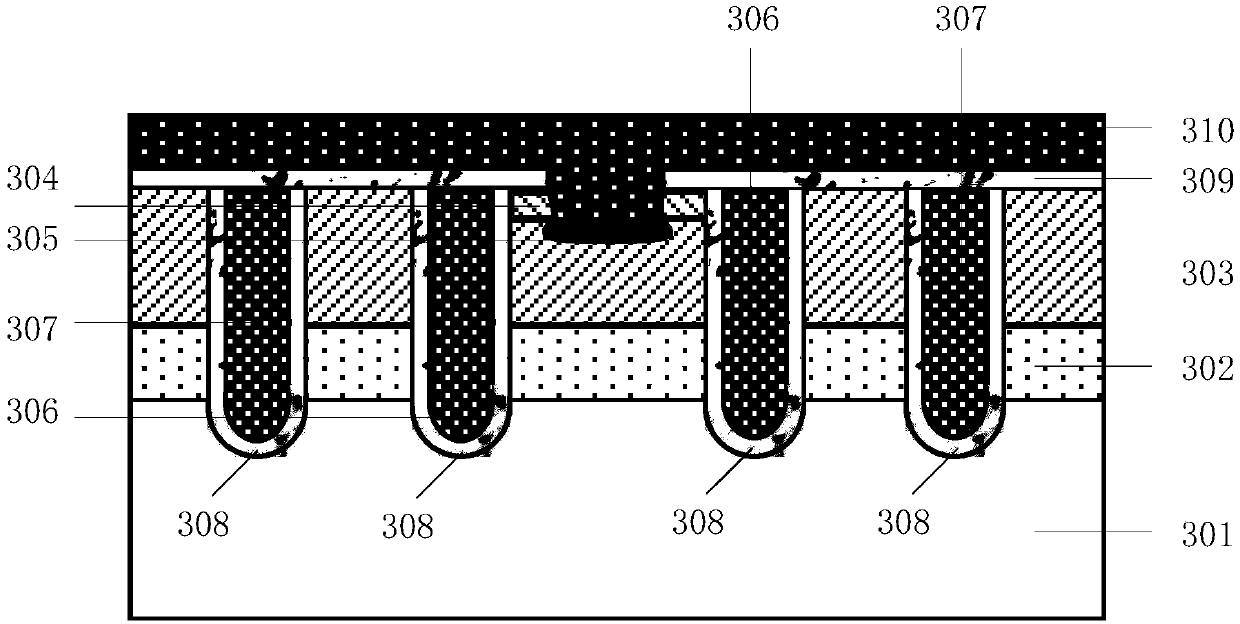

CMOS image sensor structure with crosstalk improvement

A semiconductor device includes a substrate, a device layer, an anti-reflective coating layer, reflective structures, a composite grid structure, a passivation layer and color filters. The device layer is disposed on the substrate, in which trenches are formed in the device layer and the substrate. The anti-reflective coating layer conformally covers the device layer, the substrate and the trenches. The reflective structures are disposed on the anti-reflective coating layer in the trenches respectively. The composite grid structure overlies the anti-reflective coating layer and the reflective structures. The composite grid structure includes cavities passing through the composite grid structure, and the composite grid structure includes a metal grid layer and a dielectric grid layer sequentially stacked on the reflective structures. The passivation layer conformally covers the composite grid structure. The color filters respectively fill the cavities. The invention provides the CMOS image sensor structure with the crosstalk improvement.

