Patents

Literature

42results about How to "Slow down scaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

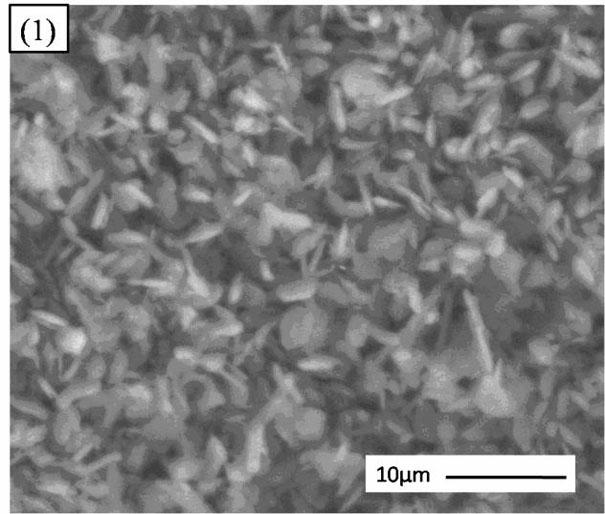

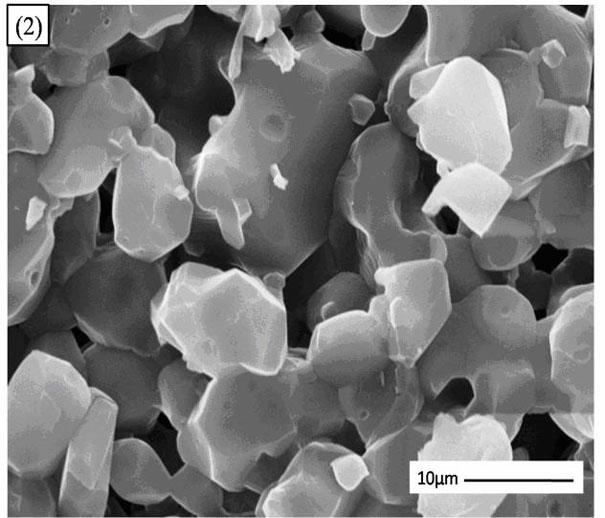

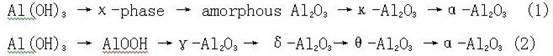

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

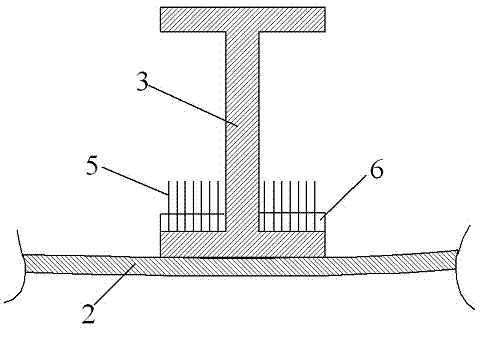

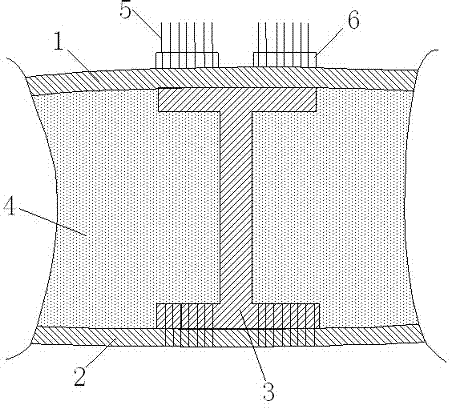

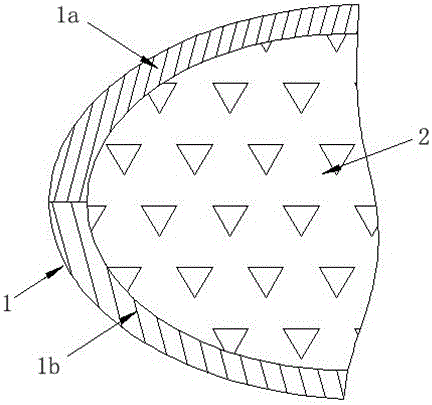

Z-pin reinforced composite wind turbine blade and manufacturing method thereof

ActiveCN104552994AImprove connection strengthImprove fatigue resistanceFinal product manufactureWind motor componentsTurbine bladeFibrous composites

The invention relates to a Z-pin reinforced foam sandwich composite wind turbine blade and a manufacturing process thereof, belonging to the technical field of fiber composite reinforcing. The manufacturing process comprises the following steps: implanting Z-pin into a foam preform, and preparing a composite connection layer; laying an upper half shell and a lower half shell in a wind turbine blade mould, and implanting Z-pin into a connecting part of the lower half shell and the connection layer in the direction perpendicular to the shell; pouring a foaming material in a lower mould, and then closing an upper mould; after the foaming of the foaming material is finished, taking down the upper mould, implanting Z-pin perpendicular to the shell from the outside at a joint of the upper half shell and the upper half part of the connection layer, and then closing the upper mould; solidifying the Z-pin reinforced composite wind turbine blade. The manufacturing process provided by the invention has the advantages of obviously improving the connection strength and the fatigue resistance performance of the joint of the upper shell and the lower shell of the composite wind turbine blade, and avoiding the structural damage caused by ungluing of the upper and the lower shells, and the Z-pin is light in weight and high in strength, so that the requirement of the wind turbine blade for the material is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

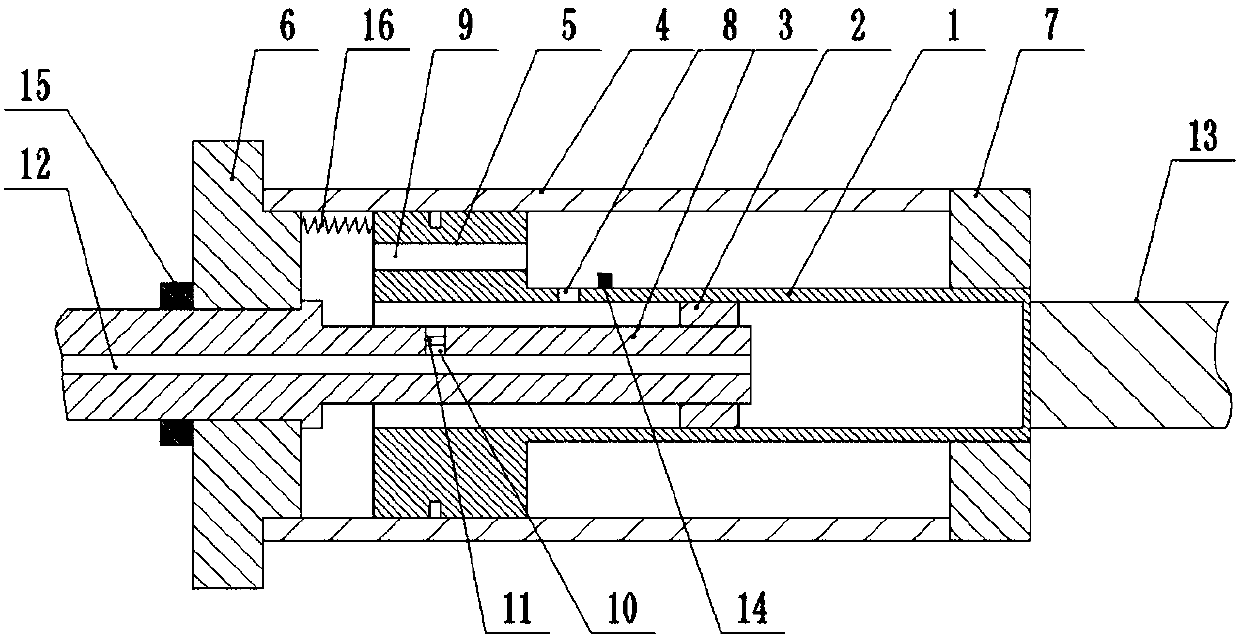

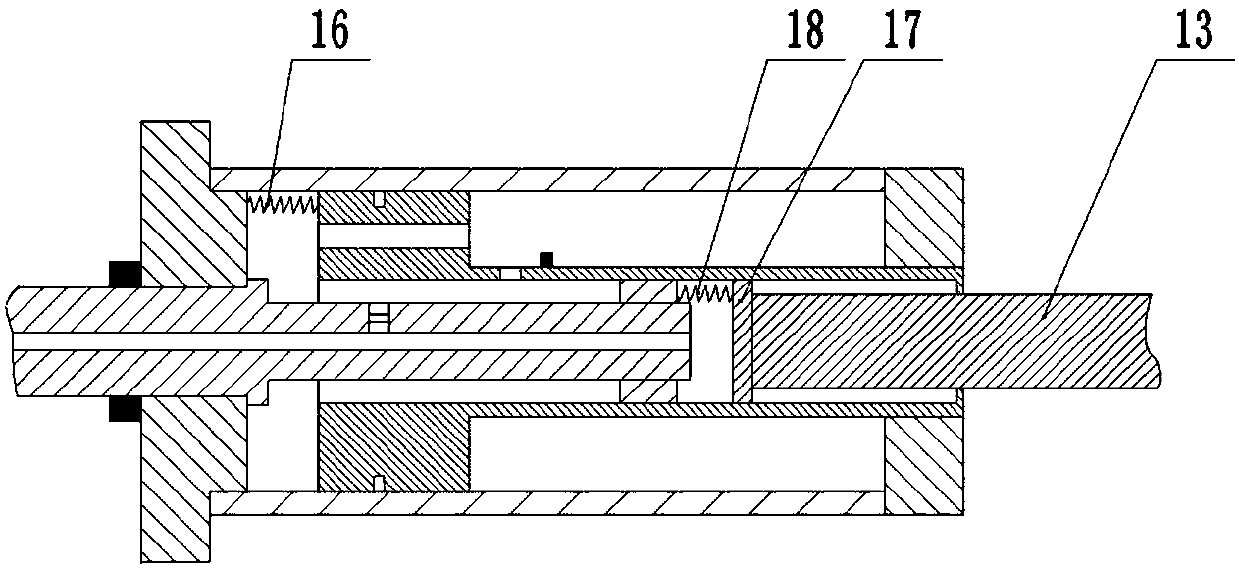

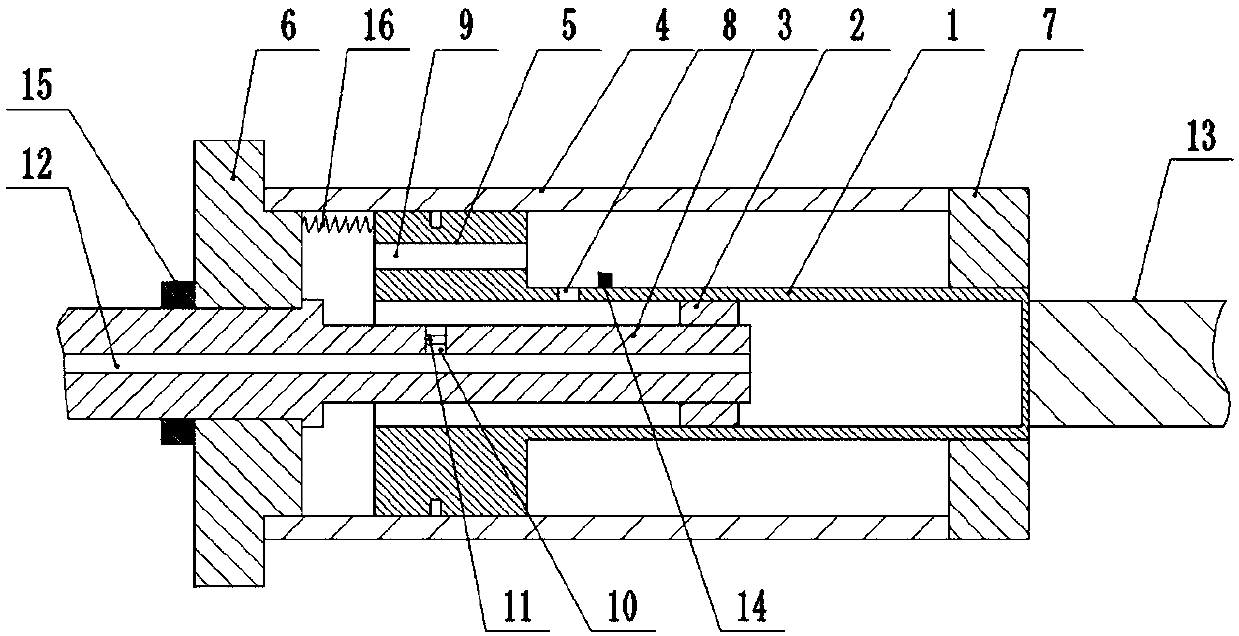

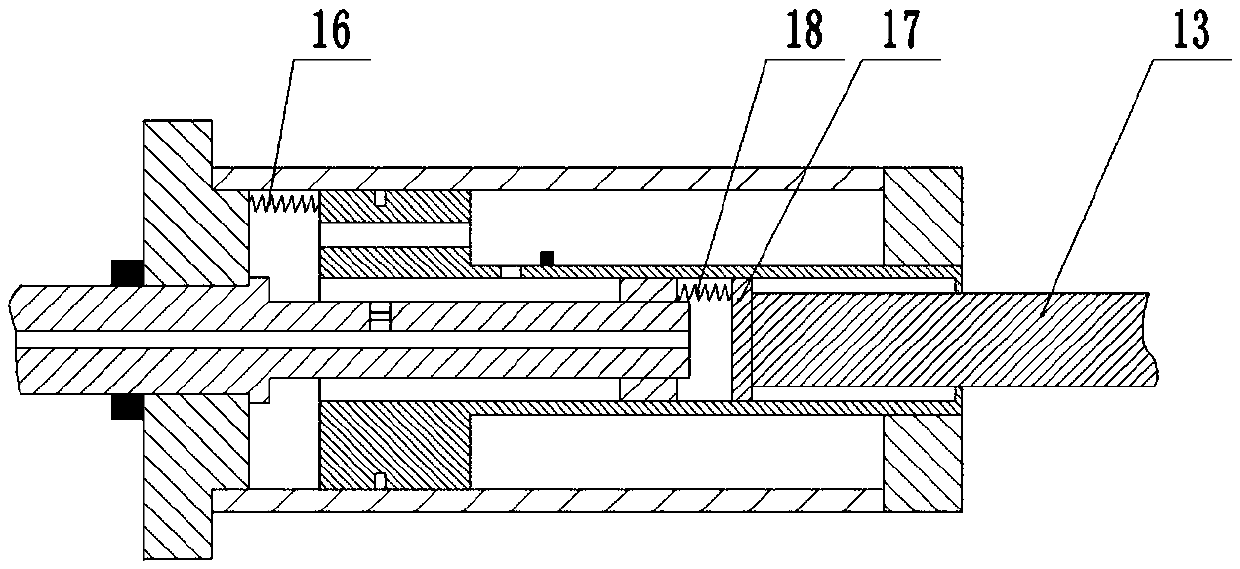

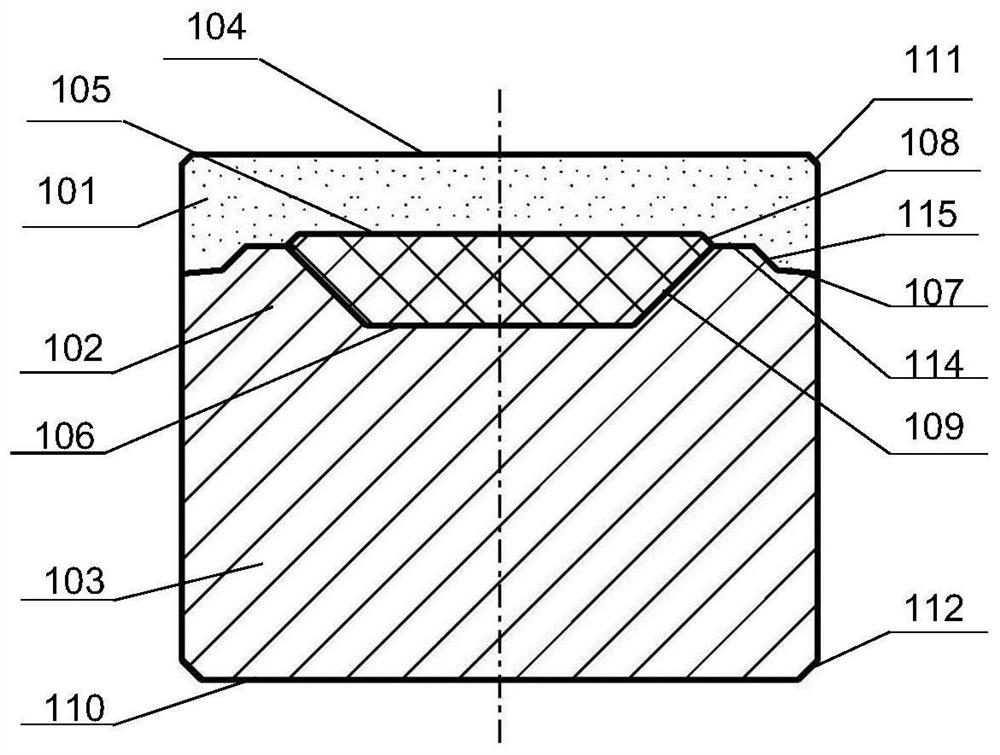

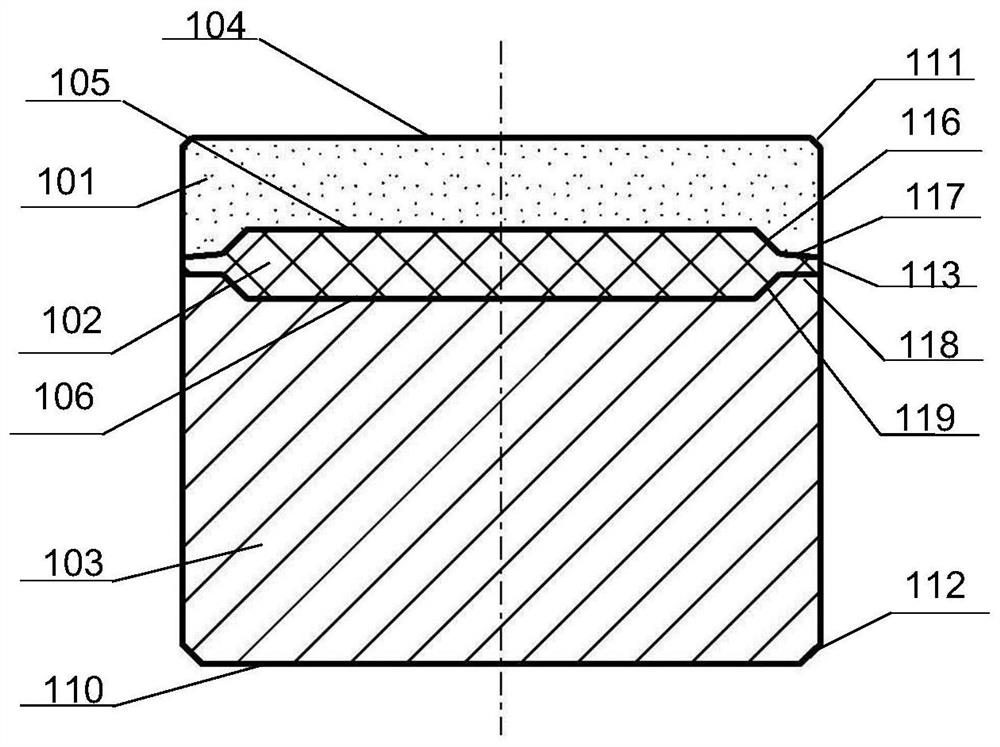

Two-way quick hydraulic cylinder

ActiveCN108050123AStrong pullSlow down scalingFluid-pressure actuatorsHydraulic cylinderPulp and paper industry

