Forming method of heterogeneous composite grid skin cabin

A composite material and forming method technology, which is applied in the field of special-shaped composite material grid skin compartment forming, can solve the problems of large loss of silicone rubber, poor rib position accuracy, and large product size deviation, etc., to ensure smooth compaction, The effect of reducing the possibility of deformation and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0045] Through the following steps, the present invention realizes one-time integral solidification molding of the carbon fiber prepreg cabin section of the special-shaped composite material grid.

[0046] Step (1), making special-shaped composite material mesh carbon fiber prepreg compartment forming mold

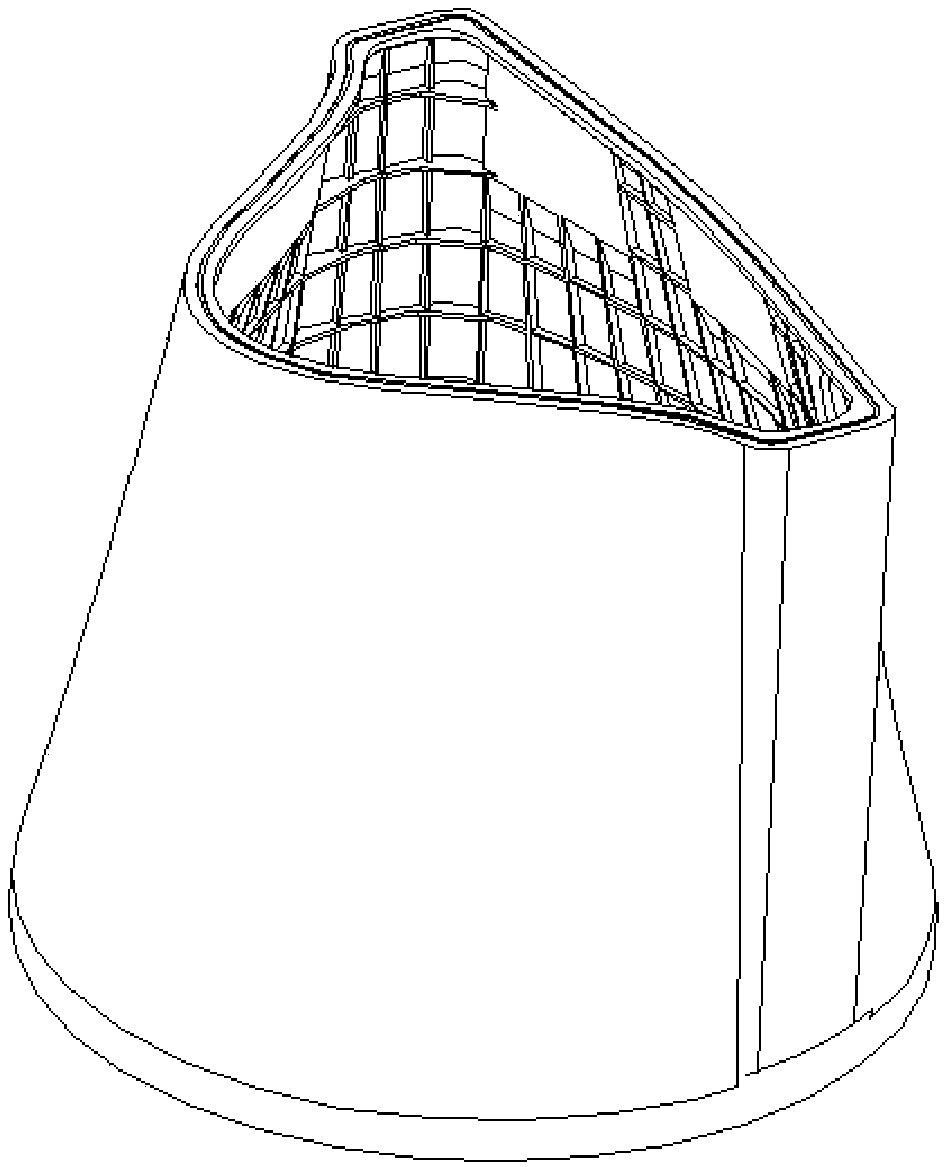

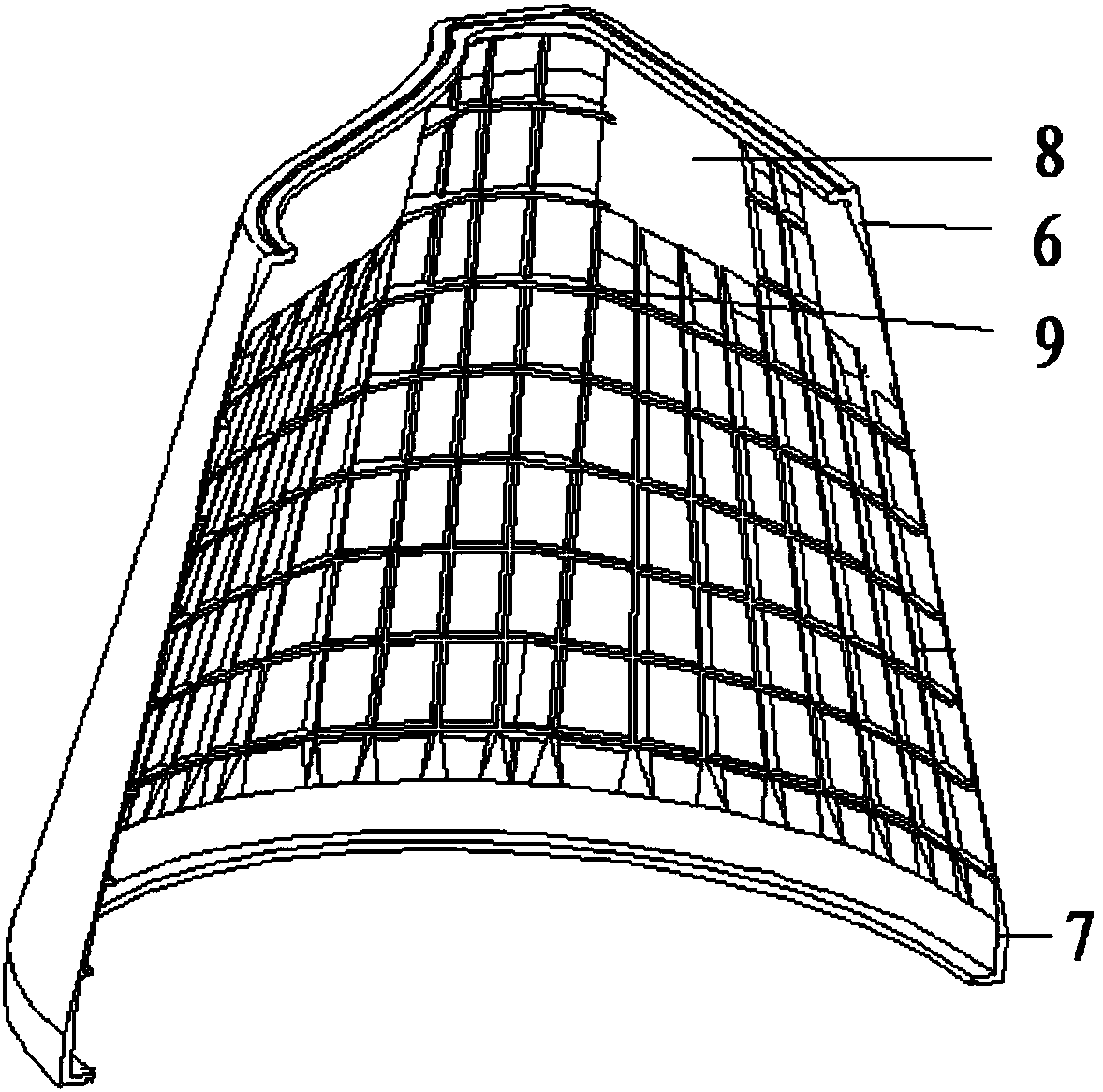

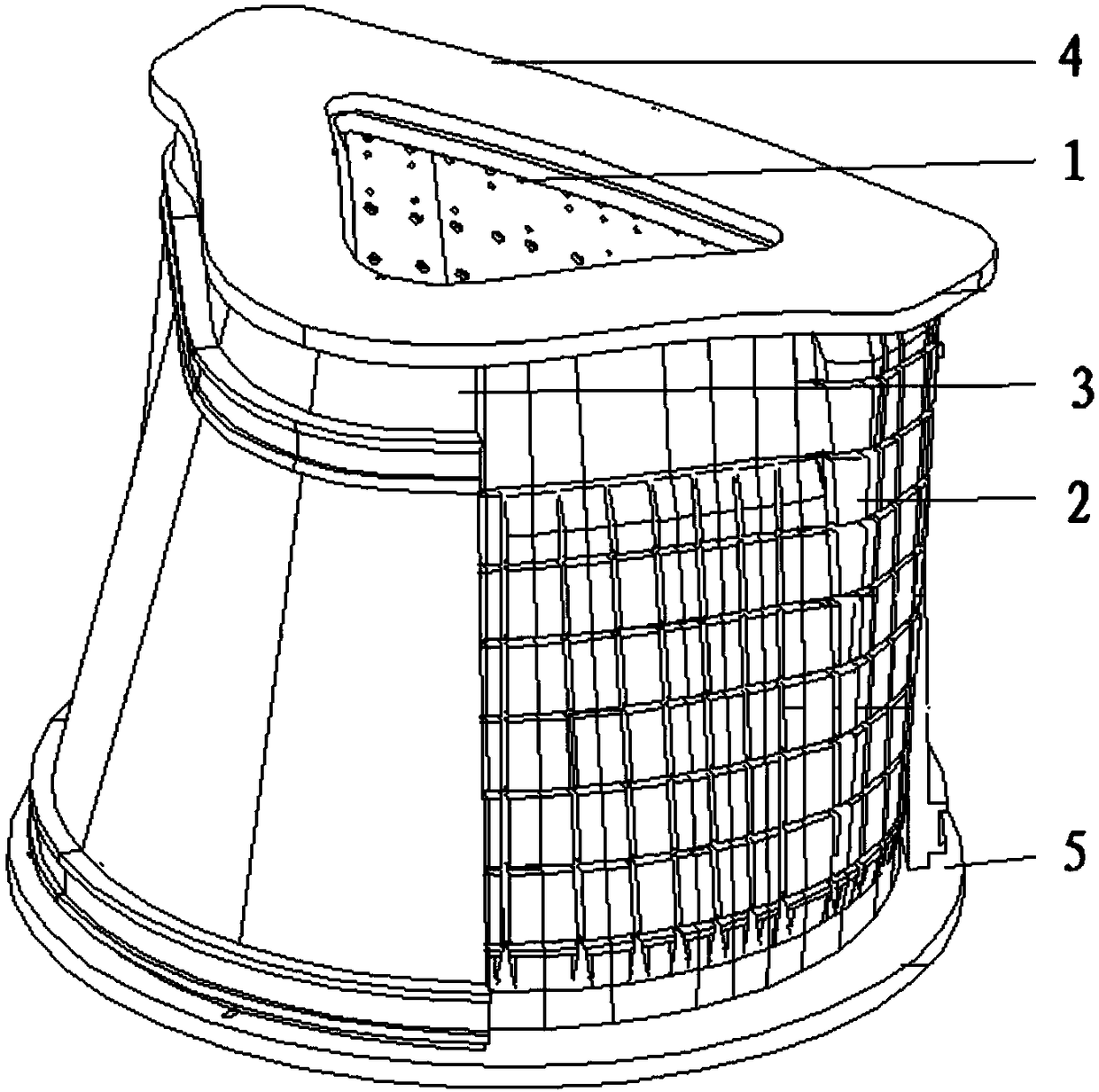

[0047] Such as image 3Shown is a schematic diagram of the special-shaped composite material grid carbon fiber prepreg cabin mold. It can be seen from the figure that the special-shaped composite material grid carbon fiber prepreg cabin molding mold includes a core mold 1, a split male mold 2, an outer female mold 3, and an upper end The frame pressure ring 4 and the lower frame pressure ring 5; wherein, the core mold 1 is located at the center of the forming mold; the split male mold 2 is covered on the outer wall of the core mold 1; the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com