Patents

Literature

33results about How to "Increase defect concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat insulating layer based on la2zr2o7 for high temperatures

InactiveUS20040101699A1Improve the overall coefficientLow thermal conductivityMolten spray coatingEfficient propulsion technologiesThermal coefficientLanthanum

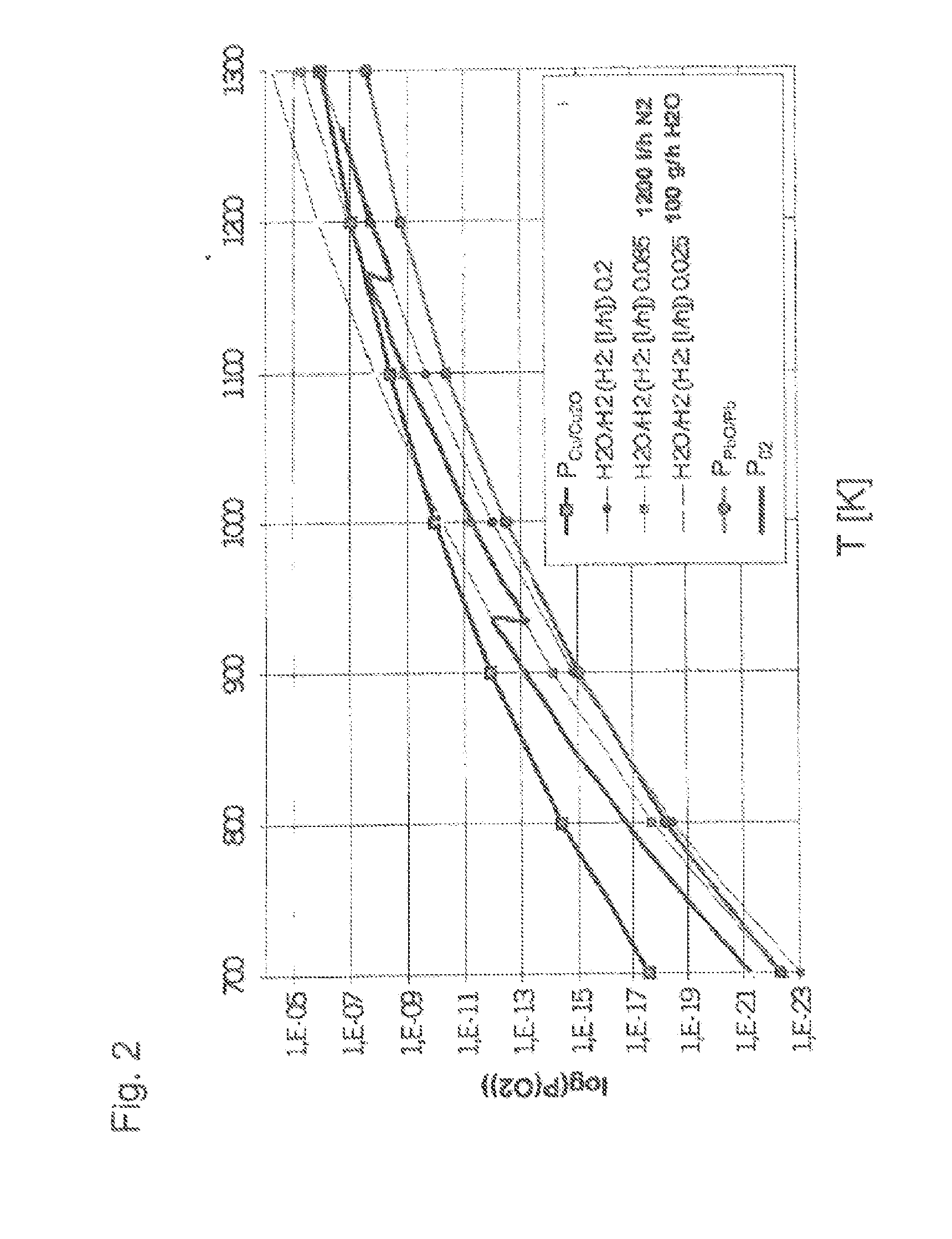

The invention relates to a heat insulating layer on a metallic substrate for using for high temperatures, especially for temperatures above 1300° C. Starting with a base of La2Zr2O7, the properties of the heat insulating substance to be used as the heat insulating layer are regularly improved, by substituting lanthanum cations with ions of elements Nd, Eu, Dy, Sm and / or Gd. An additional, at least partial substitution of the zirconium cations by Ce, Hf or Ta is advantageous. Improving the properties results especially in a high thermal coefficient of dilation alpha and low heat conductivity lambda.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

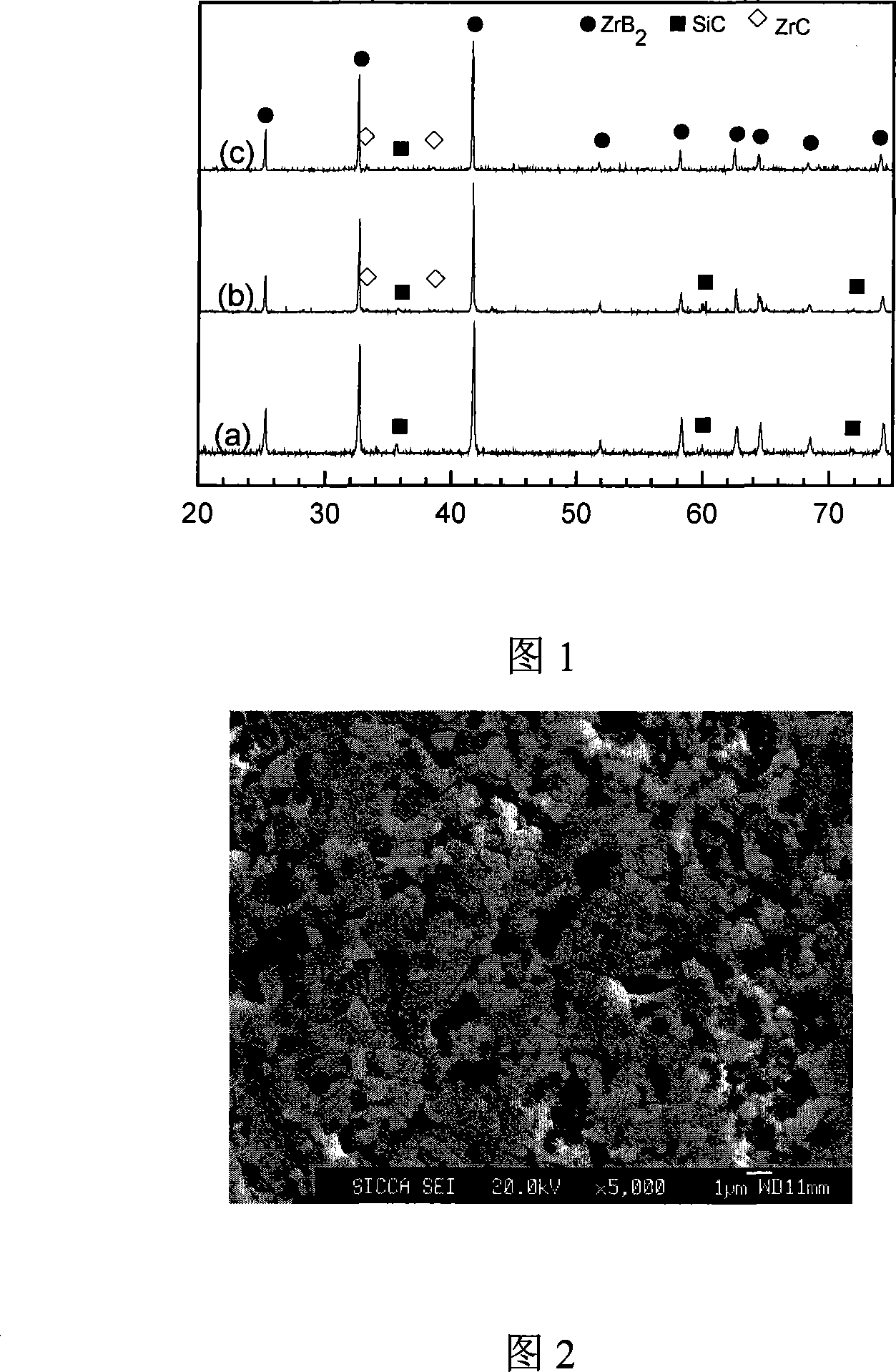

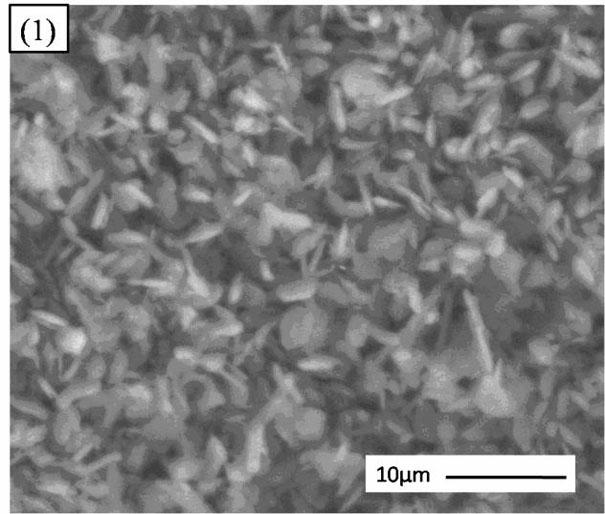

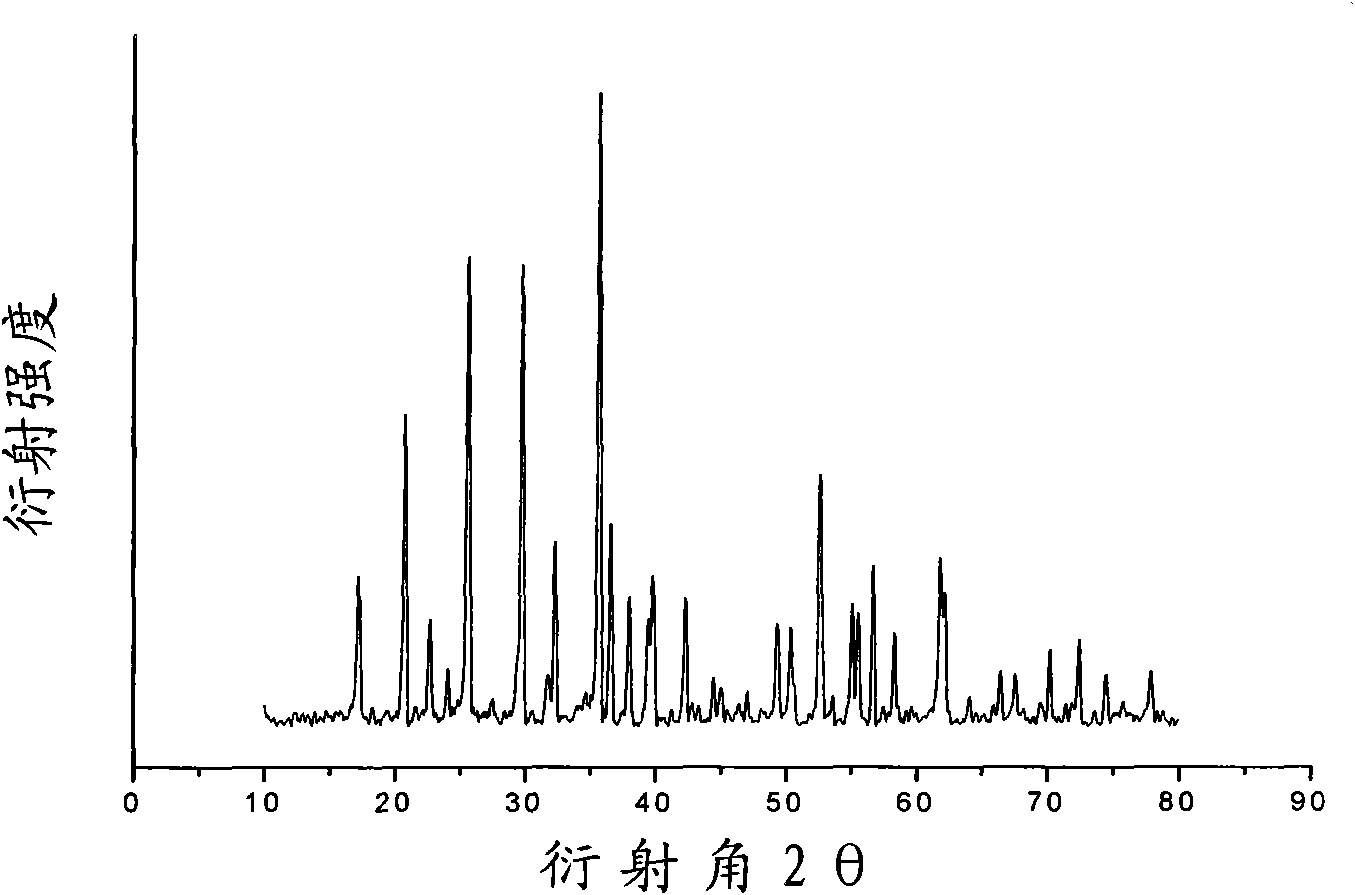

Method for preparing ZrB2-SiC-ZrC diphase ceramic material

The invention relates to a process for preparing ZrB2-SiC-ZrC complex phase ceramic materials, which is characterized in that purity of zirconium powder is not less than 98%, silicon powder and boron carbide powder are used as raw materials, batching according to reaction equation (2+x)Zr+(1-x)Si+B4C=2ZrB2+(1-x)SiC+ZrC, 0<=x<=0.5 of generating ZrB2-SiC-ZrC, then, materials containing different components are obtained. The raw materials after being ball ground and dried are sintered with heat pressing between 1500-1700DEG C by adjusting sintering technique parameter and employing self-propagating reaction of the raw materials generated in the process of heating up, thereby obtaining the ZrB2-SiC-ZrC complex phase ceramic materials of different components. Relative density of the materials prepared by the invention is larger than 97%, bending strength is 600-900MPa, fracture toughness property is 4.5-6MPa,m1 / 2, and hardness is 16-19GPa.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

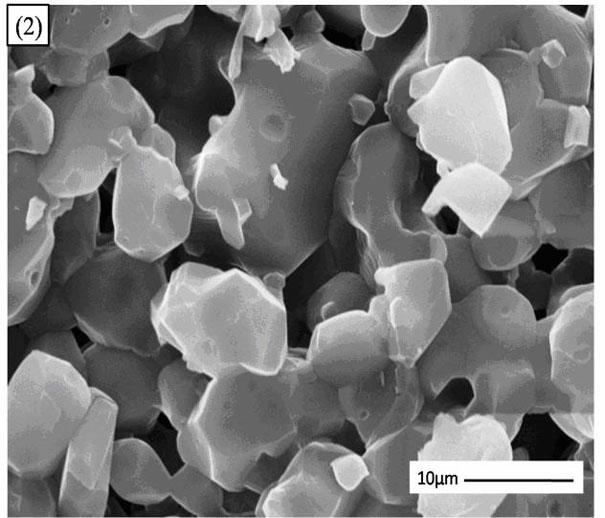

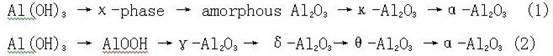

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

ESD/EOS Performance by Introduction of Defects

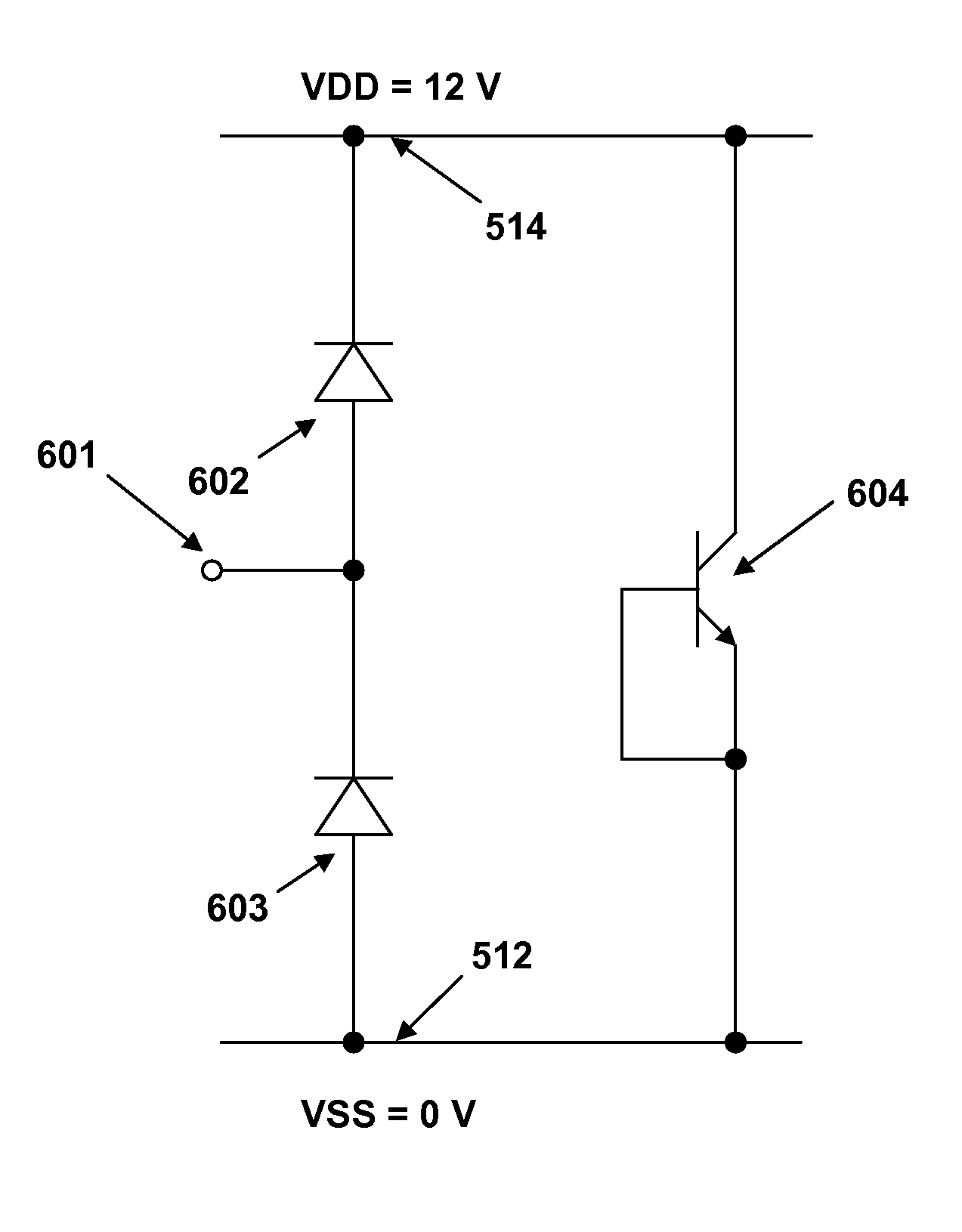

ActiveUS20090185316A1Enhance defect concentrationFast and reliableTransistorSemiconductor/solid-state device detailsPhysicsAvalanche diode

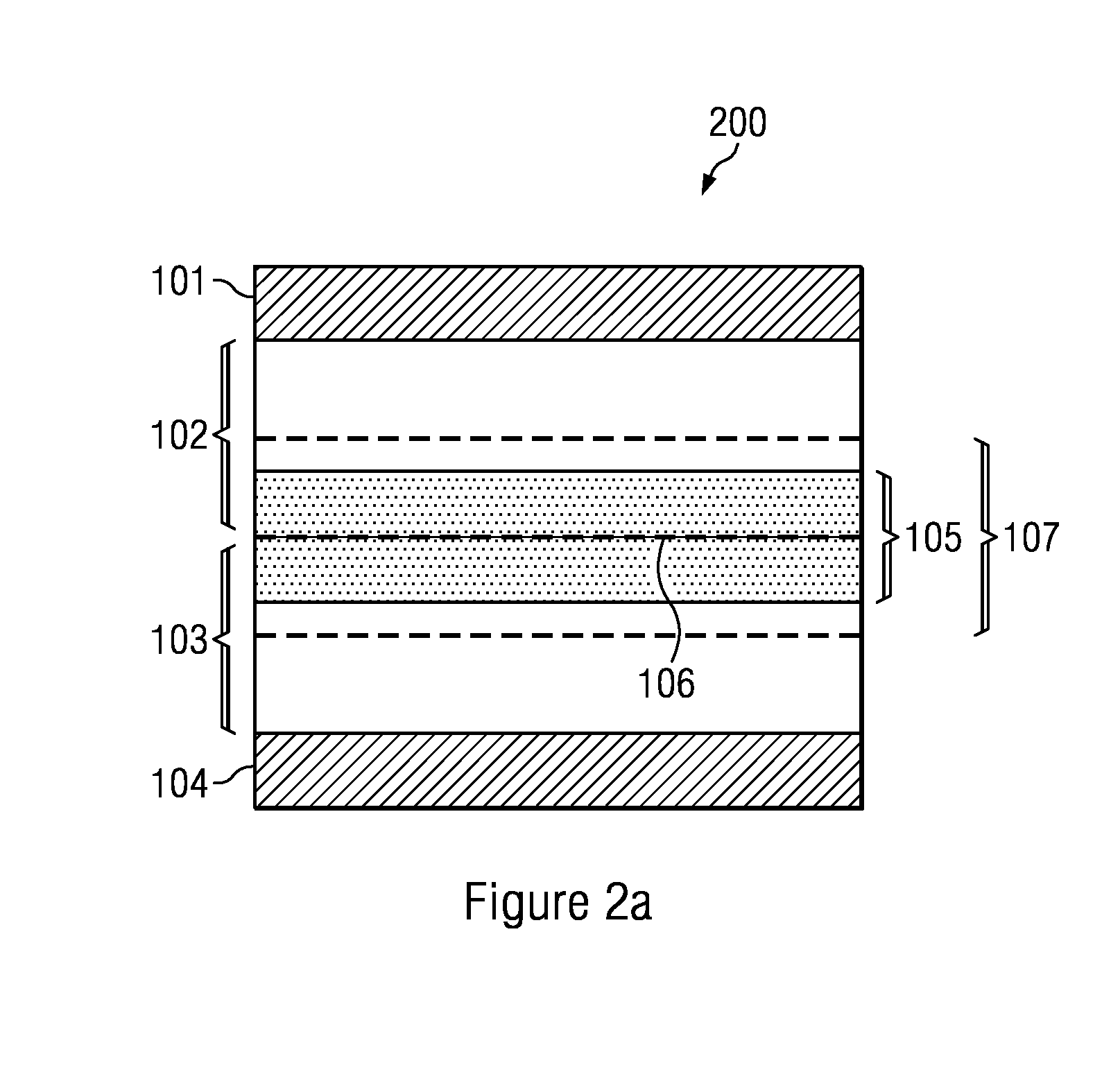

The invention relates to an avalanche diode that can be employed as an ESD protection device. An avalanche ignition region is formed at the p-n junction of the diode and includes an enhanced defect concentration level to provide rapid onset of avalanche current. The avalanche ignition region is preferably formed wider than the diode depletion zone, and is preferably created by placement, preferably by ion implantation, of an atomic specie different from that of the principal device structure. The doping concentration of the placed atomic specie should be sufficiently high to ensure substantially immediate onset of avalanche current when the diode breakdown voltage is exceeded. The new atomic specie preferably comprises argon or nitrogen, but other atomic species can be employed. However, other means of increasing a defect concentration level in the diode depletion zone, such as an altered annealing program, are also contemplated.