The invention belongs to the technical field of hydraulic equipment, and specifically discloses a two-way quick hydraulic cylinder. The two-way quick hydraulic cylinder comprises a cylinder barrel, apiston and a piston rod, wherein a sleeve is arranged at the outer side of the cylinder barrel; one end of the cylinder barrel is connected with a pushing rod; the other end of the cylinder barrel isconnected with a sealing disc; the sealing disc is in sliding and sealing connection with the sleeve; a plurality of oil conducting holes are formed in the sealing disc; one end of the sleeve is connected with a bottom disc; a plurality of first elastic pieces are connected on the bottom disc of the sealing disc; a central hole is formed in the shaft center of the bottom disc; the piston rod is fixedly connected with the bottom disc through the central hole; one end, connected with the pushing rod, of the cylinder barrel is in sliding and sealing connection with a fixed ring; the piston rod isin sliding and sealing connection with the central hole of the bottom disc; an oil outlet hole is formed in the cylinder barrel; and a through oil inlet hole is formed in the piston rod in the axialdirection. The two-way quick hydraulic cylinder is mainly used on hydraulic equipment, and solves the problem that telescopic length is inaccurate as a result of high telescopic speed at the last telescopic stage of the hydraulic cylinder.

Owner:CHONGQING WEIQING HYDRAULIC MACHINERY CO LTD

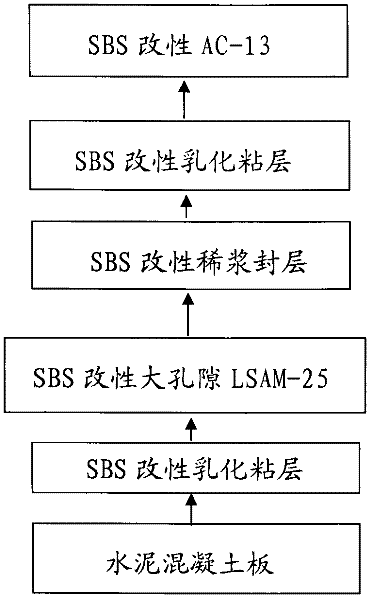

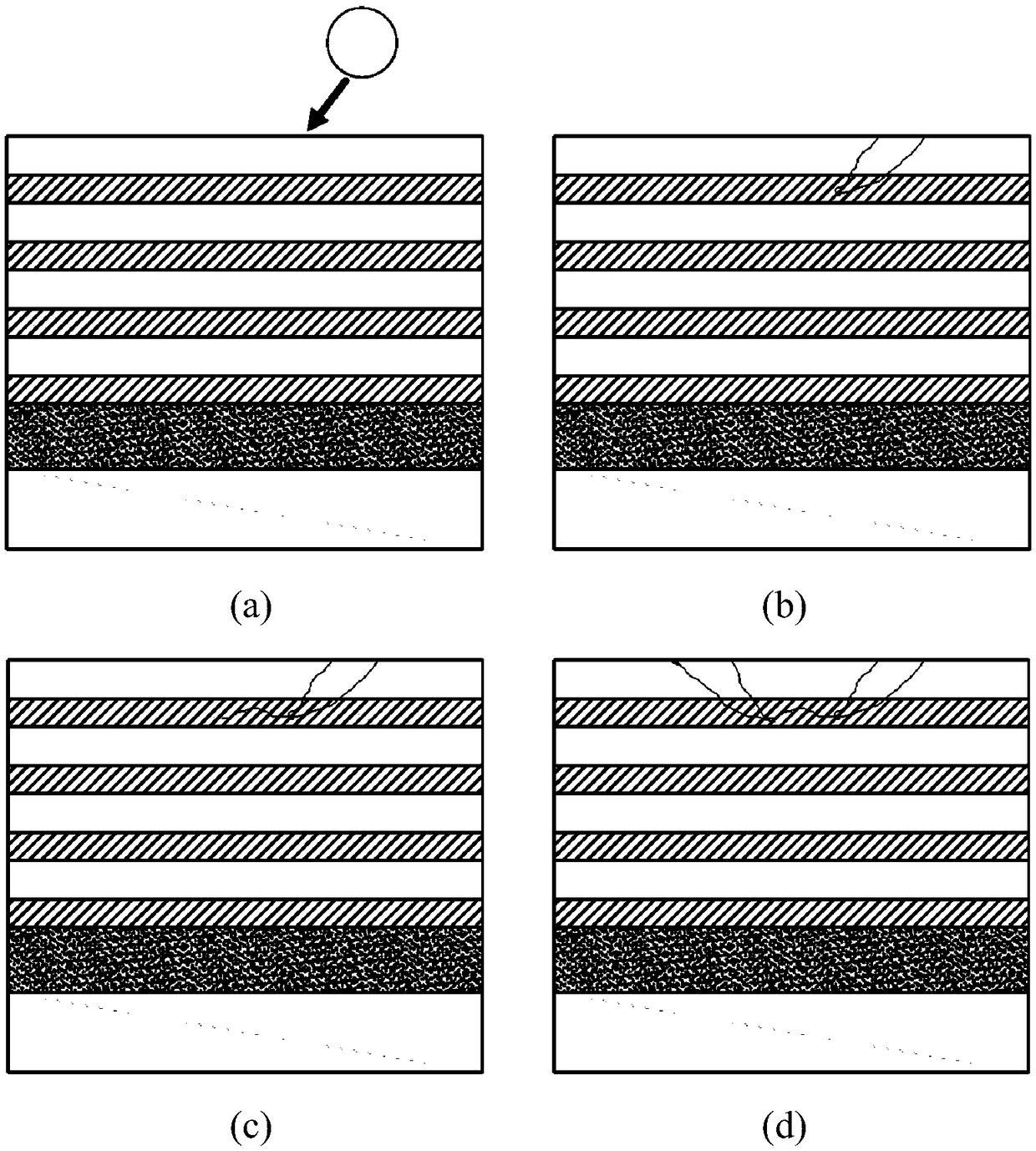

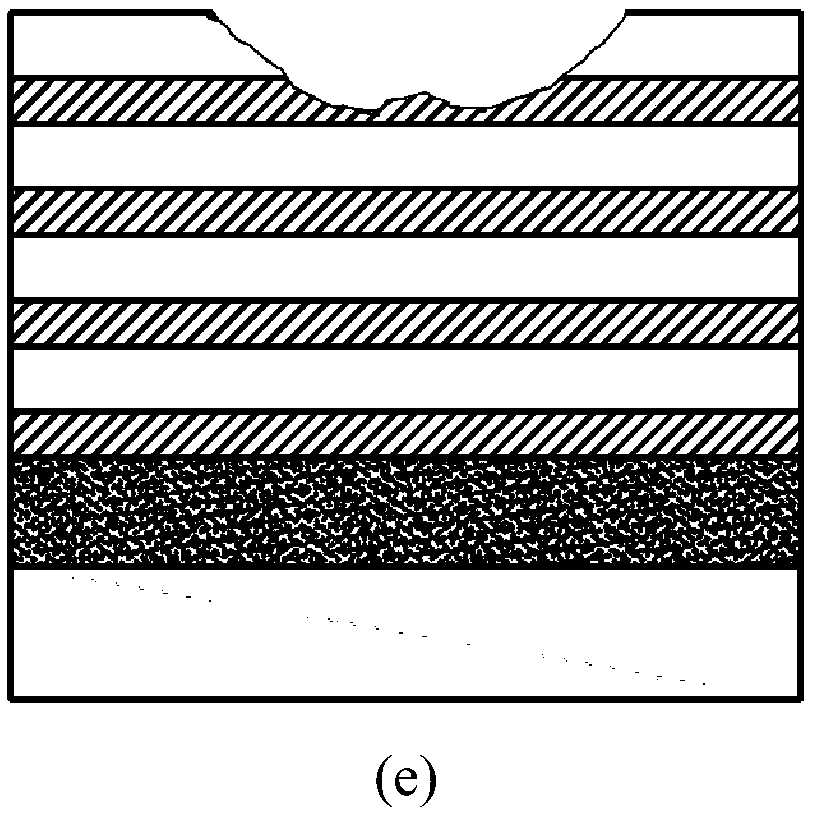

Thin-layer asphalt pavement overlaid with old cement concrete suitable for heavy-duty coal transportation traffic

The invention relates to a thin-layer asphalt pavement overlaid with old cement concrete suitable for heavy-duty coal transportation. The cement concrete slab is provided with a rubber mastic high elastic stress absorption belt and a rubber mastic high elastic stress absorption belt. SBS modified macroporous LSAM-25 with a thickness of 6-8 mm is arranged on the top, and a SBS modified slurry seal layer with a thickness of 1 cm is arranged on the top of the SBS modified macroporous LSAM-25, and the top of the SBS modified slurry seal layer SBS modified AC-13 with a thickness of 4cm is set, and SBS is passed between SBS modified AC-13 and SBS modified slurry seal layer, SBS modified macroporous LSAM-25 and rubber mastic high elastic stress absorption belt The porosity of the modified emulsified adhesive layer connected with SBS modified macroporous LSAM-25 ranges from 18% to 22%. The pavement has excellent bearing capacity and high temperature stability, good anti-reflective cracking effect, long service life of the pavement, and can meet the needs of heavy-duty traffic such as coal transportation.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Wheat scab control method

InactiveCN104488618ASlow down scalingReduce infection ratePlant protectionAgricultural scienceInfection rate

The invention discloses a wheat scab control method. The method includes 1, preparing selenium solution; 2, on a sunny day, spraying the selenium solution with the certain concentration on wheat in flowering period for 1 to 3 times through a spray device, allowing the wheat to serve as a treatment group, and spraying water on wheat serving as a control group; 3, on a sunny day for 3 to 5 days after flowering, namely in the early filling period, spraying the selenium solution on the treatment group through the spray device for 1 to 3 times, and spraying water on the control group; 4, recording the gibberella expanding speed on panicle portions of the treatment group and control group; 5, recording the diseased panicle rates of the treatment group and control group after 21 to 25 days after flowering; 6, recording grain infection rate after harvesting. The gibberella expanding speed on the panicle portions and the grain infection rate can be decreased significantly, and the wheat nutritional value can be increased and human, animal and plant health can be promoted through proper application.

Owner:YANGZHOU UNIV

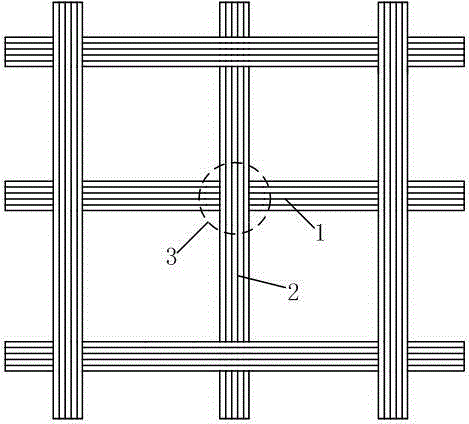

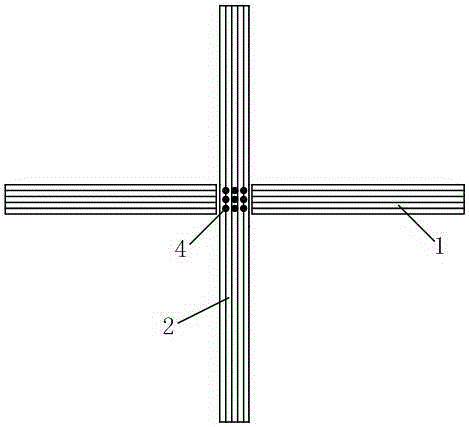

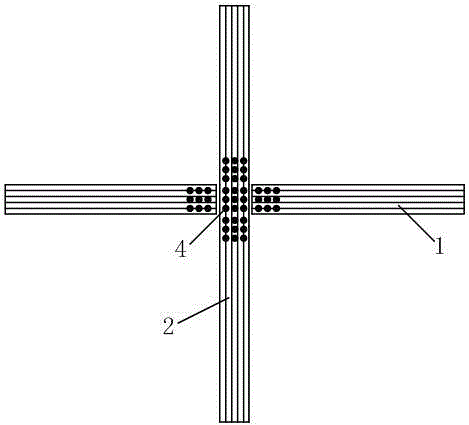

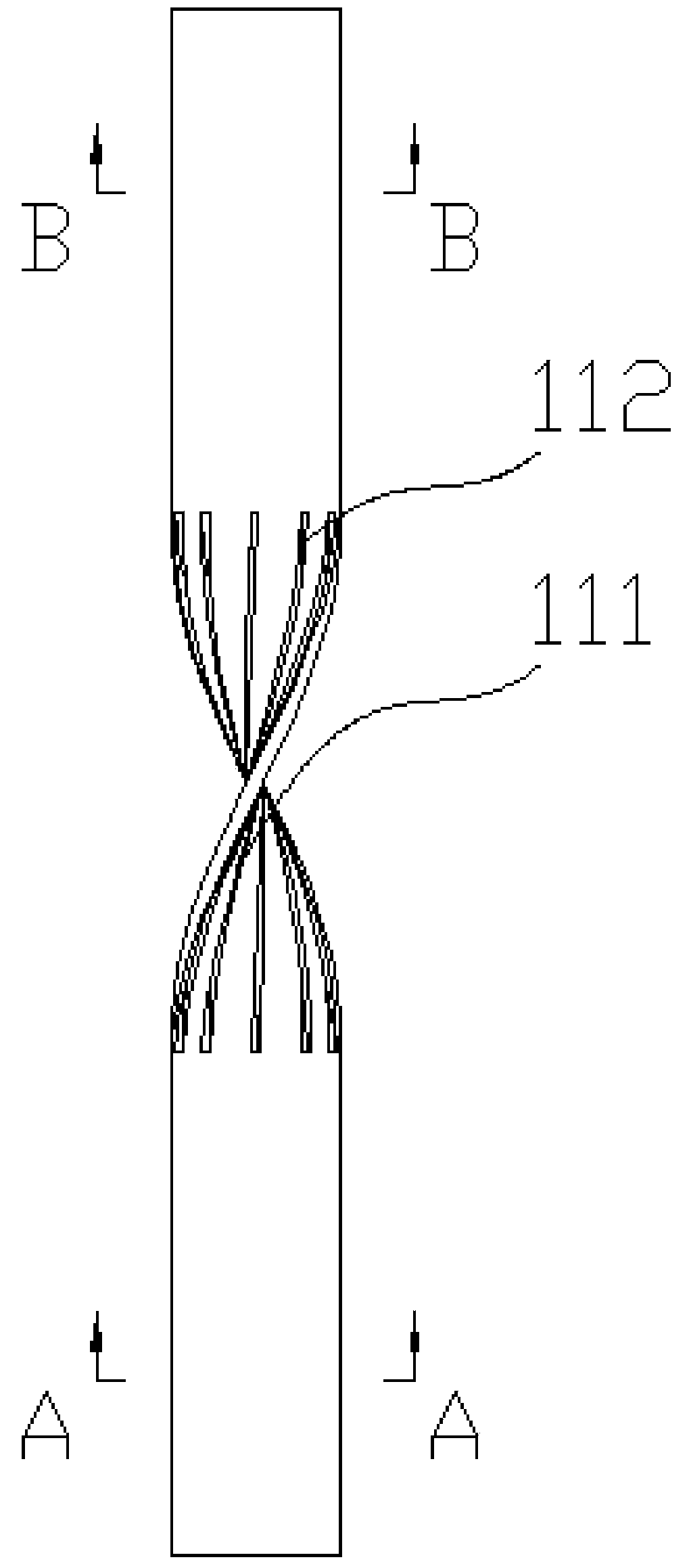

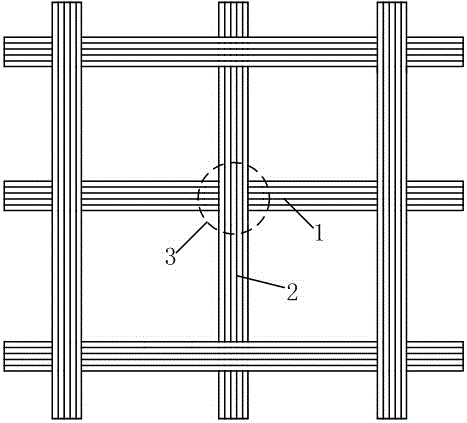

Z-pin reinforced composite grid structure and manufacturing method thereof

The invention relates to a Z-pin reinforced composite grid structure and a manufacturing method thereof, belonging to the technical field of fibrous composite reinforcement. The manufacturing method comprises the following steps: planning movement locus of a fiber placement head by a design procedure through a specially-designed grid fiber placement device, and overlaying a grid structure on a grid forming mould by adopting a shearing-continuing placement process; preparing high-performance Z-pin by an advanced pultrusion device, designing a Z-pin parameter, and implanting the Z-pin in a foam prefab; implanting the Z-pin at the structure node part of a grid by ultrasonic implant equipment; and reinforcing the Z-pin reinforced composite grid stiffened structure. According to the invention, the problems of uniform thickness caused by repeated prepreg layering and layered bridging resulted from crossed fiber layers at the node parts can be solved, connection strength and anti-fatigue performance of the node parts also can be obviously enhanced, and Z-pin is light, high in strength and small in fiber damage.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