Owner:TAIWAN SEMICON MFG CO LTD

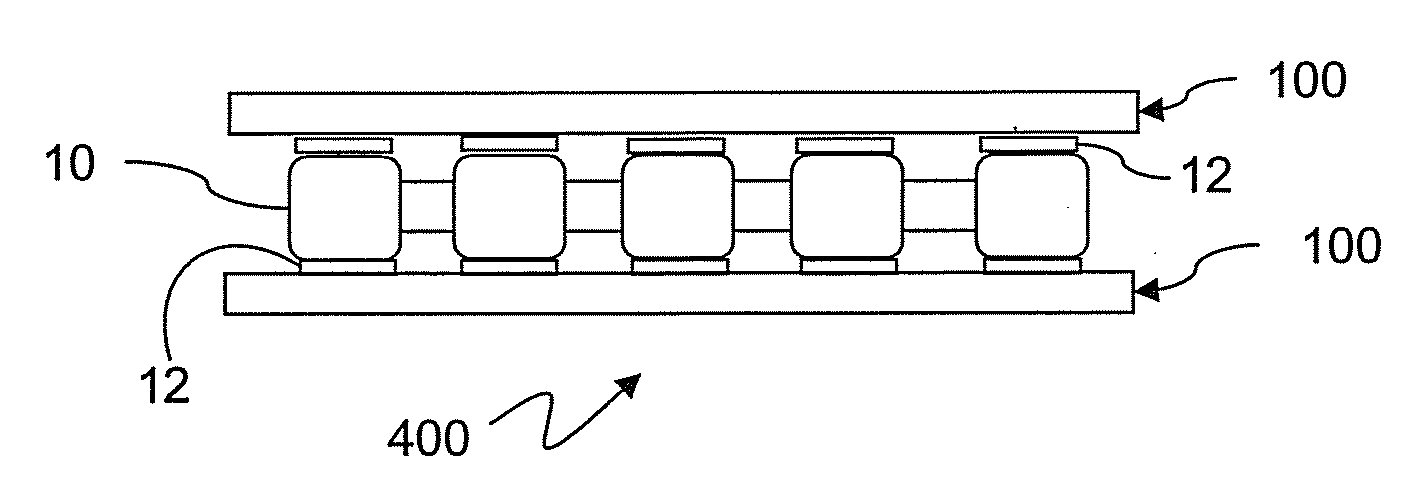

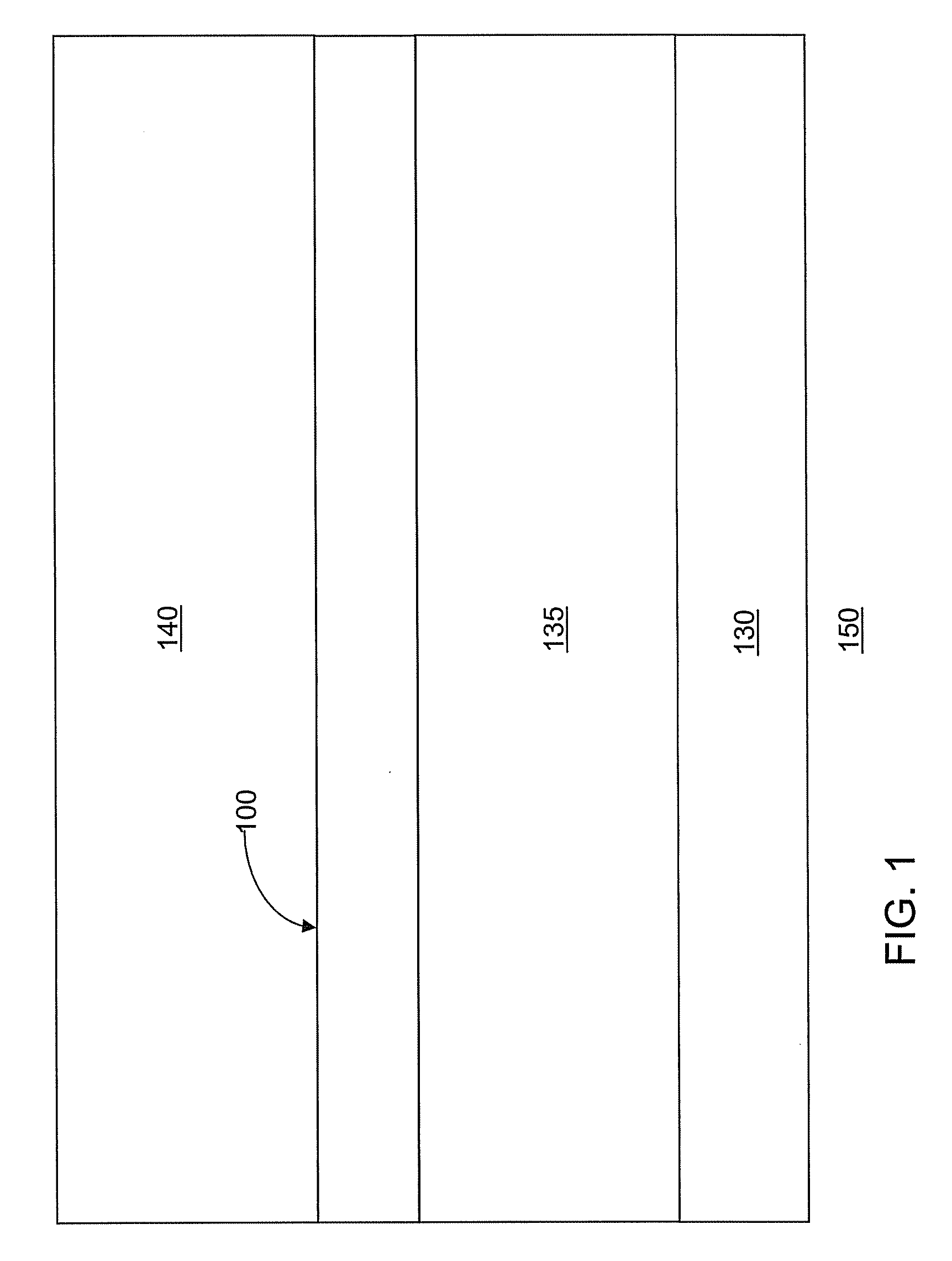

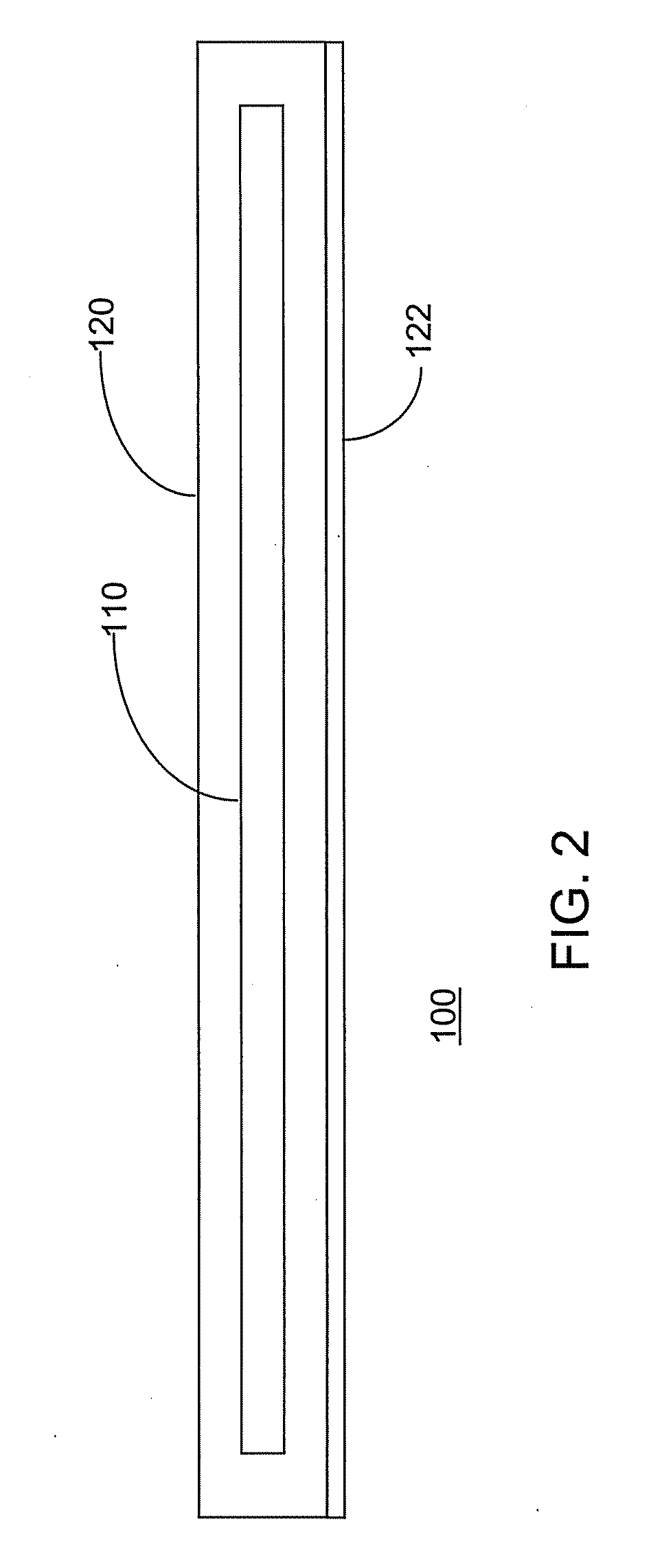

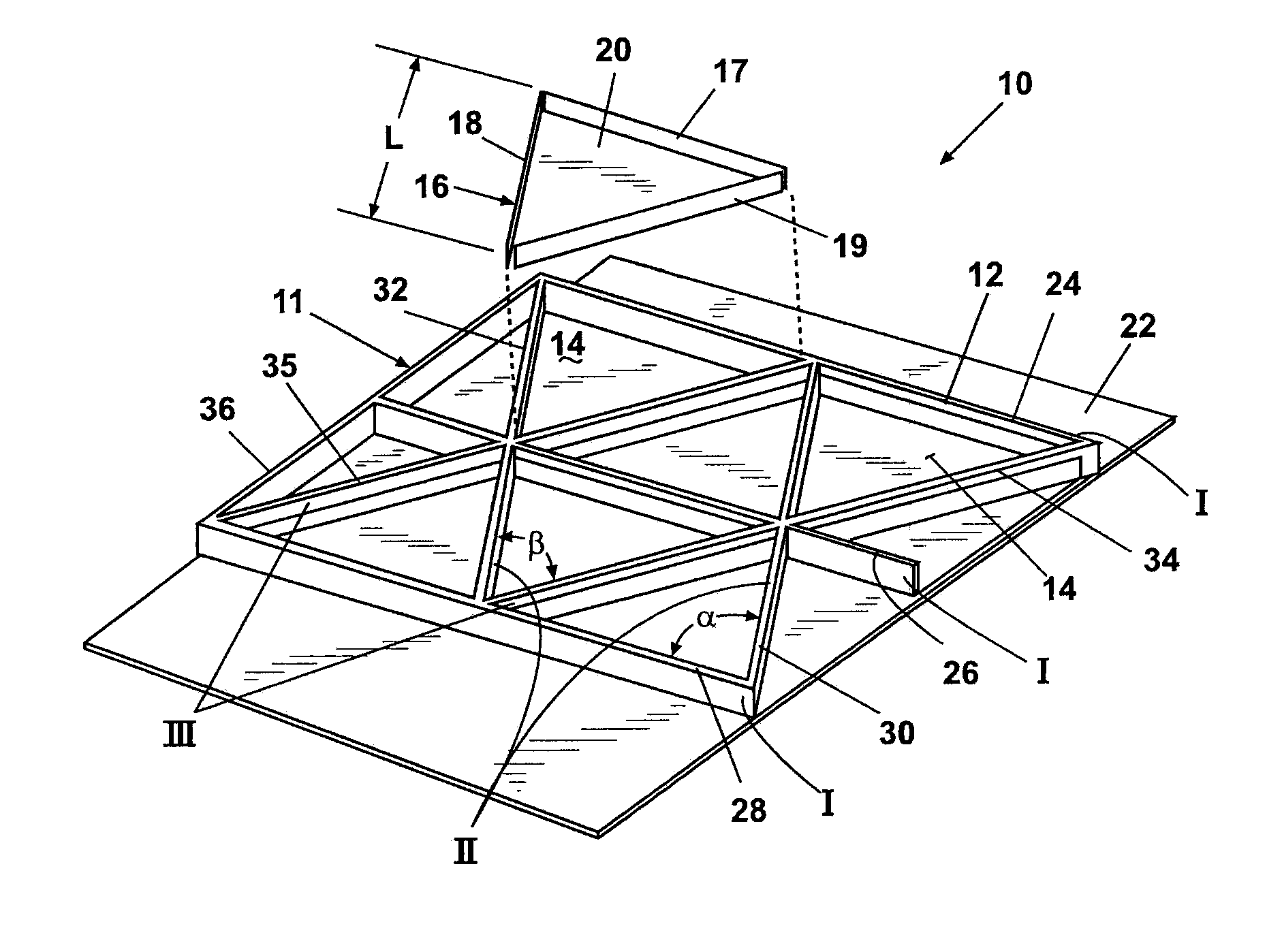

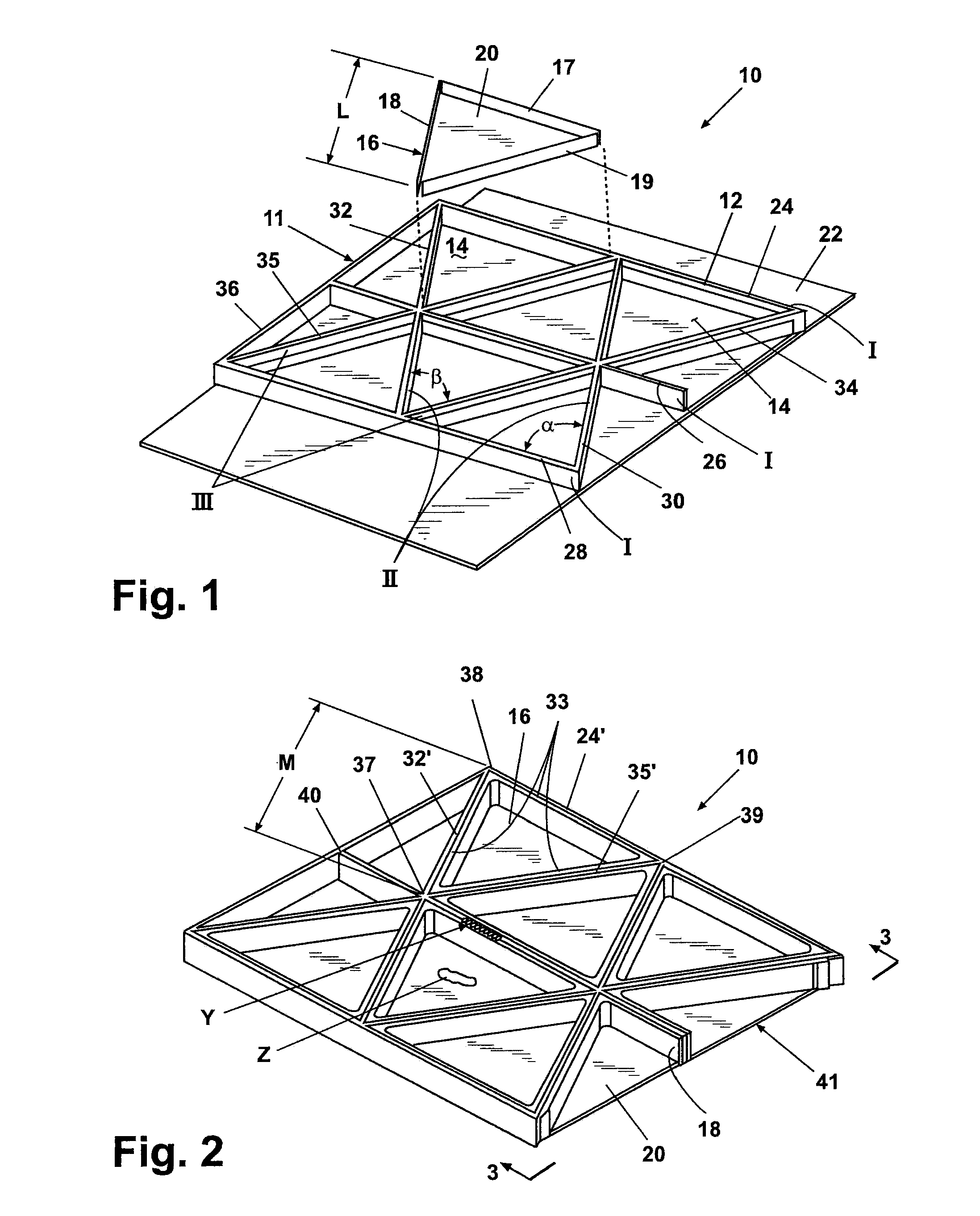

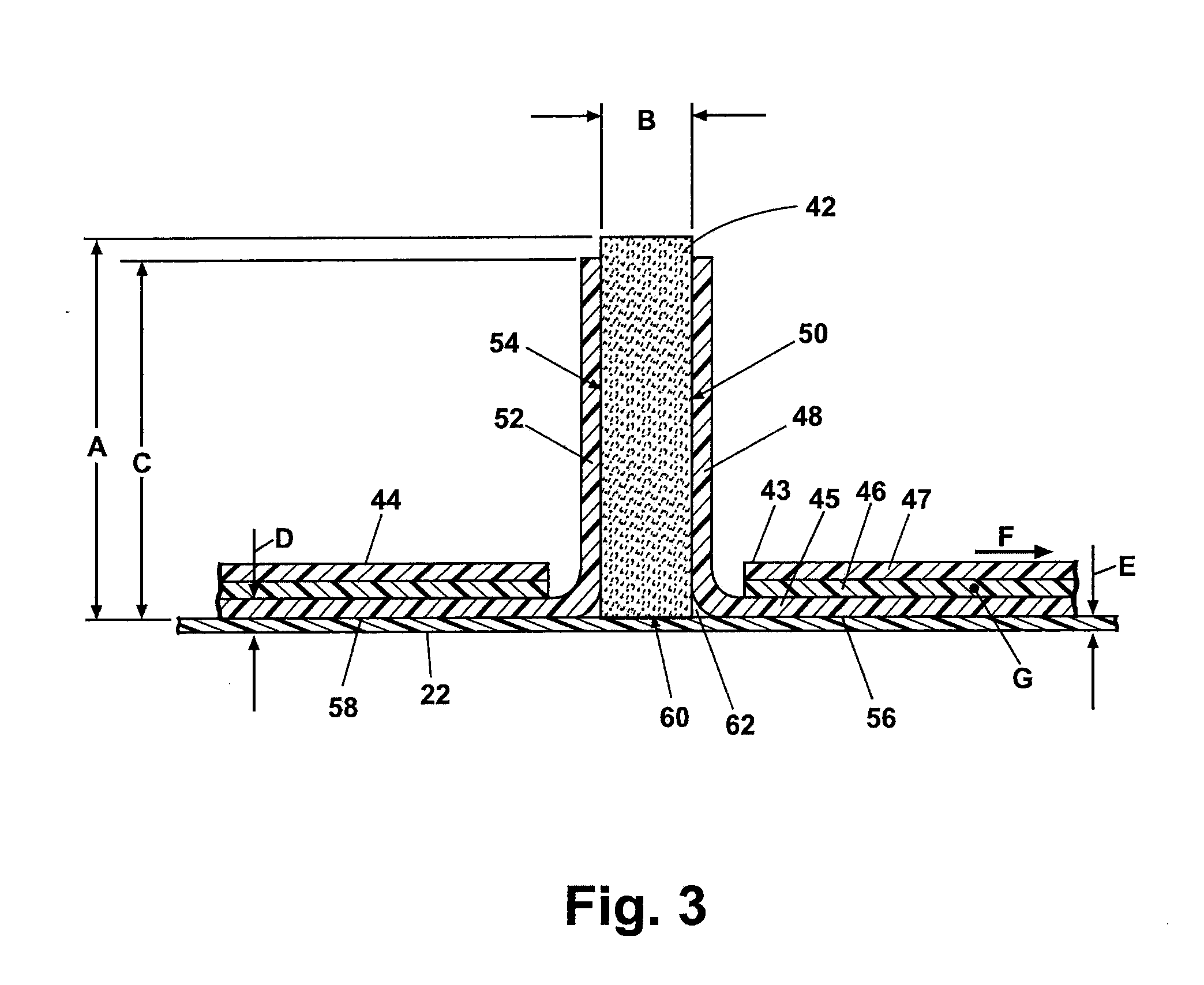

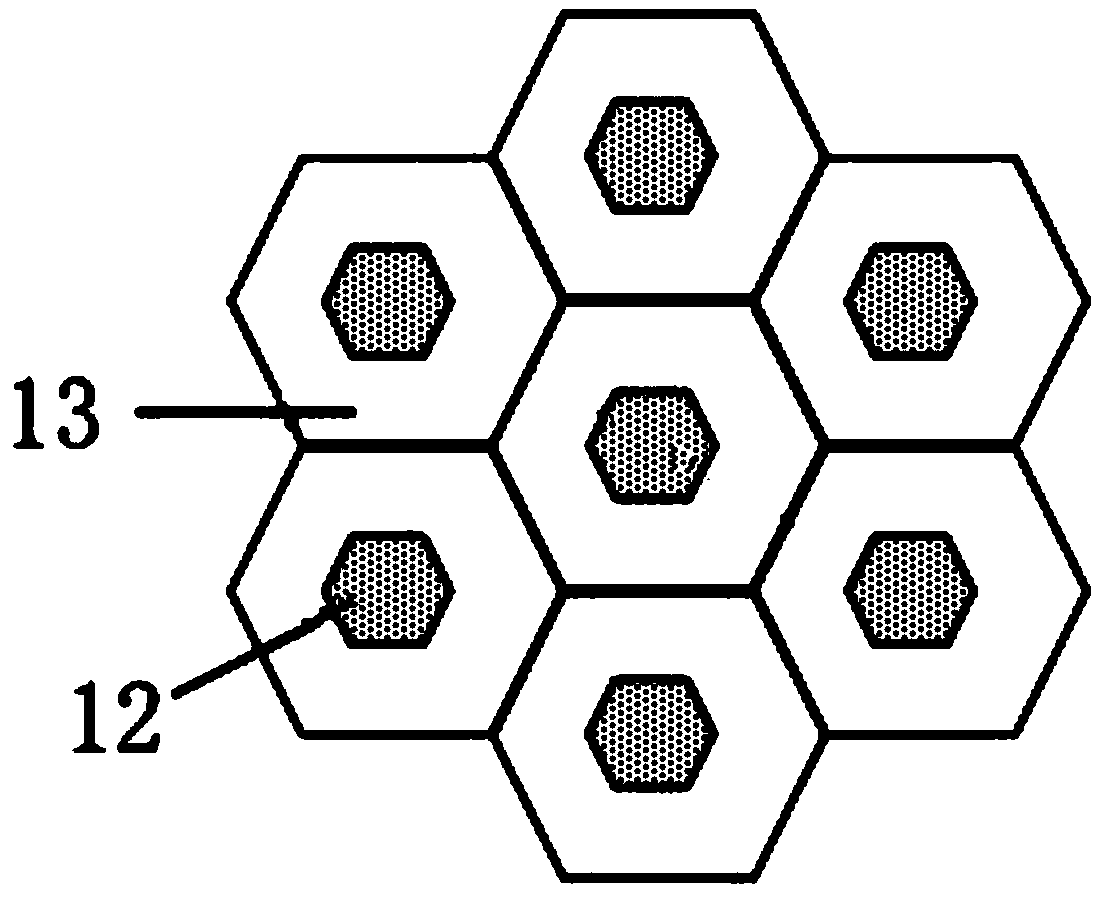

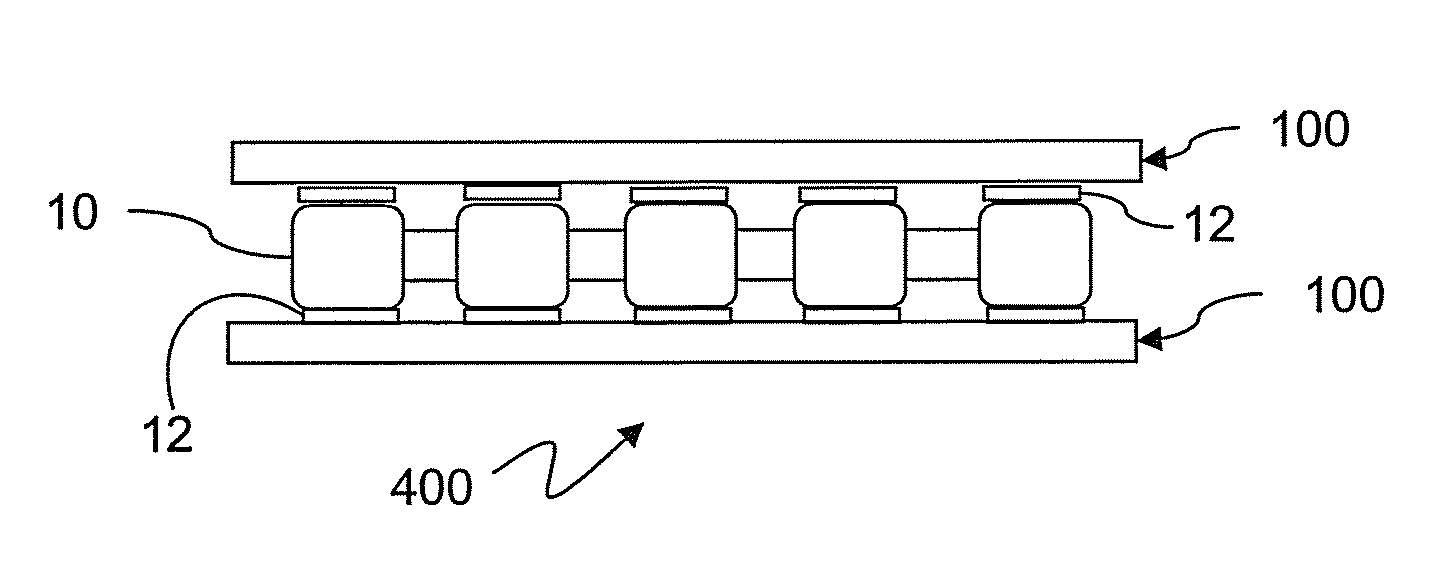

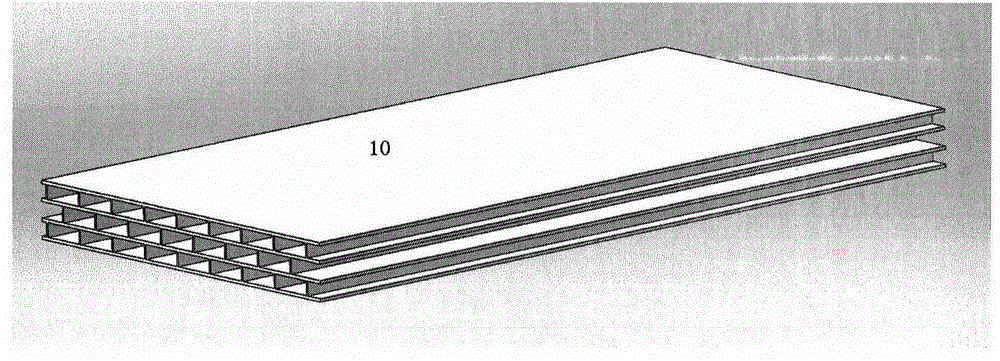

Cellular composite grid-stiffened structure

InactiveUS20090038744A1Simple structureImproves Structural IntegrityMechanical working/deformationLaminationComposite gridBiomedical engineering

A cellular composite structure includes a grid having groups of angularly intersecting ribs. The ribs of each group are oriented substantially in the same direction to each other and angularly oriented from the other rib groups. An additional rib defines a composite structure outer perimeter wall and can be differently angularly oriented from the other ribs. A contiguous rib wall is created by segments of ribs defined by rib intersections. The contiguous rib wall bounds a cavity. A multilayer sheet cap member with extending walls to engage the contiguous rib wall is positioned within the cavity. The engagement walls extend from individual sheet perimeter portions angularly oriented to the sheet. The ribs and cap member have pre-impregnated resin. Heating the cap member and ribs activates the resin and co-cures the composite structure.