Owner:INFINEON TECH AG

Silicon oxycarbide film and RRAM (resistive random access memory)

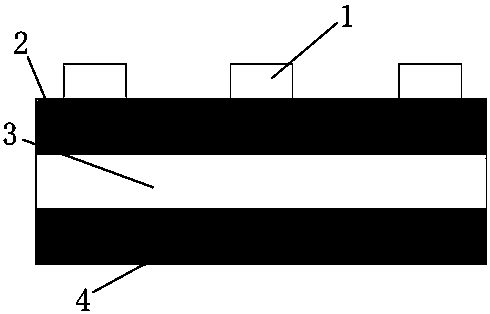

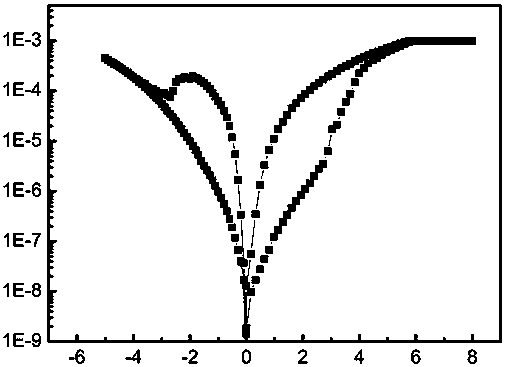

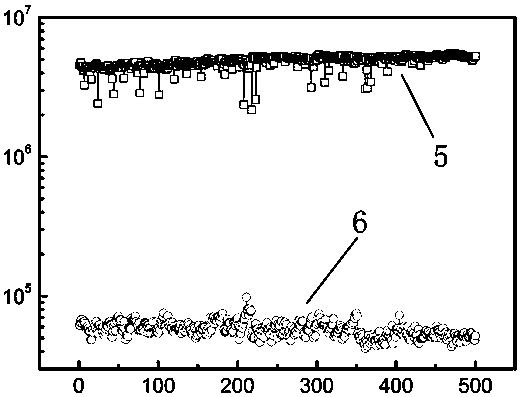

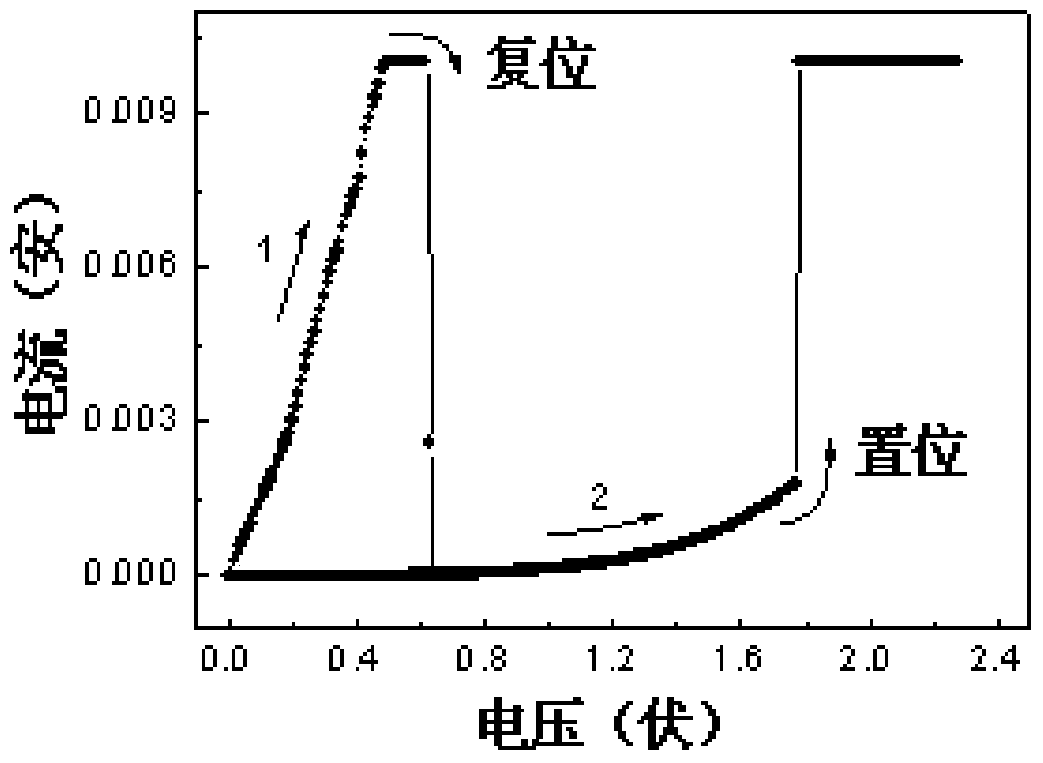

ActiveCN105977379AIncrease defect concentrationGood resistive propertiesElectrical apparatusStatic random-access memoryRandom access memory

The invention provides a silicon oxycarbide film and an RRAM (resistive random access memory). The molecular formula of a silicon oxycarbide film resistive material is SiCxOy, wherein x is from 1.21 to 0.21, y is from 1.45 to 2.01, and x and y are in negative correlation. The thickness of the film is 50nm or less. The RRAM comprises a top electrode, a resistive dielectric layer, a substrate and a back electrode, and is characterized in that the resistive dielectric layer is the silicon oxycarbide film. The top electrode is made of Ag and Al. The RRAM is prepared by a material compatible with the COMS technology, and physical deposition film equipment is mainly used in a preparation process. No high-temperature technology is employed, and the consumption of energy is reduced. Silicon oxycarbide films with different defect concentrations can be obtained through the control of gas proportion. For an SiC0.202.01 material, the switch ratio reaches 500, and can completely meet the actual demands (the switch ratio is greater than 10). Meanwhile, the RRAM based on the silicon oxycarbide material has a self-rectification effect, thereby simplifying the design of an external circuit.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of synthetic magnesium calcium sand and preparation method thereof

InactiveCN102285806AHigh purityNo damage to high temperature performanceCalcium hydroxideMechanical press

The invention relates to synthetic calcium magnesite and a preparation method thereof. The preparation method comprises the steps of firstly carrying out ball milling on 25-30wt% of calcium hydroxide and 70-75wt% of magnesium hydroxide to reach the grain size within 30 mu m, heating the ball-milled mixture in a muffle furnace to 700-900 DEG C, and insulating heat for 0.25-0.5 hour; adding water the amount of which is 20-25wt% of the mixture to the calcined mixture, and digesting for 1-2 hours; and then adding an additive the amount of which is 1-3wt% of the digested mixture to the digested mixture, stirring, carrying out mechanical press shaping by a semi-dry method, naturally drying for 12-15 hours, baking at the temperature of 100-120 DEG C for 12-15 hours, finally firing in a high-temperature furnace at the temperature of 1600-1750 DEG C, insulating heat for 3-5 hours and crushing to obtain the synthetic calcium magnesite. The preparation method provided by the invention has the advantages of simple process and no need for special synthesis equipment and treatment technology. The synthesized calcium magnesite has the characteristics of high purity, wide application range, good sintering performance, good hydration resistance, and no influence on high-temperature use performance.

Owner:WUHAN UNIV OF SCI & TECH

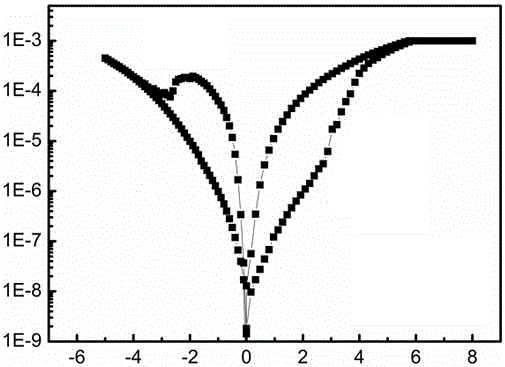

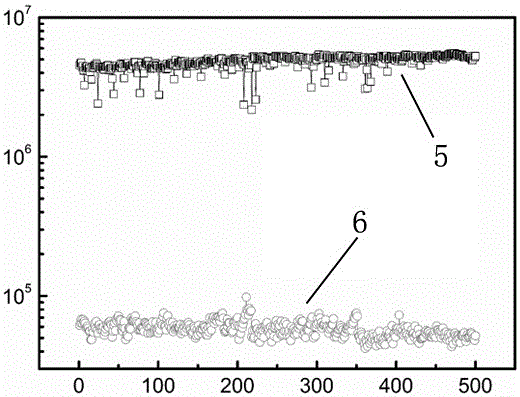

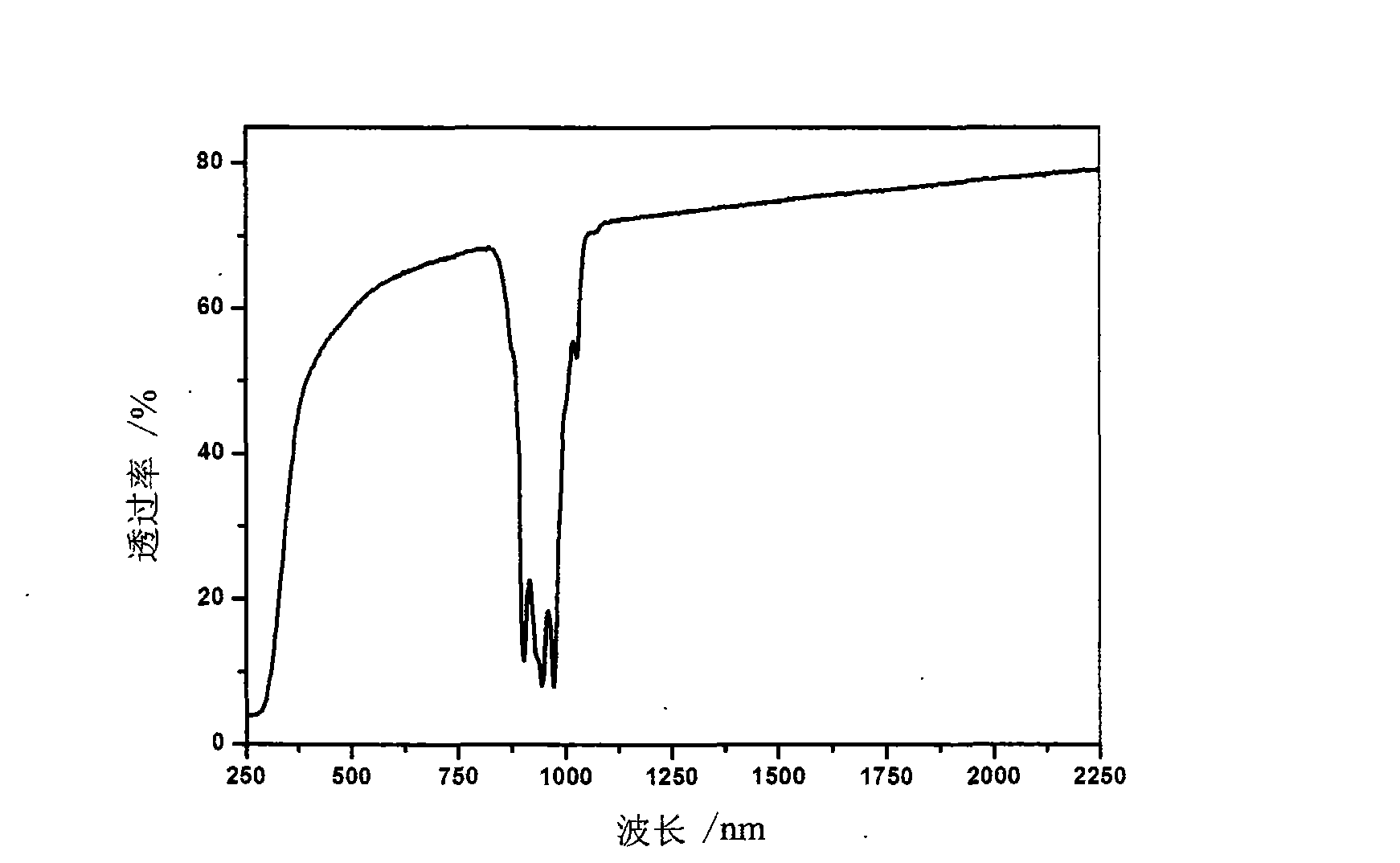

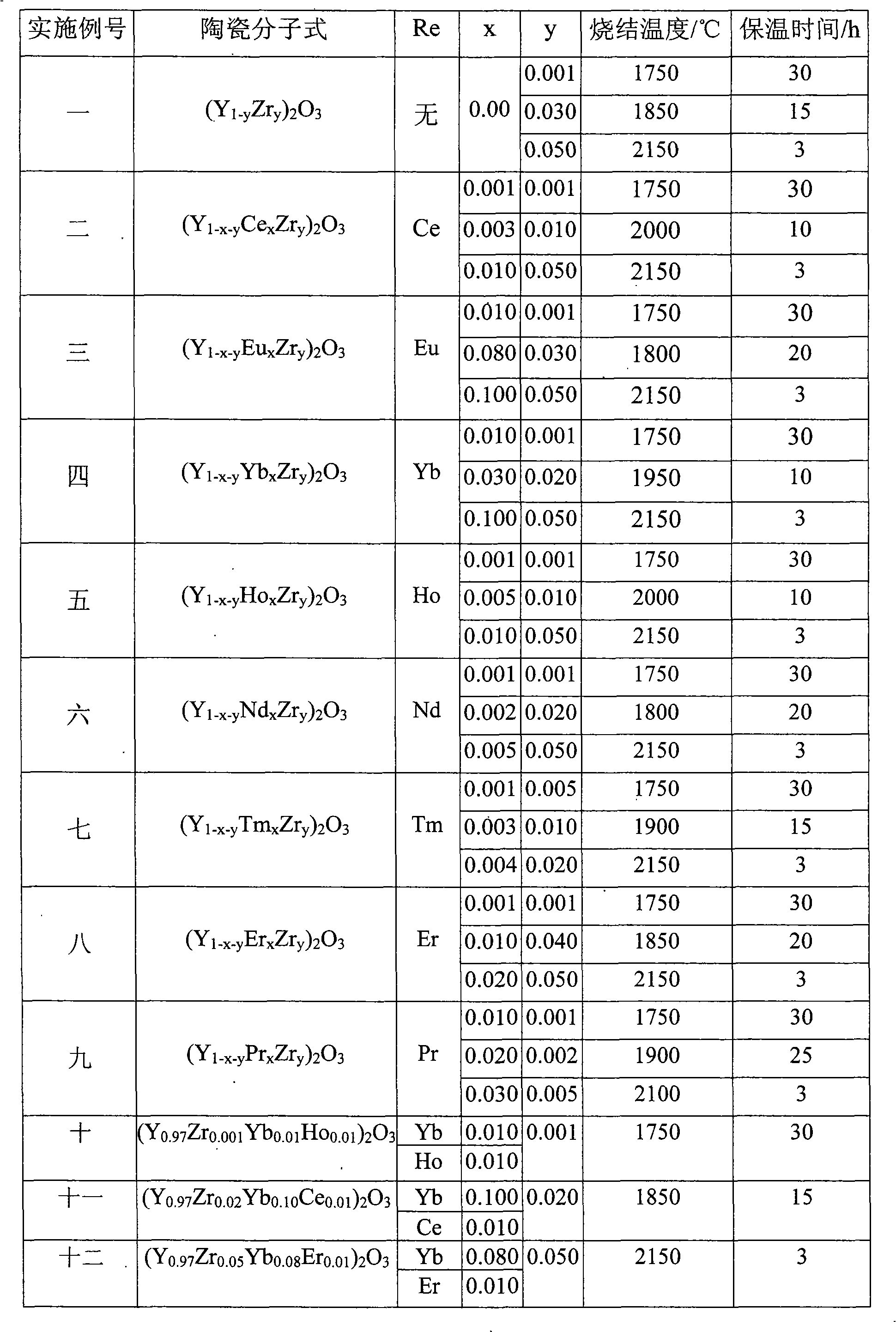

Zirconium-doped yttria base transparent ceramic and preparation method thereof

The invention relates to zirconium-doped yttria base transparent ceramic and a preparation method thereof. The structural formula of the ceramic is (Y(1-x-y)RexZry)2O3, wherein Re is a rare earth element selected from Yb, Nd, Tm, Ho, Ce, Er, Pr and Eu, or double-elements of Yb doped with Ho, Ce, Er, Pr and Eu; x is more than or equal to 0.00 and is less than or equal to 0.10, and y is more than orequal to 0.001 and is less than or equal to 0.05. The zirconium-doped yttria base transparent ceramic prepared by the method has higher transparency and compactness.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