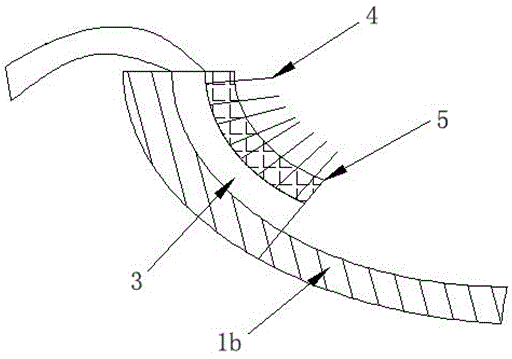

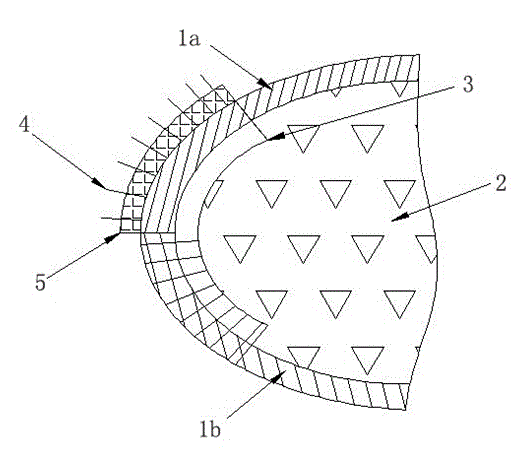

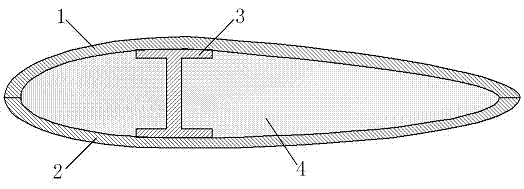

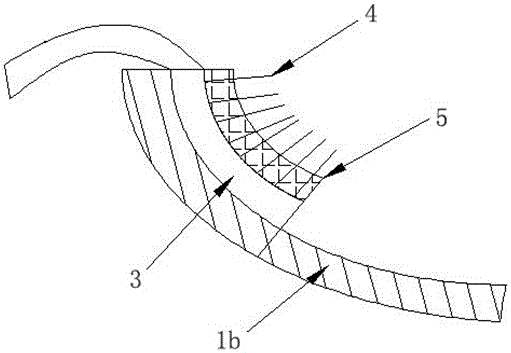

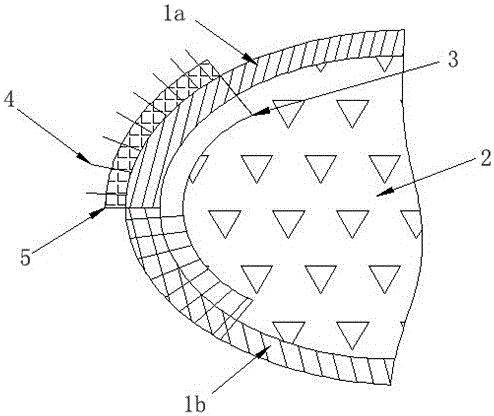

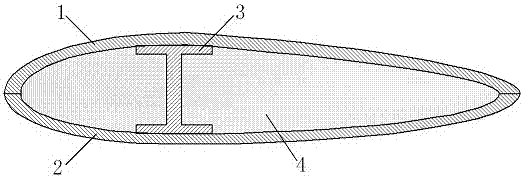

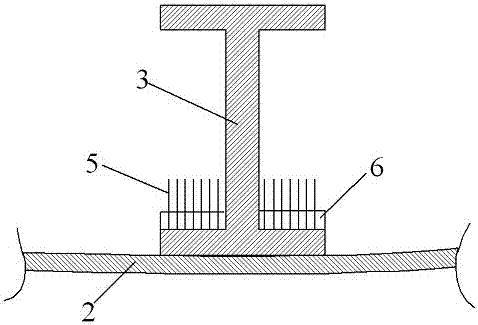

Z-pin reinforced composite material wind power blade structure and manufacturing method thereof

ActiveCN104847595AImprove interlayer toughnessAvoid damageFinal product manufactureWind energy generationFiberElectricity

The invention discloses a Z-pin reinforced composite material wind power blade structure. The Z-pin reinforced composite material wind power blade structure comprises an upper half blade shell, a lower half blade shell and a main beam, wherein the upper half blade shell and the lower half blade shell are matched to form a blade cavity, the upper edge of the main beam and the inner wall of the upper half blade shell are tightly attached to form an upper connecting surface, the lower edge of the main beam and the inner wall of the lower half vane shell are tightly attached to form a lower connecting surface, Z-pins which have pinning and bridging functions and improve the connecting strength between the main beam and the upper half blade shell as well as between the main beam and the lower half blade shell are arranged at the connecting positions of the upper connecting surface and the lower connecting surface, and the part, located on two sides of the main beam, of the blade cavity is filled with foam. The Z-pin reinforced composite material wind power blade structure can obviously improve the layered rigidity of composite material laminated wood. A manufacturing method is simple. The Z-pin reinforced composite material wind power blade structure is high in designability, is easy to form overall and further has the advantages of being good in weight-reducing property, resistant to shearing, high in stripping resistance and small in damage to fibers.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

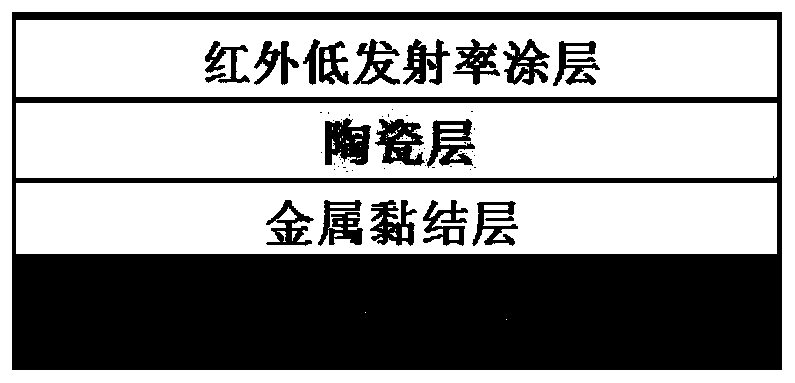

Thickness-adjustable heat insulation/infrared stealth composite coating, titanium alloy material with surface coated with coating and preparation method of titanium alloy material

ActiveCN111118439AWith thermal insulationWith high temperature infrared stealth performanceMolten spray coatingAluminateCeramic coating

The invention relates to the field of high-temperature functional ceramic coating materials, and particularly discloses a thickness-adjustable thermal insulation / infrared stealth composite coating. The composite coating is of a multi-layer stacked structure and sequentially comprises a metal bonding layer, a ceramic layer and an infrared low-emissivity layer from inside to outside, the ceramic layer is a lanthanum phosphate-hexaaluminate composite ceramic layer, and the infrared low-emissivity layer is a low-emissivity coating which is formed by taking Bi2O3-Al2O3-TiO2-Li2O-SiO2 series low-melting-point glass as a binding phase and taking silver as a conductive phase. A titanium alloy material with the surface coated with the coating and a preparation method of the titanium alloy materialare further provided. The heat insulation / infrared stealth composite coating has the characteristics of excellent thermal shock resistance and high-temperature infrared low emissivity; and the thickness of the coating can be regulated and controlled according to different actual application requirements, and the density and the heat insulation performance of the coating surface can be regulated.

Owner:NAT UNIV OF DEFENSE TECH

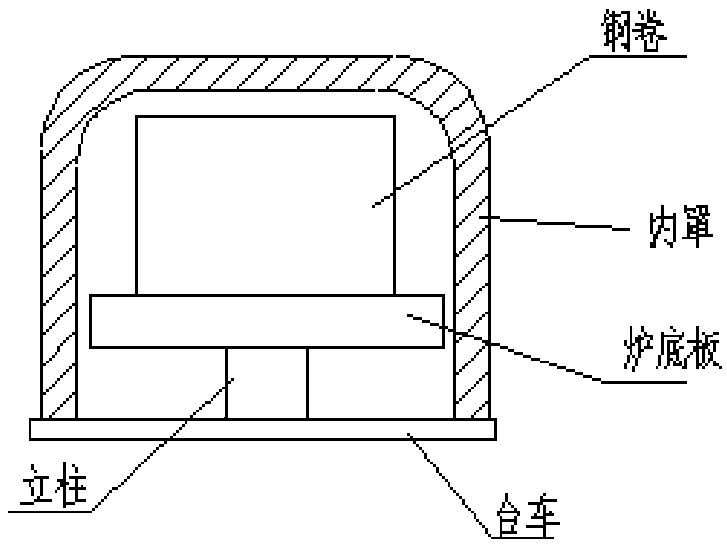

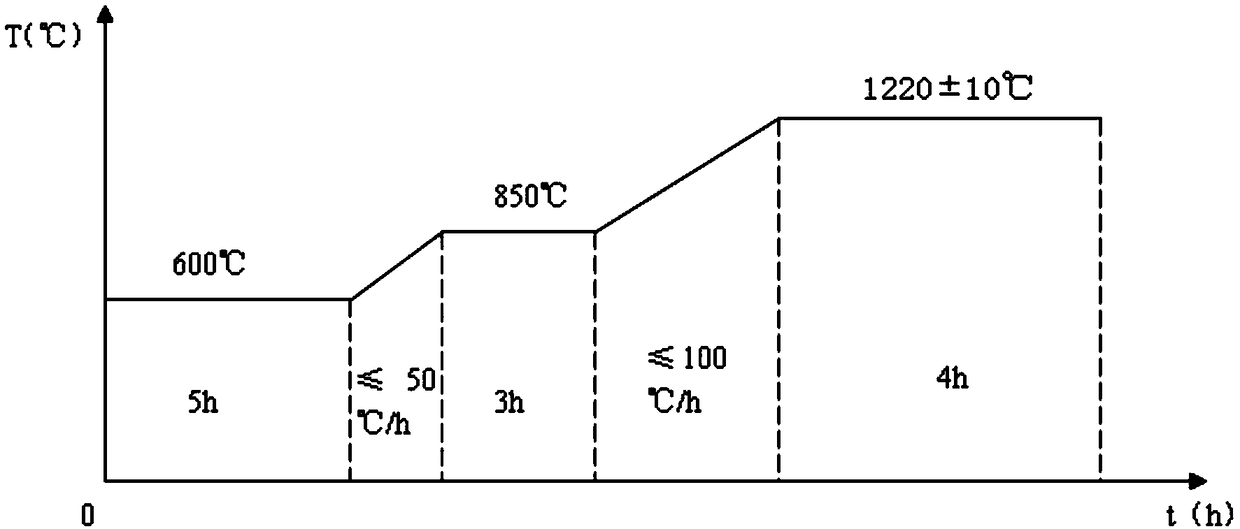

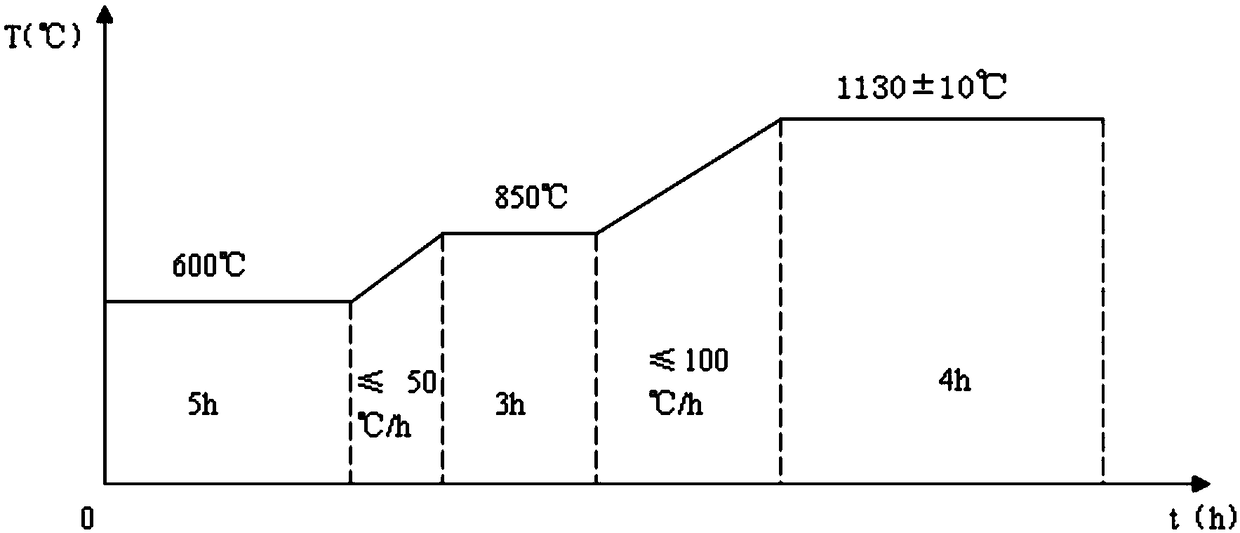

High temperature-resistant high strength stainless steel plate for hearth plate and production method

InactiveCN109022735AImprove organizational stabilityReduce harmful inclusion contentSteel platesUltimate tensile strength

The invention relates to a high temperature-resistant high strength stainless steel plate for a hearth plate and a production method thereof. The strength stainless steel plate for a hearth plate hasthe yield strength being greater than or equal to 30 MPa under the high temperature of 1200 DEG C, and comprises the following components in weight percent: 0.05-0.08% of C; 0.40-0.80% of Si; 1.00-1.60% of Mn; less than or equal to 0.010% of P; less than or equal to 0.010% of S; 0.02-0.09% of N; 10.0-12.0% of Ni; 22.00-24% of Cr; 0.10-0.50% of Mo; 0.02-0.05% of Nb; 0.040-0.090% of V; 0.01-0.04% ofTi; and the balance Fe and inevitable impurities. According to the invention, improvements are made from the component and the production method, the high-temperature strength of the hearth plate isimproved, and the service life of the hearth plate is prolonged.