Owner:THE BOEING CO

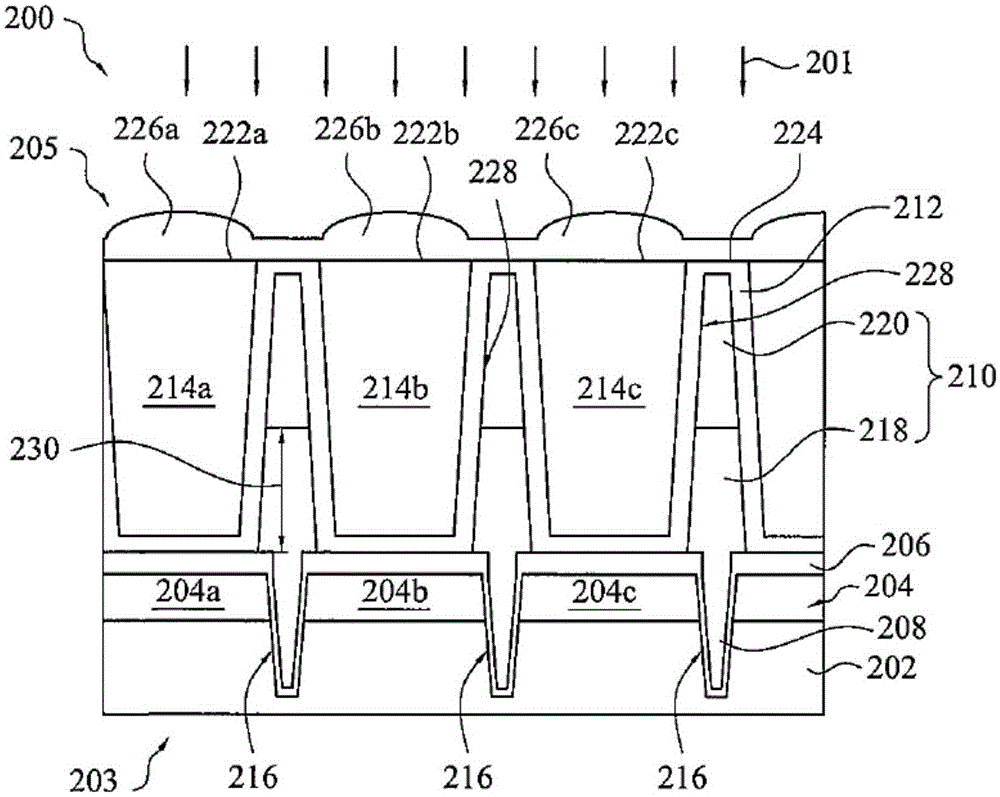

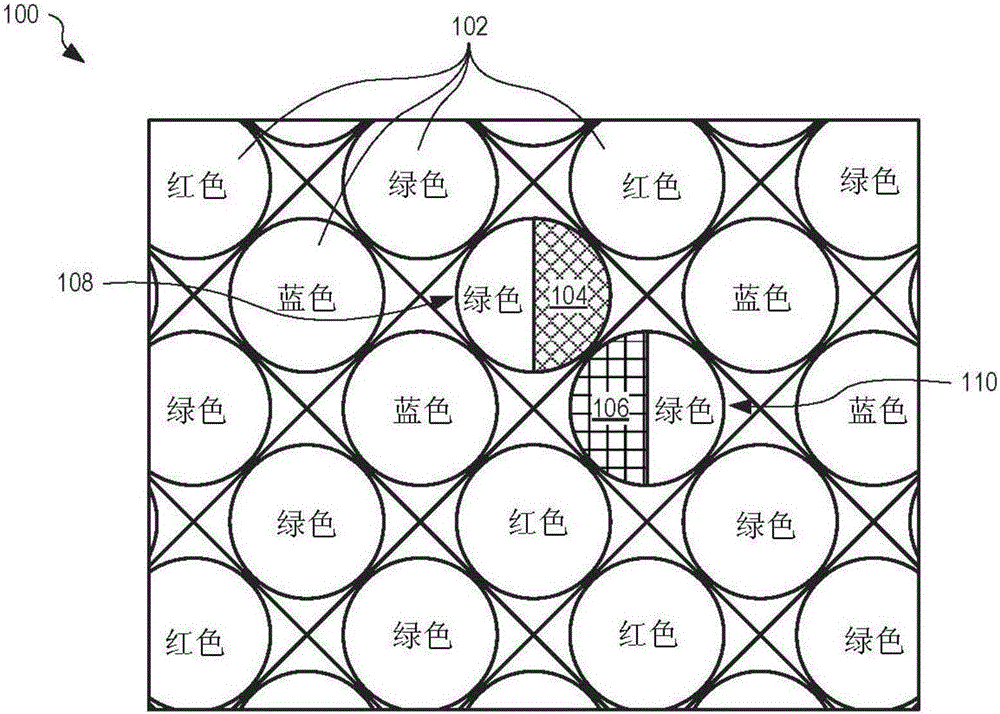

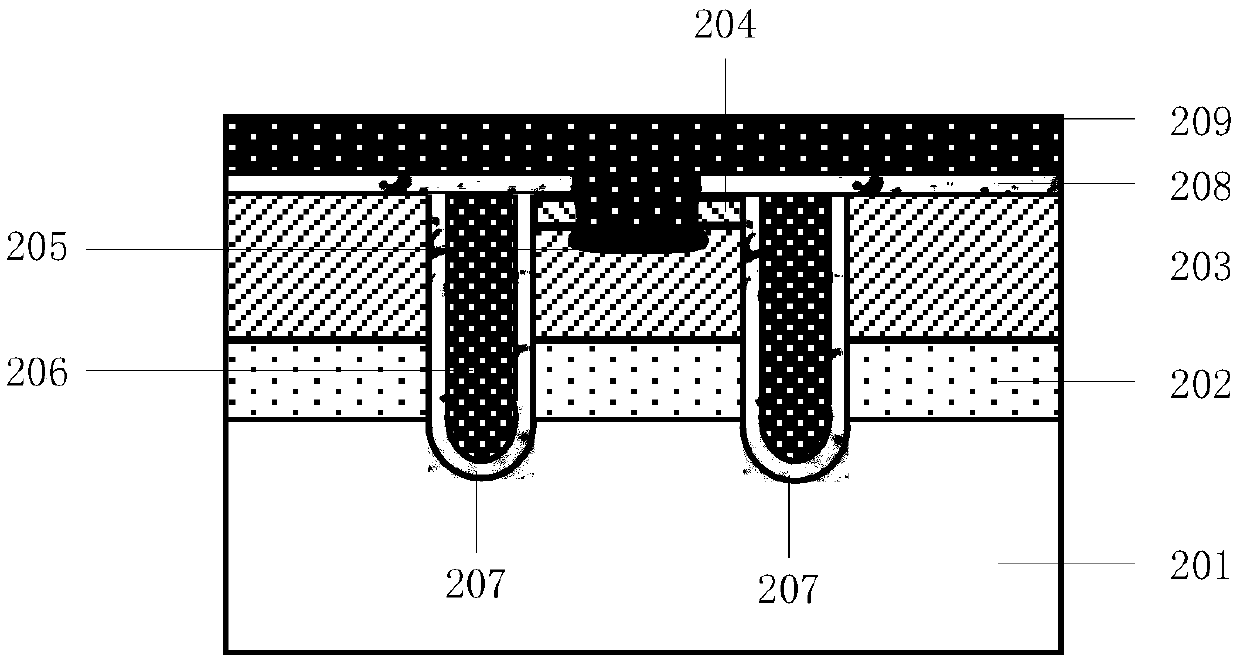

Integrated circuit, integrated circuit of image sensor and manufacturing method thereof

The present disclosure relates to an image sensor having autofocus function and associated methods. In some embodiments, the integrated circuit has a photodiode array with a plurality of photodiodes disposed within a semiconductor substrate and a composite grid overlying the photodiode array and having a first plurality of openings and a second plurality of openings extending vertically through the composite grid. The integrated circuit further has an image sensing pixel array with a plurality of color filters disposed in the first plurality of openings. The integrated circuit further has a phase detection pixel array having a plurality of phase detection components that are smaller than the plurality of color filters and that have a low refractive index (low-n) material with a refractive index (n) smaller than a refractive index of the plurality of color filters, wherein the phase detection components are disposed in the second plurality of openings. An embodiment of the invention further provides an integrated circuit, the integrated circuit of the image sensor and a manufacturing method thereof.