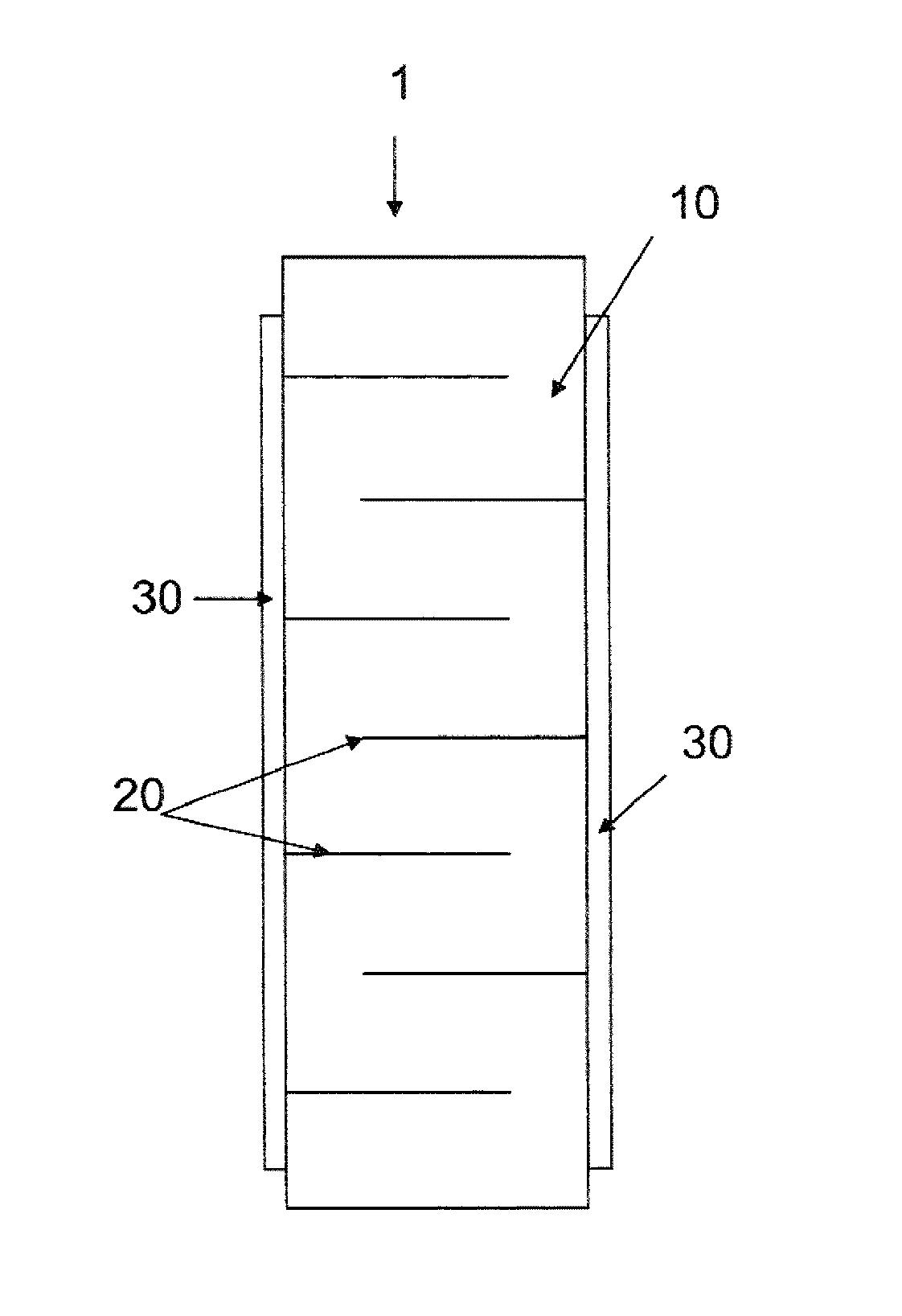

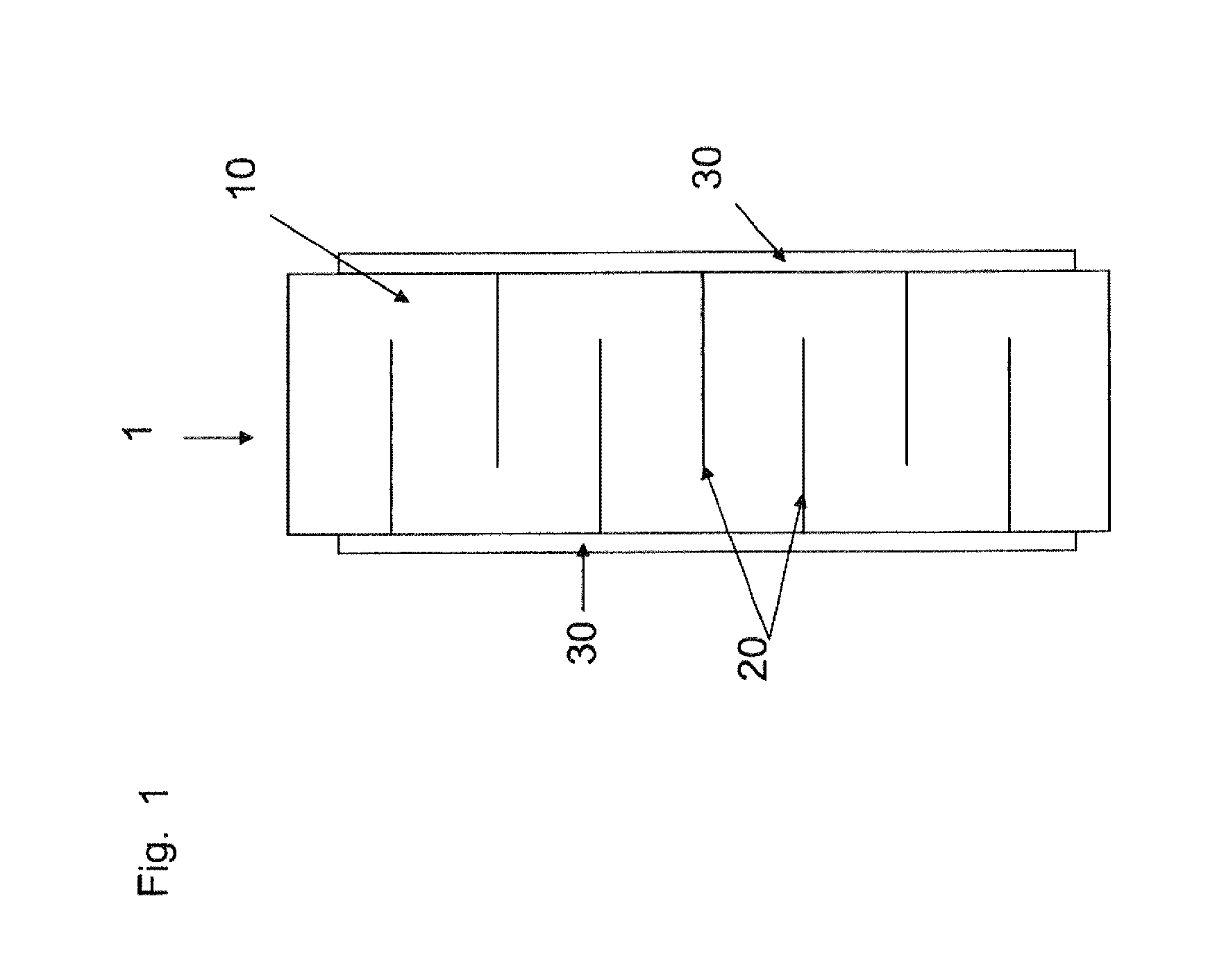

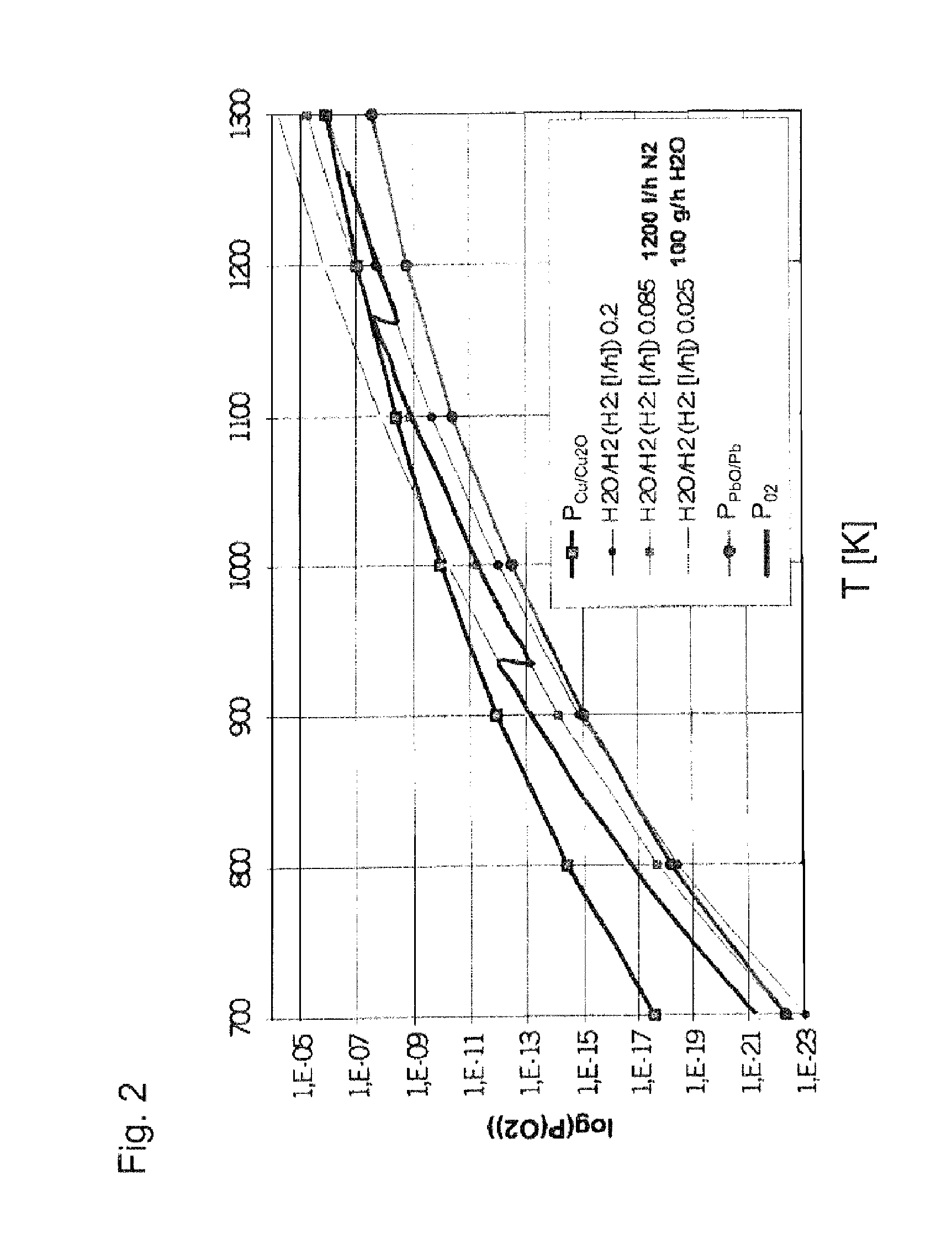

Piezoelectric component and method for producing a piezoelectric component

ActiveUS9570669B2Sufficient sinter densificationIncrease defect concentrationPiezoelectric/electrostrictive devicesRare earthZirconium

A piezoelectric component has at least one piezoelectric ceramic layer and at least one electrode adjacent the piezoelectric ceramic layer. The piezoelectric ceramic layer has a piezoelectric ceramic material of the general formula Pb1-x-y-[(2a-b) / 2]-p / 2V[(2a-b) / 2-p / 2]″CupBaxSry[(TizZr1-z)1-a-bWaREb]O3, where 0≦x≦0.035, 0≦y≦0.025, 0.42≦z≦0.5, 0.0045≦a≦0.009, 0.009≦b≦0.011, 2a>b, p≦2a−b, RE is a rare earth metal, and V″ is a Pb vacancy.

Owner:EPCOS AG

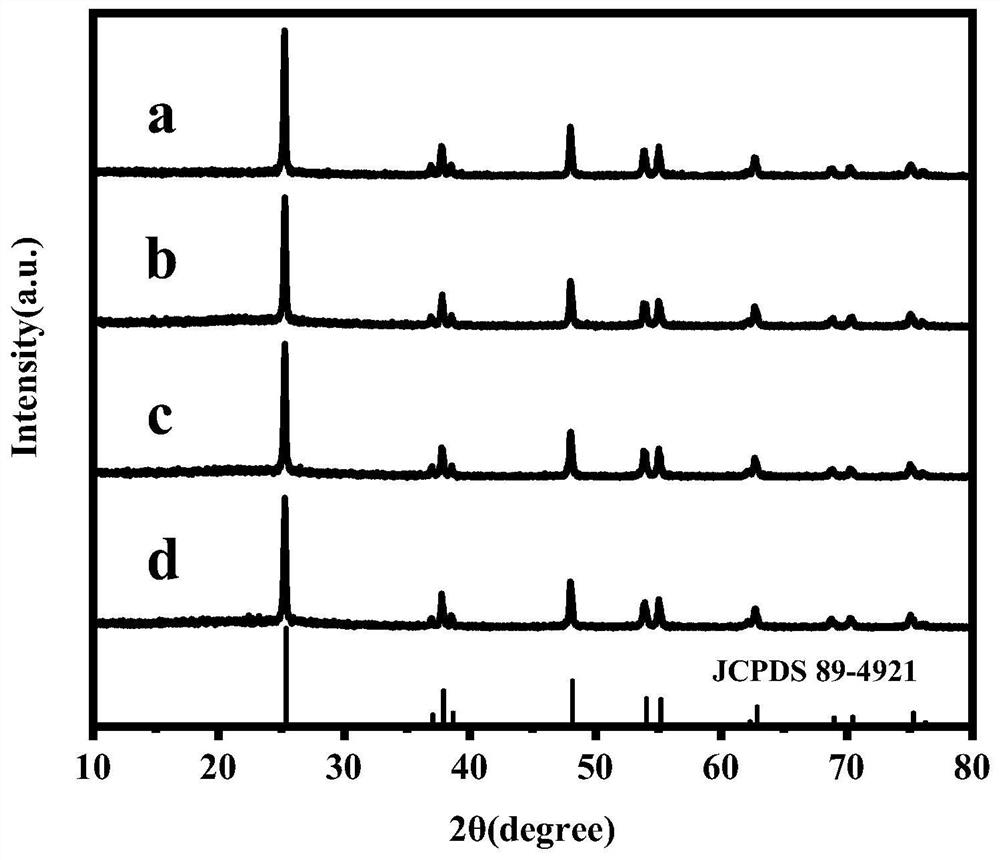

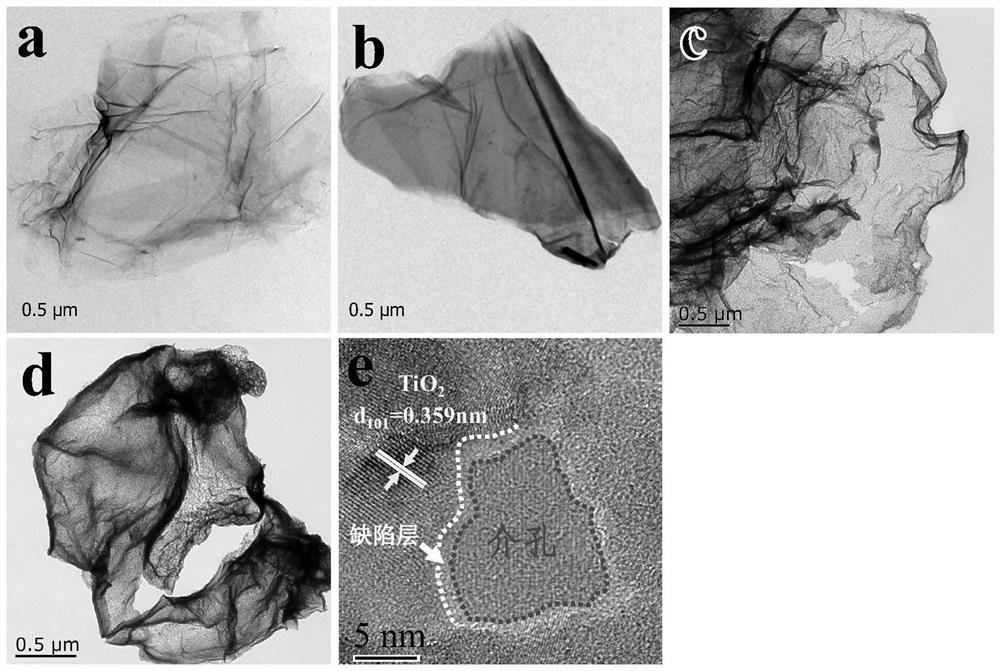

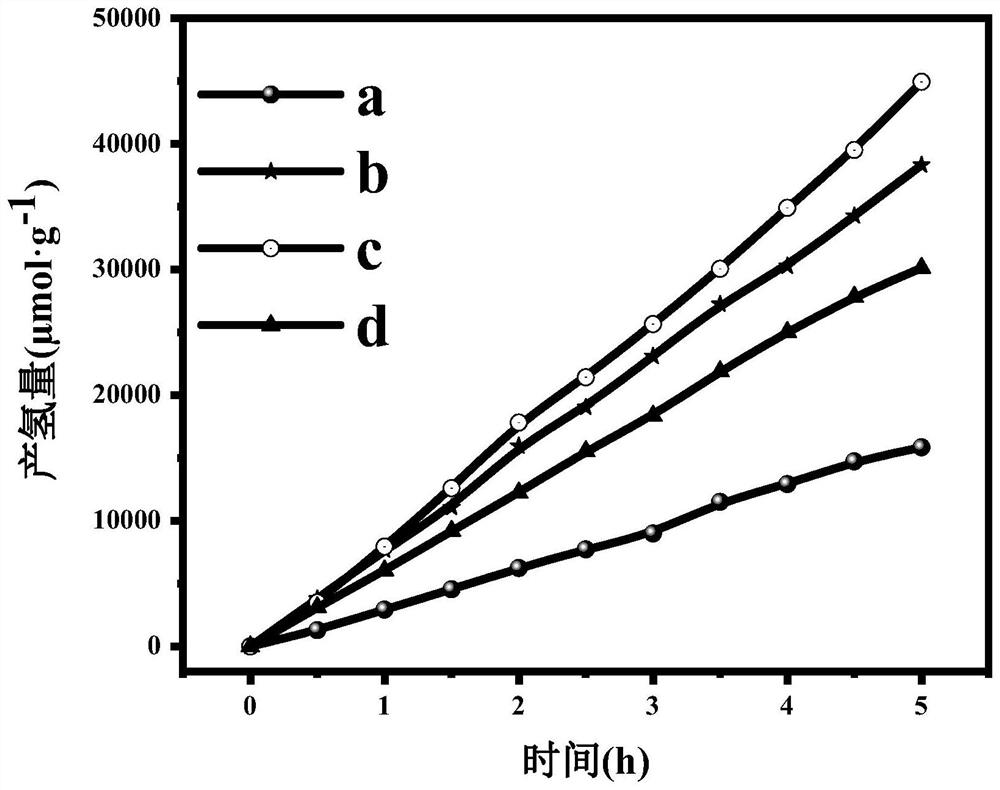

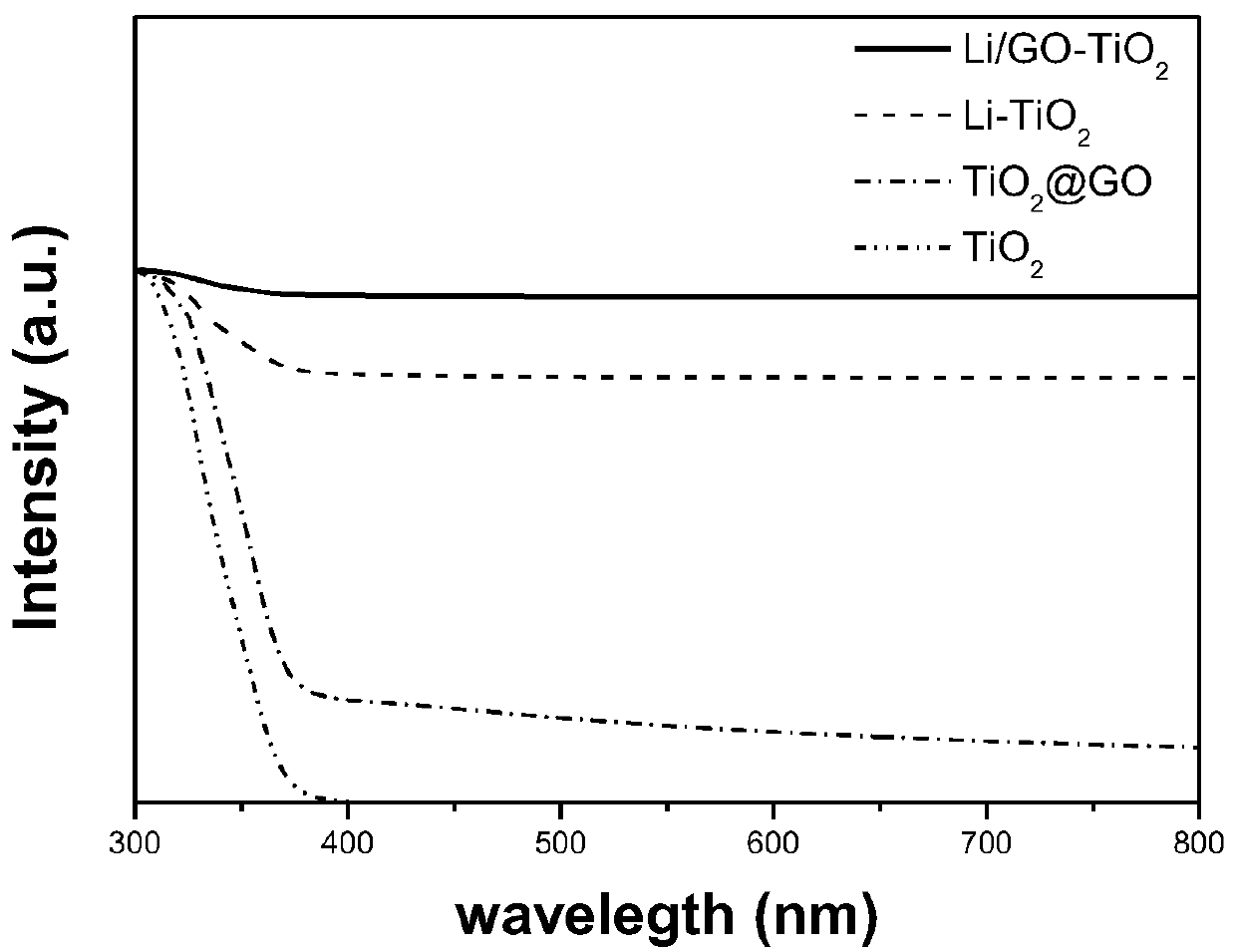

2D porous TiO2 nanosheet rich in surface defects and preparation method of 2D porous TiO2 nanosheet

PendingCN111646500AAvoid stackingIncrease defect concentrationPhysical/chemical process catalystsTitanium dioxidePhoto catalysisPhotogenerated electron

The invention belongs to the field of nano materials, the invention discloses a preparation method of a 2D porous TiO2 nanosheet photocatalyst rich in surface defects. The preparation method comprisesthe following steps: preparing graphene oxide by a Hummers method, preparing GO@Ti (OH) 4 by an oil bath method, preparing a 2D porous TiO2 nanosheet by calcining, and further preparing the 2D porousTiO2 nanosheet rich in surface defects by hydrogen reduction. Through cooperation of the 2D porous TiO2 nanosheet and defect engineering, active sites and edge sites of the nano photocatalyst are fully exposed, the recombination rate of photo-induced electron holes is reduced, the sunlight utilization rate is increased, and then the photocatalytic performance of the nano photocatalyst is improved. The material can be used for photocatalytic decomposition of water to produce hydrogen, which is of great significance to the development of clean energy.