Owner:武汉钢铁有限公司

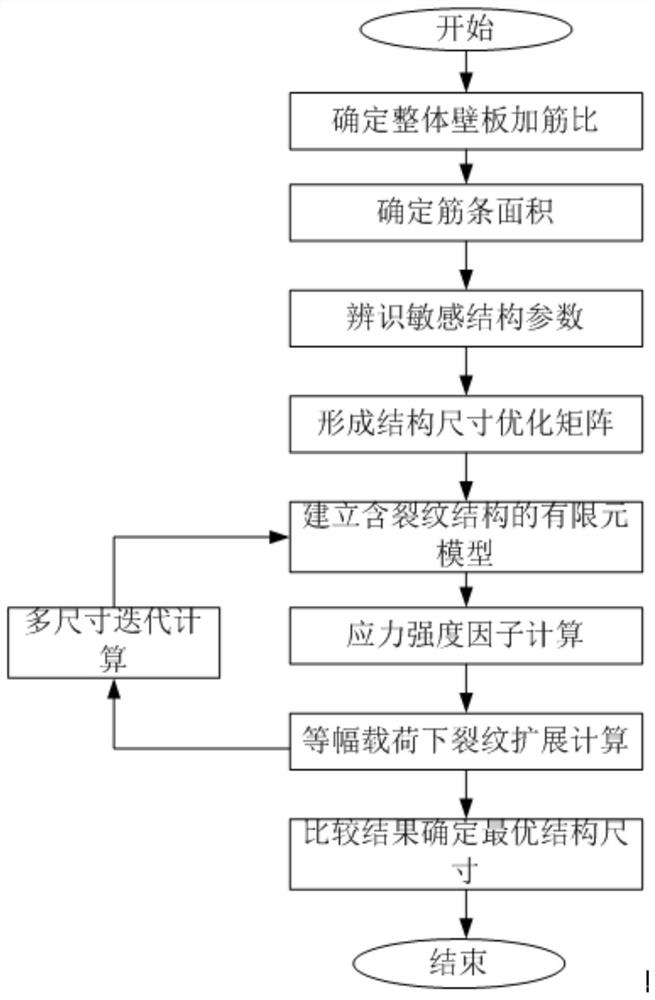

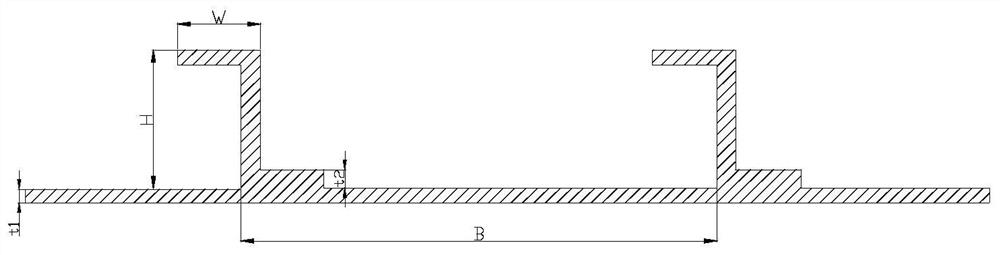

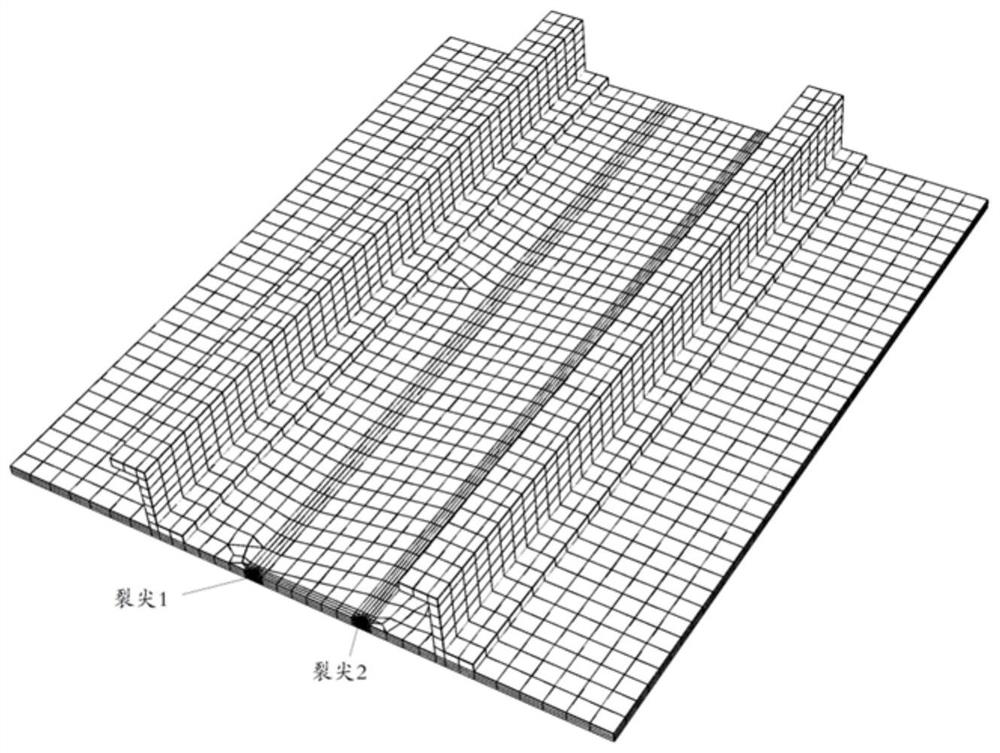

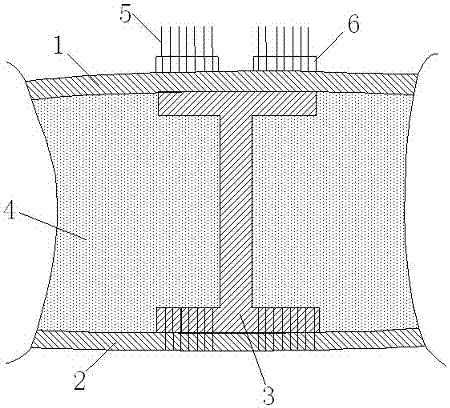

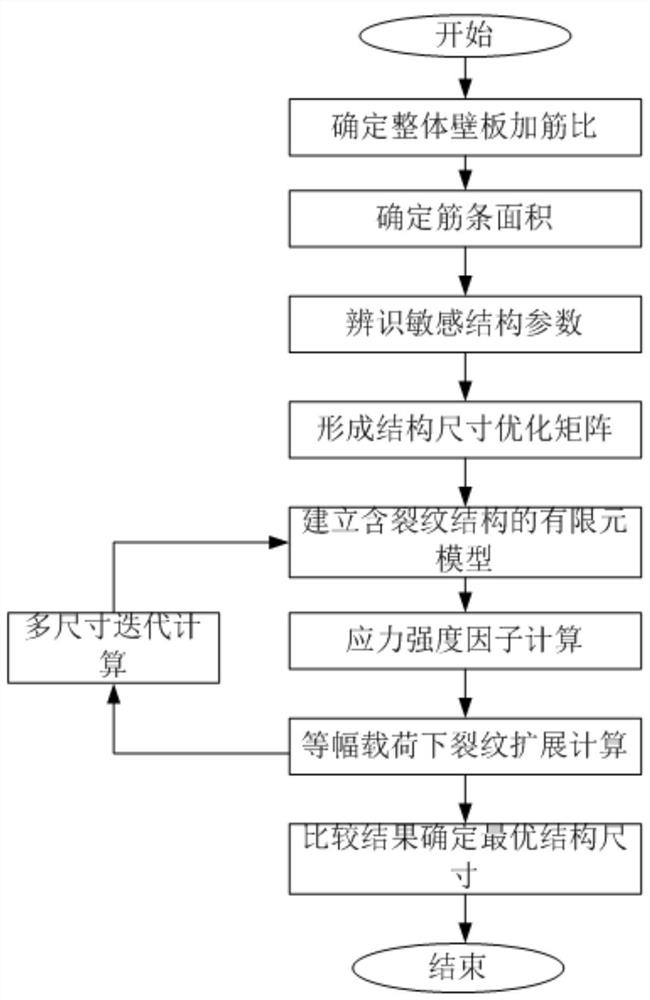

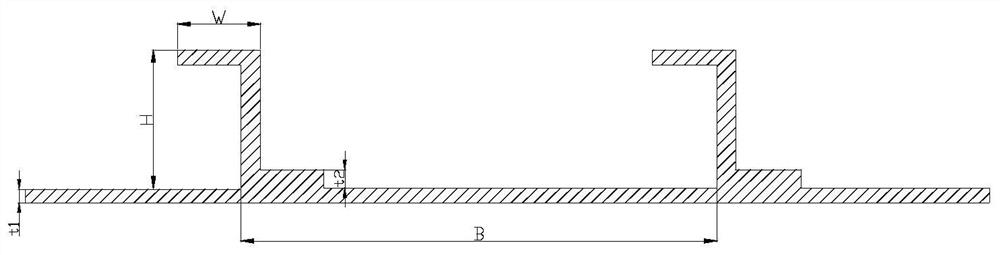

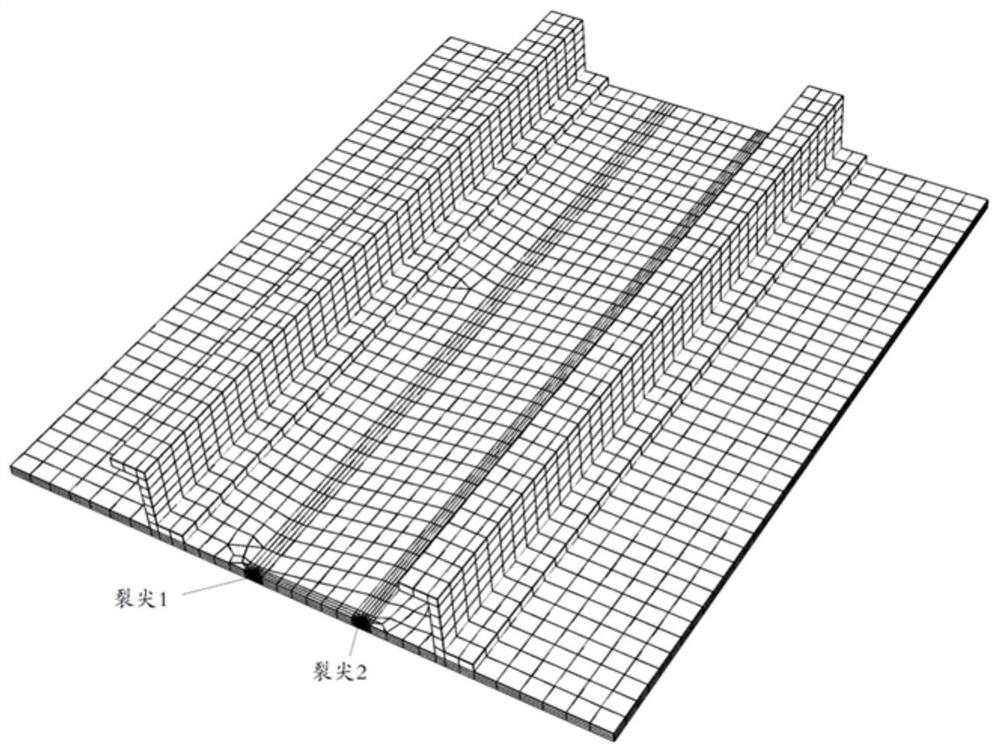

Rib integral wall plate damage tolerance optimization method

InactiveCN112733262AImproved damage tolerance performanceEasy to useGeometric CADDesign optimisation/simulationElement modelAlgorithm

The invention belongs to the field of aircraft structure damage tolerance design, and discloses a rib integral panel damage tolerance optimization method, which comprises the steps of integral panel reinforcement ratio determination, rib sensitive parameter recognition, structure size optimization matrix establishment, crack-containing integral panel finite element model establishment, stress intensity factor k calculation and crack propagation life calculation. And determining optimal structure parameters through comparison of crack propagation lives under different sizes.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

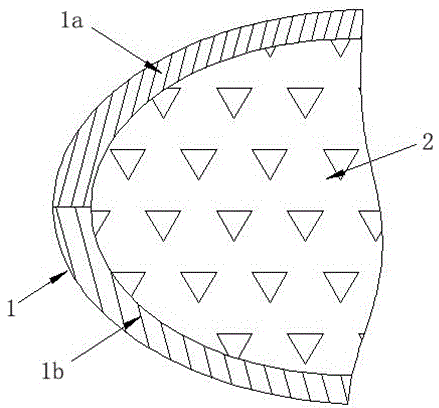

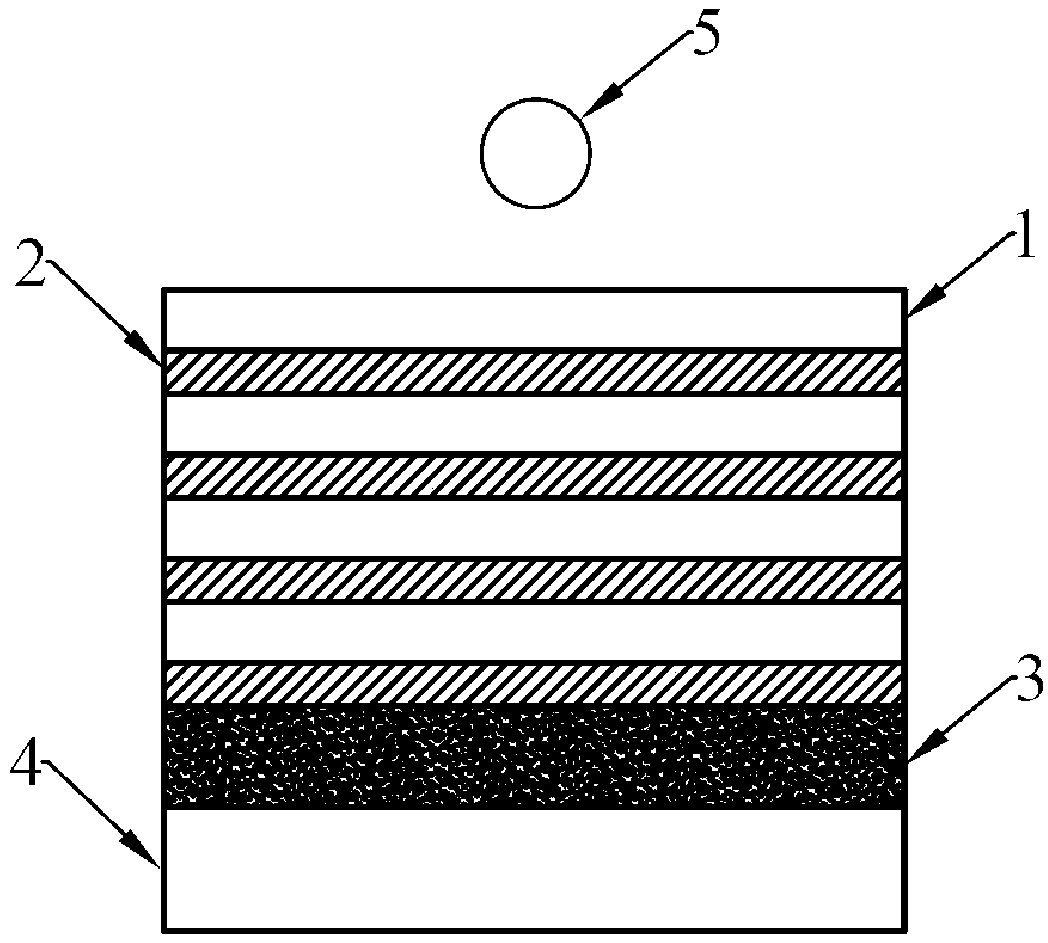

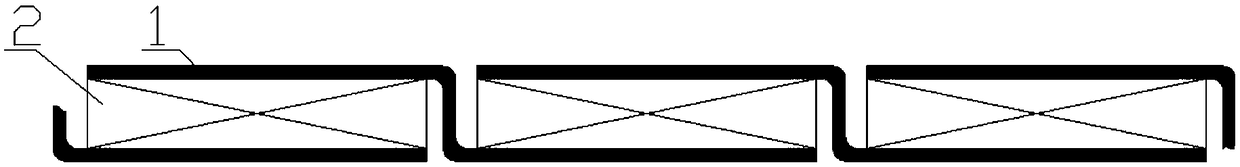

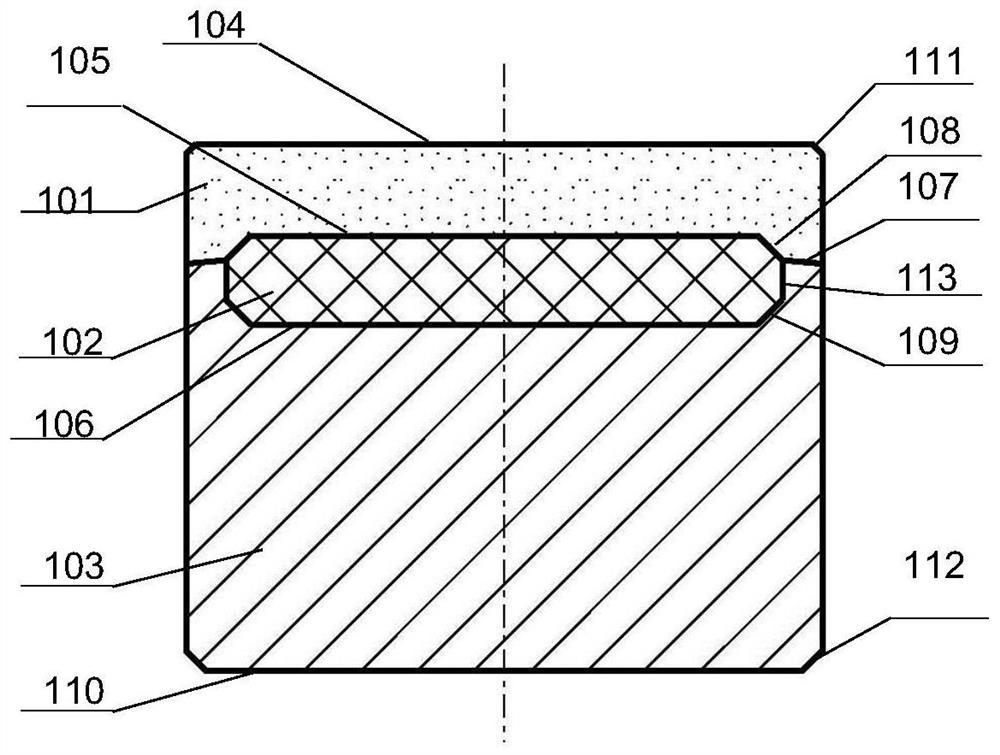

Novel water erosion resistant composite coating structure

InactiveCN108754425AImproves scouring wear behaviorHigh bonding strengthVacuum evaporation coatingSputtering coatingSoft layerGas phase

The invention discloses a novel water erosion resistant composite coating structure. The novel water erosion resistant composite coating structure comprises a transition layer (3) disposed on a substrate (4) and a plurality of composite coating layers, wherein the composite coating layers are disposed on the transition layer (3) by physical vapor deposition. Each of the composite coating layers includes a metal Me soft layer (2) and a metal nitride MeN hard layer (1), wherein the metal Me soft layer (2) and the metal nitride MeN hard layer (1) are disposed in sequence from inside to outside. According to the novel water erosion resistant composite coating structure, due to the fact that a single-layer TiN and ZrN film layer has multiple inherent defects in the anti-erosion performance, thesingle-layer TiN and ZrN film layer is used as a ceramic hard film, the internal stress is generally larger in the preparation process, thicker deposition is difficult to achieve directly, and the single-layer TiN and ZrN film layer is arranged at the edge of a workpiece, so that the film layer is prone to cracking and falling off at a later time. When the thickness of the film layer is thinner,and the protection requirements of relevant components are difficult to meet by the anti-erosion performance of the film layer, so that a more effective measure is to adopt multilayer structure film layers in order to meet the engineering application requirements.