Owner:TAIWAN SEMICON MFG CO LTD

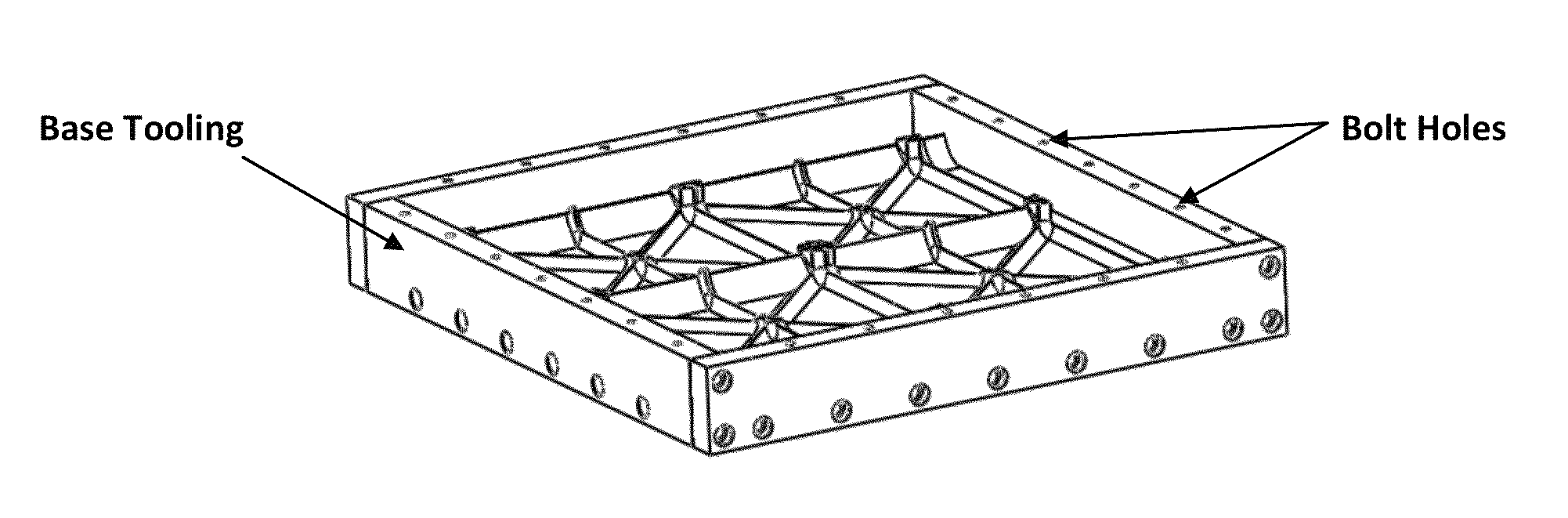

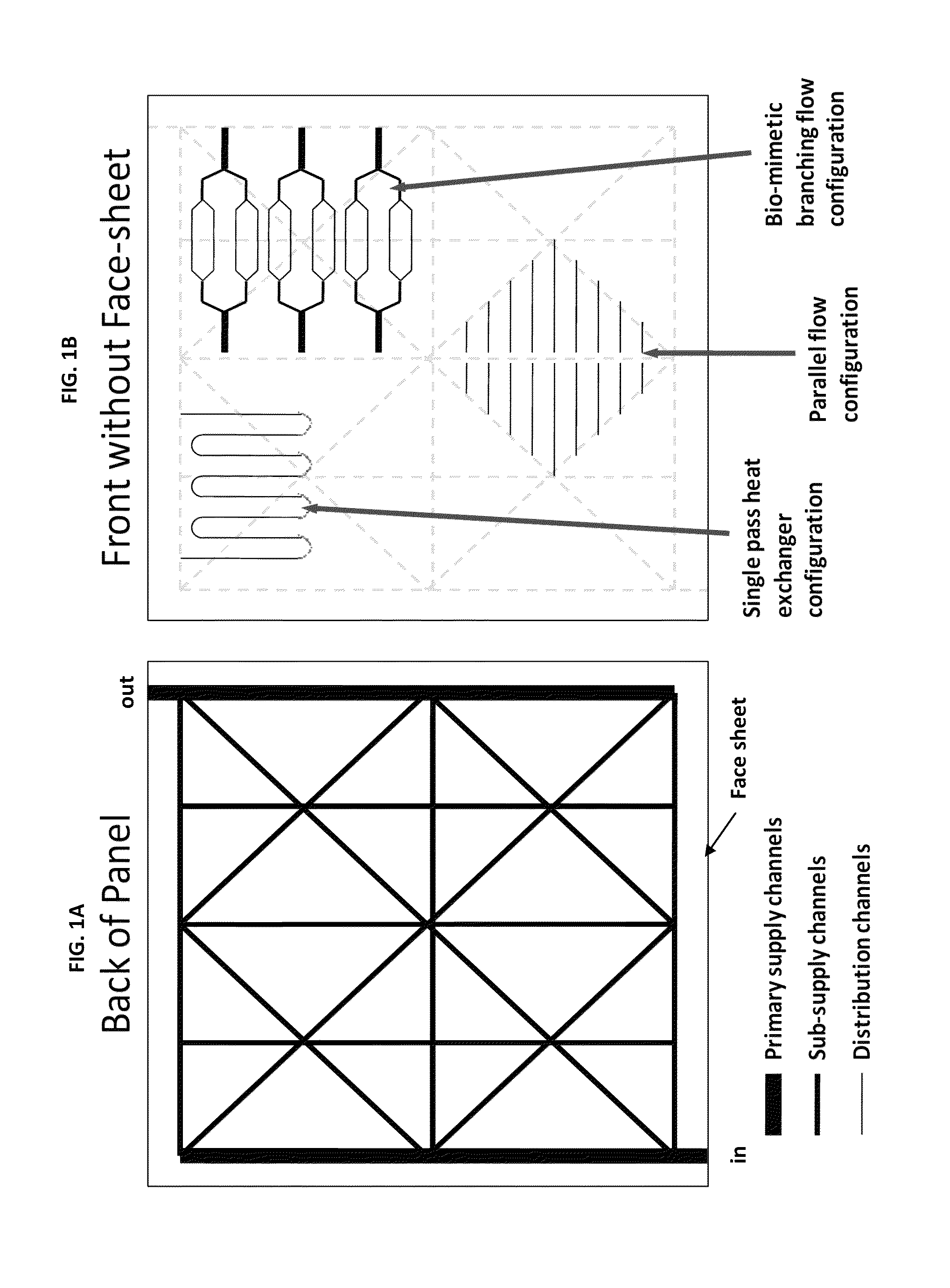

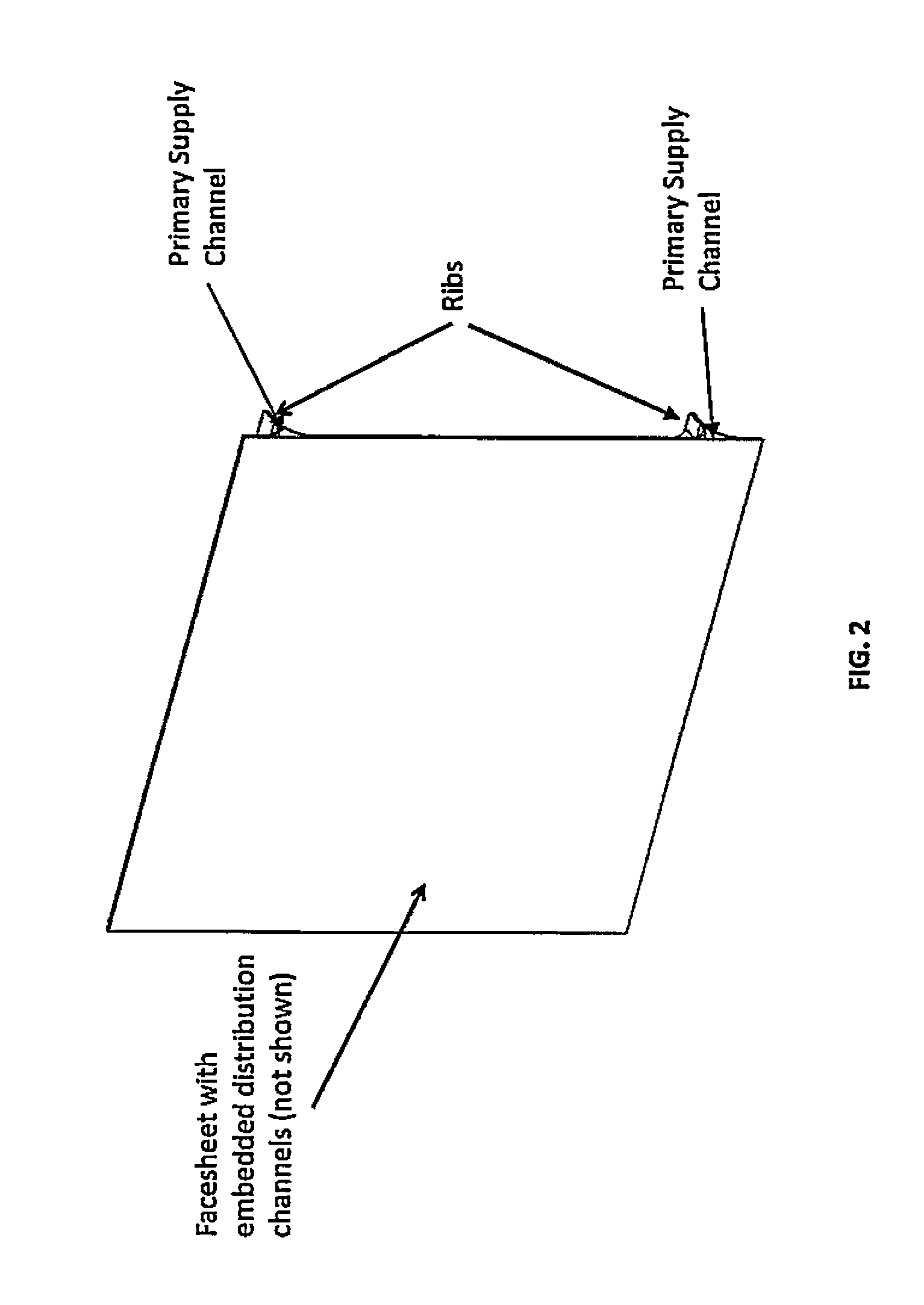

Method for fabricating composite grid-stiffened structures with integrated fluid channels

ActiveUS8657984B1Good physical propertiesPromotes self-healingLayered productsHeat exhanger conduitsEngineeringHigh pressure

A method for fabricating a grid-stiffened panel which incorporates a network of fluid channels and passageways into the ribs and face sheet is described. The method is comprised of a base tooling assembly, an expansion tooling assembly, a composite prepreg, plugs, a face sheet and a network of valves and pumps, wherein the prepreg is draped over said expansion tooling and assembled with the base tooling assembly to form a rib structure. Channel plugs are placed therein such that gaps between adjacent expansion tooling blocks are filled, and the entire rib structure assembly is autoclaved. The face sheet may be comprised of a plurality of layers, whereby channels are machined into the lower layer(s). The upper layer(s) are bonded to the lower layer(s) to seal the channels, and said face sheet is bonded to the rib structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