Owner:JIANGSU UNIV

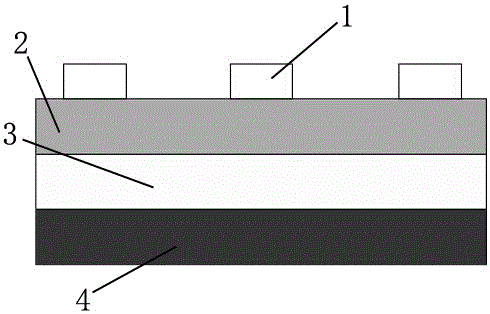

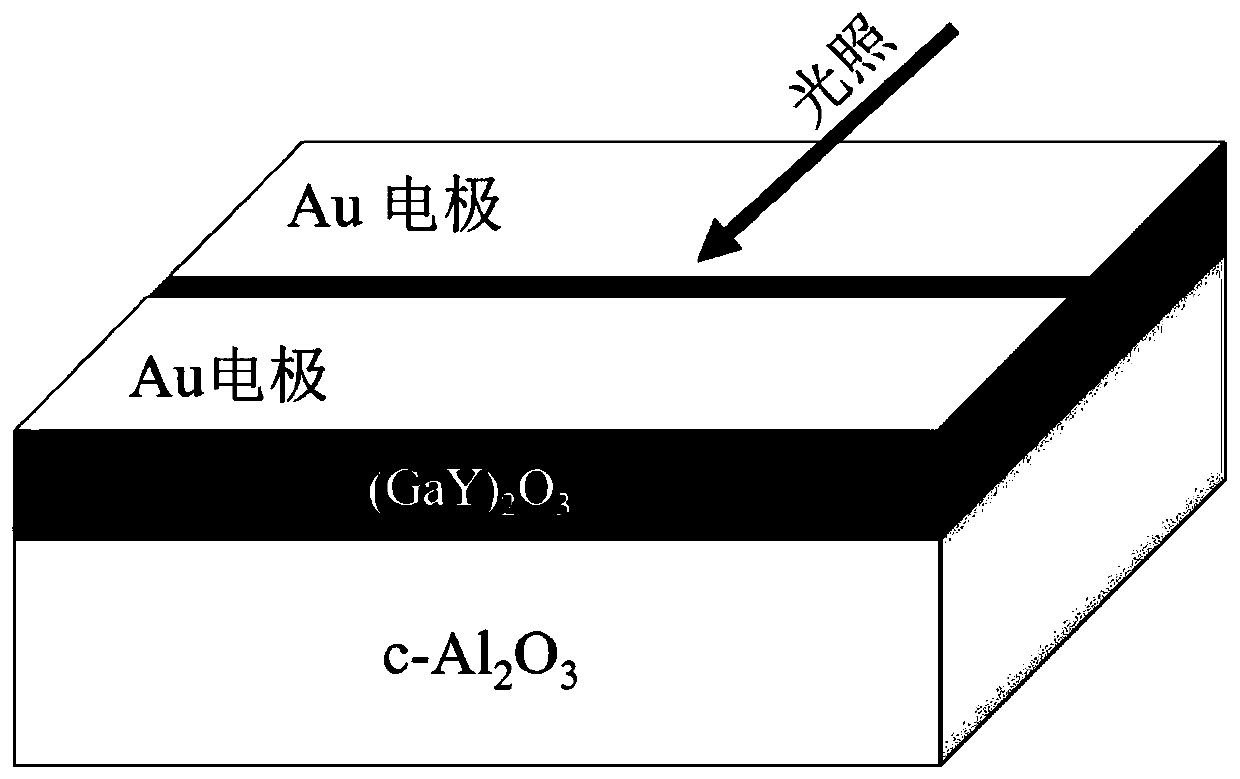

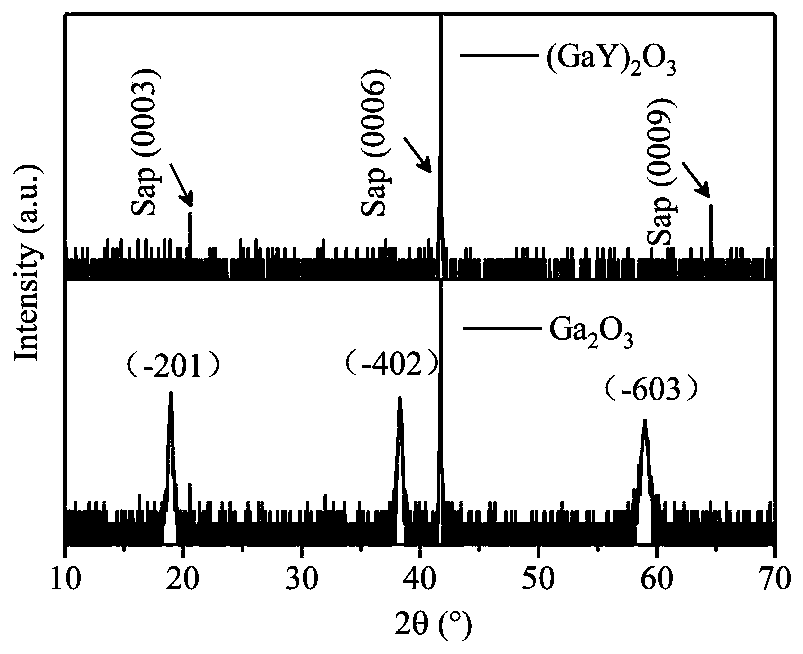

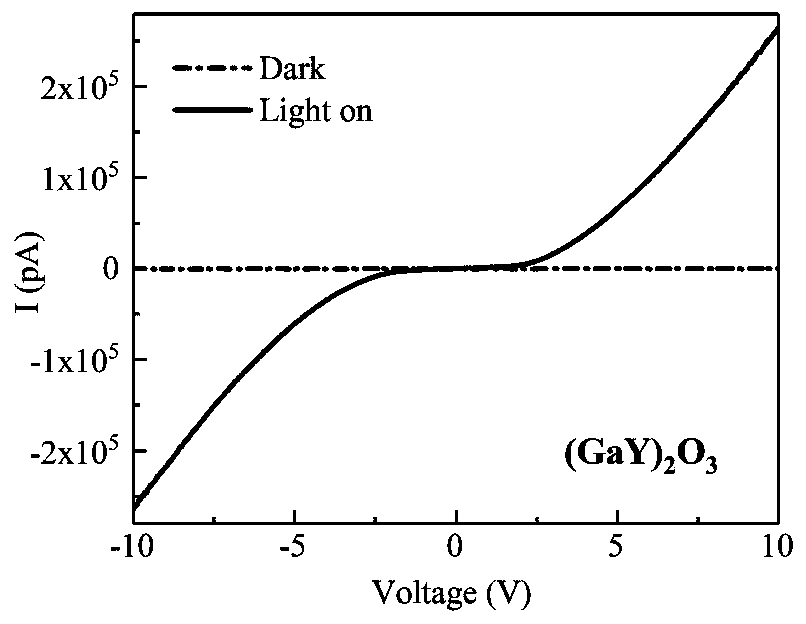

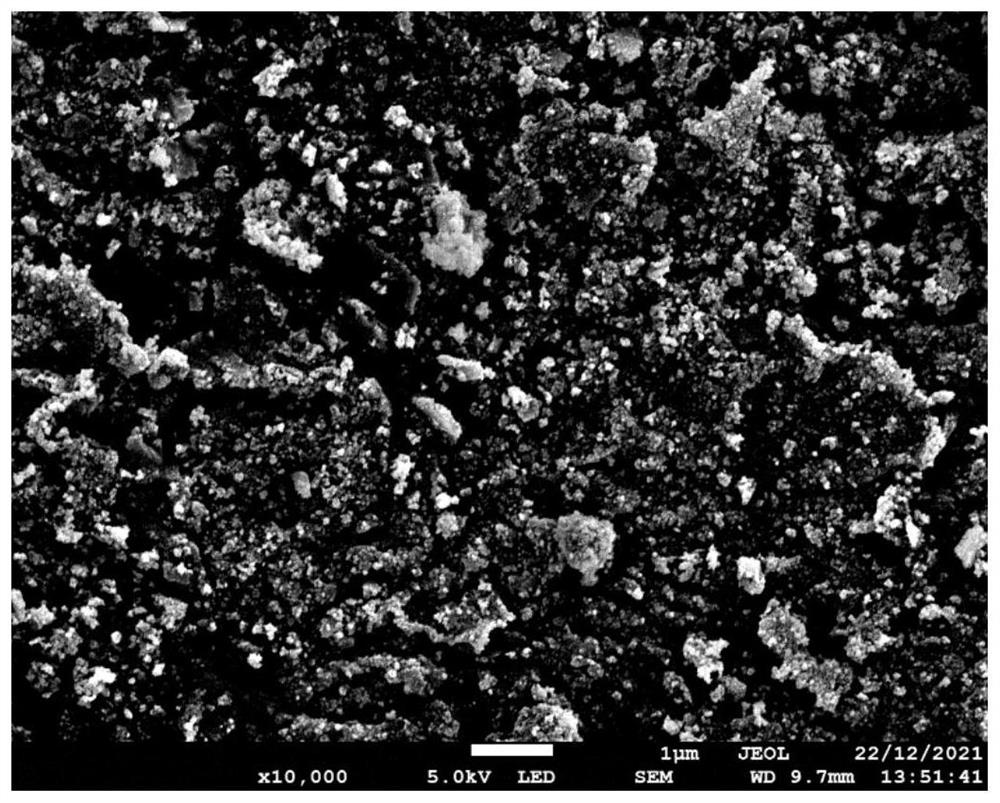

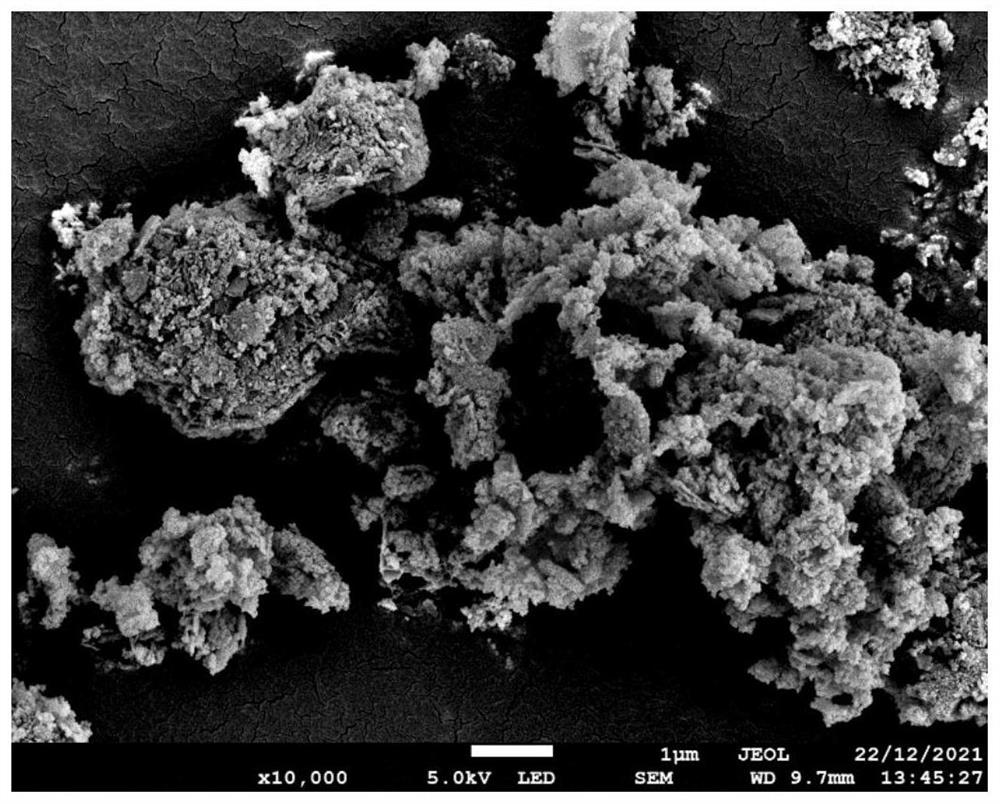

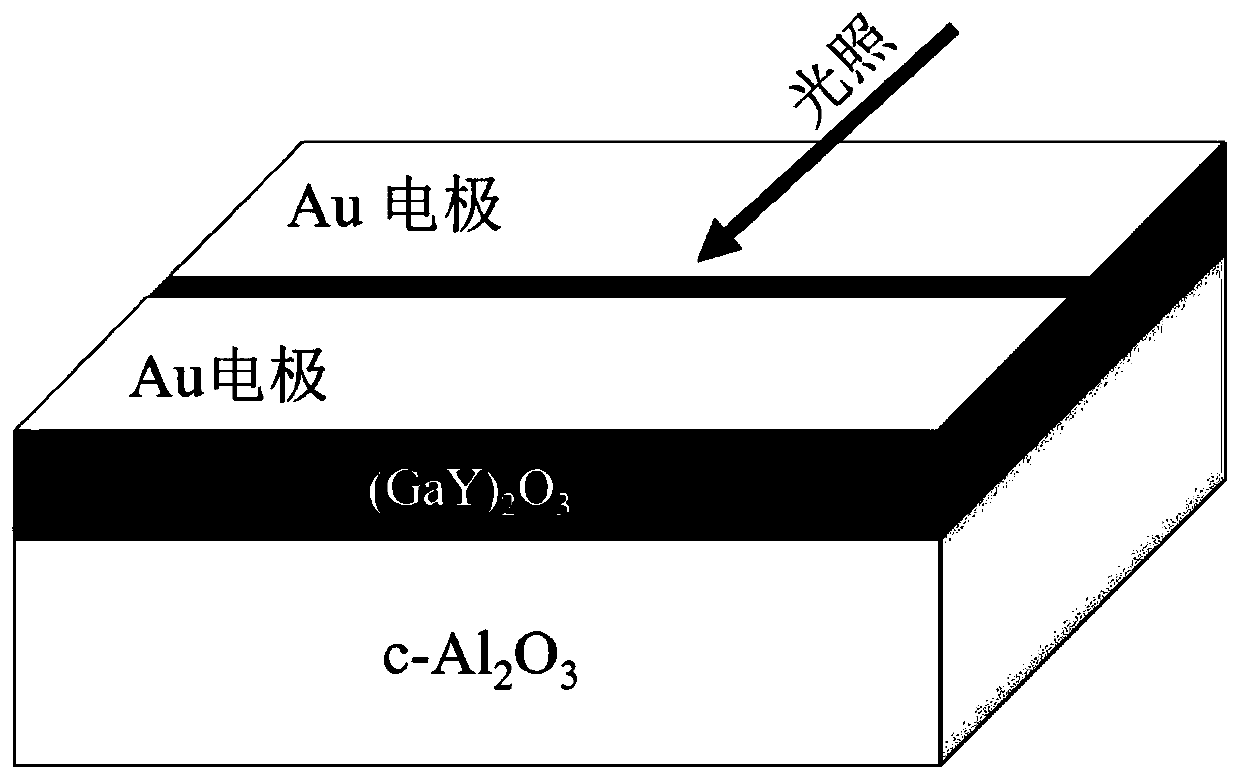

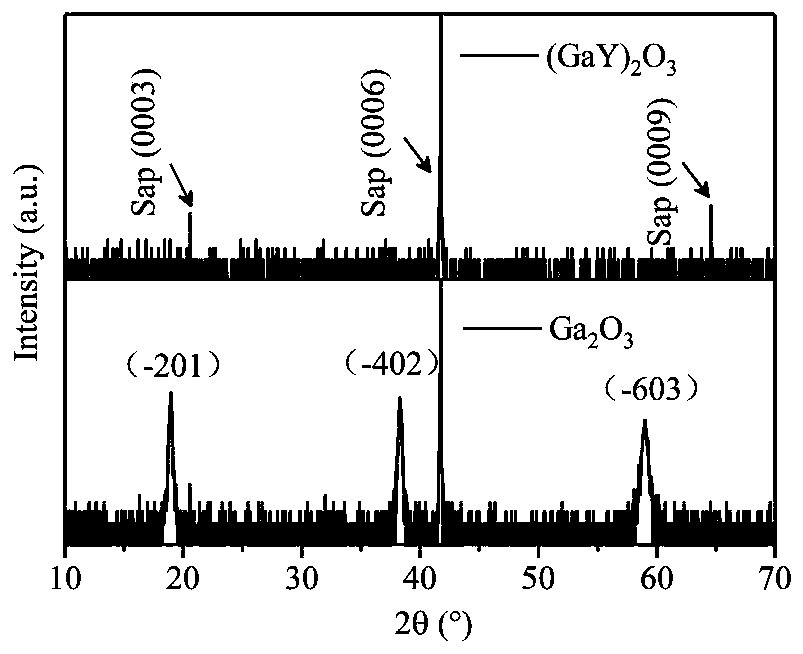

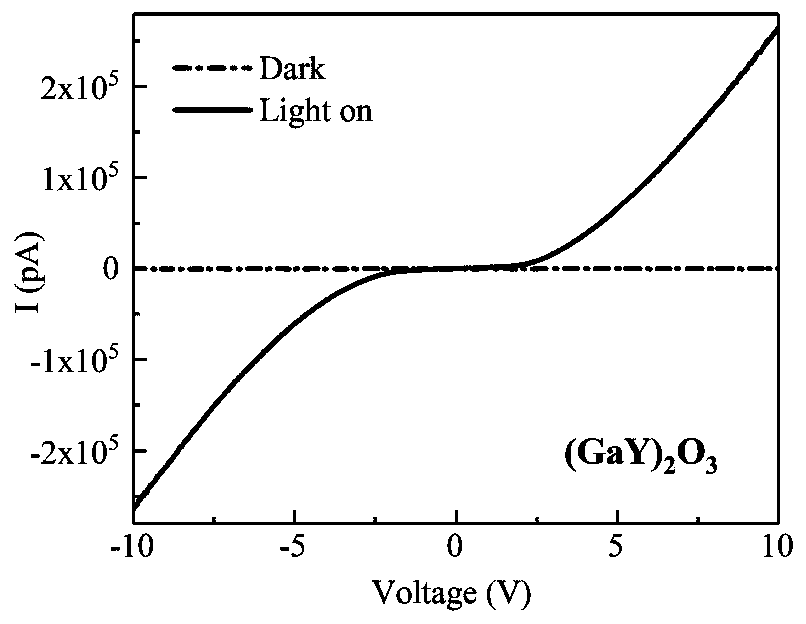

High-gain solar blind ultraviolet light detector based on (GaY)2O3 amorphous film and preparation method of high-gain solar blind ultraviolet light detector

ActiveCN110323291AReduce dark currentIncrease defect concentrationFinal product manufacturePhotovoltaic energy generationResponsivityUltraviolet lights

The invention discloses a high-gain solar blind ultraviolet light detector based on a (GaY)2O3 amorphous film and a preparation method of the high-gain solar blind ultraviolet light detector. The detector sequentially comprises a c-plane sapphire, an active layer and a pair of parallel electrodes from bottom to top, wherein the active layer is the amorphous (GaY)2O3 film. According to the invention, Y3+ ions are used for partially replacing Ga3+ ions in Ga2O3, so that the band gap of Ga2O3 is increased, and the thin film is converted into amorphous from single crystal. The amorphous (GaY)2O3 film with a higher band gap can effectively reduce the dark current of the device, and enables the cut-off wavelength to be blue-shifted to be within 280nm. Meanwhile, the amorphous (GaY)2O3 film has higher defect concentration, and the defects not only can improve the gain, but also can be used as a recombination center to promote carrier recombination, so that compared with a pure Ga2O3 device, an amorphous (GaY)2O3 device has the advantages that the responsivity is obviously improved, the relaxation time is obviously shortened, and the detection capability on deep ultraviolet light is greatly improved.