Owner:XI AN JIAOTONG UNIV

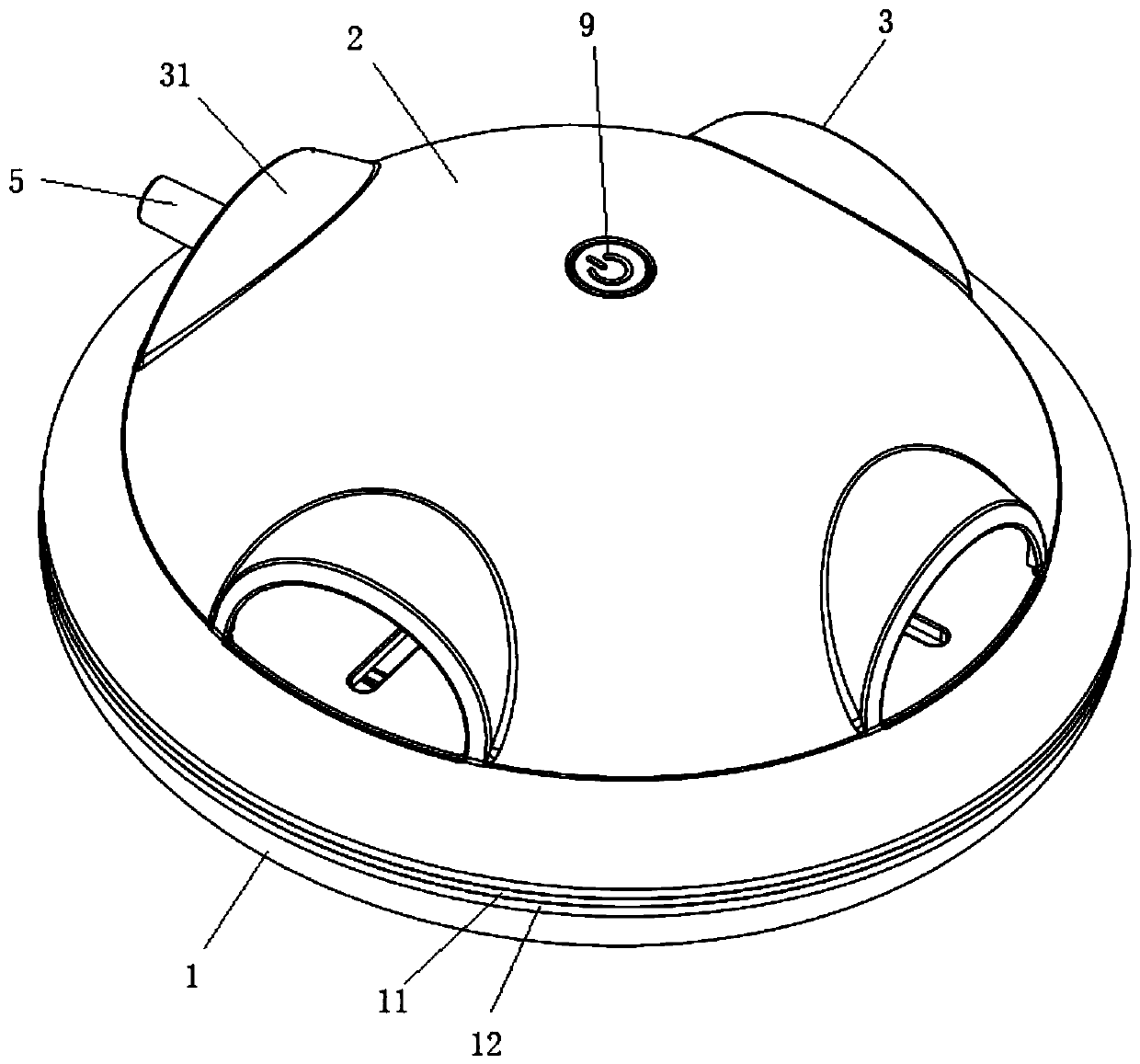

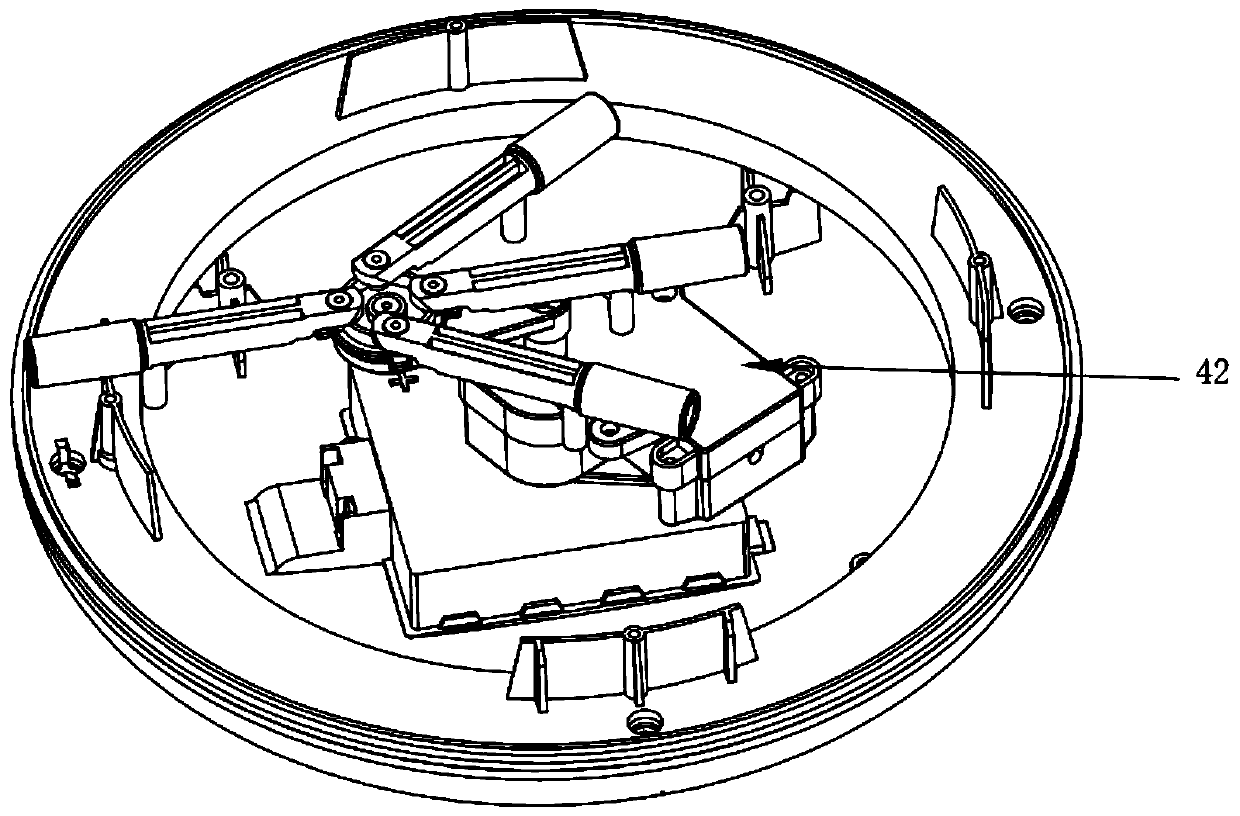

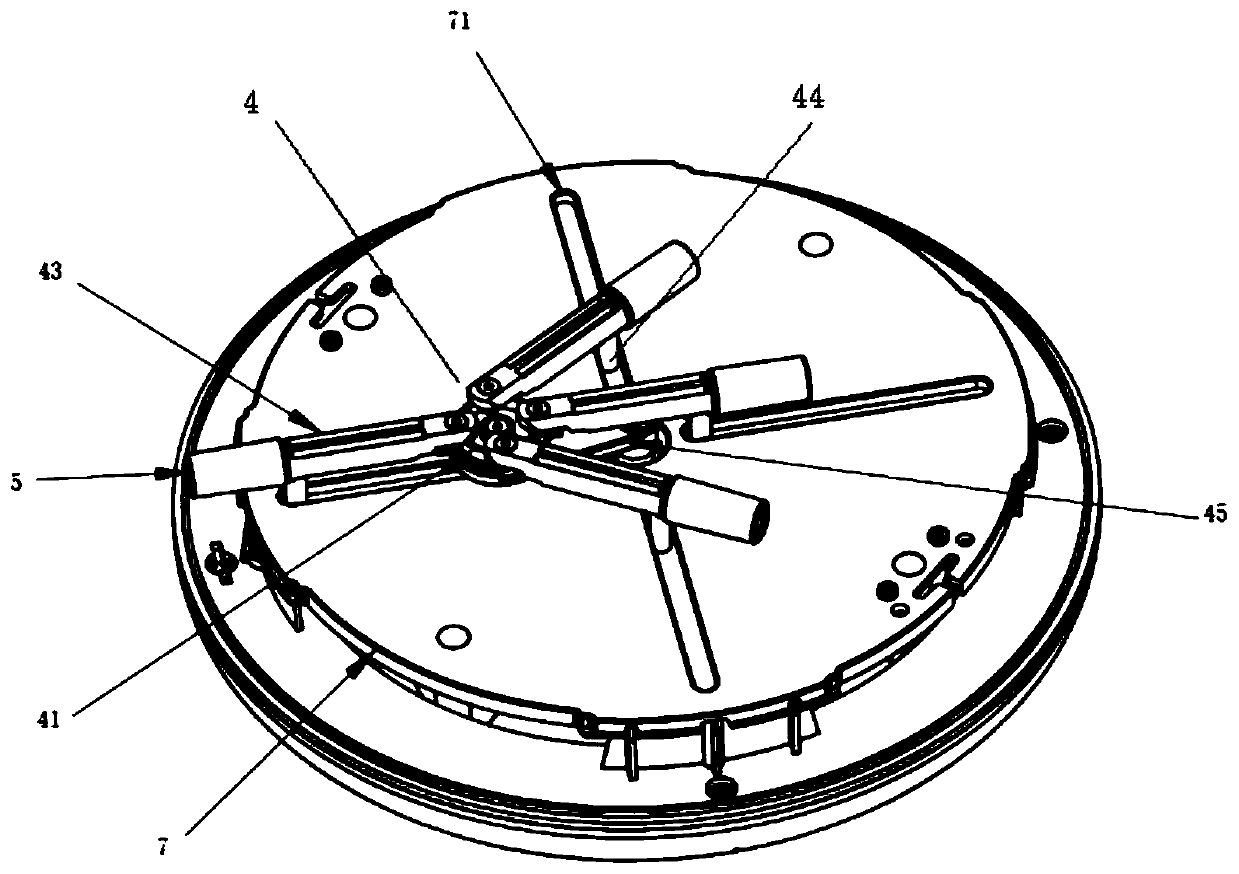

Contracting and hiding type cat amusing robot

PendingCN111011245AAchieve openAvoid contactTaming and training devicesCompanion animalMechanical engineering

The invention discloses a contracting and hiding type cat amusing robot. The technical essential adopted by the invention lies in that the contracting and hiding type cat amusing robot comprises a bottom shell and an upper shell buckled on the bottom shell, wherein two or more groups of outlets located on the same horizontal plane are formed in the periphery of the upper shell, a driving mechanismis fixedly arranged in the bottom shell, two or more groups of cat amusing connecting pieces are connected to the driving mechanism, and the number of the cat amusing connecting pieces is equal to the number of the outlets; the driving mechanism can drive the cat amusing connecting pieces to expand and contract back and forth between the outlets, and the cat amusing connecting pieces can extend out from only one group of the outlets at the same time; each cat amusing connecting piece is detachably connected with a cat amusing flying object exposed to the corresponding outlet; and a PCB and one or more sensing elements which can control starting and stopping of the driving mechanism are arranged in the bottom shell, and the sensing elements are electrically connected with the PCB. The propof the pet toy can perform random contracting and hiding, can realize benign interaction with pets, and has strong interest and favorable entertainment effects.

Owner:JIANGSU ZHONGHENG PET ARTICLES JOINT CO LTD

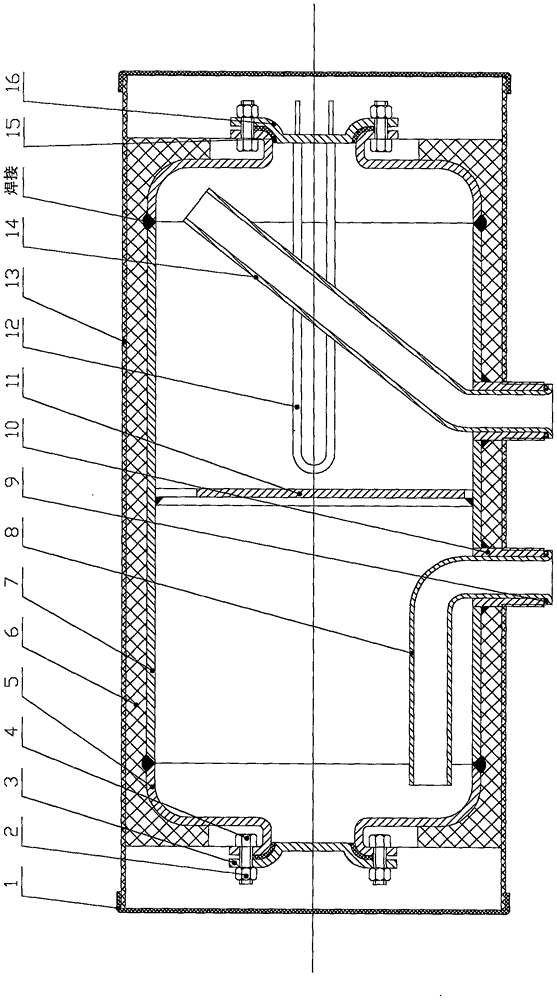

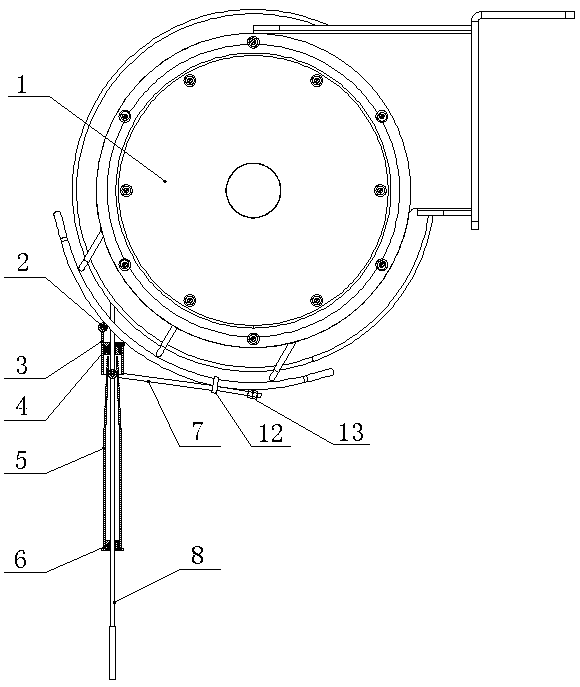

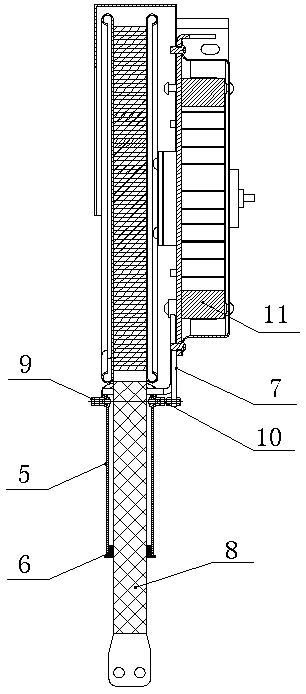

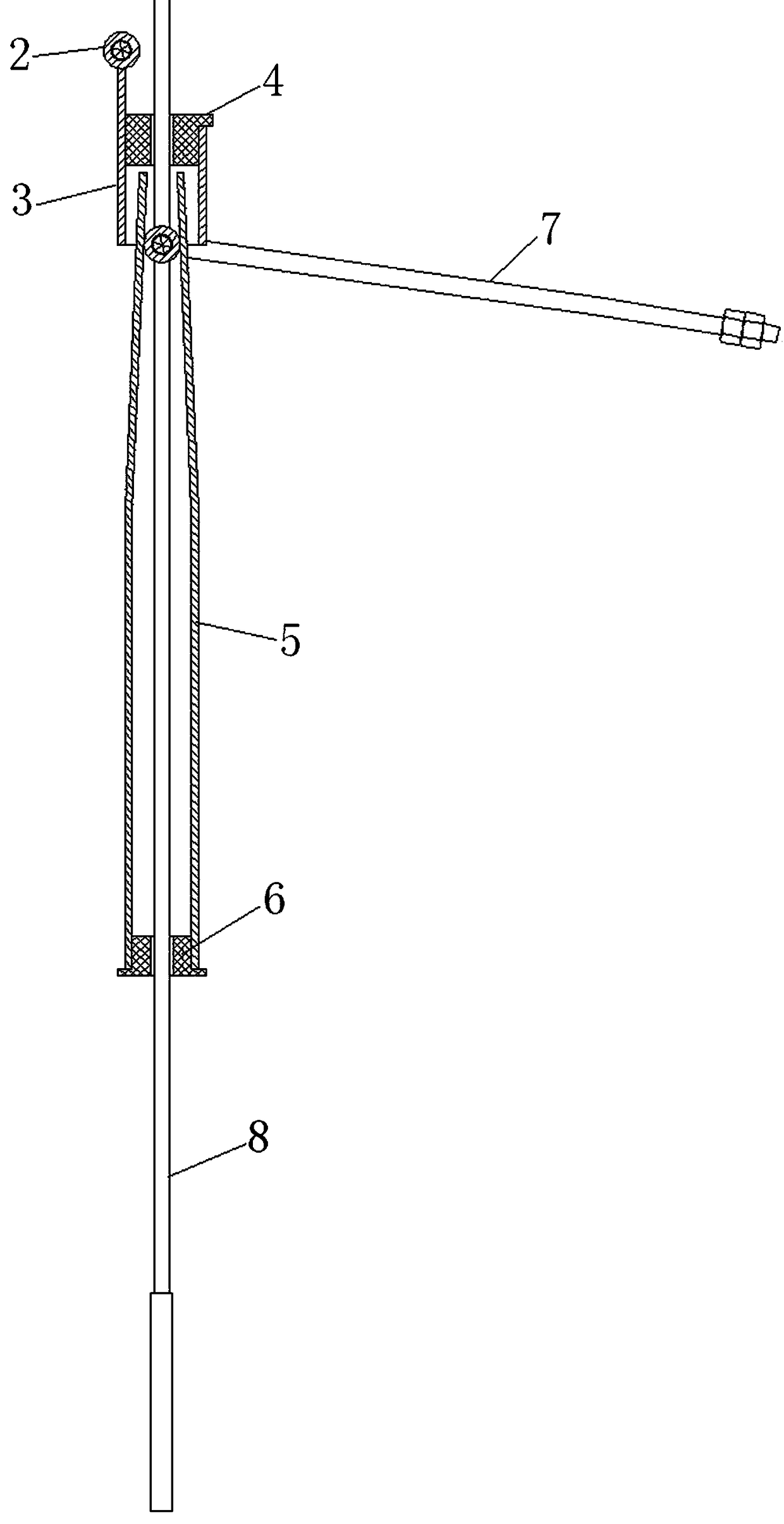

Electric water heater provided with partition board inner container

The invention provides an electric water heater provided with a partition board inner container. According to the electric water heater provided with the partition board inner container, a water inlet pipe (10) and a water outlet pipe (10) are welded to an inner container straight pipe (7) in a sealed mode; one or more partition boards (11) are fixed in the inner container straight pipe (7) to divide the inner container straight pipe (7) into two or more cavities, one ends of the partition boards (11) are provided with small holes, and the other ends of the partition boards (11) are provided with big holes; and two open seal heads (5) are welded to the two ends of the inner container straight pipe (7) in a sealing mode correspondingly, a foaming heat preservation agent is injected in the space between the outer side of the inner container and an outer surface cylinder (13) to form a heat preservation layer (6), an S-shaped thin-walled water inlet hose (8) is inserted in the water inlet pipe, an S-shaped thin-walled water outlet hose (14) is inserted in the water outlet pipe, and two cover heads (1) are fixed to the two ends of the outer surface cylinder (13) correspondingly.