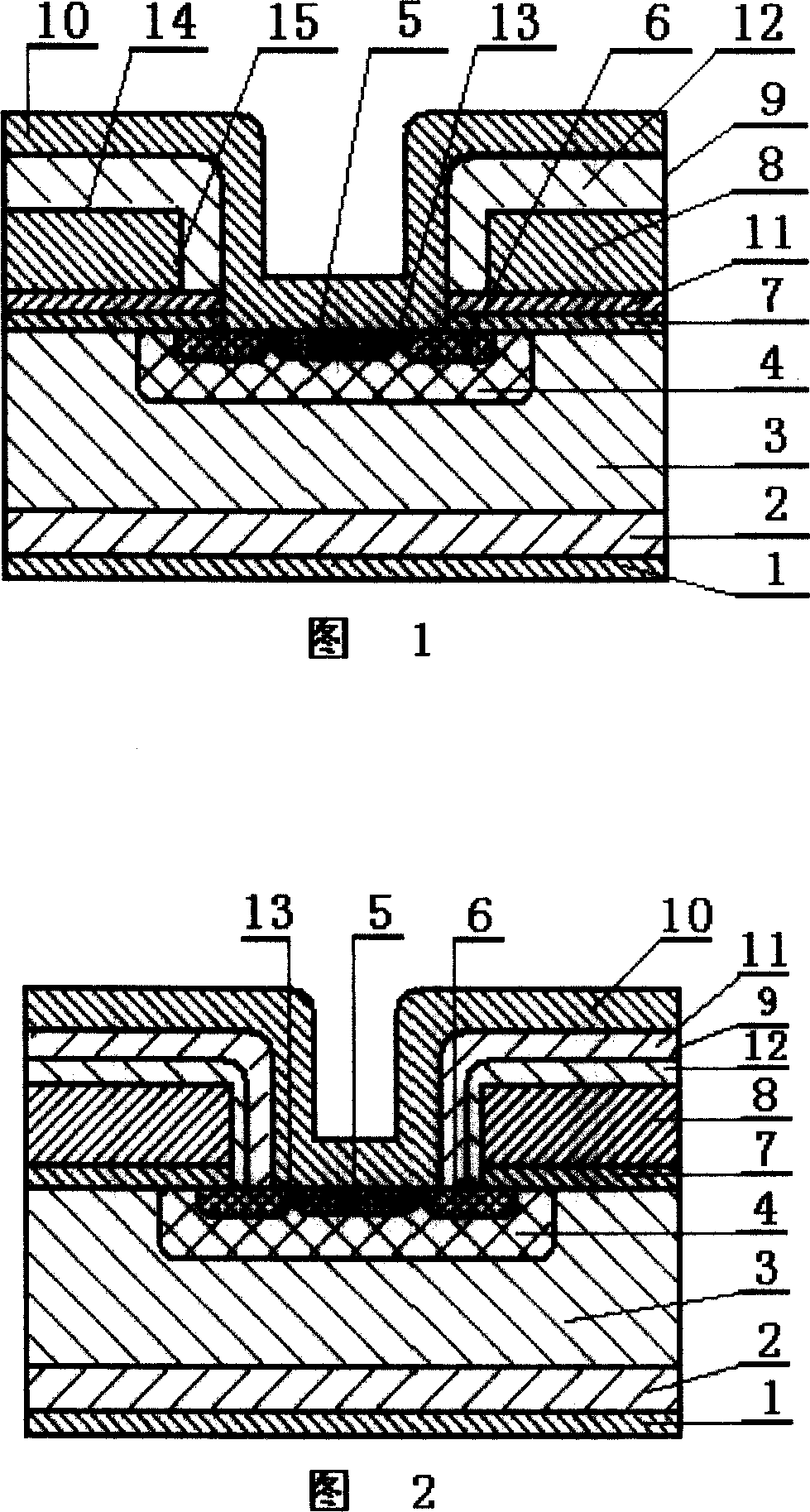

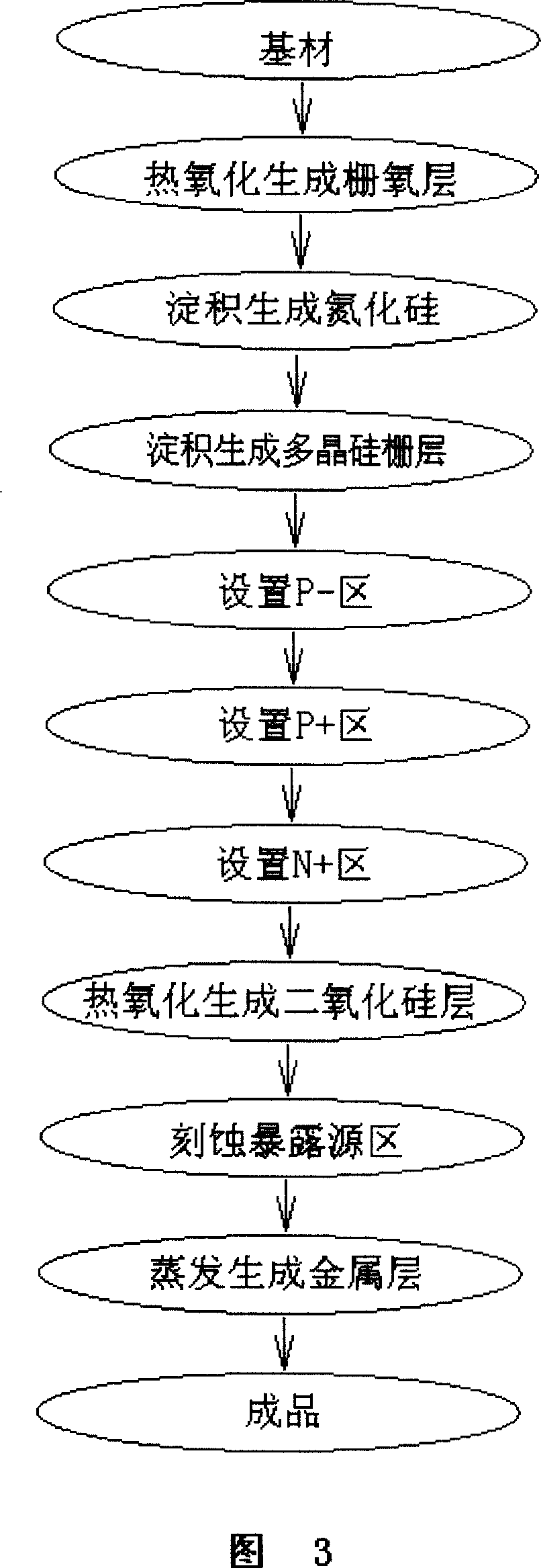

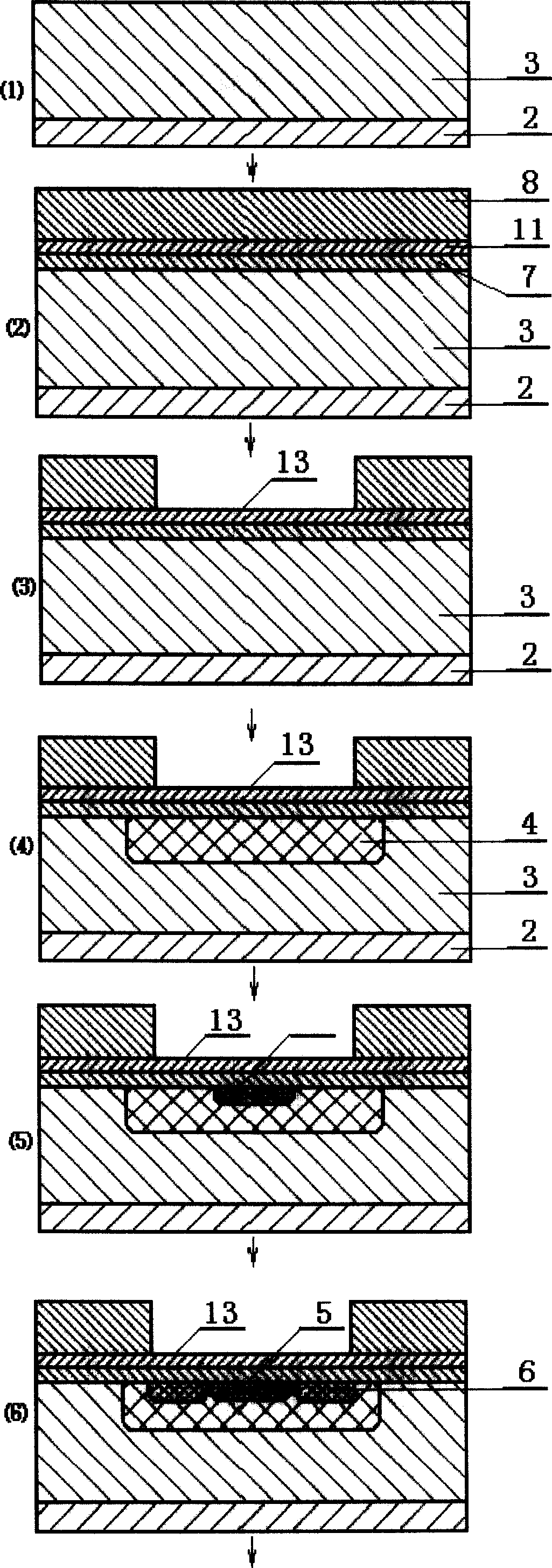

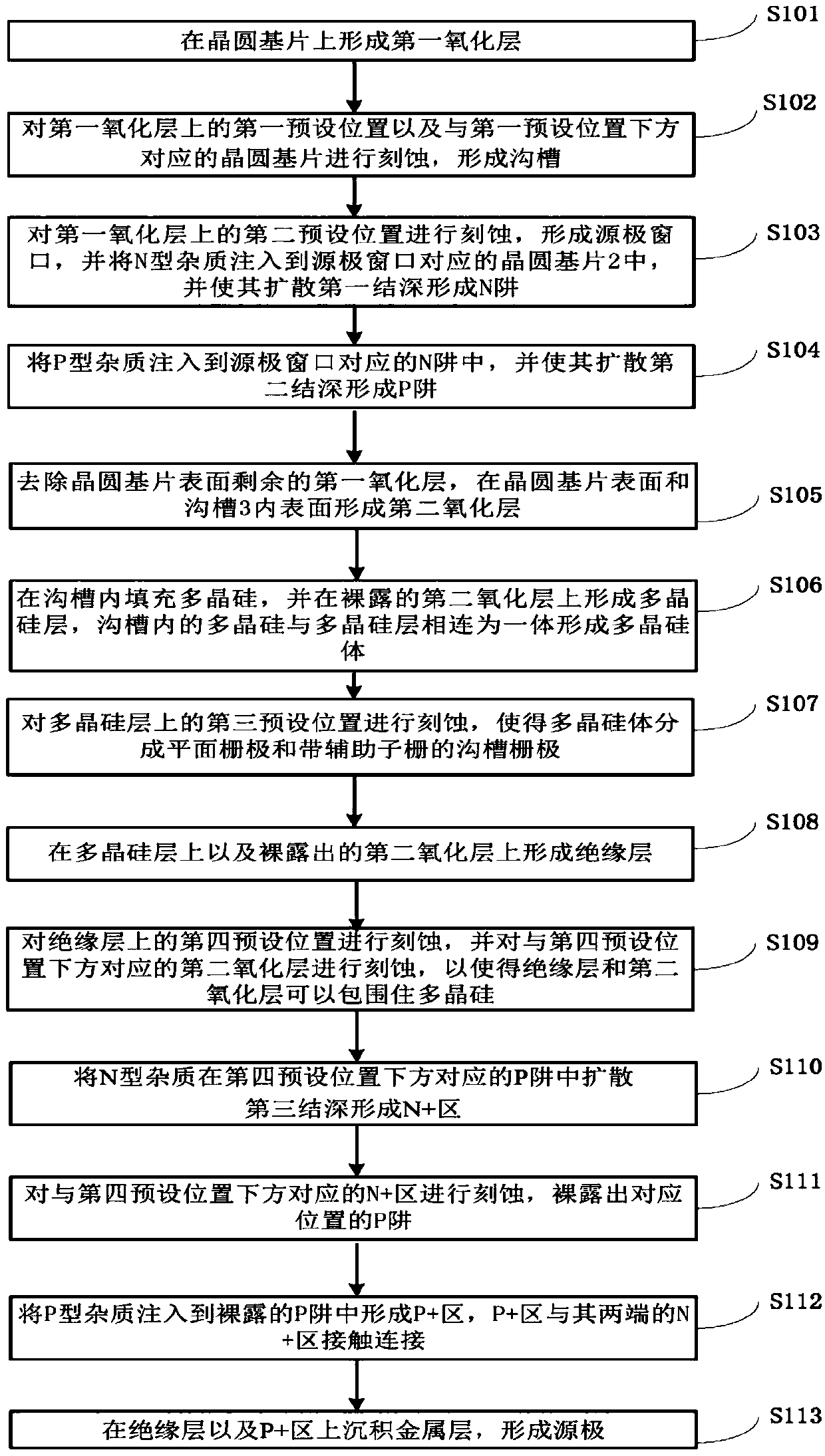

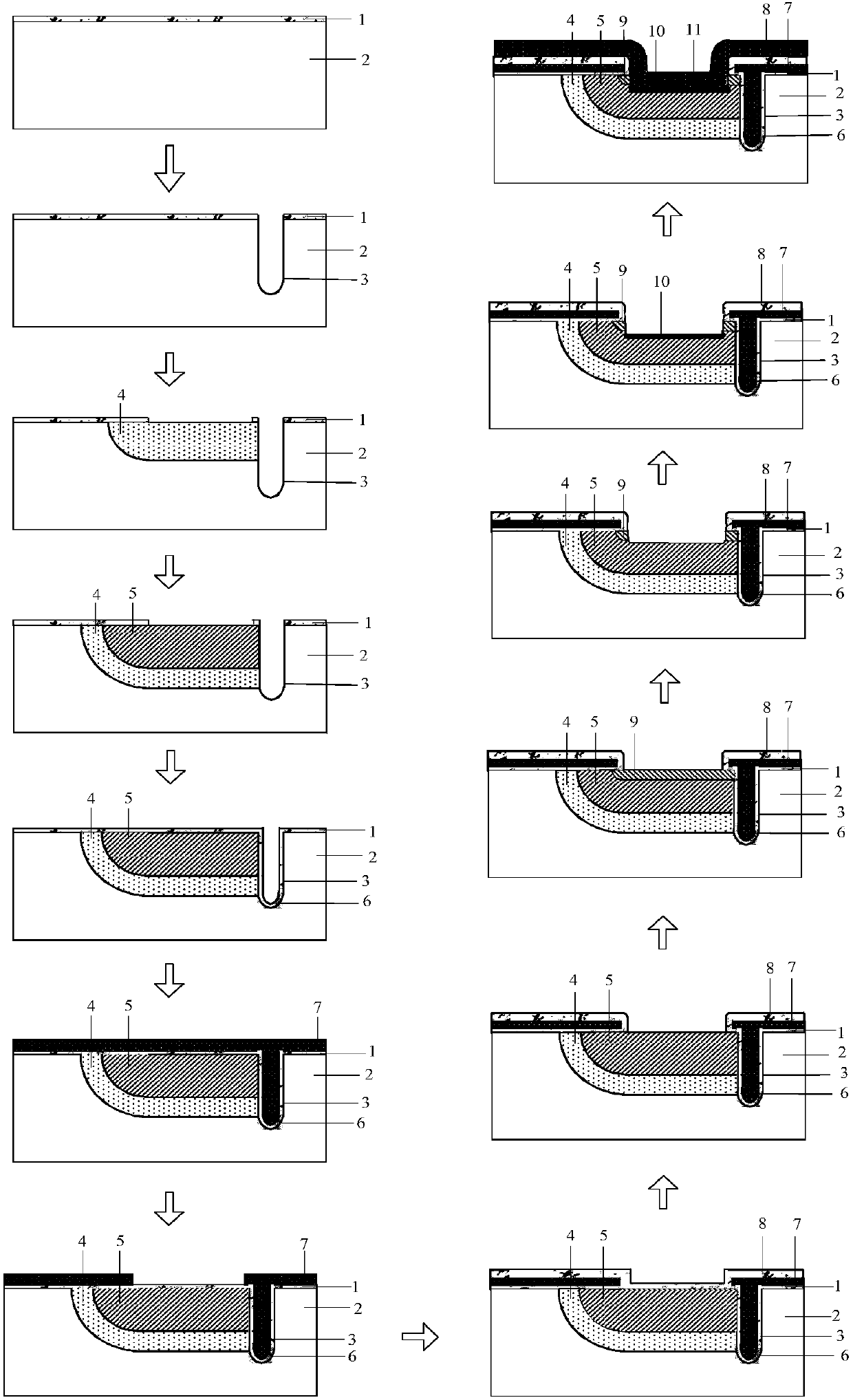

Manufacturing method for IGBT chip with composite grid

ActiveCN108682624APlanar grid has good pressure resistanceImprove pressure resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesComposite gridPolycrystalline silicon

The invention discloses a manufacturing method for an IGBT chip with a composite grid. The method comprises the following steps: forming a first oxide layer on wafer substrate; etching a first presetposition on the first oxide layer and the wafer substrate corresponding to the lower portion of the first preset position to form a groove; re-etching to remove the first oxide layer, and forming a second oxide layer on the surface of the wafer substrate and on the inner surface of the groove; filling the groove with polysilicon, forming a polysilicon layer on the second oxide layer, and forming apolysilicon body through connecting polysilicon with the polysilicon layer in the groove into one body; and etching a third preset position on the polysilicon layer to enable the polysilicon body tobe divided into a plane grid and a groove grid with an auxiliary grid. The IGBT chip with the composite grid manufactured by the manufacturing method not only has the advantages of good voltage resistance of flat grids, but also is the advantageous in that the groove grid increases the cell density, thus greatly increasing the electric current density of the chip.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