Owner:HUBEI UNIV +1

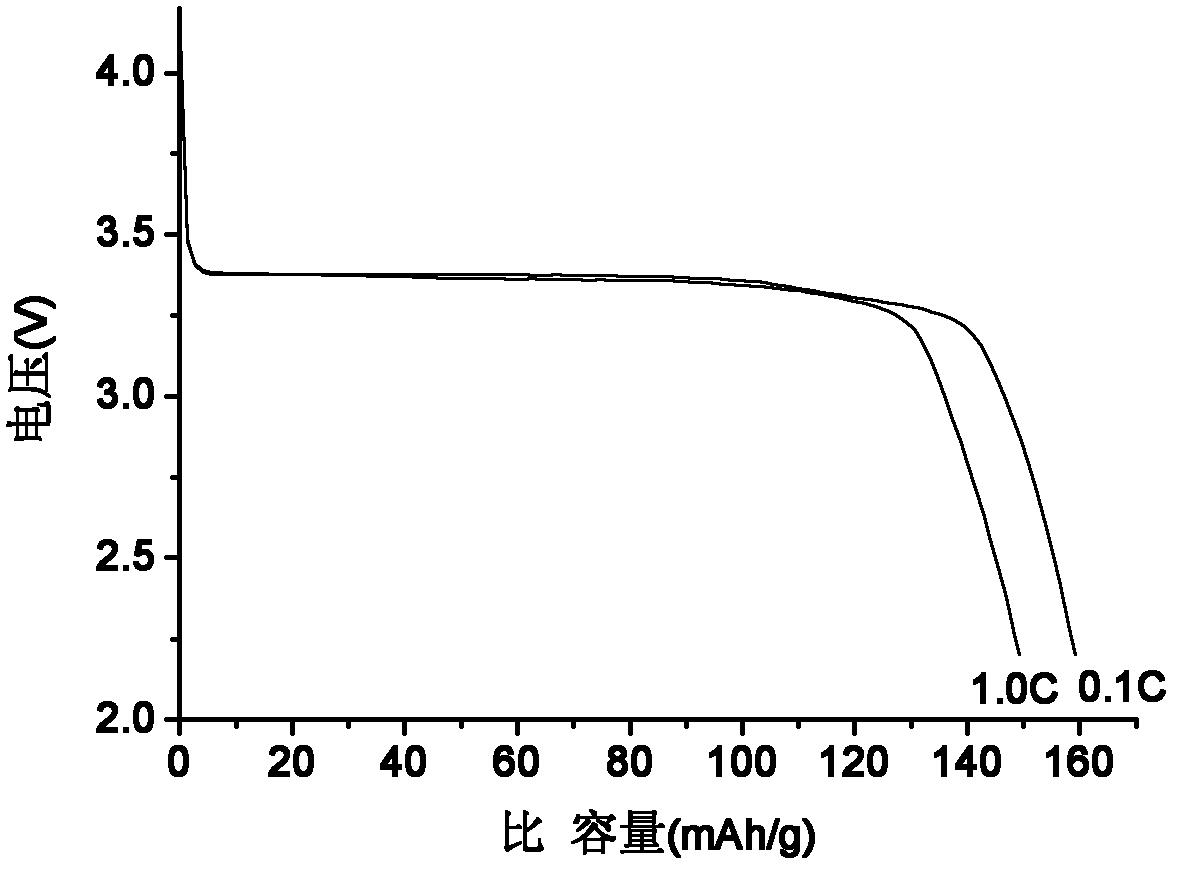

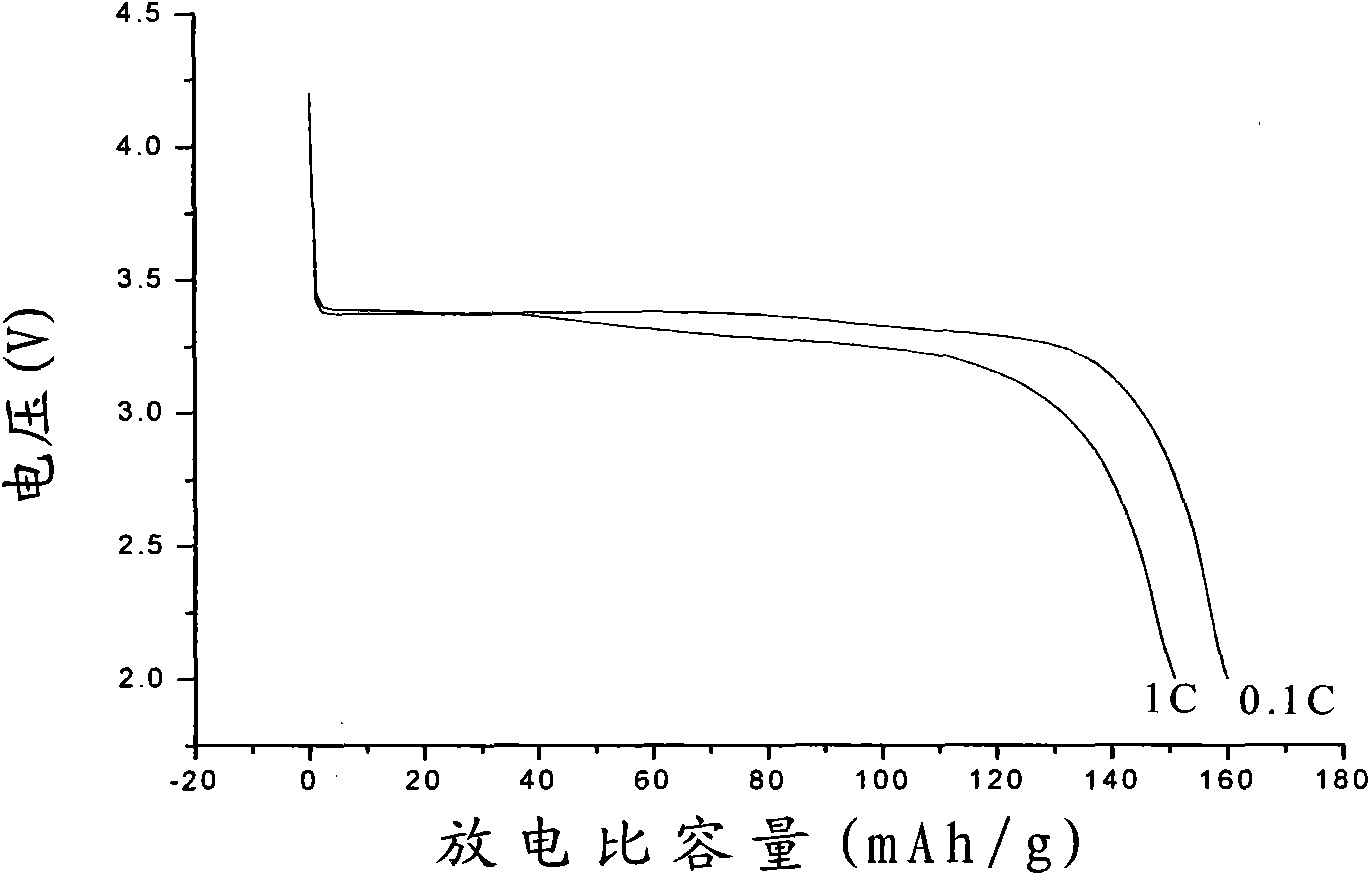

Lithium iron phosphate composite modified lithium ion battery cathode material and preparation method thereof

InactiveCN102610815ASame crystal structureHigh ion conductivityCell electrodesLithium iron phosphateRare earth

The invention discloses a lithium iron phosphate composite modified lithium ion battery cathode material and a preparation method thereof. The chemical formula of the cathode material is LiFe1-xRExPO4-REPO4 / (C+Fe2P), and a multi-phase structure with LiFe1-xRExPO4, REPO4 and Fe2P exists; REPO4, C and Fe2P are coated on the surface of the LiFe1-xRExPO4; and x ranges from 0.01 to 0.04. The method comprises the following steps of: uniformly mixing a lithium source compound, a phosphorus source compound, inorganic and organic mixed iron source compound and rare earth oxide RE2O3 so as to prepare a reaction precursor; and forging the reaction precursor so as to obtain the lithium iron phosphate composite modified lithium ion battery cathode material. The preparation method is simple and feasible and low in production cost; the prepared material has relatively high electrochemical performance and tap density; and the method is favorable for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

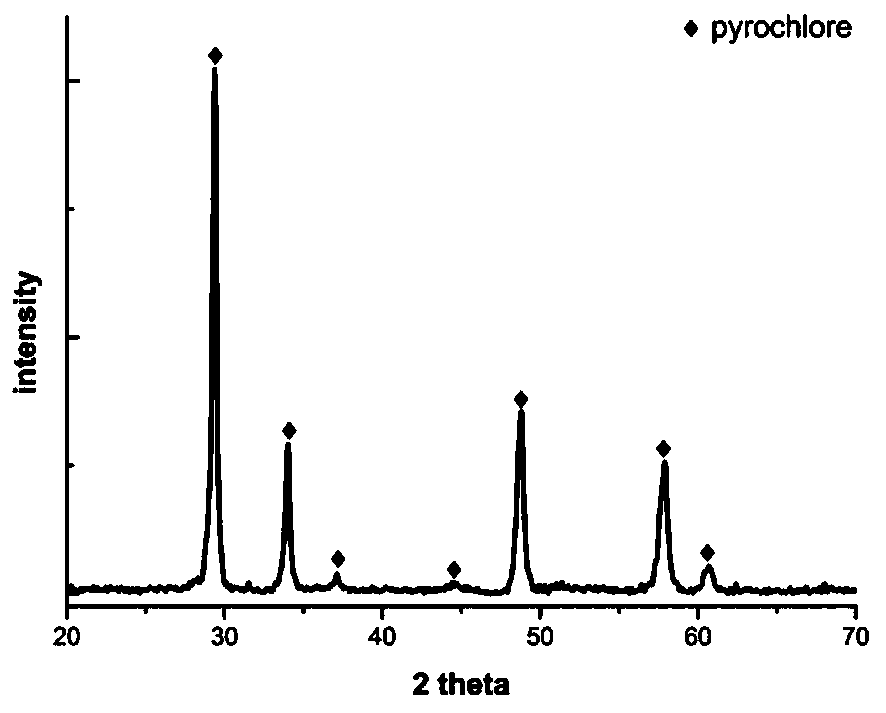

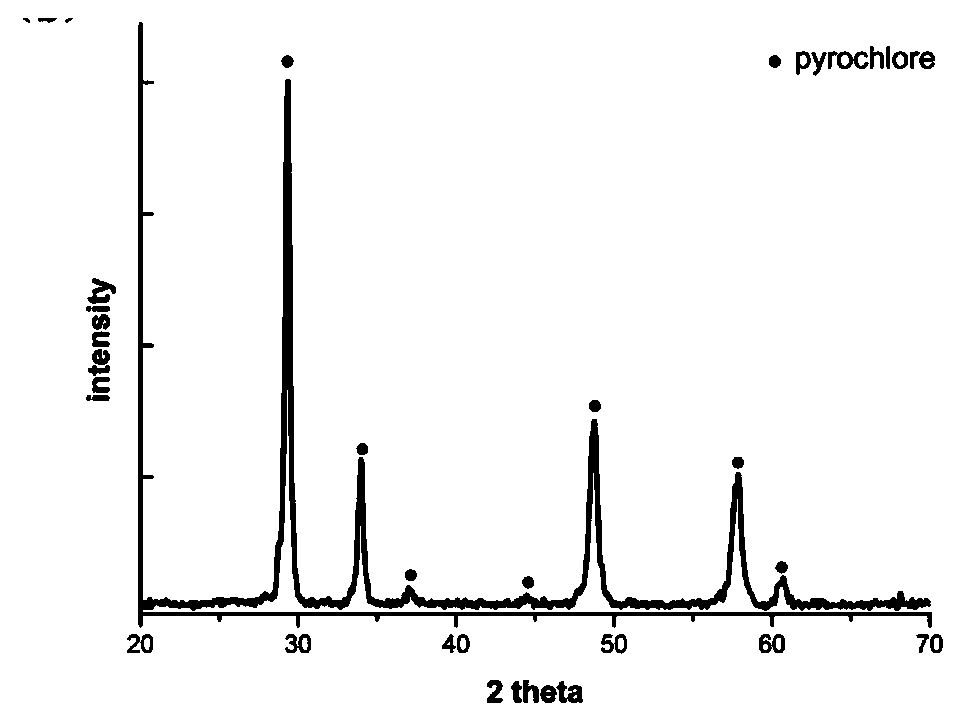

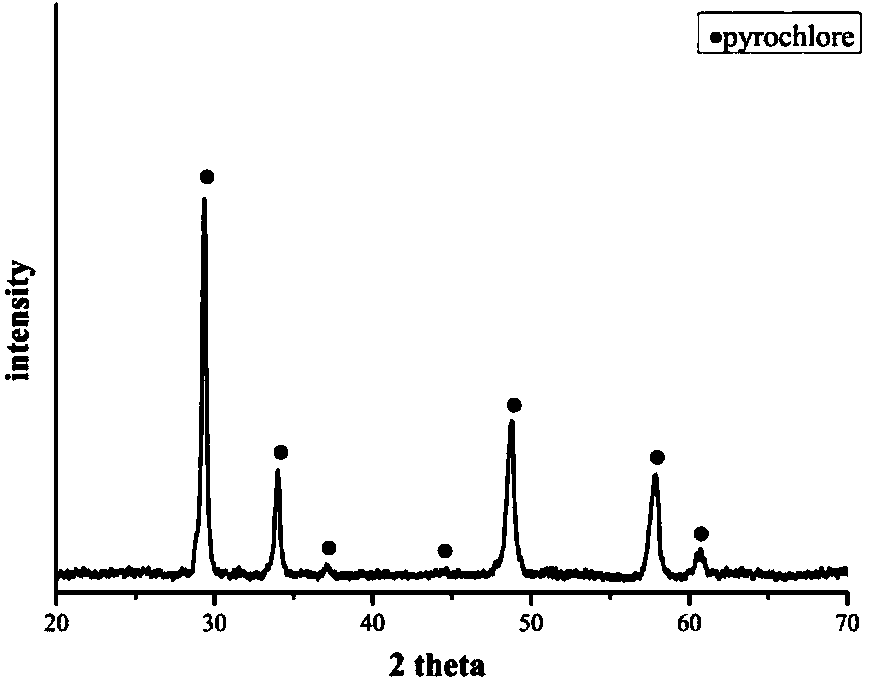

Method for rapidly curing nuclides at low temperature with assistance of electric field

InactiveCN110204332AIncrease defect concentrationShort curing timeRadioactive decontaminationSolid reactionEngineering

The invention relates to a method for rapidly curing nuclides at low temperature with the assistance of an electric field, in particular to a method for rapidly curing nuclides at the low temperaturerange of 600 DEG C or above with the assistance of the electric field, and belongs to the field of nuclear waste post-treatment. The method comprises the steps that firstly, nuclide-containing oxidesare uniformly mixed through ball milling and freeze-dried to obtain mixed powder, and then die-pressing forming is conducted; a critical electric field is applied to a sample at the temperature rangeof 600 DEG C or above, and a compound is subjected to a solid phase reaction rapidly under the function of the electric field to generate a target compound. The method has the advantages of low synthesis temperature and short time, the energy consumption is effectively reduced, the reaction time is saved, and a very convenient means is provided for low-temperature rapid synthesis of artificial rock and rapid curing of the nuclides.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Rare-earth element samarium-doped modified lithium ion battery anode material and preparation method thereof

The invention discloses a rare-earth element samarium-doped modified lithium ion battery anode material and a preparation method thereof. The method comprises the following steps of: mixing a lithium source compound, a phosphor source compound, an iron source compound, a crystalline-phase element samarium-doped compound and a carbon source compound, heating at 250-400 DEG C for 5-20h, cooling and grinding to obtain a reaction precursor; and calcining the reaction precursor at 500-800 DEG C for 10-40h, cooling to obtain an LiFe1-xSmxPO4-SmPO4 / C (x=0.01-0.04) composite rare-earth element samarium-doped modified lithium ion battery anode material. The invention can effectively control the structure and the grain diameter of the composite doped modified cathode material, improve the electronic conductivity of the material and the dispersion rate of lithium ions as well as the electrochemical performance of the material, also simplify the synthesis process of the material and be convenient for industrial mass production.