Owner:姚宇

Reversible coloring photovoltaic welding belt and photovoltaic assembly

PendingCN108520907AReduce chanceSlow down scalingPhotovoltaic energy generationSemiconductor devicesMetal coatingSolar battery

The invention relates to a reversible coloring photovoltaic welding belt. The photovoltaic welding belt comprises a welding belt matrix, a metal coating layer and a coloring layer, wherein the weldingbelt matrix is packaged with the metal coating layer in an electroplating manner, the metal coating layer is divided into an upper metal coating layer, a lower metal coating layer and a side wall metal coating layer according to the relative position of the welding belt; only the upper metal coating layer and the side wall metal coating layer are covered with the coloring layer; a reversing partis arranged on the welding belt matrix; the thickness of the welding belt matrix is h1, and the width of the welding belt matrix is w1; and the thickness of the reversing part is h2, and h2 is more than or equal to 1 / 2h1 and less than or equal to 2 / 3h1. The reversible coloring photovoltaic welding belt has the beneficial effects that on one hand, the production cost of the photovoltaic welding belt is lowered; on the other hand, the good welding performance of the photovoltaic welding belt is good, and the welding defects are avoided; and furthermore, compared with the welding belt matrix, thereversing part has a relatively small strength value, so that the situations that a solar battery piece is warped and broken in a long-term use process are avoided.

Owner:PERLIGHT SOLAR +1

Cleaning solution for removing calcium carbonate scale and preparation method and application of cleaning solution

The invention discloses a cleaning solution for removing calcium carbonate scale and a preparation method and application of the cleaning solution, and belongs to the field of chemical descaling. Thecleaning solution comprises, by mass, 3%-8% of phosphorus-free organic acid complexing agent, 10%-25% of phosphorus-free chelating agent, 2%-6% of penetration cosolvent, 0.05%-0.15% of corrosion inhibitor, and the balance water. The corrosion inhibitor is oleic acid imidazoline corrosion inhibitor and / or thiazole corrosion inhibitor. The penetration cosolvent is prepared by the following steps that anionic surfactant, polyols and clean water are added into a reaction still and heated to 30-50 DEG C, stirring is conducted for 20-40 minutes, sodium hexametaphosphate, sodium but and the clean water are added, the temperature is reduced to 15-25 DEG C, stirring is conducted for 30-50 minutes under the constant temperature conditions, and the penetration cosolvent is obtained; and the mass ratio of the anionic surfactant, the polyols to the clean water added for the first time is 1:10-20:20-30, the mass ratio of the sodium but, the sodium hexametaphosphate to the clean water added for the second time is 1:40-50:80-200, and the mass percent of the sodium but accounted for the penetration cosolvent is 0.16-0.3%. The cleaning solution is high in scale dissolving rate, good in scale inhibition effect, safe and environmentally friendly, and good in biodegradability.

Owner:PETROCHINA CO LTD

Method for inhibiting growth of gibberella saubinetii and reducing toxins of wheat scab infected grains and application of method

InactiveCN111345185AReduce the rate of diseased spikeletsSlow down the speed of expansionFertilising methodsCereal cultivationGibberella acuminataBiotechnology

The invention discloses a method for inhibiting the growth of gibberella saubinetii and reducing the toxins of wheat scab infected grains. The method comprises the following steps: inoculating gibberella saubinetii in the flowering stage of wheat, after completion of inoculation, immediately and respectively spraying a selenium preparation solution and clear water to inoculated wheat ears so as toobtain a treatment group and a control group, respectively counting the rate of diseased spikelets in the treatment group and the control group, carrying out harvesting, then measuring the toxin content of wheat grains, and comparing the disease efficacy of the treatment group and the control group so as to evaluate the prevention and treatment effects on wheat scab. The method provided by the invention can effectively inhibit the growth and toxin production of the gibberella saubinetii, reduces the susceptibility rate of the wheat scab and the toxin content of the wheat grains, can improve the nutritional value of the wheat through proper application and can promote the health of human, animals and plants.

Owner:YANGZHOU UNIV

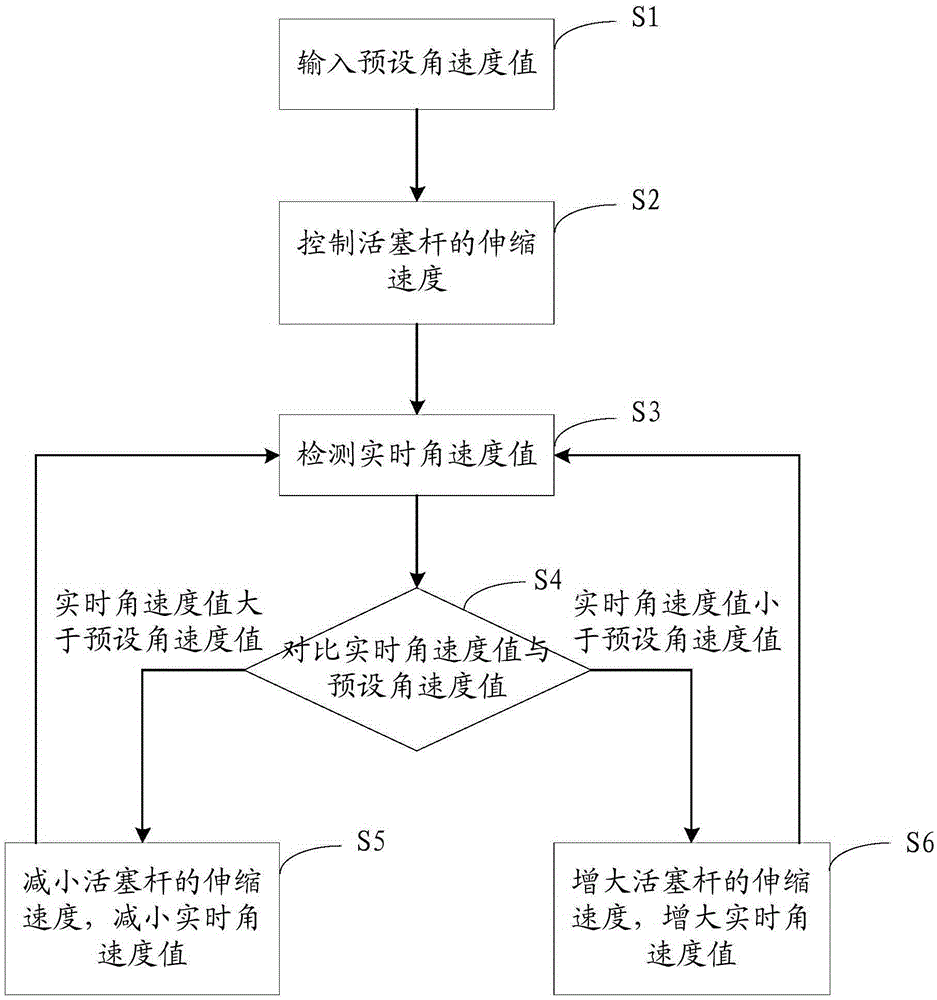

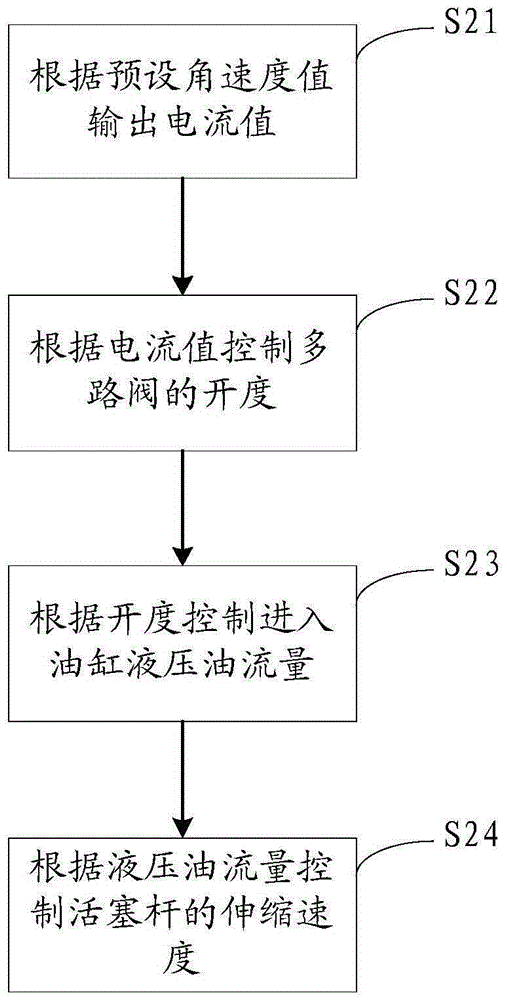

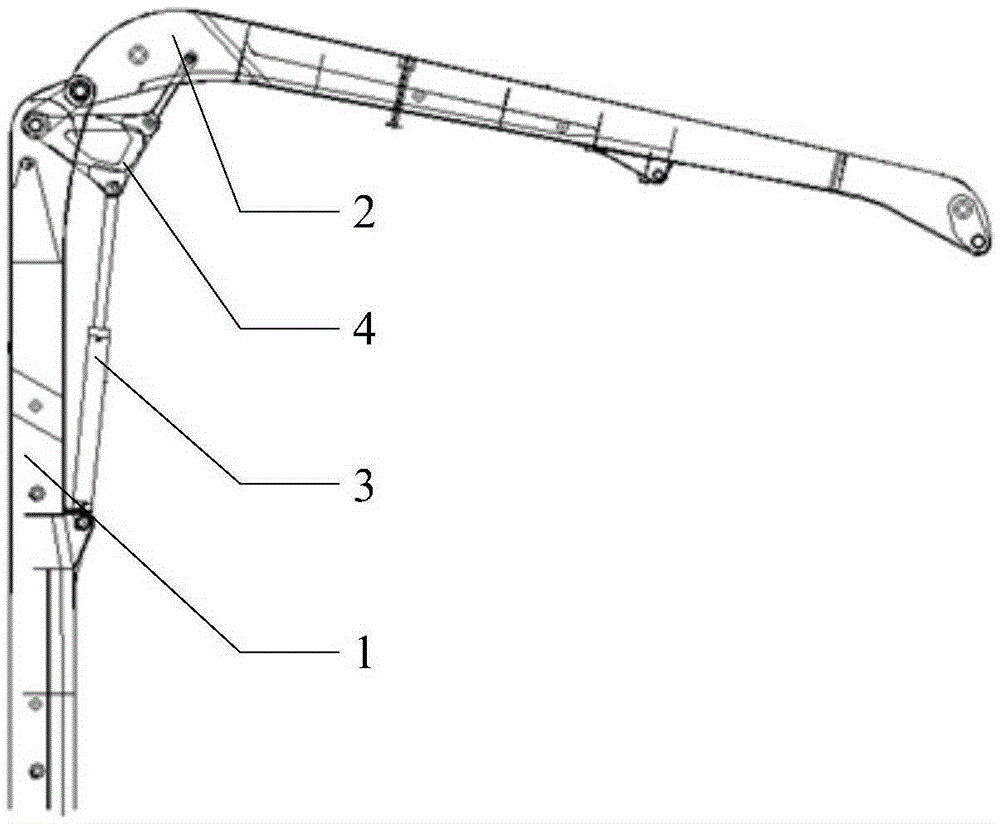

Boom control method and system

ActiveCN105275926ASlow down scalingEasy to operateBuilding material handlingFluid-pressure actuator componentsRotation velocityAngular velocity

The invention discloses a boom control method and system. The boom control method comprises the steps that a preset angular velocity value for stretching or retracting a boom is input and a controller controls the stretching and retracting speed of a piston rod of an oil cylinder according to the preset angular velocity value and further comprises the steps that the real-time angular velocity value for stretching or retracting the boom is detected and compared with the preset angular velocity value; when the real-time angular velocity value is larger than the preset angular velocity value, the controller controls the stretching and retracting speed of the piston rod to be decreased; and when the real-time angular velocity value is smaller than the preset angular velocity value, the controller controls the stretching and retracting speed of the piston rod to be increased. After the preset angular velocity value is input, the real-time angular velocity value can be controlled to be close to the preset angular velocity value so that the boom can rotate at a constant speed, accordingly, the rotating speed of the boom is controlled stably and accurately, high operability is achieved, linear following of given input can be achieved, and rapid correction can be achieved even if under the influence of external factors.

Owner:河北雷萨重型工程机械有限责任公司

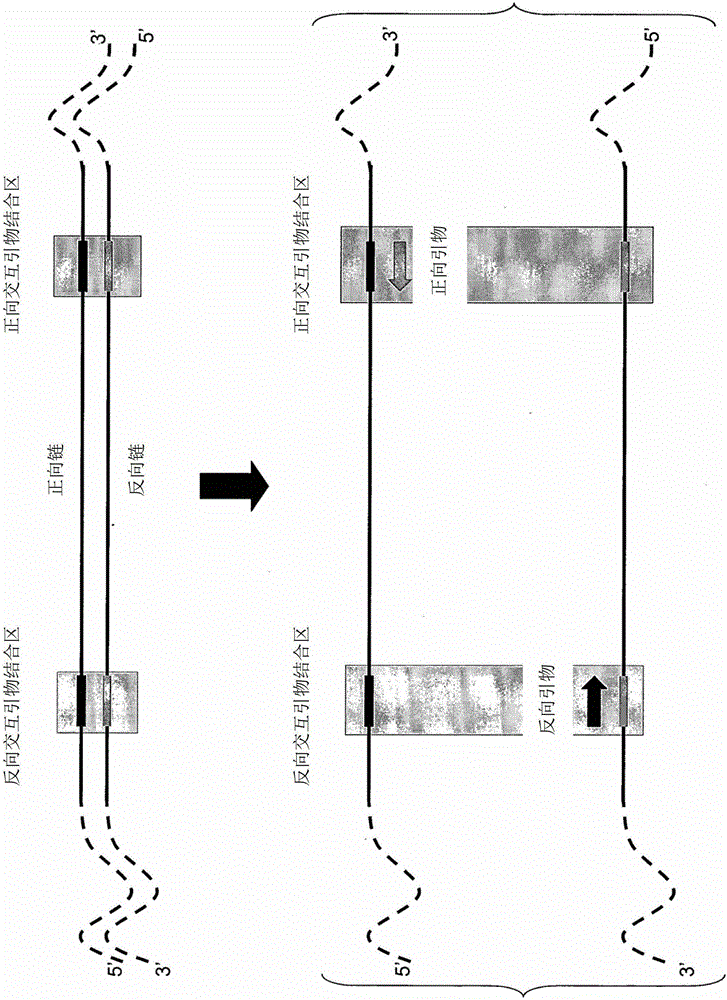

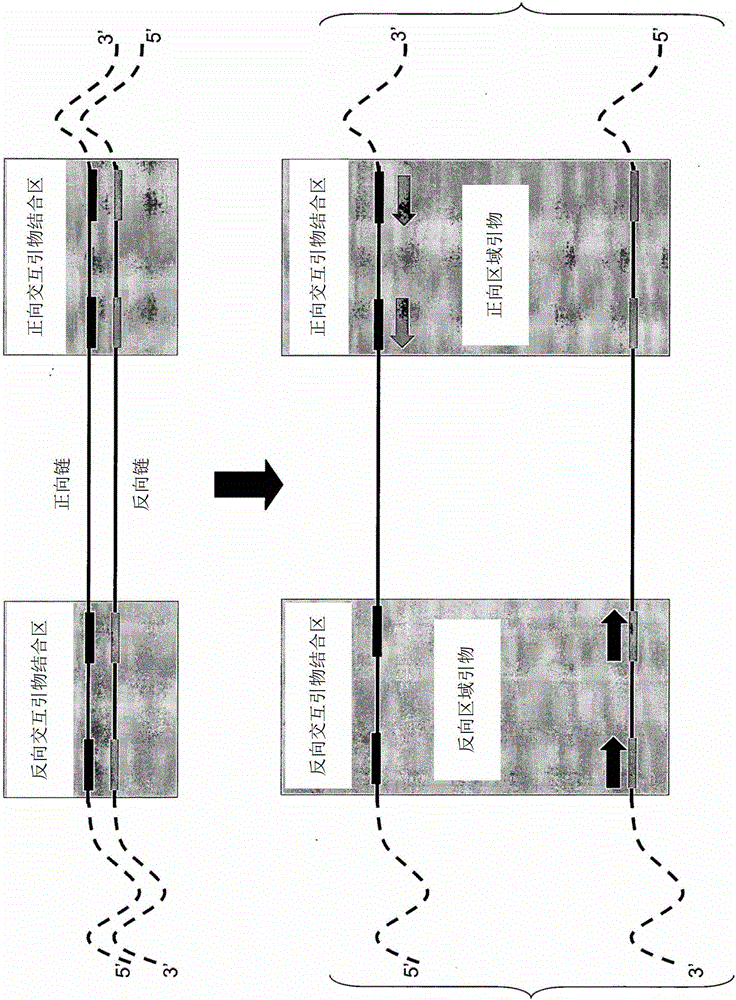

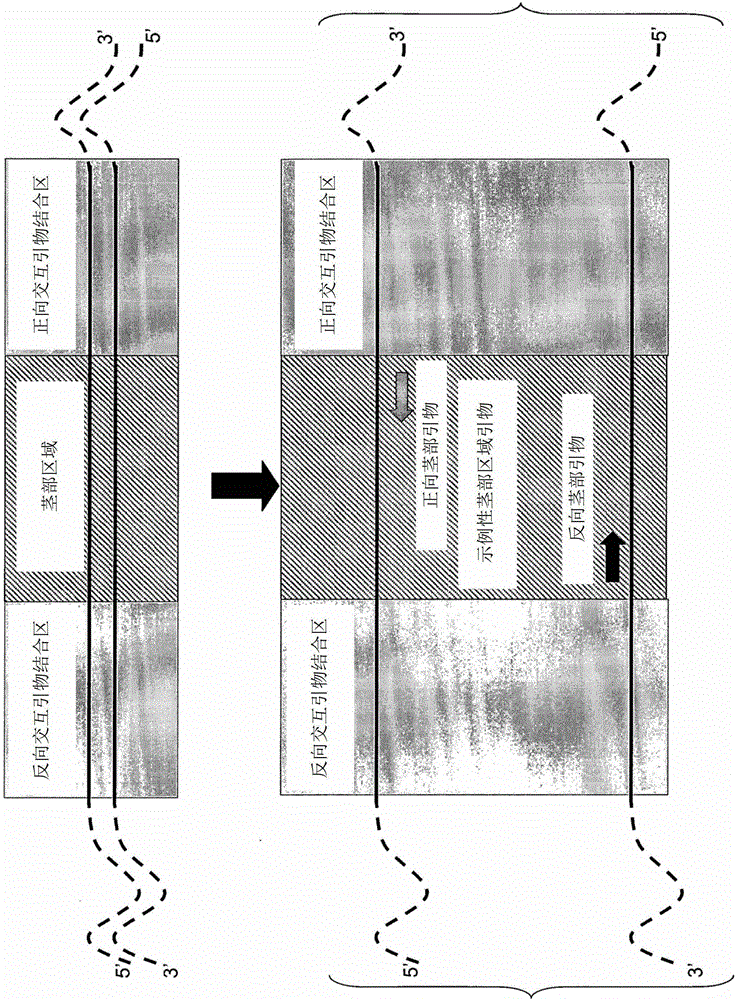

Stem Accelerated Isothermal Nucleic Acid Amplification Technology

ActiveCN102652176BReduce experiment costSlow down scalingMicrobiological testing/measurementSpecific testNucleic acid