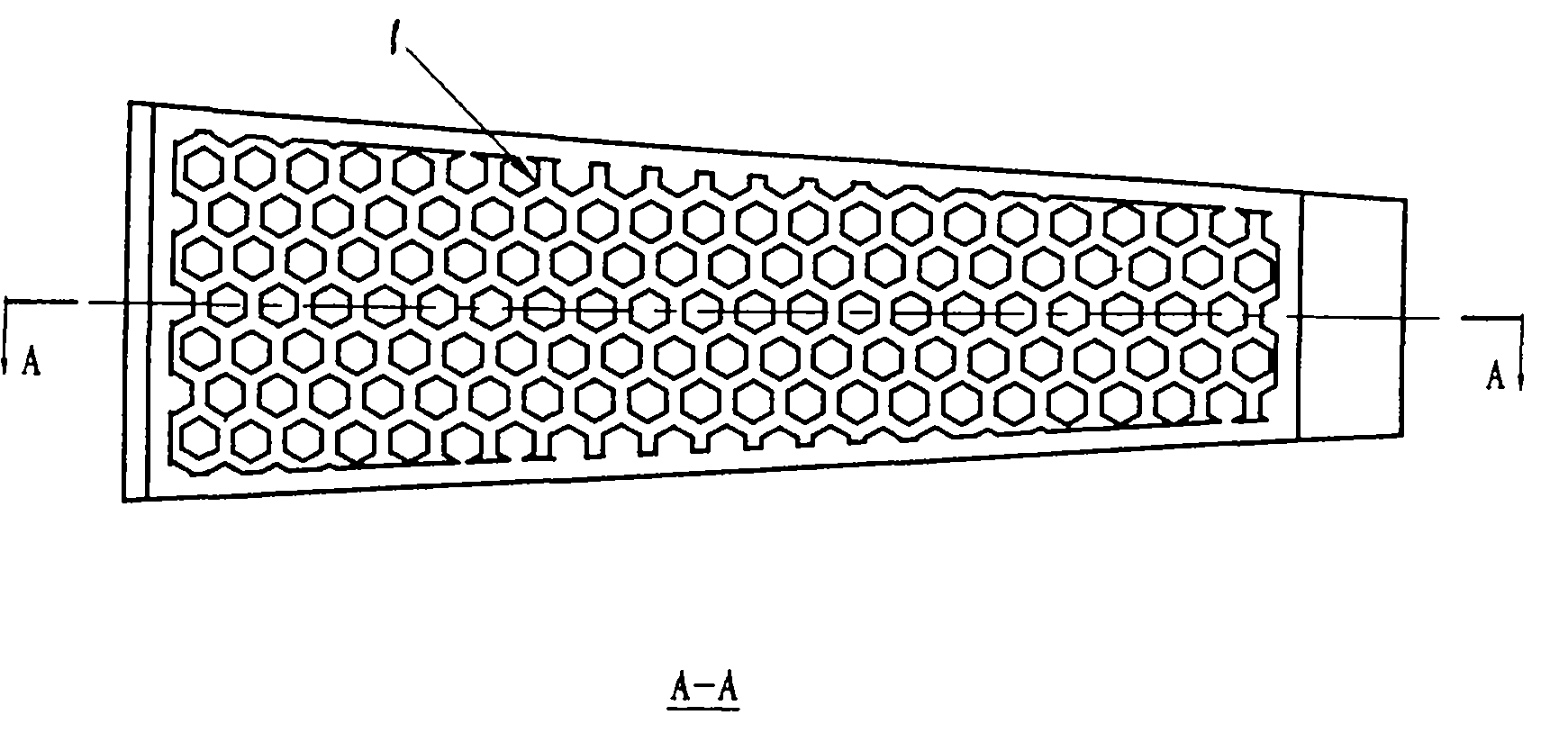

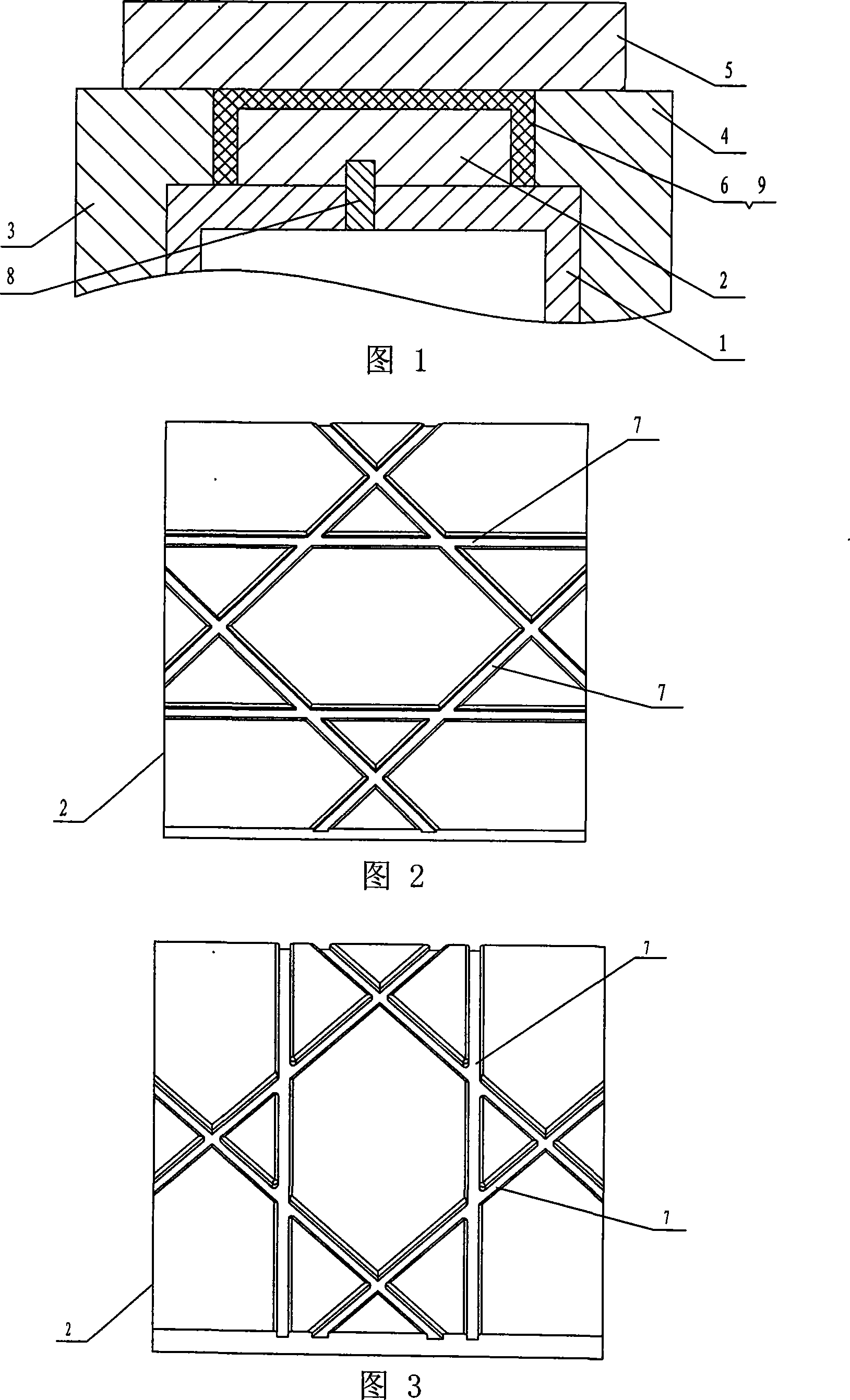

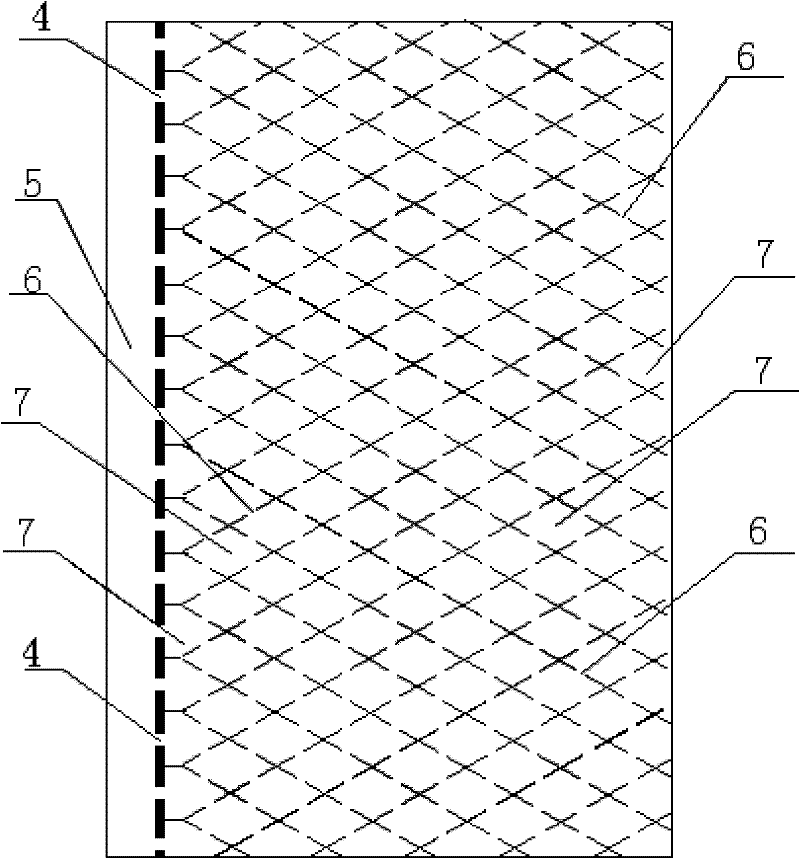

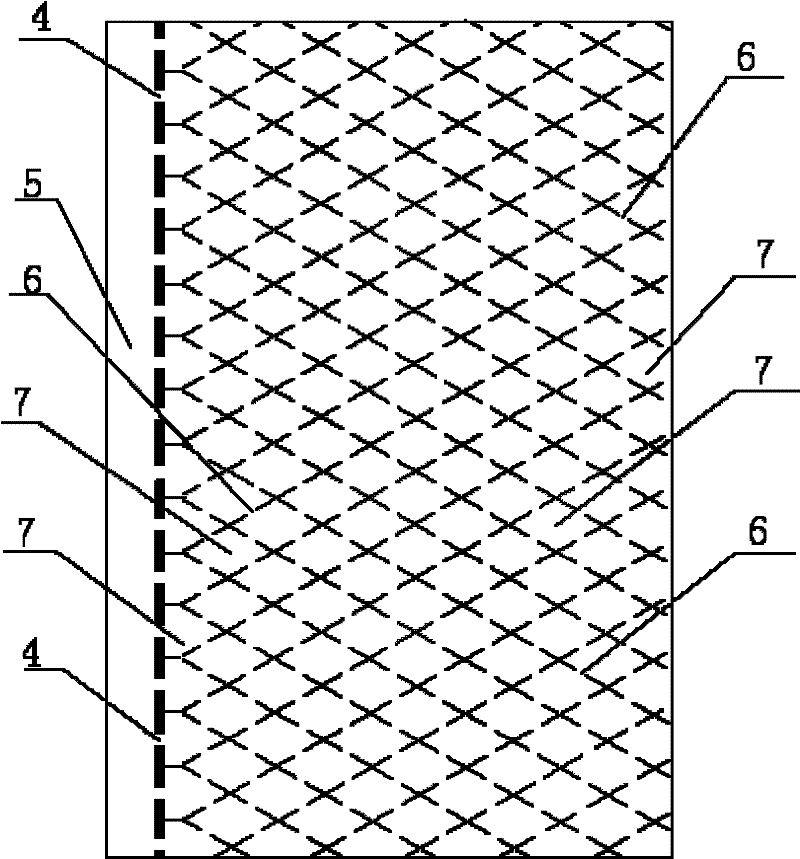

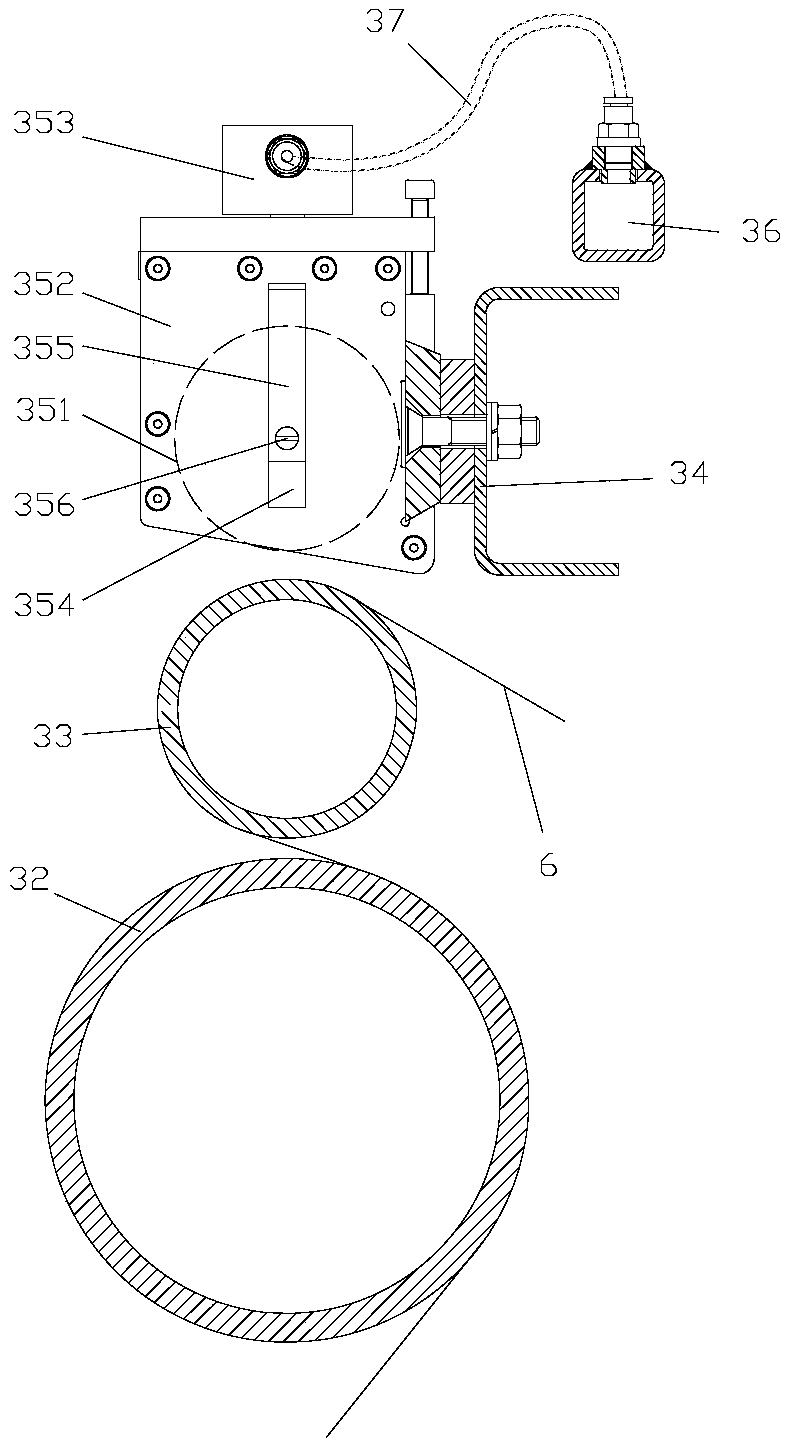

Mold of resin base complex material inner gridding skeletal rod structure and shaping method thereof

The invention discloses a mold and a component forming method of a resin-based composite material internal grid reinforcement structure, which relates to a mold of a fiber composite material component and a forming method of the component. It solves the problems of low precision, low production efficiency, high cost, poor apparent quality and difficult demoulding in the existing forming method. In the present invention, an inner grid reinforcement member of a resin-based composite material is surrounded by an inner mold (1), a split mold (2), a left flange (3), a right flange (4) and an outer mold (5). The cavity (6), the outer surface of the split mold (2) has a plurality of grooves (7), the split mold (2) and the inner mold (1) are positioned by positioning pins (8), and are connected by bolts and inner molds. Die 1 is firmly connected. The method is as follows: 1. Designing a mould; 2. Winding or laying convex ribs in the cavity; 3. Winding or laying continuous fibers impregnated with resin base in the cavity (6); 4. Forming. The invention has the advantages of high product precision, high production efficiency, reduced production cost, good apparent quality of components, easy demoulding and the like.

Owner:HARBIN FRP INST

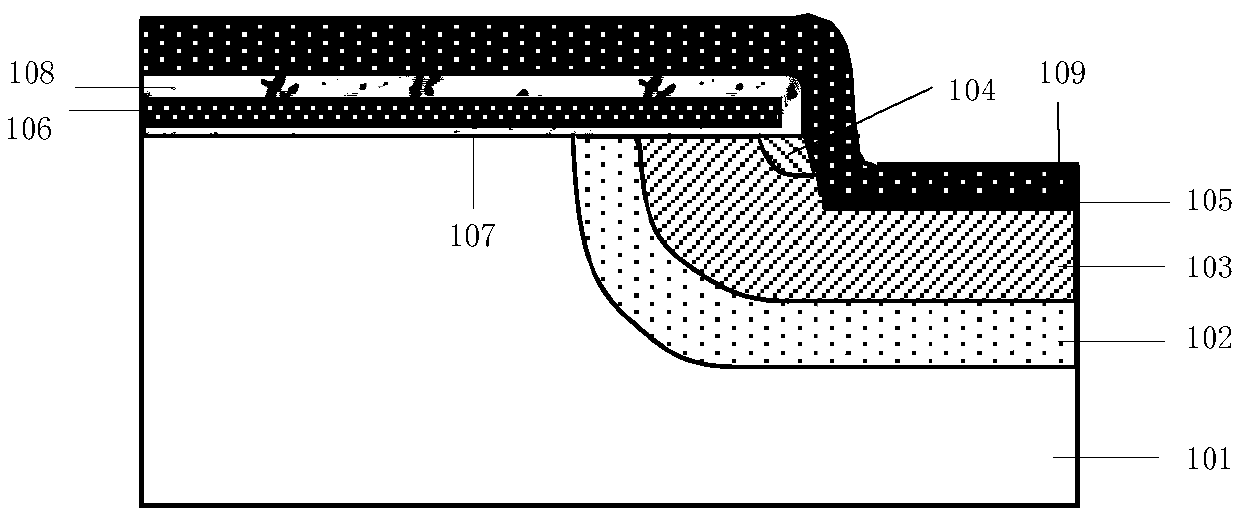

Image sensor, electronic device and its manufacturing method

The present disclosure relates to an image sensor, electronic device and its manufacturing method. In one embodiment, the present disclosure relate to an image sensor which may comprise a substrate, afirst surface and a second surface opposite to the first surface; a pixel sensor array arranged within the substrate; a composite grid arranged over a first surface of the said substrate and having an opening corresponding to a pixel sensor in the pixel sensor array; wherein the said composite grid has a dielectric layer, a hard mask layer arranged over the dielectric layer, and a metal layer surrounding the dielectric layer and the hard mask layer.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

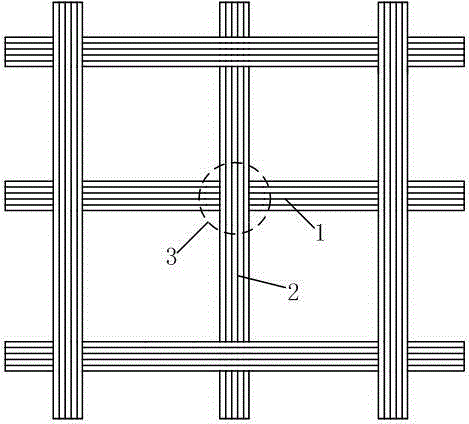

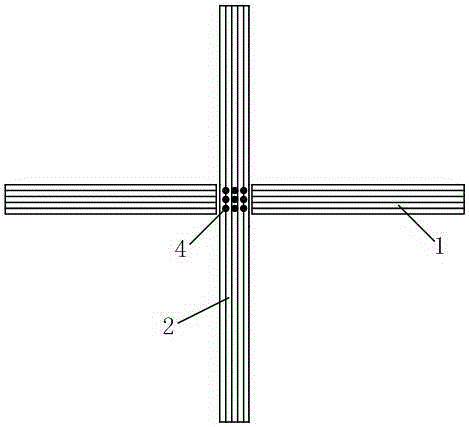

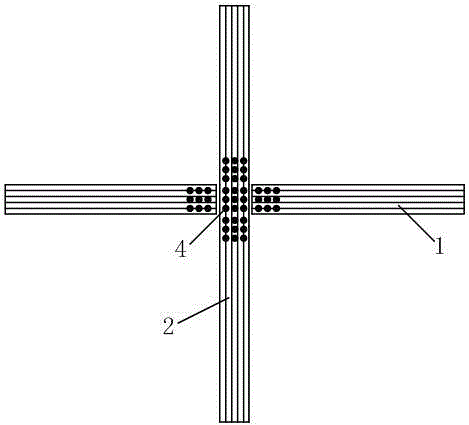

Z-pin reinforced composite grid structure and manufacturing method thereof

The invention relates to a Z-pin reinforced composite grid structure and a manufacturing method thereof, belonging to the technical field of fibrous composite reinforcement. The manufacturing method comprises the following steps: planning movement locus of a fiber placement head by a design procedure through a specially-designed grid fiber placement device, and overlaying a grid structure on a grid forming mould by adopting a shearing-continuing placement process; preparing high-performance Z-pin by an advanced pultrusion device, designing a Z-pin parameter, and implanting the Z-pin in a foam prefab; implanting the Z-pin at the structure node part of a grid by ultrasonic implant equipment; and reinforcing the Z-pin reinforced composite grid stiffened structure. According to the invention, the problems of uniform thickness caused by repeated prepreg layering and layered bridging resulted from crossed fiber layers at the node parts can be solved, connection strength and anti-fatigue performance of the node parts also can be obviously enhanced, and Z-pin is light, high in strength and small in fiber damage.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Composite grid with tack film for asphaltic paving, method of paving, and process for making a composite grid with tack film for asphaltic paving

A composite material comprises: an open grid comprising at least two sets of strands. Each set of strands has openings between adjacent strands. The sets are oriented at a substantial angle to one another. A tack film is laminated to the open grid. The tack film has first and second major surfaces, such that a material of the tack film at its first and second major surfaces includes about 50% or more of resinous non-asphaltic component and about 50% or less of asphaltic component.