Owner:SOUTH CHINA UNIV OF TECH

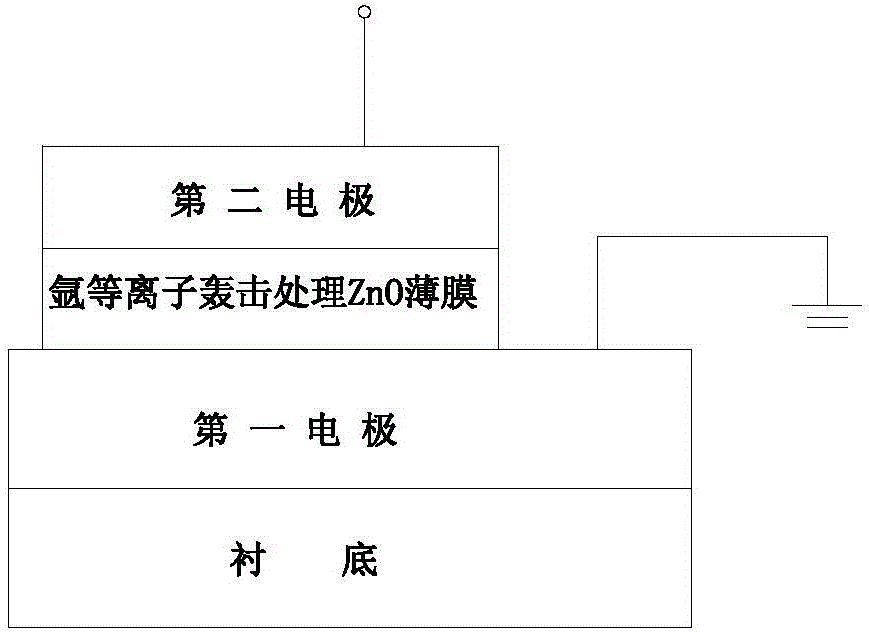

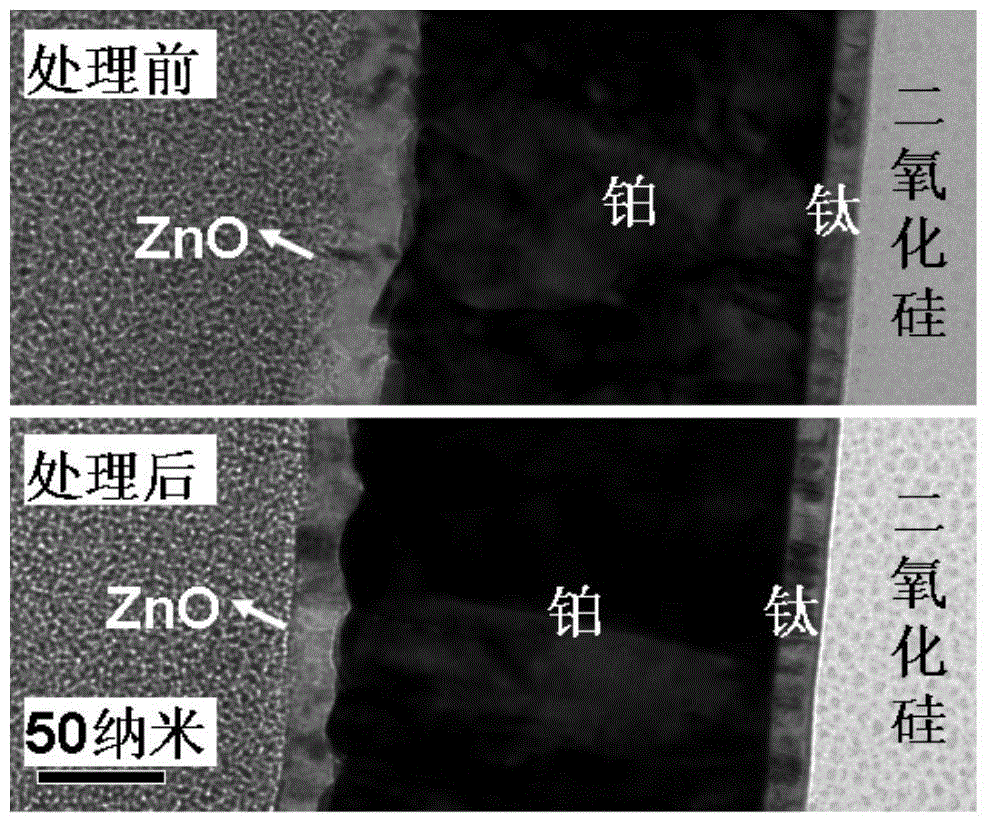

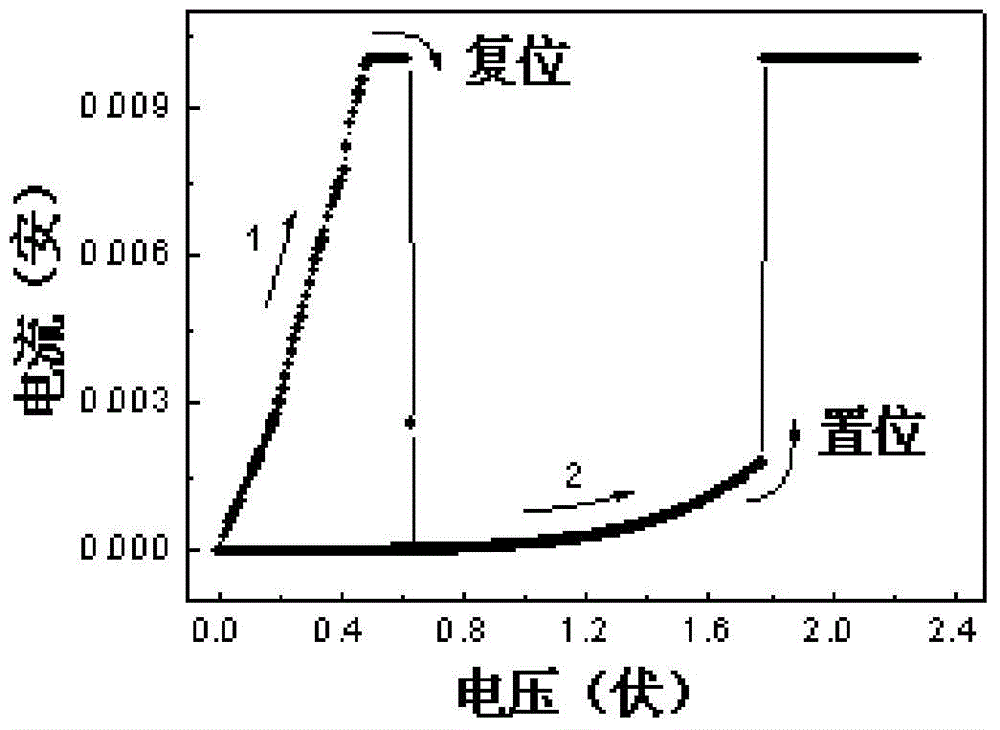

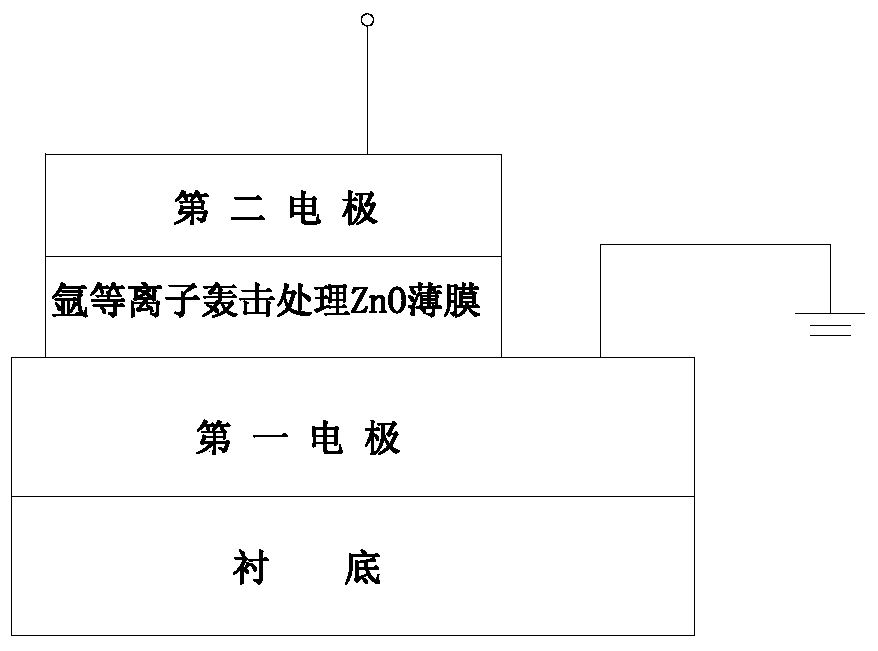

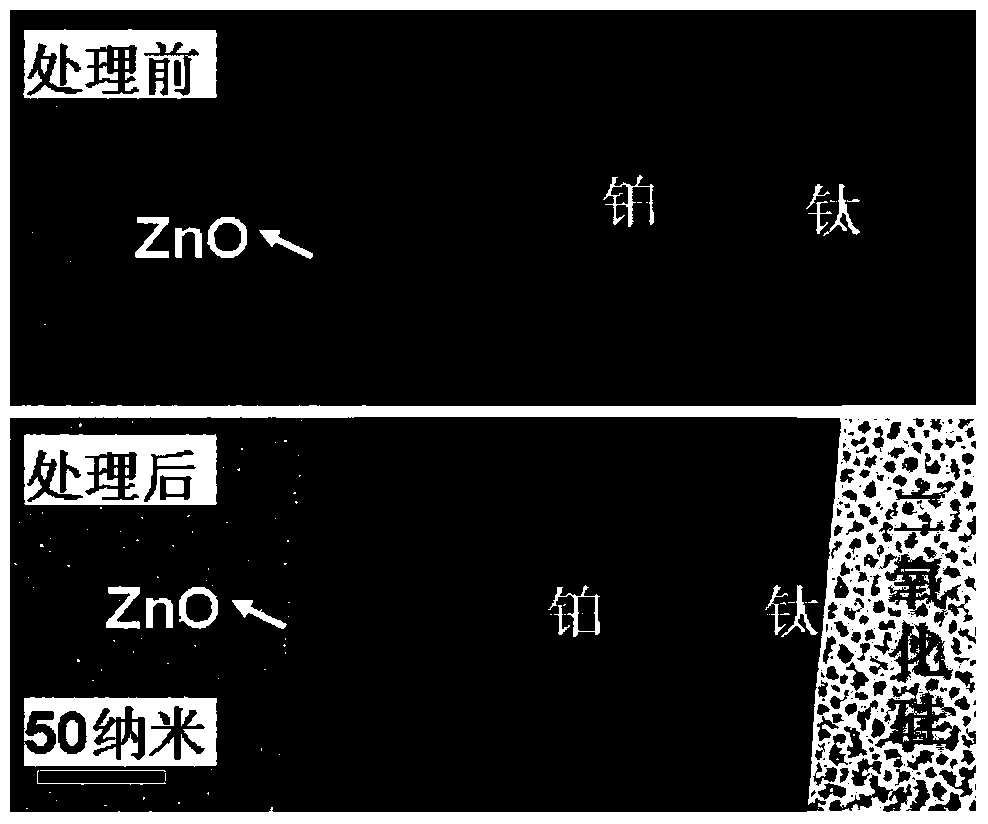

Preparation method for memory cell of resistive random access memory and product thereof

ActiveCN105098065AIncrease concentrationLower initial resistanceElectrical apparatusMedia layerArgon

The invention discloses a preparation method for a memory cell of a resistive random access memory. The method includes: step 1, a conductive film as a first electrode is formed on the surface of a substrate; step 2, a ZnO film through argon plasma bombardment treatment as an intermediate layer is prepared on the surface of the first electrode obtained by the step 1; step 3, a conductive film as a second electrode is prepared on the surface of the intermediate layer obtained by the step 2; and step 4, an isolation device is prepared on the structural basis obtained by the step 3, and the memory cell of the resistive random access memory is obtained. According to the preparation method for the memory cell of the resistive random access memory, the argon plasma bombardment treatment of the ZnO film as the intermediate medium layer is performed so that the flatness of the surface of the ZnO film is greatly improved; and the ZnO film through argon plasma bombardment treatment serves as the memory prepared by the intermediate layer, the initial presentation is the low-resistance state, the wiping of all the devices does not need the process of electric forming, and the wiping voltage is low.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

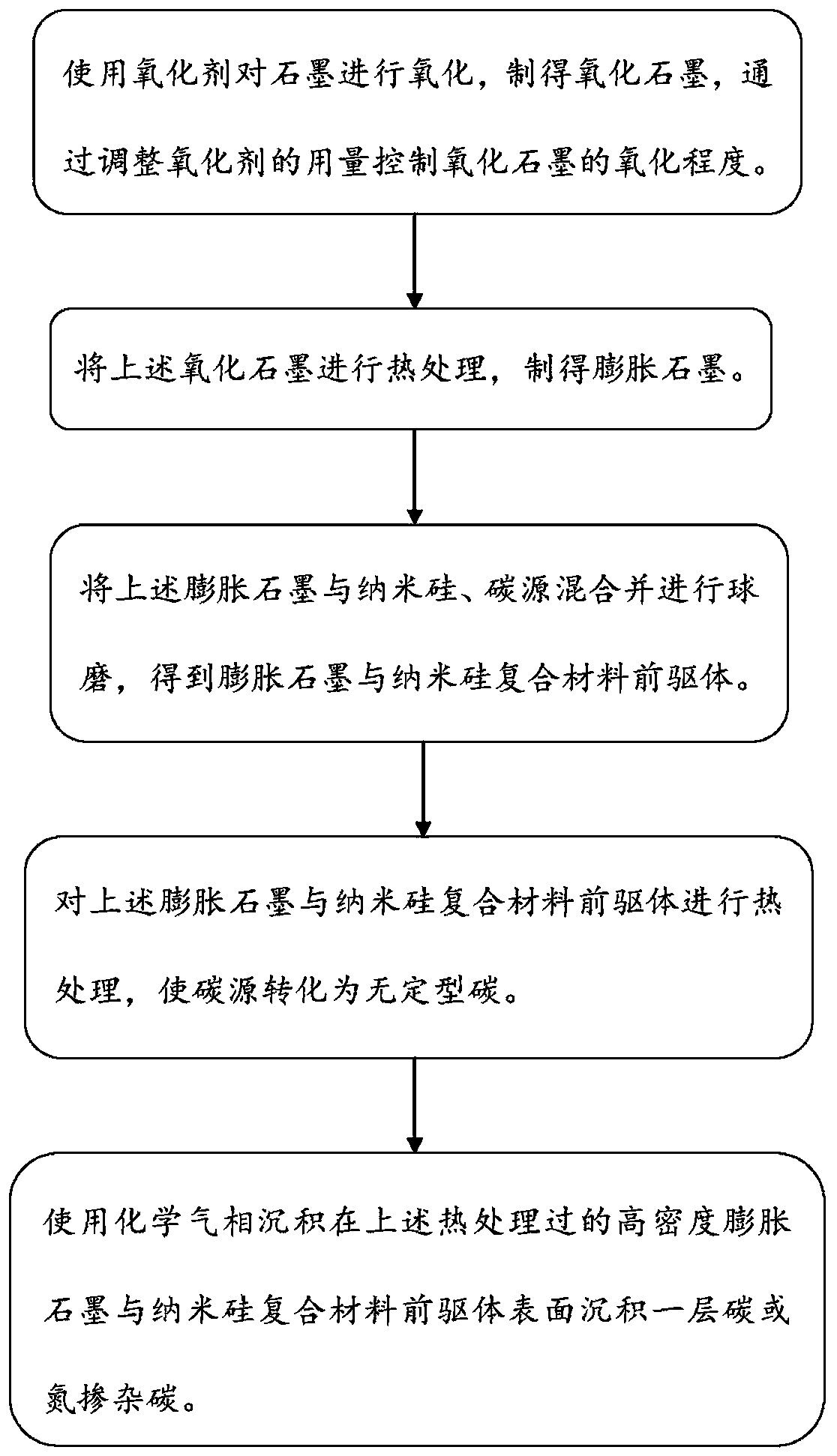

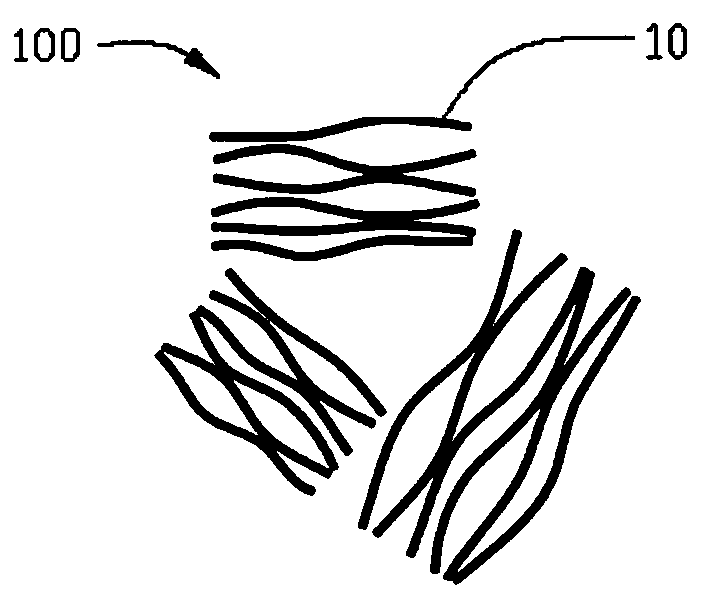

Expanded graphite and nano-silicon composite material and preparation method thereof, electrode sheet, battery

ActiveCN105355870BHigh tap densityHigh solid densityMaterial nanotechnologyCell electrodesNano siliconHigh density

The invention provides a preparation method of a high-density expanded graphite and nano-silicon composite material. The preparation method comprises the following steps: step S1, oxidizing graphite to manufacture graphite oxide; step S2, carrying out heat treatment on the graphite oxide to manufacture expanded graphite; step S3, mixing the expanded graphite with nano-silicon and a carbon source and carrying out ball-milling to obtain a high-density expanded graphite and nano-silicon composite material precursor comprising a plurality of graphite layers, the carbon source and the nano-silicon filled among the graphite layers; step S4, carrying out heat treatment on the high-density expanded graphite and nano-silicon composite material precursor so that the carbon source is converted into amorphous carbon; and step S5, depositing carbon or doped carbon on the surface of the high-density expanded graphite and nano-silicon composite material precursor after the heat treatment. Moreover, the invention also provides the high-density expanded graphite and nano-silicon composite material, an electrode plate applying the high-density expanded graphite and nano-silicon composite material, and a lithium ion battery applying the electrode plate.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for improving electrochemical performance of lithium battery positive electrode coating material

InactiveCN110176596AImprove stabilityHigh specific capacitySecondary cellsPositive electrodesHydroxyl ionOxide coating

The invention discloses a method for improving electrochemical performance of a lithium battery positive electrode coating material; the method for preparing the lithium battery positive electrode coating material comprises the following steps of weighing a certain amount of metal salt and / or alkali formed by metal ions and hydroxyl ions, and mixing the metal salt and / or alkali into a certain amount of low-carbon alcohol, and carrying out heating and dissolving to obtain a solution A; under the condition of mechanical stirring, adding a precipitant into the solution A, so that mixed latex is obtained; enabling the mixed sol obtained in the step (2) to be continuously stirred to obtain oxide sol; weighing a certain amount of positive electrode material powder, adding into the oxide sol obtained in the step (3), mixing under the mechanical stirring condition and standing, and washing the lower-layer precipitate, and drying to obtain the oxide coating-coated positive electrode material powder; and mixing the positive electrode material powder with a strong reducing agent, putting into a furnace, and carrying out heating and cooling to obtain a final product.

Owner:启东启澳新材料科技发展有限公司

Near-infrared high-afterglow material and preparation method thereof

ActiveCN107057697AImprove performanceExcellent afterglow performanceLuminescent compositionsAlcoholSolvent

The invention relates to a near-infrared high-afterglow material and a preparation method thereof and aims to solve the technical problem that existing near-infrared long-afterglow materials are weak in afterglow intensity and short in afterglow time. A molecular formula of the near-infrared high-afterglow material is (Zn1-xCax)3(Ga0.995Cr0.005)2G22O10, wherein x is greater than or equal to 0.01 and smaller than or equal to 0.03. The preparation method includes: well mixing zinc oxide, calcium oxide, gallium oxide, chromium oxide and germanium oxide according to a chemical dosage ratio, adding a mixture into water, boiling the water, and adding nitric acid to dissolve the oxides to obtain a solution; mixing the solution with a mixed solution of water, alcohol and oleic acid to obtain a mixed solution, and performing hydrothermal reaction to obtain a solid-phase product; subjecting the solid-phase product to pre-sintering and high-temperature sintering to obtain the near-infrared high-afterglow material. The near-infrared high-afterglow material can be used in the technical field of bioluminescent imaging.

Owner:HARBIN INST OF TECH

Preparation method of defect-rich metal oxide (sulfide)/graphene oxide composite material

InactiveCN110280232ABandgap width narrowedEasy to operateMetal/metal-oxides/metal-hydroxide catalystsMetallic lithiumElectrochemical response

The invention provides a preparation method of a defect-rich metal oxide (sulfide) / graphene oxide composite material. A metallic lithium sheet, a graphene oxide sol and a selected oxide or sulfide are uniformly stirred in a liquid phase, and the obtained mixture is washed and dried to obtain the composite material having a certain defect concentration. The stirring step of the method is carried out in an anoxic and anhydrous environment, and excess hydrochloric acid is added after a sufficient reaction in order to remove the remaining lithium sheet. The material prepared in the invention has a large number of surface defects, so photochemical and electrochemical reactions can be easily promoted; and compounding of metal oxide (sulfide) with the graphene oxide can greatly expand the light absorption range, increase the specific surface area and improve the conductivity, so the photochemical and electrochemical properties of the oxide (sulfide) material are improved. The method is carried out at room temperature, has the advantages of simplicity in operation, and low cost, and provides a new idea for the preparation of photocatalysts and energy storage materials.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