The invention relates to the technical field of nucleic acid amplification. In particular, the present invention relates to stem-accelerated isothermal nucleic acid amplification techniques. The present invention relates to a method using a stem primer which improves rapid and specific amplification of a test sample.

Owner:LUMORA LTD

A kind of z-pin reinforced composite grid structure and its manufacturing method

The invention relates to a Z-pin reinforced composite grid structure and a manufacturing method thereof, belonging to the technical field of fibrous composite reinforcement. The manufacturing method comprises the following steps: planning movement locus of a fiber placement head by a design procedure through a specially-designed grid fiber placement device, and overlaying a grid structure on a grid forming mould by adopting a shearing-continuing placement process; preparing high-performance Z-pin by an advanced pultrusion device, designing a Z-pin parameter, and implanting the Z-pin in a foam prefab; implanting the Z-pin at the structure node part of a grid by ultrasonic implant equipment; and reinforcing the Z-pin reinforced composite grid stiffened structure. According to the invention, the problems of uniform thickness caused by repeated prepreg layering and layered bridging resulted from crossed fiber layers at the node parts can be solved, connection strength and anti-fatigue performance of the node parts also can be obviously enhanced, and Z-pin is light, high in strength and small in fiber damage.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

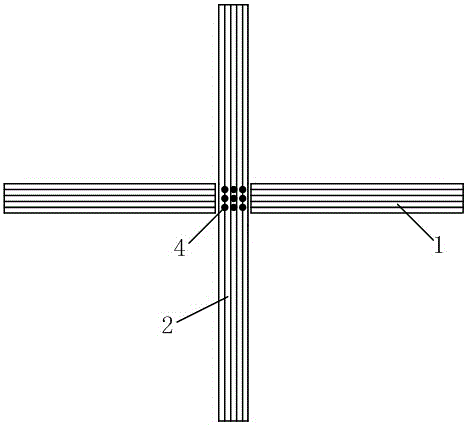

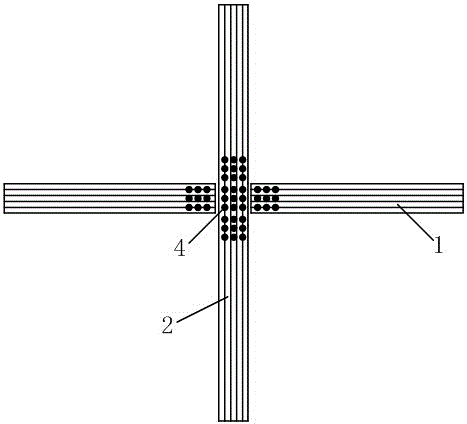

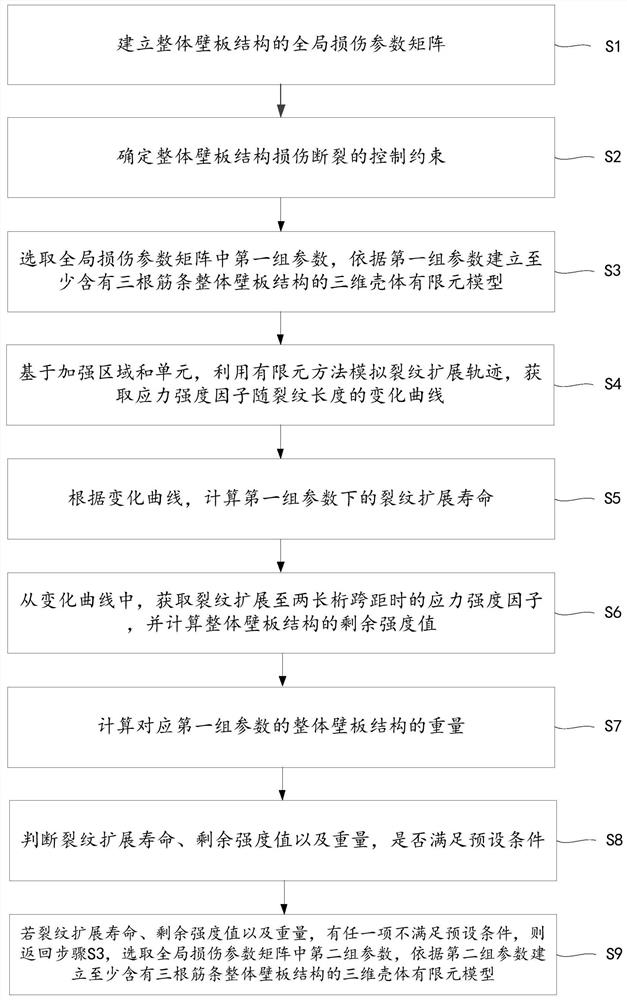

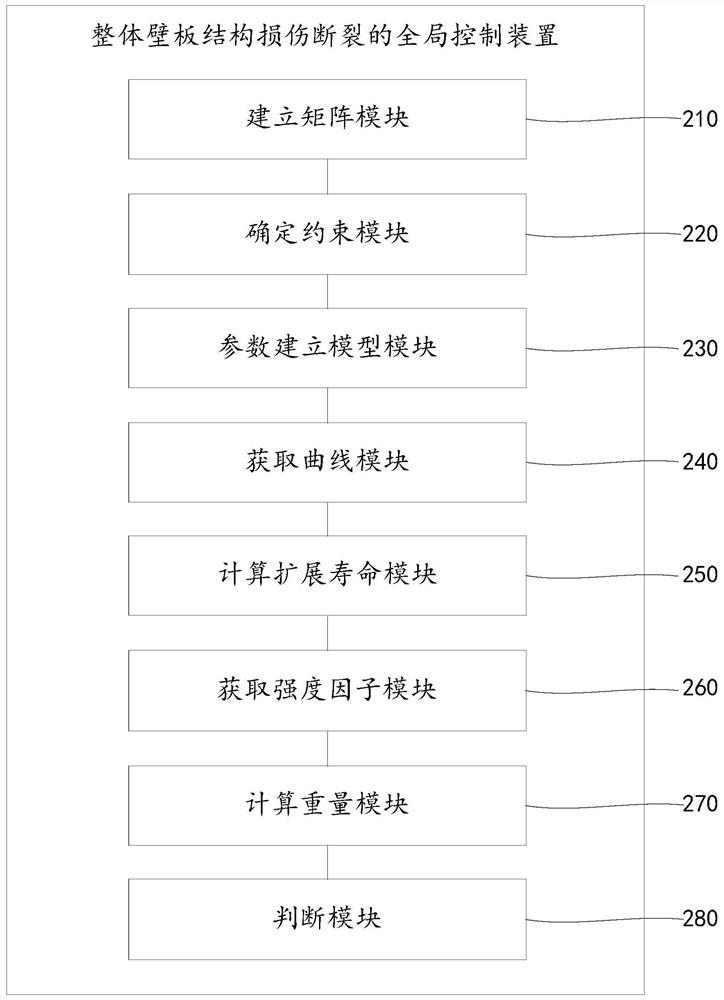

Global control method and device for damage and fracture of integral wallboard structure

ActiveCN113343529AImproved damage tolerance performanceEasy to useSustainable transportationDesign optimisation/simulationFlight vehicleResidual strength

The invention discloses a global control method and device for damage fracture of an integral panel structure, and relates to the field of aircraft structure damage tolerance design, and the method comprises the steps: building a global damage parameter matrix of the integral panel structure; determining a control constraint; selecting a first group of parameters, and establishing a three-dimensional shell finite element model containing at least three rib integral wallboard structures according to the first group of parameters; simulating a crack propagation track by using a finite element method based on the reinforced area and unit, and obtaining a change curve of the stress intensity factor along with the crack length; according to the change curve, calculating the crack propagation life, the residual strength value and the weight under the first group of parameters; judging whether the crack propagation life, the residual strength value and the weight meet preset conditions or not; and if any one does not meet the preset condition, returning to the step of selecting a second group of parameters. According to the method and device, the crack propagation speed is delayed to the maximum extent, the damage tolerance performance of the whole wallboard is improved, and rapid iteration of optimization design is guaranteed.

Owner:TSINGHUA UNIV +2

Two-way fast hydraulic cylinder

ActiveCN108050123BStrong pullSlow down scalingFluid-pressure actuatorsHydraulic cylinderHydraulic equipment

Owner:CHONGQING WEIQING HYDRAULIC MACHINERY CO LTD

High impact toughness polycrystalline diamond carbide composite sheet and manufacturing method thereof

ActiveCN110919004BImprove sintering performanceImprove toughness and strengthDrill bitsUltra-high pressure processesThermal dilatationBond interface

The invention discloses a polycrystalline diamond hard alloy composite sheet with high impact resistance and toughness, which comprises a cemented carbide substrate and a diamond composite layer. The thermal expansion coefficient and elastic modulus coefficient of the block are between the thermal expansion coefficient and elastic modulus coefficient of the diamond material constituting the diamond composite layer and the cemented carbide material constituting the cemented carbide matrix; It is composed of two or more mixtures of metals of transition elements and their carbides, nitrides, carbonitrides and diamond powder. The polycrystalline diamond cemented carbide composite sheet with high impact resistance and toughness proposed by the present invention reduces the influence of the high temperature and high pressure sintering process on the overall performance of the cemented carbide substrate, and at the same time reduces the internal residual stress of the composite sheet and improves the overall impact resistance of the composite sheet toughness.

Owner:WUHAN NINESTONES SUPERABRASIVES CO LTD

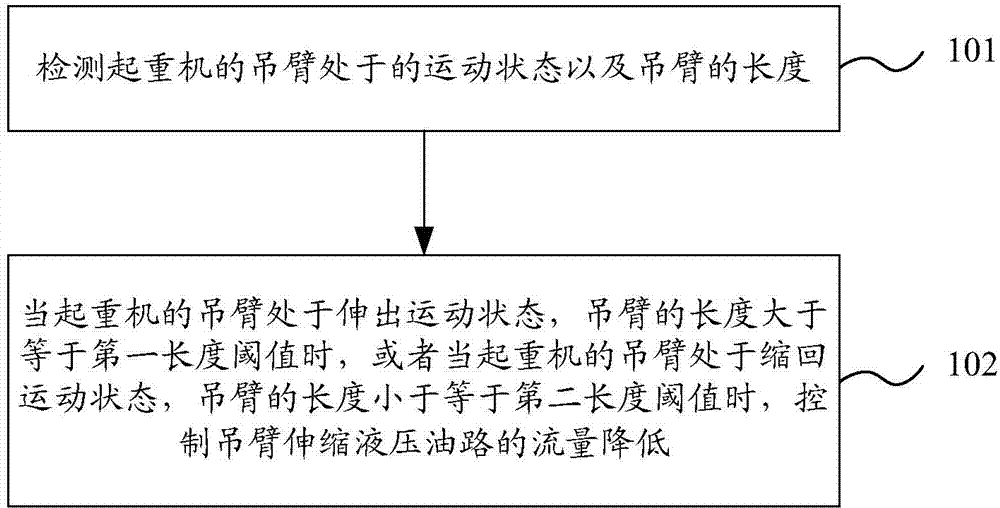

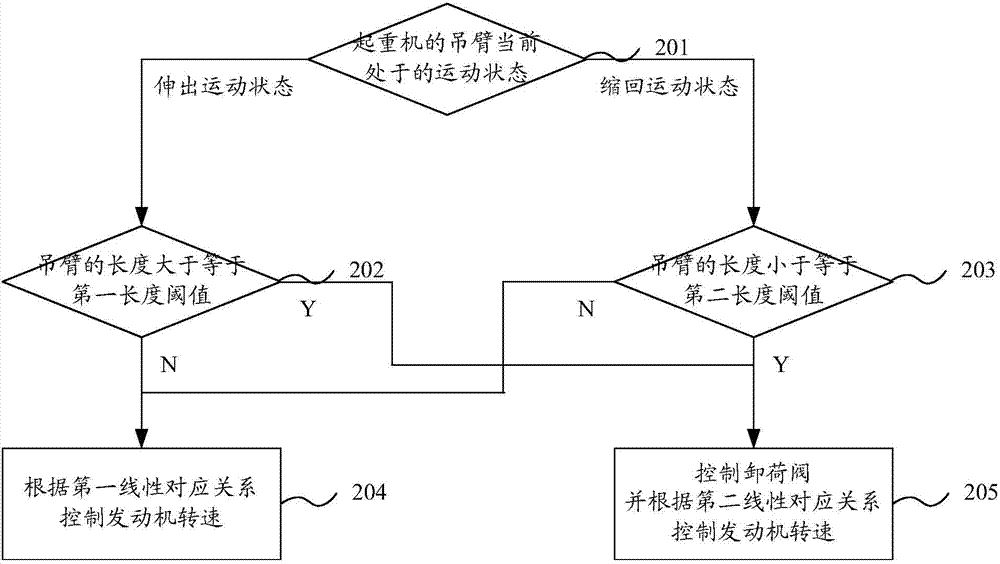

Method, device and system for controlling suspension arm of crane, as well as crane

ActiveCN103663209BIncrease job securitySlow down scalingLoad-engaging elementsCranesHydraulic circuitEngineering

The invention discloses a method, a device and a system for controlling a suspension arm of a crane, as well as the crane, which can improve the operation safety of the crane. The method for controlling the suspension arm comprises the following steps: detecting the motion state of the suspension arm of the crane and the length of the suspension arm; controlling to reduce the flow of a telescopic hydraulic circuit when the suspension arm of the crane is in an extending motion state, and the length of the suspension arm is more than or equal to the threshold of a first length, or when the suspension arm of the crane is in a retracting motion state, and the length of the suspension arm is less than or equal to the threshold of a second length.