Owner:SAINT GOBAIN TECHN FABRICS AMERICA INC

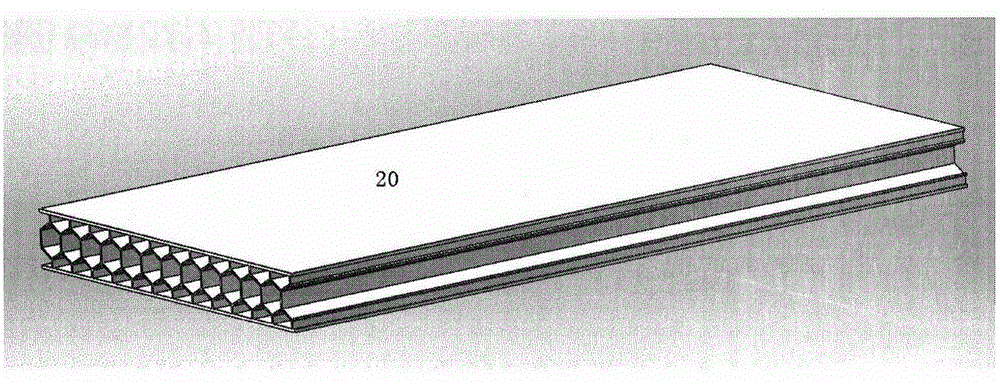

Multilayer composite grid sound barrier and application of multilayer composite grid sound barrier

InactiveCN105369923ALight in massImprove structural strengthHull panellingsFuselage insulationSound barrierIsolation layer

The invention provides a multilayer composite grid sound barrier. The multilayer composite grid sound barrier is of a multilayer composite three-dimensional structure, and comprises surface layers, a plurality of middle sound isolation layers and light-weight sandwich layers, wherein the surface layers are positioned on the surfaces of the two sides of the multilayer composite grid sound barrier; the middle sound isolation layers are positioned between the two surface layers; the light-weight sandwich layers are positioned between the surface layers and the middle sound isolation layers and between the middle sound isolation layers and fill gaps; the surface layers and the middle sound isolation layers are made of sound isolation materials or composite sound isolation materials; the light-weight sandwich layers are made of sound absorption material. The sound barrier also comprises keels; the keels are positioned between the surface layers and the middle sound isolation layers, connect the surface layers and the middle sound isolation layers and connect the middle sound isolation layers to form a three-dimensional grid structure; and the keels positioned at the two sides of the each middle sound isolation layer are not overlapped with the extension lines of the keels arranged at the other side of the middle sound isolation layer. The multilayer composite grid sound barrier has excellent sound isolation performance; meanwhile, good heat insulation performance is realized; the structure is firm, simple and reasonable; the weight is light; the thickness is small; the installation is convenient; the production and manufacturing process is simple; and the cost is low. The invention also provides application of the multilayer composite grid sound barrier.

Owner:北京谐声昊普声学技术有限公司

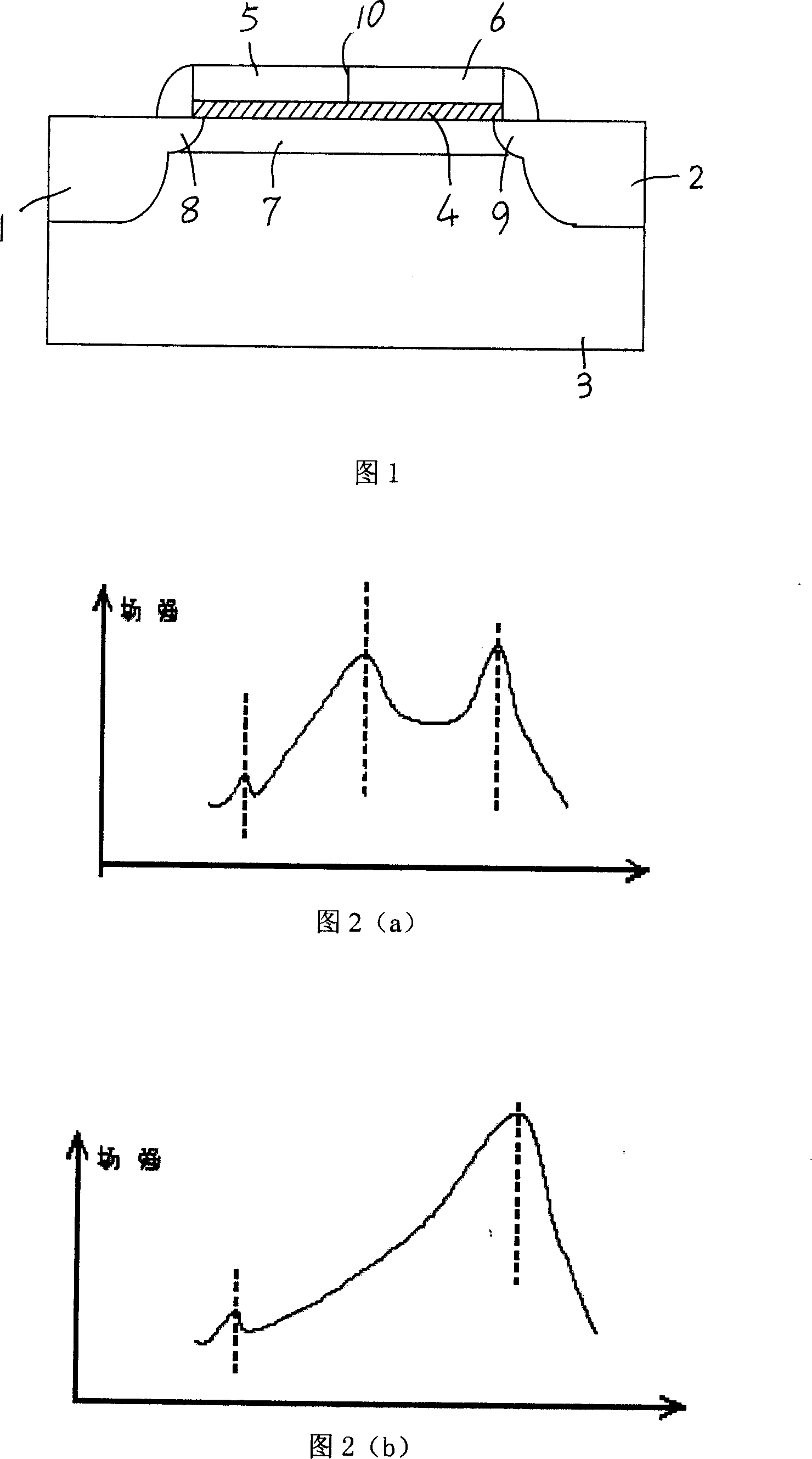

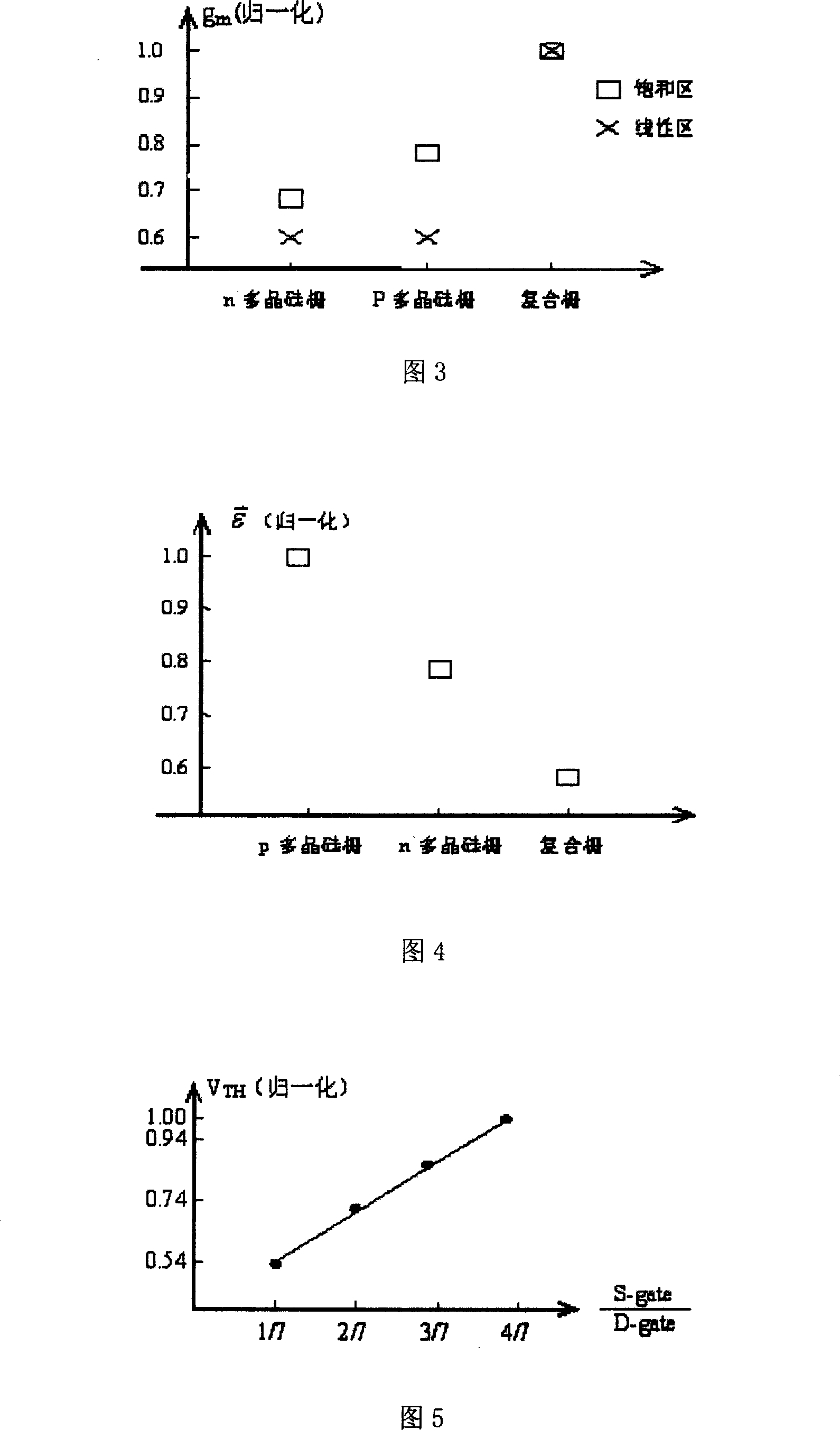

Homojunction combined gate field effect transistor

InactiveCN1953206AIncrease drive currentImprove transconductanceSemiconductor devicesDriving currentEngineering

The invention relates to a composite grid field effect transistor. Wherein, the grid, source, leak and substrate form the main body; the insulated layer is between grid and substrate; the groove is on the substrate between source and leak; the source extends shallow source extending area at the left end of groove; the grid extends shallow leak extending area at the right end; the invention is characterized in that the grid is composite grid and multi-crystal grid, while the left and right parts are different in conductive types; the left grid toward to source is P-type multi-crystal grid, while the left part toward leak is N-type multi-crystal grid. The invention can obtain radio MOSFET driving current, transconductance and cut-off frequency, and release the maximum field strength, thermal electronic effect and short-groove effect at the end of leak drift area.

Owner:ANHUI UNIVERSITY

bt composite safety explosion-proof metallized film

InactiveCN102290233AEdge thickening completeUndamagedThin/thick film capacitorFixed capacitor electrodesCapacitanceMetal filament

The invention discloses a BT composite safety explosion-proof metallized film, which comprises a conductive metal layer and an insulating film medium layer. A blank margin with a certain width is reserved at one end, and the metal layer is a BT composite grid structure, including an edge thickening area (5), a metallized grid (7), and connecting adjacent metallized grids ( 7) The metallized filaments (6) and the narrow strips of metallization (4) connecting the edge thickened areas (5) and the adjacent metallized grids (7). With such a structure, the edge thickening area is independent and complete, and the metallized film can be well attached when winding the capacitor core, and the gold spraying can be absorbed well; The strips of metal plating are connected, the original metallized filaments are not damaged, and the capacitor capacity is not easily attenuated.

Owner:TONGLING QILI ELECTRONICS MATERIALS

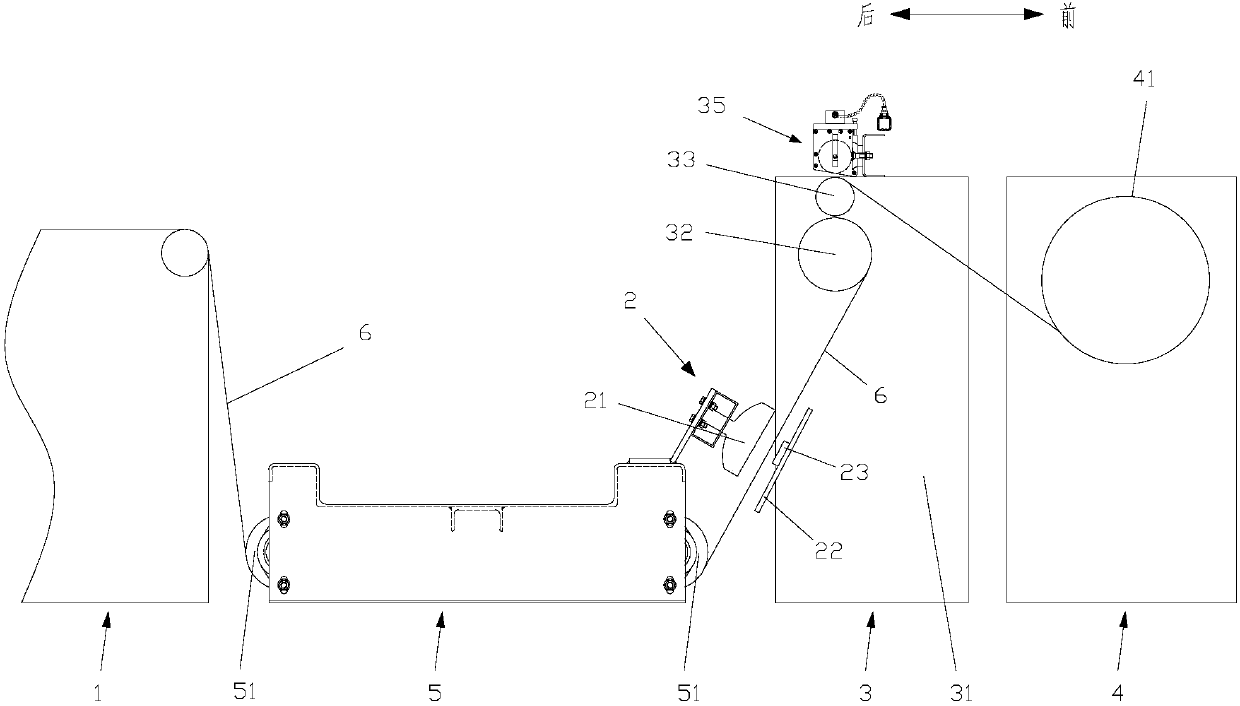

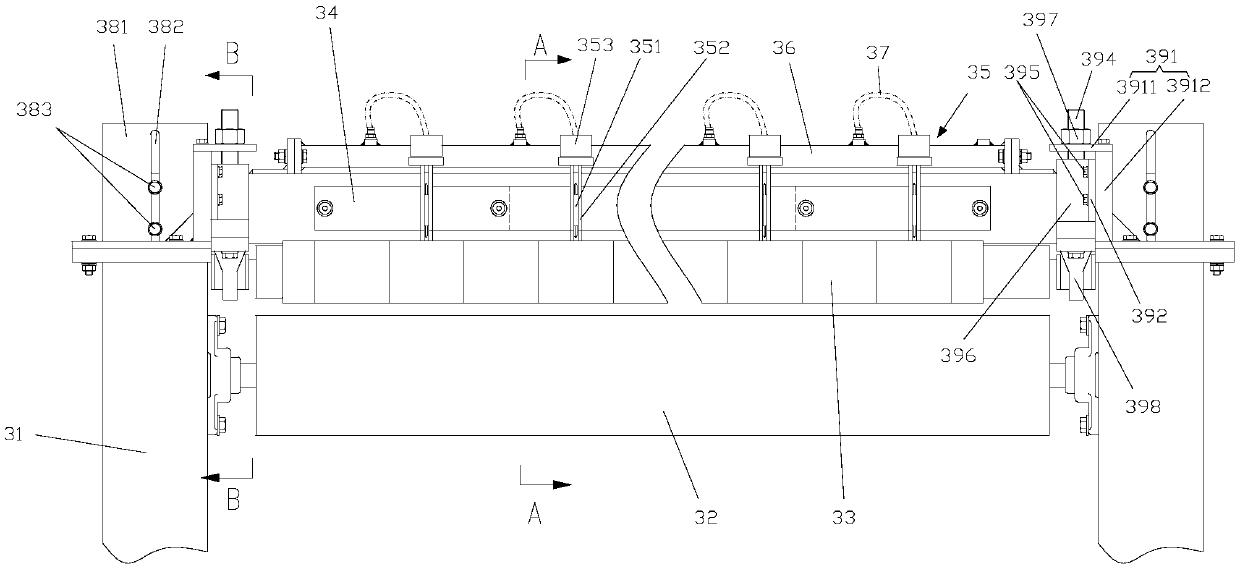

Composite net-shaped grid manufacturing equipment for storage battery

ActiveCN107919478AIncrease productivityElectrode carriers/collectorsSevering textilesEngineeringHot melt

The invention discloses composite net-shaped grid manufacturing equipment for a storage battery. The composite net-shaped grid manufacturing equipment comprises a weaving machine, a heating mechanism,a cutting mechanism and a take-up mechanism, wherein the weaving machine is used for weaving grid composite lines and hot-melting lines to form a composite grid net, the composite grid net is dividedinto a plurality of grid strips along meridians according to a set width, the hot-melting lines are woven at edges of two sides of each grid plate, the heating mechanism is used for heating the hot-melting lines woven in the composite grid net so that the hot-melting lines are molten and are pasted with wefts of the composite grid net, the cutting mechanism is used for cutting the meridian between two adjacent grid strips so that the composite grid net is cut to form the plurality of independent grid strips and is simultaneously used for cutting redundant parts of edges of the grid strips ata left end and a right end, the take-up mechanism comprises a plurality of take-up units, and each take-up unit is used for correspondingly winding each grid strip. By the composite net-shaped grid manufacturing equipment, weaving, edge locking, cutting and take-up of the composite grid net can be achieved, each process is continuously operated, and the production efficiency is improved.

