BSI CMOS image sensor with improved phase detecting pixel

An image sensor and phase detection technology, applied in the field of image sensors, can solve problems such as phase detection capability degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

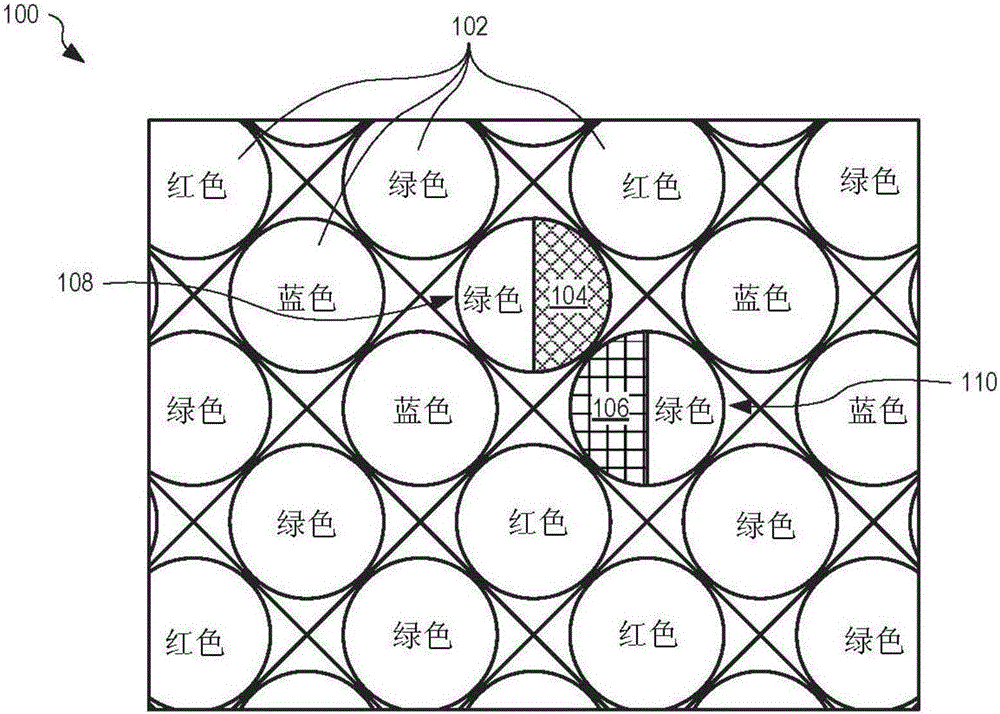

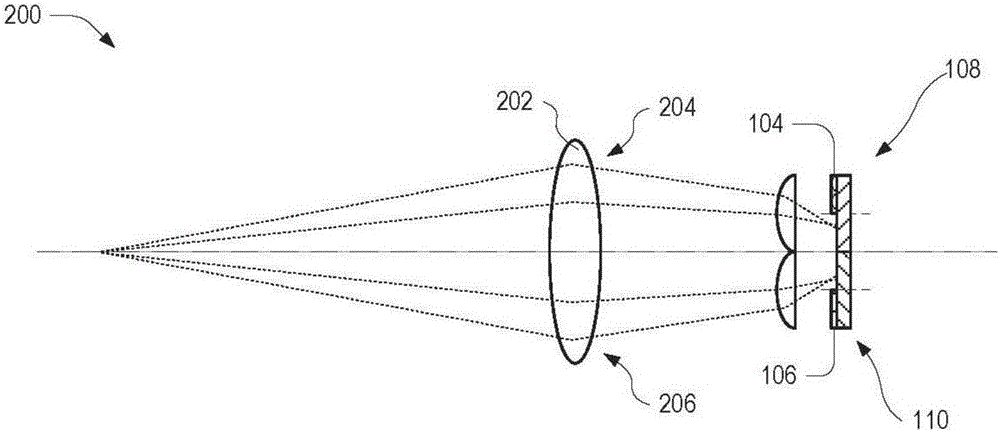

[0016] figure 1 A pixel pattern is shown for a backside illuminated (BSI) complementary metal oxide semiconductor (CMOS) image sensor 100 having a plurality of pixels 102 each having a color filter and a lens, where two pixels are each configured with a right phase detection pixel (PDP) mask 104 and left PDP mask 106 to operate as PDPs 108 and 110 . figure 2 is showing figure 1 A schematic diagram of an exemplary operation of the PDP 108 to detect light from the first side 204 of the objective lens 202 and an exemplary operation of the PDP 110 to detect light from the second side 206 of the objective lens 202 . Phase detection pixels 108, 110 may be used within the camera to improve autofocus by detecting differences in phase with respect to the focus of the object being captured. The cameras adjust focus to align with the detected phases from PDPs 108 and 110 .

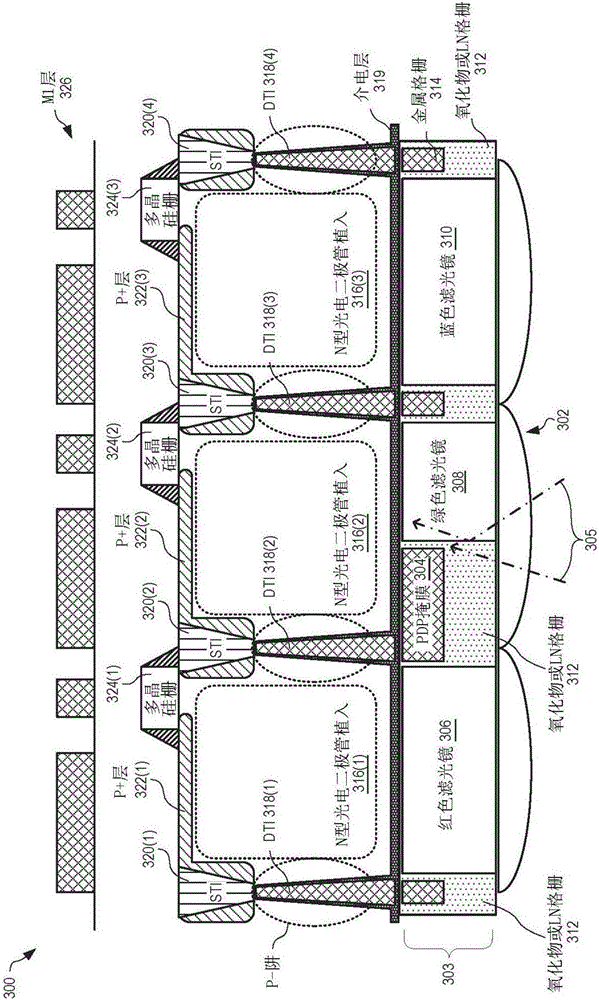

[0017] 3 is a cross-section of part of a related art BSI CMOS image sensor 300 showing the structure of a rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com