Owner:ZOOMLION HEAVY IND CO LTD

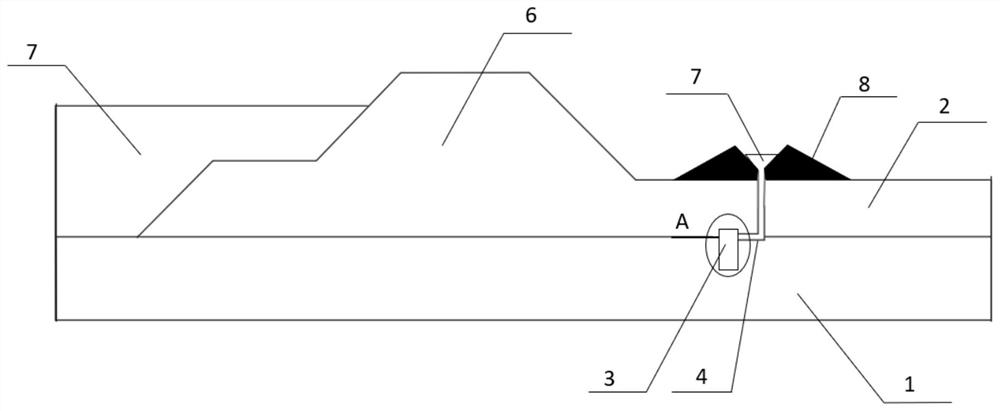

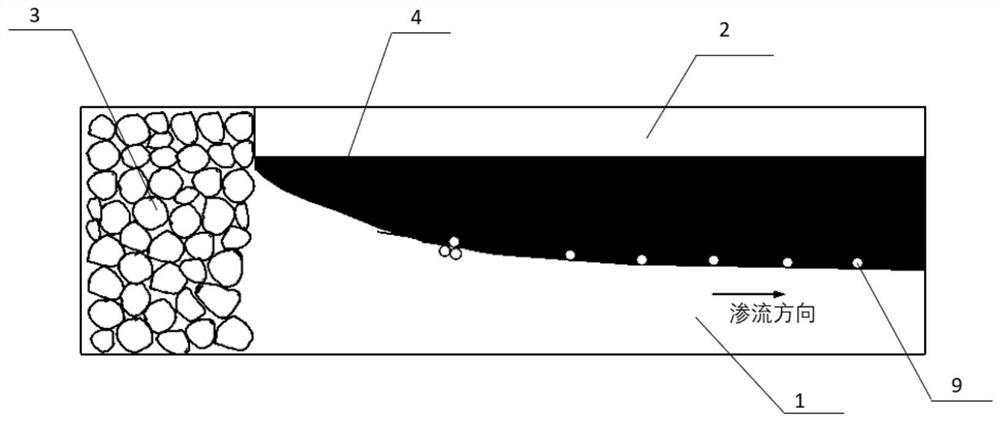

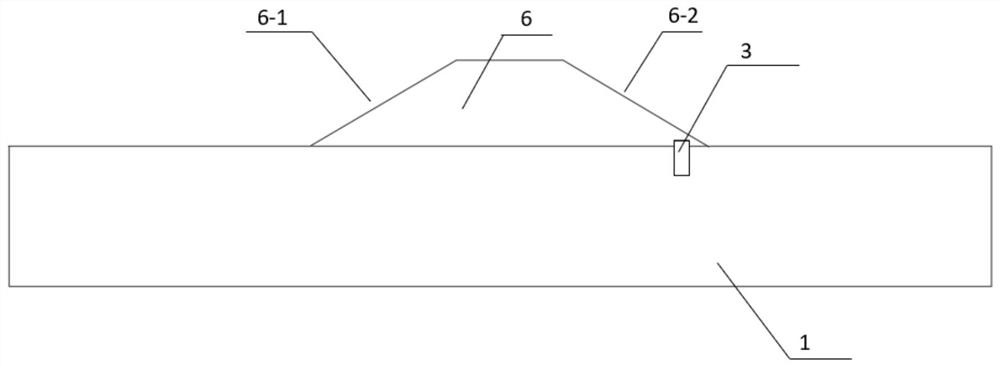

Design and construction method of a risk-relief reinforcement measure for suppressing embankment foundation piping

ActiveCN112962516BSlow down scalingPrevent leakageClimate change adaptationMarine site engineeringSoil massArchitectural engineering

Owner:HOHAI UNIV

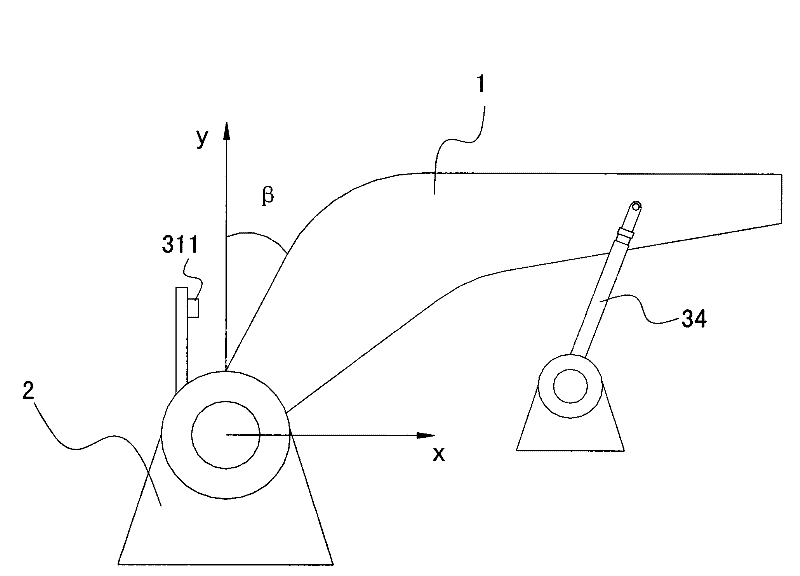

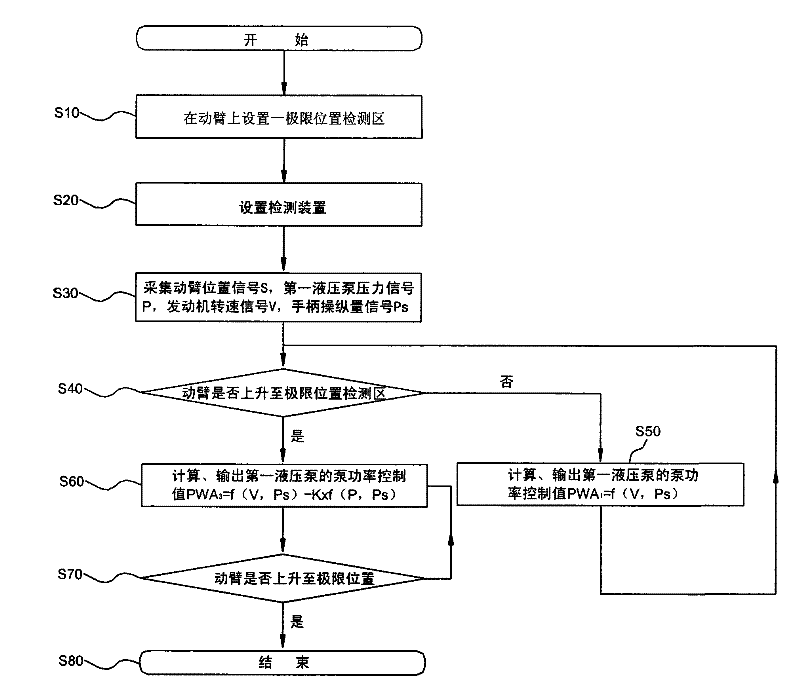

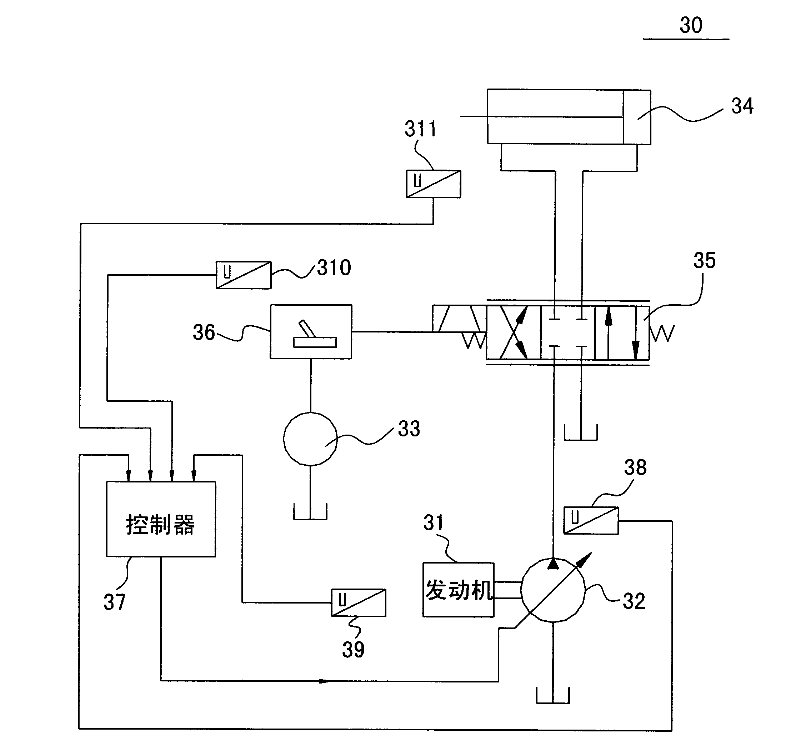

Method for controlling rising velocity of movable arm of excavator, control system and excavator

ActiveCN101666105BSimple structureSlow down scalingMechanical machines/dredgersControl systemControl signal

The invention discloses a method for controlling the rising velocity of a movable arm of an excavator, a control system for realizing the method and an excavator containing the control system. The control system comprises an engine, a first hydraulic pump, a second hydraulic pump, a movable arm oil cylinder, a main control valve, an operating handle, a controller and a plurality of detecting devices. The movable arm is provided with a limit position detecting zone. The controller judges whether the movable arm rises to the limit position detecting zone according to signals fed back from the detecting devices, calculates and outputs a control signal to the first hydraulic pump, adjusts the output power of the first hydraulic pump in time, and reduces the stretching velocity of the movable arm oil cylinder until the action terminal velocity is zero so as to effectively realize the buffer function, increase the service life of the movable arm oil cylinder and enhance the reliability of the complete machine. When the excavator works in a worksite with complex working condition, the accident rate can be effectively reduced, and the efficiency of construction operation is increased; andmoreover, the control system has simple structure, and the control method is convenient to realize.

Owner:BEIQI FOTON MOTOR CO LTD

Z-pin reinforced composite wind turbine blade and manufacturing method thereof

ActiveCN104552994BImprove connection strengthImprove fatigue resistanceFinal product manufactureMachines/enginesTurbine bladeFibrous composites

The invention relates to a Z-pin reinforced foam sandwich composite wind turbine blade and a manufacturing process thereof, belonging to the technical field of fiber composite reinforcing. The manufacturing process comprises the following steps: implanting Z-pin into a foam preform, and preparing a composite connection layer; laying an upper half shell and a lower half shell in a wind turbine blade mould, and implanting Z-pin into a connecting part of the lower half shell and the connection layer in the direction perpendicular to the shell; pouring a foaming material in a lower mould, and then closing an upper mould; after the foaming of the foaming material is finished, taking down the upper mould, implanting Z-pin perpendicular to the shell from the outside at a joint of the upper half shell and the upper half part of the connection layer, and then closing the upper mould; solidifying the Z-pin reinforced composite wind turbine blade. The manufacturing process provided by the invention has the advantages of obviously improving the connection strength and the fatigue resistance performance of the joint of the upper shell and the lower shell of the composite wind turbine blade, and avoiding the structural damage caused by ungluing of the upper and the lower shells, and the Z-pin is light in weight and high in strength, so that the requirement of the wind turbine blade for the material is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

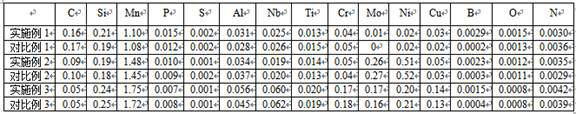

A kind of production method of micro-alloyed steel that can be hot-transported and hot-charged

The invention provides a hot delivery and hot charging production method of micro-alloyed steel. The micro-alloyed steel comprises the component of Fe, and further comprises C, Si, Mn, P, S, Al, Nb, Ti, Cr, Mo, Ni, Cu, B, N, O, and unavoidable impurity elements, wherein O is less than or equal to 0.002%, Nb is less than or equal to 0.11%, Ti is 0.08%-0.020%, and Ti / N is greater than or equal to 3.4, B is 0.001%-0.004%. The hot delivery and hot charging technology comprises the following steps that (1)when a continuous casting slab is subjected to straightening, surface temperature is 850-950 DEG C, and when hot delivery and hot charging are carried out, the surface temperature is 500-850 DEG C; a casting blank is preferentially and directly sent and delivered by using a roller way, or after number spraying is carried out, the casting blank is lifted off a line, but not stacked, and then delivered onto a furnace after natural cooling; (2)and during the heating process, the temperature of a preheating section hearth is greater than the surface temperature of the casting blank when the casting blank is subjected to hot delivery and hot charging. The hot delivery and hot charging production method of the micro-alloyed steel effectively avoids the star shake of steel plate surface caused by hot delivery and hot charging at two phase regions of micro-alloyed steel continuous castingslab, so that the industrial production of the micro-alloyed steel by hot delivery and hot delivery is possible, the production cost is reduced, and the hot delivery and hot charging technology is simple.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

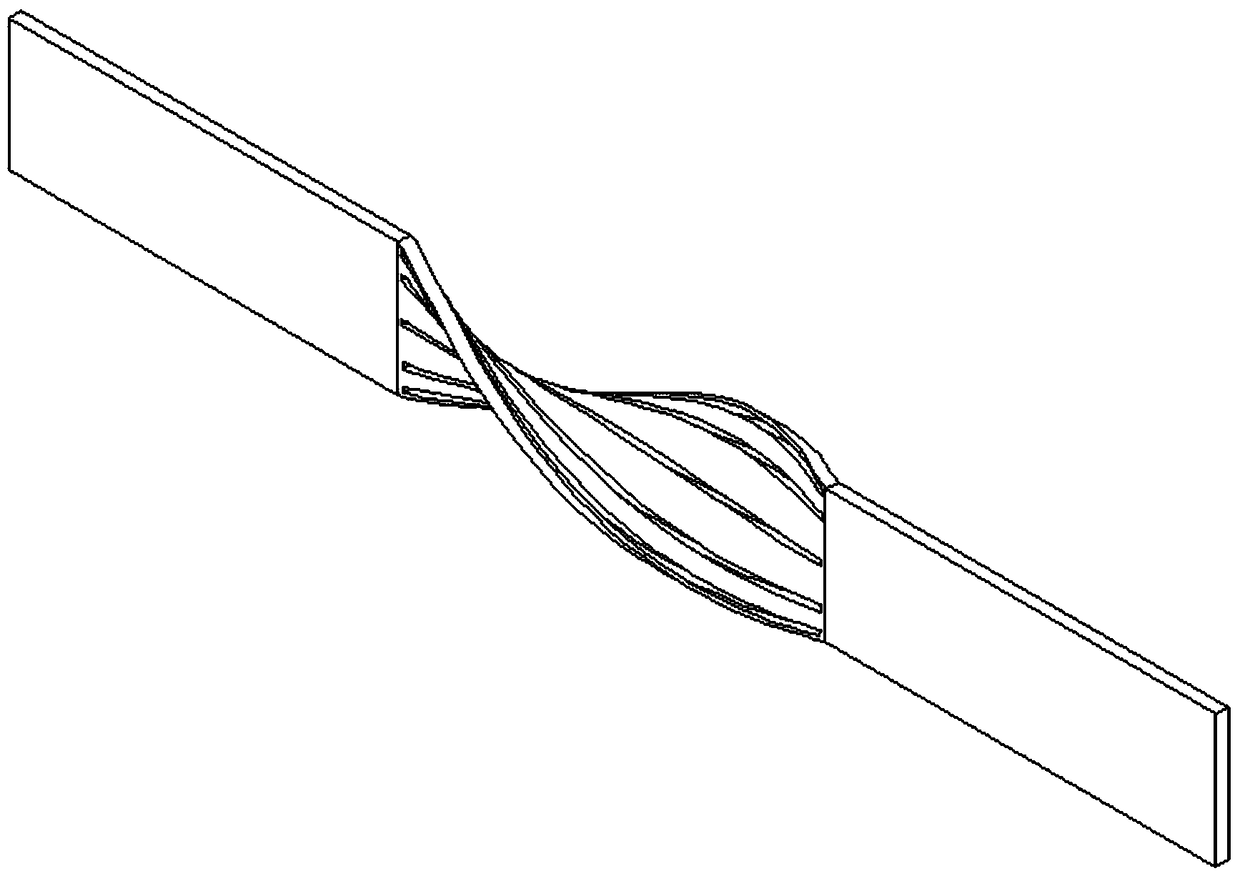

Lightning current shunt with self-locking device and mounting method

PendingCN108557594AAvoid Harmful VibrationExtended service lifeLarge containersVoltage/current isolationSelf lockingEngineering

The invention discloses a lightning current shunt with a self-locking device. The lightning current shunt comprises a lightning current shunt mechanism, wherein a flat spiral spring and a copper wovenbelt are arranged in the lightning current shunt mechanism; one end of the flat spiral spring is fixed on a housing of a lightning current shunt structure, and the other end of the flat spiral springis fixed on a main shaft connected with a reel; one end of the copper woven belt is fixed to the interior of the reel in the lightning current shunt structure, and the other end of the copper woven belt passes through the self-locking device fixed on the lightning current shunt structure; and the self-locking device can exert a counter-acting force onto the copper woven belt which tends to stretch in a swinging state, so that the stretching speed of the copper woven belt is reduced, and the flat spiral spring is in a stable state. The lightning current shunt with the self-locking device is simple in structure and novel in design. The service life of the flat spiral spring is prolonged.

Owner:江苏驭雷安全科技有限公司

A kind of z-pin reinforced composite wind power blade structure and manufacturing method thereof

ActiveCN104847595BImprove interlayer toughnessAvoid damageFinal product manufactureMachines/enginesFiberElectricity

The invention discloses a Z-pin reinforced composite material wind power blade structure. The Z-pin reinforced composite material wind power blade structure comprises an upper half blade shell, a lower half blade shell and a main beam, wherein the upper half blade shell and the lower half blade shell are matched to form a blade cavity, the upper edge of the main beam and the inner wall of the upper half blade shell are tightly attached to form an upper connecting surface, the lower edge of the main beam and the inner wall of the lower half vane shell are tightly attached to form a lower connecting surface, Z-pins which have pinning and bridging functions and improve the connecting strength between the main beam and the upper half blade shell as well as between the main beam and the lower half blade shell are arranged at the connecting positions of the upper connecting surface and the lower connecting surface, and the part, located on two sides of the main beam, of the blade cavity is filled with foam. The Z-pin reinforced composite material wind power blade structure can obviously improve the layered rigidity of composite material laminated wood. A manufacturing method is simple. The Z-pin reinforced composite material wind power blade structure is high in designability, is easy to form overall and further has the advantages of being good in weight-reducing property, resistant to shearing, high in stripping resistance and small in damage to fibers.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Damage tolerance optimization method for rib integral panel

PendingCN113190923AImproved damage tolerance performanceEasy to useGeometric CADDesign optimisation/simulationElement modelAlgorithm

The invention belongs to the field of aircraft structure damage tolerance design, and discloses a rib integral panel damage tolerance optimization method, which comprises the steps of integral panel reinforcement ratio determination, rib sensitive parameter identification, structure size optimization matrix establishment, crack-containing integral panel finite element model establishment, stress intensity factor k calculation and crack propagation life calculation, and determining optimal structural parameters by comparing the crack propagation lives under different sizes.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com