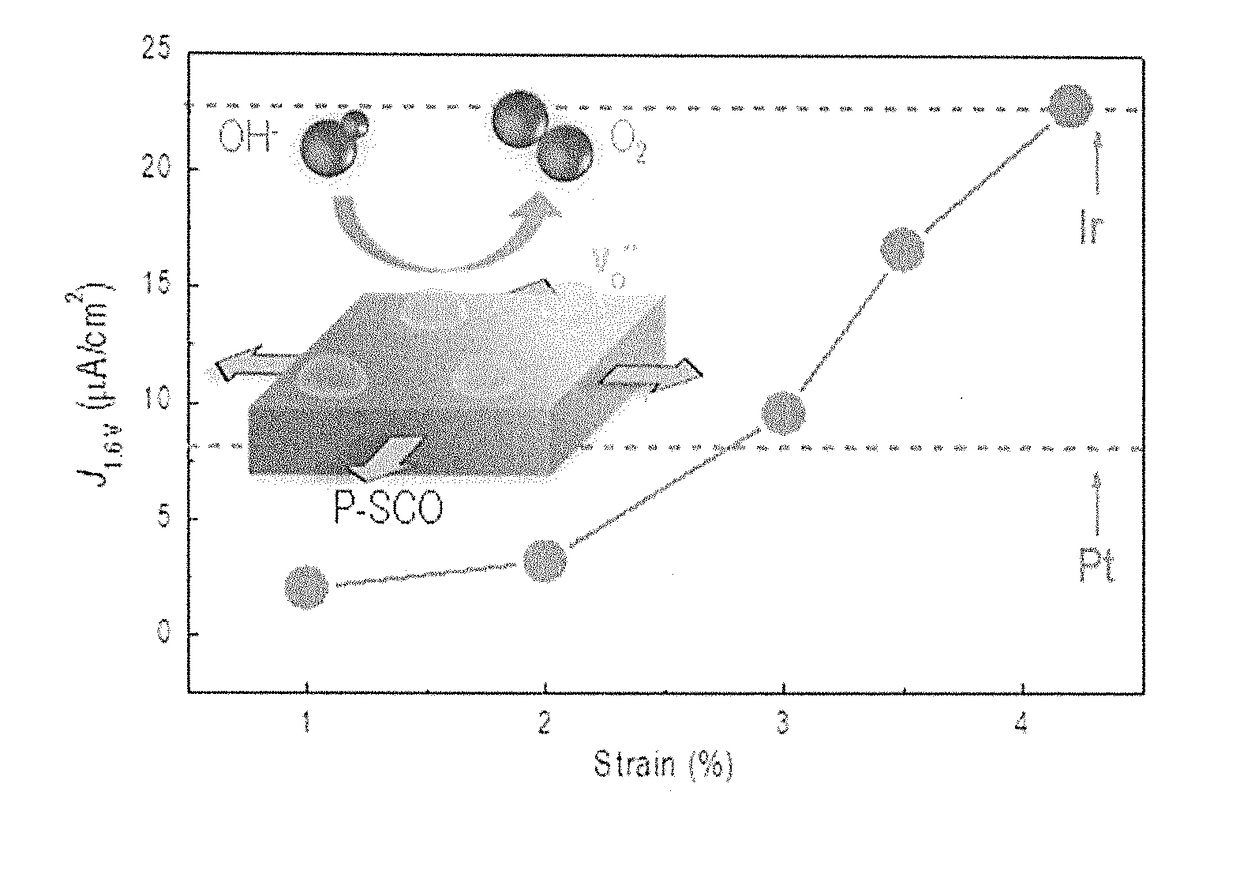

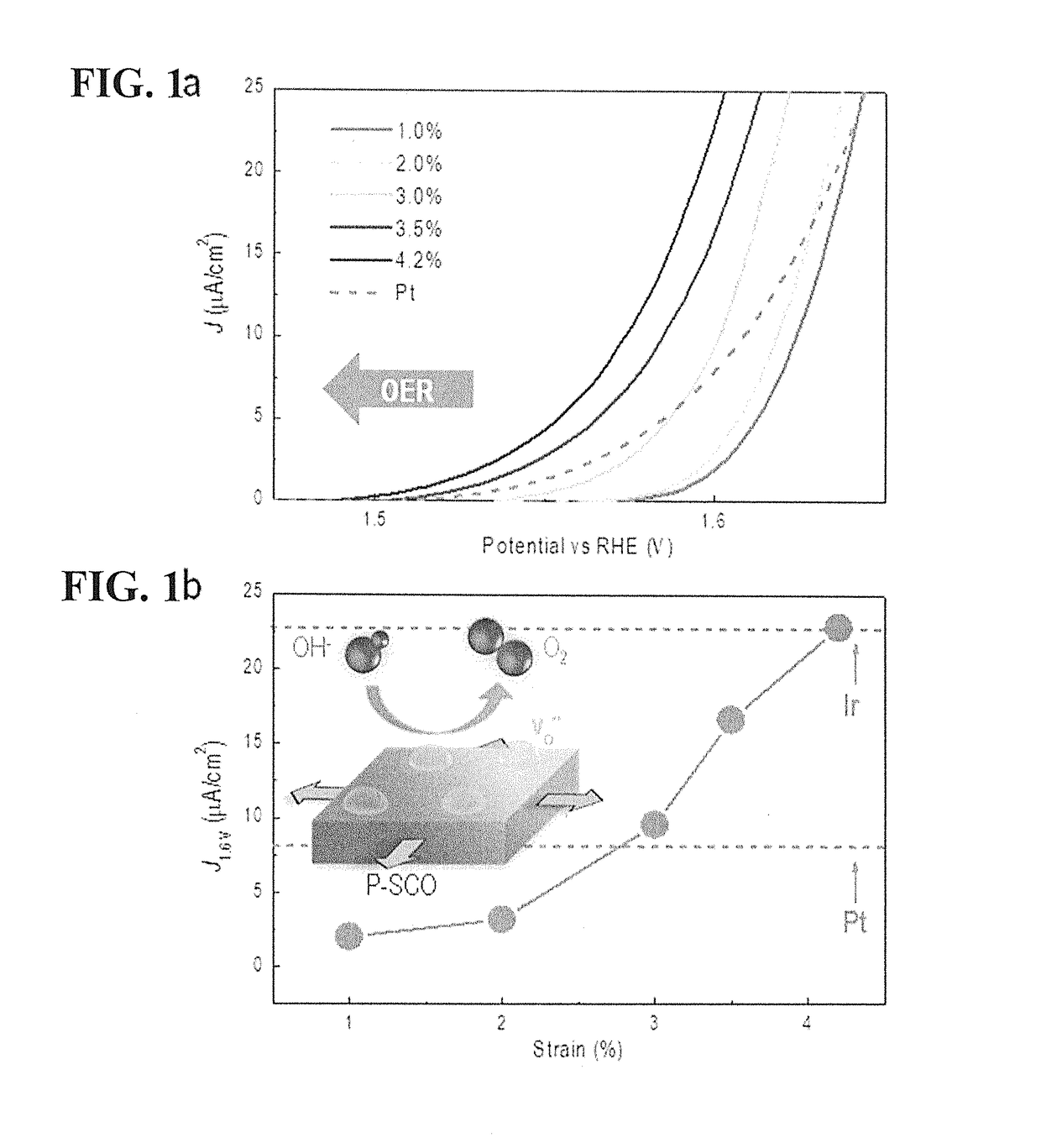

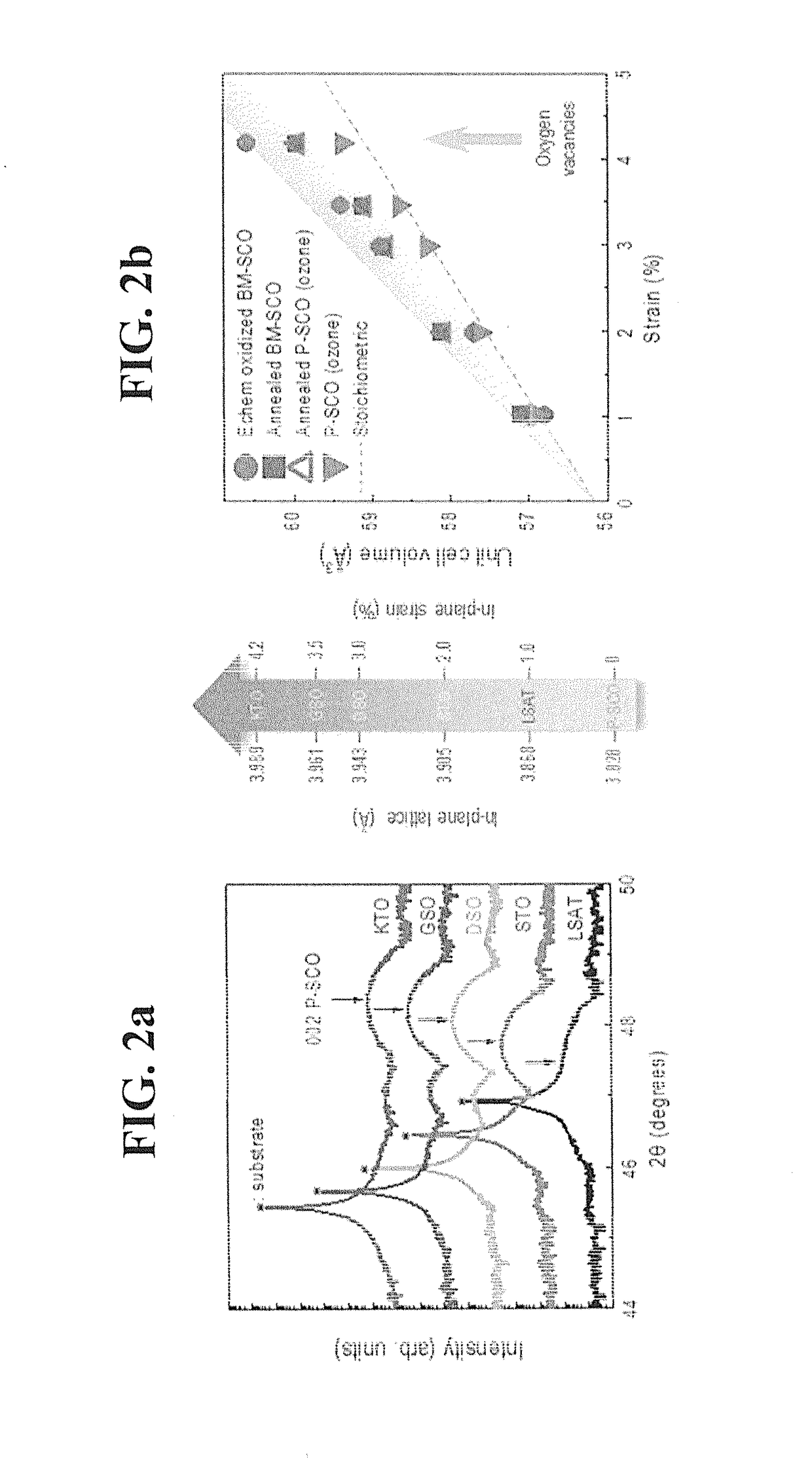

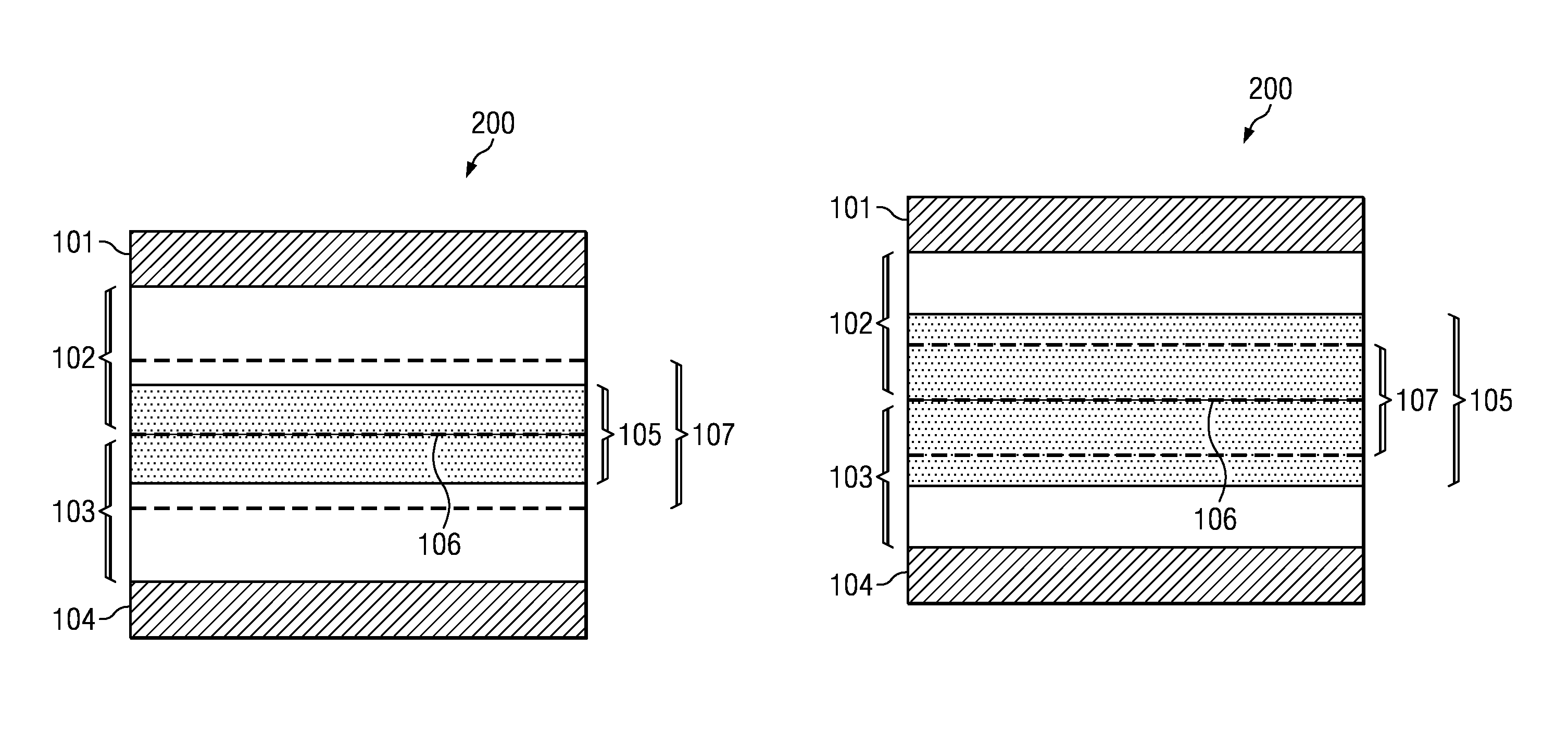

Strain enhancement of functional oxygen defects in electrochemical metal oxides

InactiveUS20170077522A1High catalytic activityAccurately tailoredPolycrystalline material growthAfter-treatment detailsTensile strainOxygen vacancy

Methods for tailoring an oxygen defect concentration, such as oxygen vacancies, in a transition metal oxide and the resulting materials are provided. An epitaxial strain, such as in the form of a biaxial tensile strain of up to 5%, is applied to the transition metal oxide to increase the oxygen defect concentration in the transition metal oxide to result in a product comprising the transition metal oxide having an increased oxygen defect concentration.

Owner:UCHICAGO ARGONNE LLC +1

Avalanche diode having an enhanced defect concentration level and method of making the same

ActiveUS8791547B2Reliable and fast turn-onIncrease defect concentrationTransistorSemiconductor/solid-state device detailsPower flowNitrogen

The invention relates to an avalanche diode that can be employed as an ESD protection device. An avalanche ignition region is formed at the p-n junction of the diode and includes an enhanced defect concentration level to provide rapid onset of avalanche current. The avalanche ignition region is preferably formed wider than the diode depletion zone, and is preferably created by placement, preferably by ion implantation, of an atomic specie different from that of the principal device structure. The doping concentration of the placed atomic specie should be sufficiently high to ensure substantially immediate onset of avalanche current when the diode breakdown voltage is exceeded. The new atomic specie preferably comprises argon or nitrogen, but other atomic species can be employed. However, other means of increasing a defect concentration level in the diode depletion zone, such as an altered annealing program, are also contemplated.

Owner:INFINEON TECH AG

Fuel-cell catalyst doping with porous diamond carrier and preparation method

InactiveCN108777310AHigh catalytic activityImprove structural stabilityMaterial nanotechnologyCell electrodesAlloy compositeOxidation resistant

The invention provides a fuel-cell catalyst doping with a porous diamond carrier and a preparation method. A flaky metal electrode material is used as a substrate; an arc plasma is used for depositinga diamond film on a surface layer; a used gas source is hydrogen, argon and methane; a mixed gas of the hydrogen and the methane is sprayed through a nozzle in a plasma muzzle; the argon and a gas-state / steam-state doping source is sprayed through a nozzle outside the muzzle by loading nano platinum / tin alloy powder, and a composite material doping with porous diamond / alloy is formed on the surface layer of the substrate. According to the fuel-cell catalyst doping with the porous diamond carrier and a preparation method provided by the invention, the porous nano diamond is used as a carrier for coating the nano alloy, and the porous nano diamond is used as the carrier so as to have high oxidation resistance and good active metal dipersibility, so that the stability of the catalyst is improved, and the defect that the catalytic activity of the catalyst is further reduced since the active metal dipersibility cannot be controlled when current nano diamond particles are used as the carrier is further overcome.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Synthetic calcium magnesite and preparation method thereof

InactiveCN102285806BHigh purityNo damage to high temperature performanceCalcium hydroxideMechanical press

The invention relates to synthetic calcium magnesite and a preparation method thereof. The preparation method comprises the steps of firstly carrying out ball milling on 25-30wt% of calcium hydroxide and 70-75wt% of magnesium hydroxide to reach the grain size within 30 mu m, heating the ball-milled mixture in a muffle furnace to 700-900 DEG C, and insulating heat for 0.25-0.5 hour; adding water the amount of which is 20-25wt% of the mixture to the calcined mixture, and digesting for 1-2 hours; and then adding an additive the amount of which is 1-3wt% of the digested mixture to the digested mixture, stirring, carrying out mechanical press shaping by a semi-dry method, naturally drying for 12-15 hours, baking at the temperature of 100-120 DEG C for 12-15 hours, finally firing in a high-temperature furnace at the temperature of 1600-1750 DEG C, insulating heat for 3-5 hours and crushing to obtain the synthetic calcium magnesite. The preparation method provided by the invention has the advantages of simple process and no need for special synthesis equipment and treatment technology. The synthesized calcium magnesite has the characteristics of high purity, wide application range, good sintering performance, good hydration resistance, and no influence on high-temperature use performance.

Owner:WUHAN UNIV OF SCI & TECH

A silicon carbide thin film and resistive variable memory

ActiveCN105977379BIncrease defect concentrationGood resistive propertiesElectrical apparatusThin membraneSilicon oxide