Owner:肇庆中特能科技投资有限公司

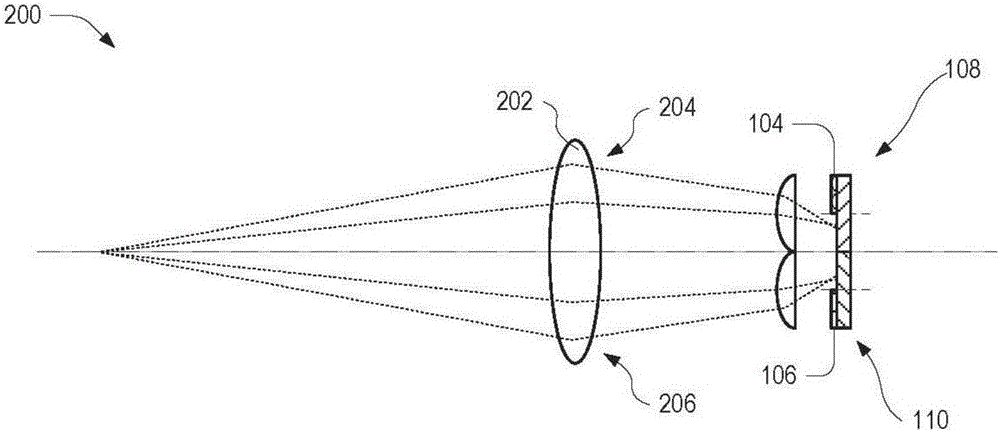

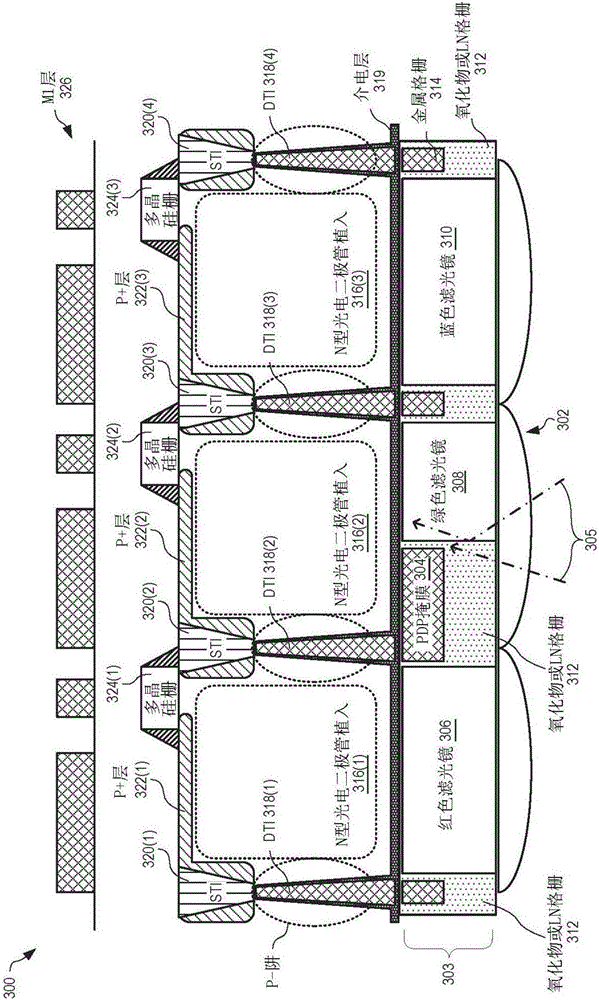

BSI CMOS image sensor with improved phase detecting pixel

An improved back side illuminated (BSI) complementary metal oxide semiconductor (CMOS) image sensor, and associated methods, improve phase detecting capability. The BSI CMOS image sensor has an array of pixels that include a phase detecting pixel (PDP), a composite grid formed of a buried color filter array and composite metal / oxide grid, and a photodiode implant corresponding to the PDP. A PDP mask is fabricated with a deep trench isolation (DTI) structure proximate the PDP and positioned to mask at least part of the photodiode implant such that the PDP mask is positioned between the composite grid and the photodiode implant.

Owner:OMNIVISION TECH INC

Composite grid IGBT chip with three-dimensional channel

ActiveCN108682688AHigh densityReduce power consumptionSemiconductor devicesVoltage dropComposite grid

The invention discloses a composite grid IGBT chip with a three-dimensional channel. The chip includes multiple cells. Each of the cells includes: a trench polysilicon gate electrode located in an intermediate area of the cell; a first oxide layer surrounding the trench polysilicon gate electrode; P well areas formed by injecting P type impurities into the cell on both side areas of a trench; doping areas formed by injecting impurities into the P well areas on both sides of the trench, wherein the width of the doping areas is smaller than the width of the P well areas, and the doping areas include an N++ doping area and a P++ doping area; second oxide layers are located on two side areas, being on the cell, of the doping areas, wherein the second oxide layers are used for covering the surface of the two side areas of the two P well areas, the surface of the P well areas without the doping areas, and partial doping areas; planar polysilicon gate electrodes formed on the second oxide layers; and third oxide layers covering the planar polysilicon gate electrodes. The chip can enable the electric current density of the IGBT chip to be improved, so as to reduce a conducting voltage drop.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

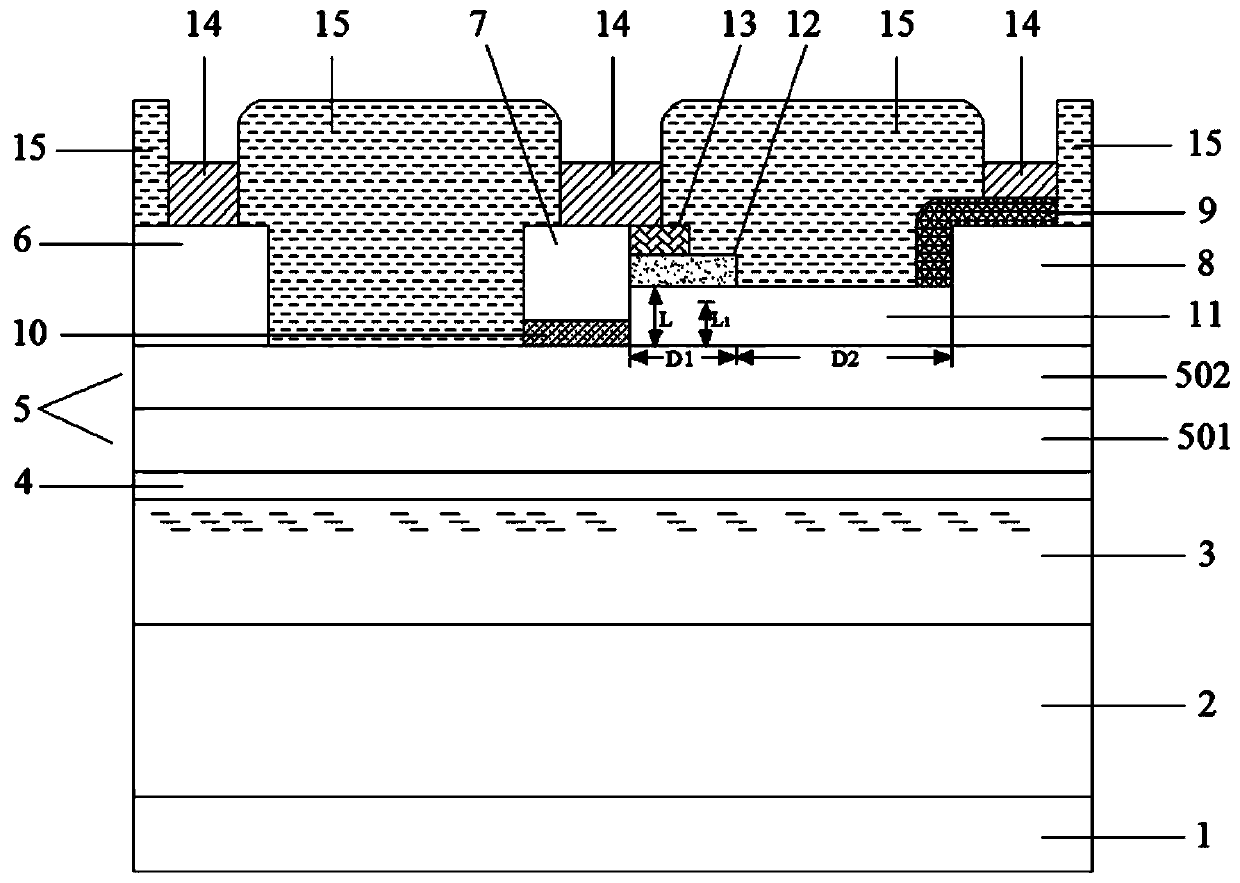

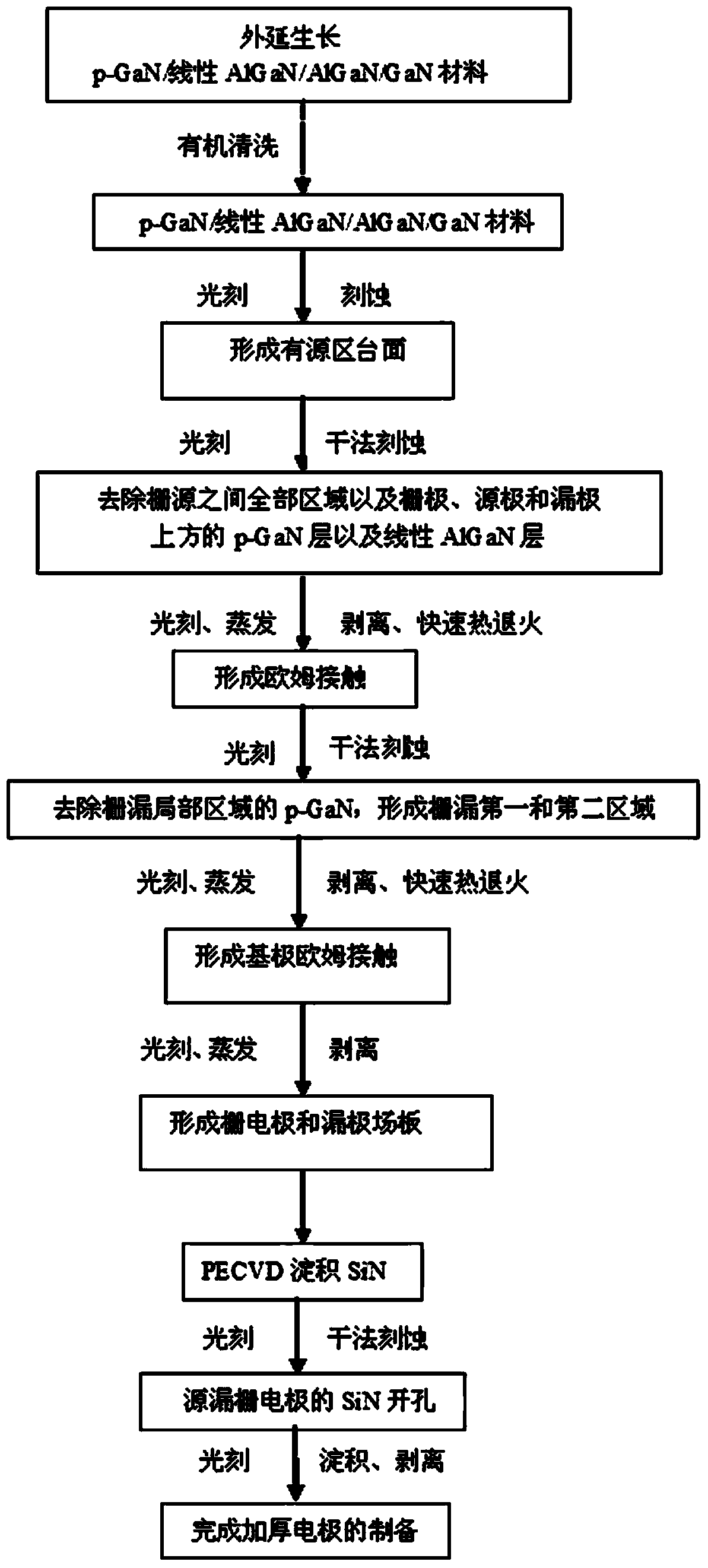

Composite drain-based AlGaN/GaN MIS-HEMT (Metal-Insulator-Semiconductor High-Electron-Mobility Transistor) high-voltage device and fabrication method thereof

InactiveCN103745992APrevents electric field spikesImprove breakdown voltageSemiconductor devicesGate leakage currentMetal insulator

The invention discloses a composite drain-based AlGaN / GaN MIS-HEMT (Metal-Insulator-Semiconductor High-Electron-Mobility Transistor) high-voltage device and a fabrication method thereof. The structure of the device comprises a substrate, a GaN buffer layer, an intrinsic GaN channel layer, an AlN isolating layer and an AlGaN barrier layer sequentially from the bottom up, a source, a grid and a composite drain are arranged on the AlGaN barrier layer, and an insulating medium layer is arranged between the grid and the AlGaN barrier layer; a linear AlGaN layer, a P-type GaN epitaxial layer and a base are sequentially epitaxially arranged on the top of the AlGaN barrier layer between the grid and the composite drain. The invention has the advantages that: when the device is switched on, the 2DEG (2-dimensional electron gas) concentration of a first region and a second region between the grid and the drain increases, and the resistance decreases; when the device is switched off, the 2DEG of the first region is reduced, the 2DEG of the second region is the same as when the device is switched on, the width of the depletion region of the device is increased, the distribution of an electric field is changed, and the breakdown voltage of the device is increased; the composite grid structure prevents the electric field peak from appearing at the edge of the drain, thus increasing the breakdown voltage of the device; an insulated grid structure prevents grid leakage current, and thereby the performance of the device is enhanced.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com