Owner:ZHEJIANG NORMAL UNIVERSITY

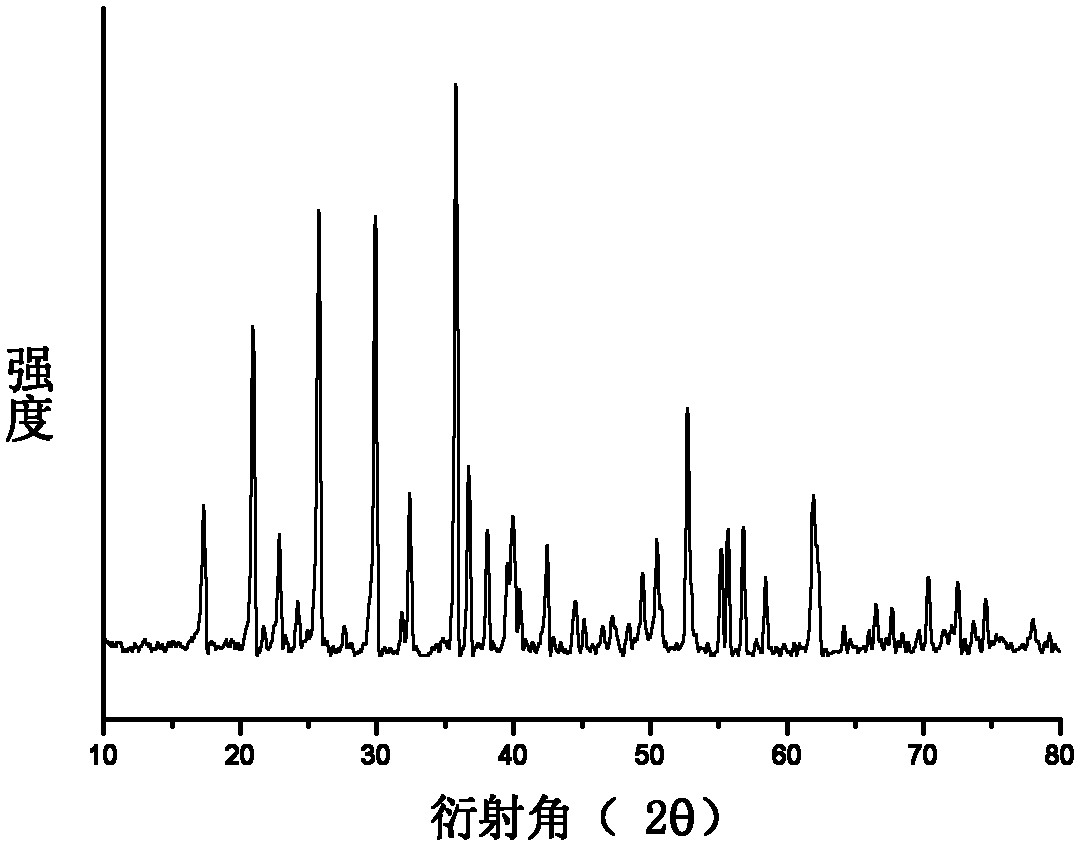

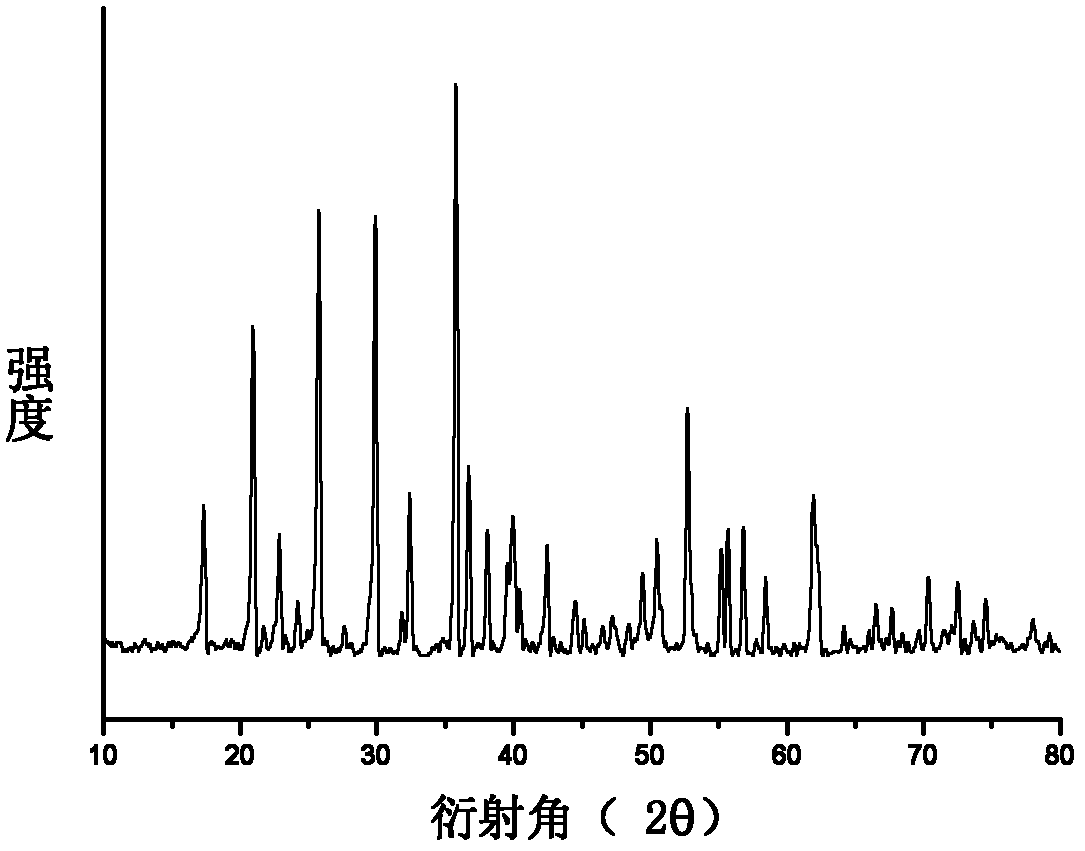

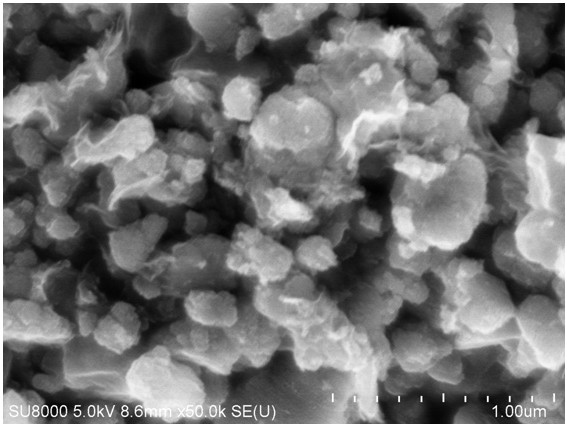

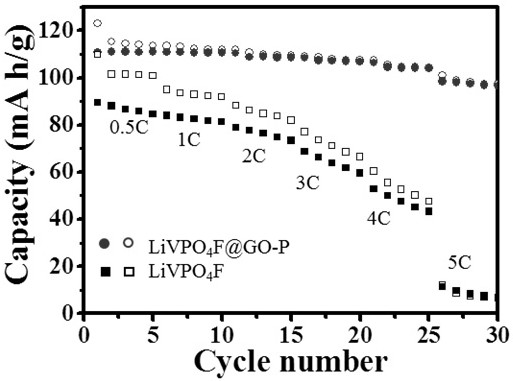

Aluminum-doped lithium vanadium fluorophosphate/phosphatized graphene oxide composite material and preparation method thereof, and application in lithium ion battery

PendingCN112018365AImprove conductivitySimple processSecondary cellsPositive electrodesGraphene coatingFreeze-drying

The invention discloses an aluminum-doped lithium vanadium fluorophosphate / phosphatized graphene oxide composite material and a preparation method thereof, and application in a lithium ion battery. The preparation method adopts a step-by-step process and comprises the following steps: (1) preparing a lithium vanadium phosphate / graphene composite material precursor by a microwave solvothermal method; (2) preparing an aluminum-doped lithium vanadium fluorophosphate / phosphatized graphene oxide composite material by a molten salt method; and (3) washing the sample, and carrying out freeze drying to obtain the pure-phase aluminum-doped lithium vanadium fluorophosphate / phosphatized graphene oxide composite material. According to the invention, the composite material can be obtained through one-time sintering, the used process is simple, the sample purity is high, graphene coating is uniform, the ionic and electronic conductivity of the composite material is obviously improved, and the assembled lithium ion battery has excellent electrochemical performance.

Owner:福建巨电新能源股份有限公司

A preparation method and product of a storage unit of a resistive random access memory

ActiveCN105098065BErase and write voltage is smallIncrease defect concentrationElectrical apparatusRandom access memoryThin membrane

The invention discloses a method for preparing a storage unit of a resistance random access memory. Step 1, forming a conductive film on the surface of a substrate as a first electrode; Step 2, preparing an argon plasma bombardment treatment on the surface of the first electrode obtained in step 1 The ZnO thin film is used as the intermediate layer; step 3, the conductive film is prepared on the surface of the intermediate layer obtained in step 2 as the second electrode; step 4, an isolated device is prepared on the basis of the structure obtained in step 3, and the resistive random access memory is obtained storage unit. The invention provides a method for preparing a storage unit of a resistive random access memory, which performs argon plasma bombardment treatment on a ZnO thin film as an intermediate medium layer, thereby greatly improving the flatness of the surface of the ZnO thin film; ZnO treated with the argon plasma bombardment The memory prepared by the thin film as the intermediate layer initially exhibits a low-resistance state, and the erasing and writing of all devices does not require an electrical formation process, and the erasing and writing voltage is relatively small.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

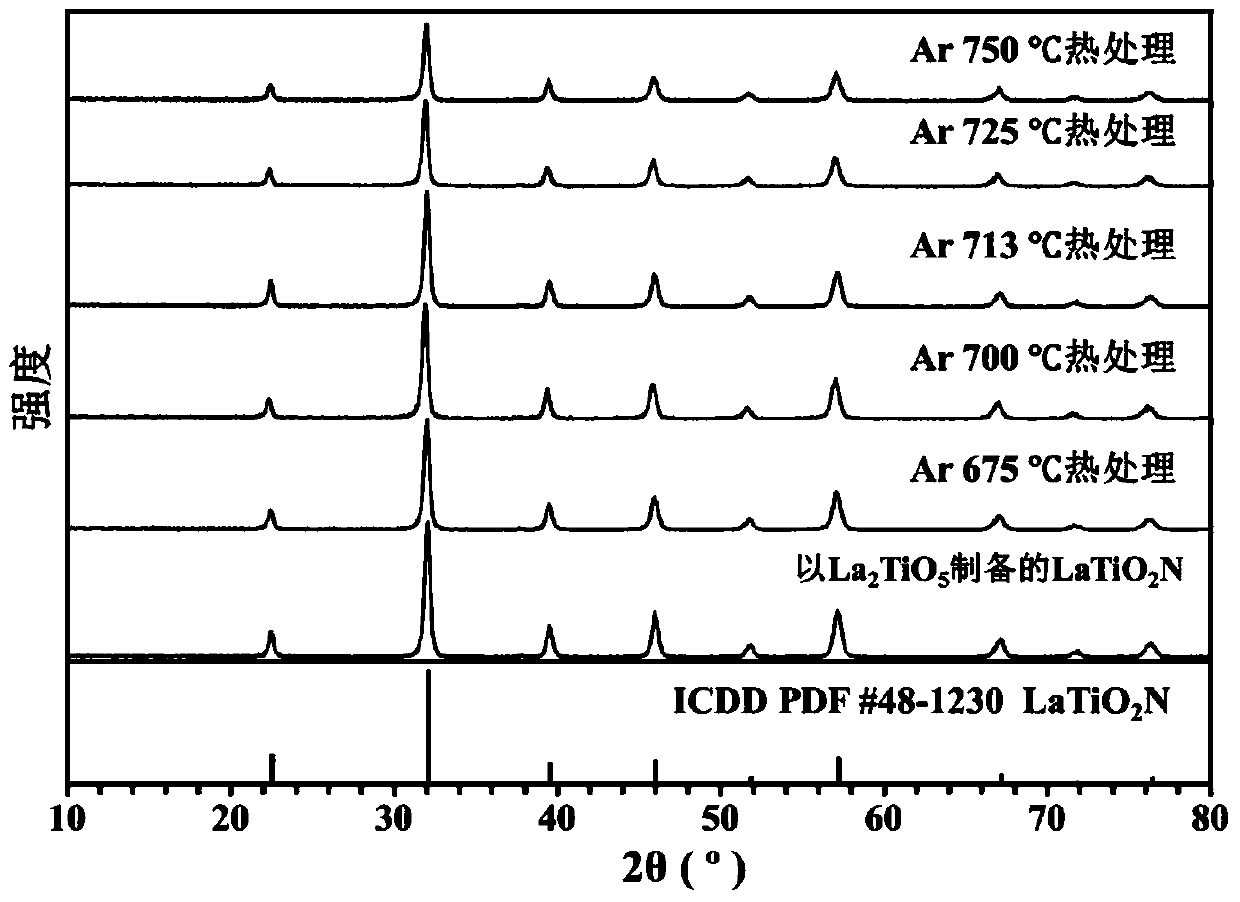

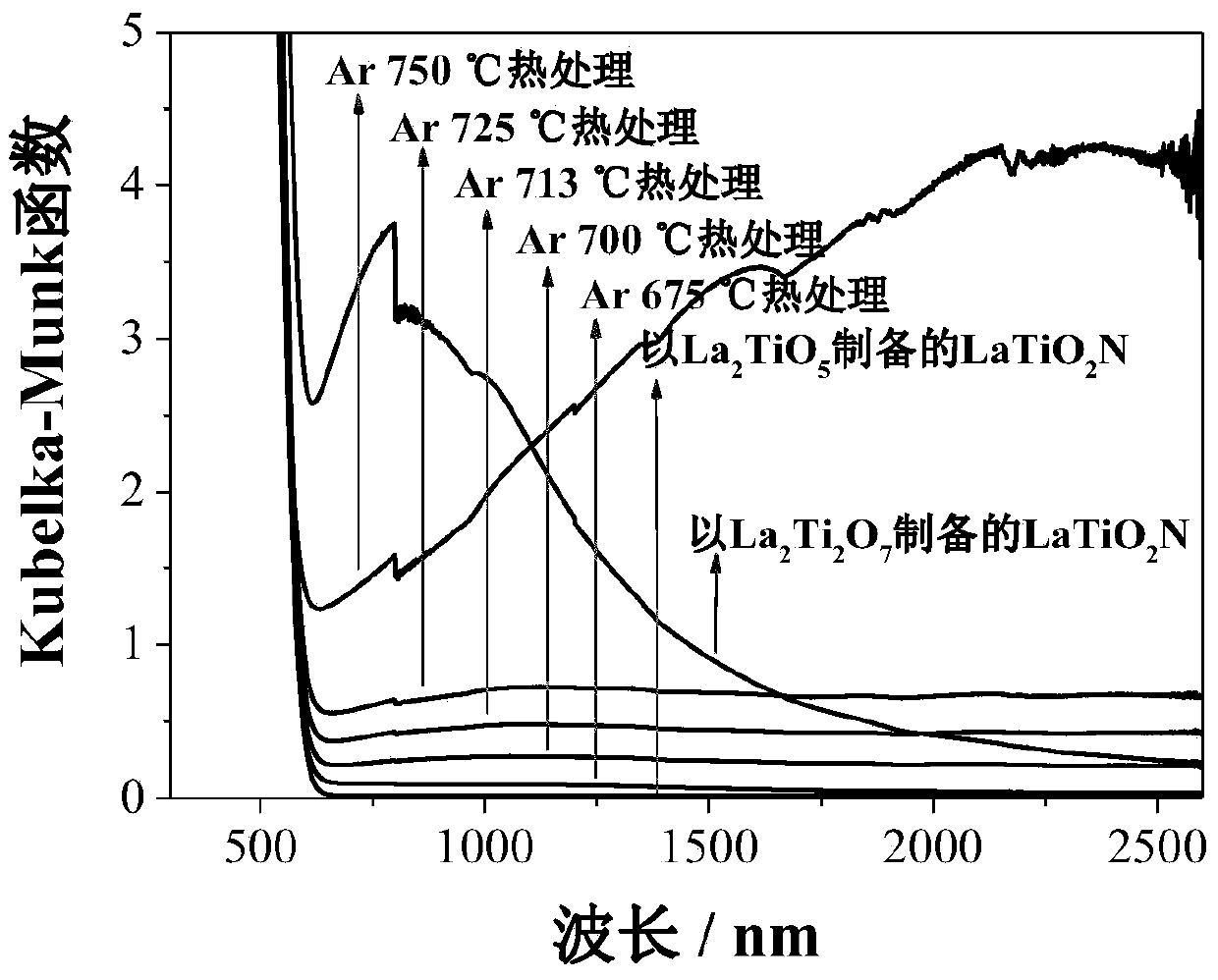

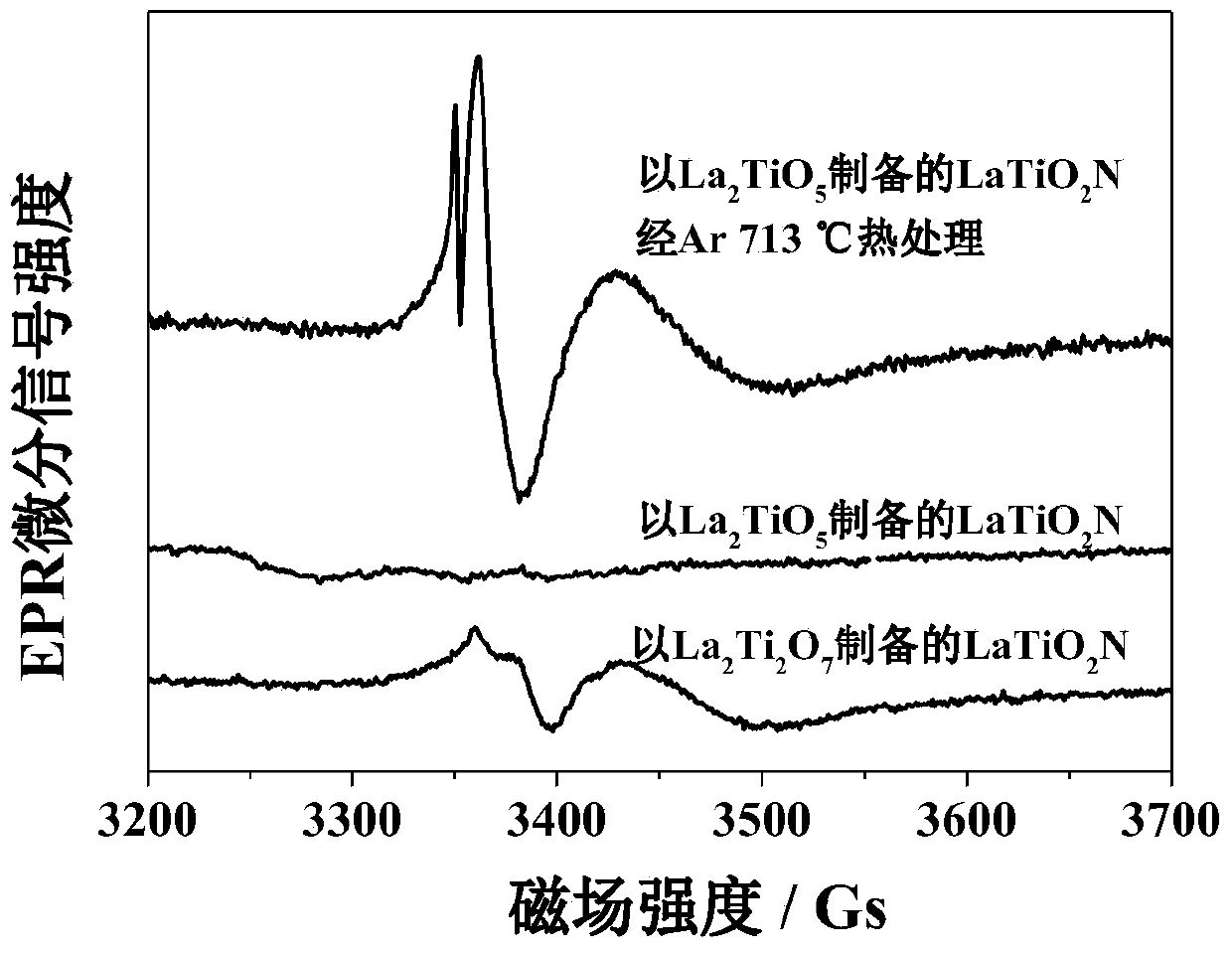

Perovskite-type lanthanum-titanium oxynitride semiconductor photocatalyst and its preparation and application

ActiveCN107583661BInhibition decreasedInhibition formationPhysical/chemical process catalystsOxygen preparationPhysical chemistryLanthanum

Take La 2 TiO 5 As a single precursor, thermal ammonolytic nitridation was performed in a high temperature ammonia atmosphere to prepare LaTiO with absorption band edges around 600 nm without defects detectable by EPR and UV‑Vis‑NIR spectroscopy 2 N semiconductor, annealed in inert atmosphere to obtain LaTiO with adjustable defect concentration 2 N, increasing LaTiO 2 N photocatalytic activity. or with La 2 Ti 2 O 7 As a single precursor, thermal ammonolysis nitridation under high temperature ammonia atmosphere to prepare LaTiO with defects 2 N semiconductor, inert atmosphere annealing treatment further increases defect concentration and improves LaTiO 2 N photocatalytic activity. In this method, La 2 TiO 5 As a precursor, it can effectively inhibit the reduction of Ti in the high-temperature nitridation process, inhibit the formation of low-valent Ti defects or impurity phases, and provide a comprehensive basis for the regulation of defect concentration; simple inert atmosphere annealing is used to form anion vacancy defects, and by changing the annealing process, anion vacancy defects are formed. The parameters can easily adjust the defect concentration to realize the optimization of photocatalytic activity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Piezoelectric Component and Method for Producing a Piezoelectric Component

ActiveUS20140232238A1Improve propertySufficient sinter densificationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallurgyRare earth

A piezoelectric component has at least one piezoelectric ceramic layer and at least one electrode adjacent the piezoelectric ceramic layer. The piezoelectric ceramic layer has a piezoelectric ceramic material of the general formula Pb1-x-y-[(2a-b) / 2]-p / 2V[(2a-b) / 2-p / 2]″CupBaxSry[(TizZr1-z)1-a-bWaREb]O3, where 0≦x≦0.035, 0≦y≦0.025, 0.42≦z≦0.5, 0.0045≦a≦0.009, 0.009≦b≦0.011, 2a>b, p≦2a-b, RE is a rare earth metal, and V″ is a Pb vacancy.

Owner:EPCOS AG

Antibacterial edge band as well as preparation method and application thereof

The invention provides an antibacterial edge band and a preparation method and application thereof.The method includes the steps that PVC resin, a lubricant, auxiliaries, toner and a nano magnesium-based active factor antibacterial material are evenly mixed in a powdering machine, colloidal particles are prepared through a parallel twin-screw granulator, and the addition amount of the nano magnesium-based active factor antibacterial material is 0.5-1%; and extruding and molding the colloidal particles by a conical double-screw extruder at 160-170 DEG C, pressing textures, and printing to obtain the antibacterial edge band. The prepared nano magnesium-based active factor antibacterial material for the antibacterial edge band is small in mixing amount, uniform, low in cost and excellent in antibacterial effect, and the performance of the edge band is not affected.

Owner:CENT SOUTH UNIV +1

Method for preparing conductive powder by recoating aluminum-doped nano zinc oxide with aluminum

InactiveCN103570056BHigh whitenessIncrease defect concentrationMaterial nanotechnologyZinc oxides/hydroxidesAluminum doped zinc oxideZno nanoparticles

The invention discloses a method for preparing conductive powder by recoating aluminum-doped nano zinc oxide with aluminum. The method comprises the following steps: firstly, preparing aluminum-doped zinc oxide powder; secondly, coating the aluminum-doped zinc oxide powder with an aluminum-containing film; finally, mixing the coated aluminum-doped zinc oxide powder with zinc powder, grinding, and calcining in an inert gas atmosphere to obtain the conductive powder. The method has the advantages that the zinc oxide conductive powder is prepared through primary aluminum doping and secondary aluminum coating, the primary aluminum doping improves the whiteness and the water dispersion of the nano zinc oxide and reduces the particle size of the nano zinc oxide, and the secondary aluminum coating further increases the defect concentration of zinc oxide crystals and improves the conductivity of the nano zinc oxide; the aluminum-doped zinc oxide is coated with a thin oxide film, so that zinc ions in water are unlikely to dissolve out, and the ball milling process of the zinc powder and the aluminum-doped zinc oxide is facilitated; the prepared conductive powder is high in conductive ability, small in particle size, light in color, wide in sources of raw materials, low in production cost, simple in preparation method, high in security, relatively light in environmental pollution, and suitable for industrial mass production.

Owner:JIANGSU DONGTAI FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com