Antibacterial edge band as well as preparation method and application thereof

An edge banding and antibacterial sealing technology, applied in the field of home furnishing materials, can solve the problems of uneven coating, short validity period, reduced antibacterial performance, etc., and achieve the effect of increasing the concentration of lattice defects, excellent antibacterial effect, and improving antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a preparation method of antibacterial edge banding, comprising;

[0037] S1. Provide raw materials such as PVC resin, lubricant, additives, toner, and nano-magnesium-based active factor antibacterial materials, mix them evenly in a powder machine, and use a parallel twin-screw granulator to make granules;

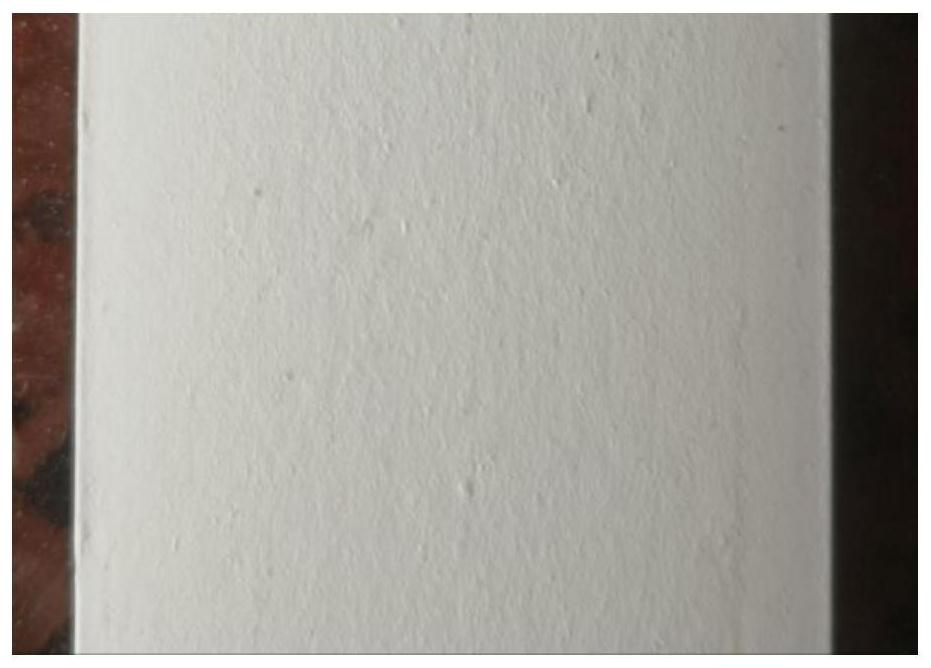

[0038] S2, the granules are extruded through a conical twin-screw extruder at 160-170°C, and textured during the shaping process and evenly coated with a bonding agent on the back to obtain a substrate;

[0039] S3, printing on the substrate to obtain the antibacterial edge banding.

[0040] In this embodiment, the prepared antibacterial edge banding is added with nano-magnesium-based active factor antibacterial materials during the powdering process, and the antibacterial material has a small and uniform content, low cost, excellent antibacterial effect, and does not affect the performance of the edge banding.

[0041] Further, in the micelle...

Embodiment 1

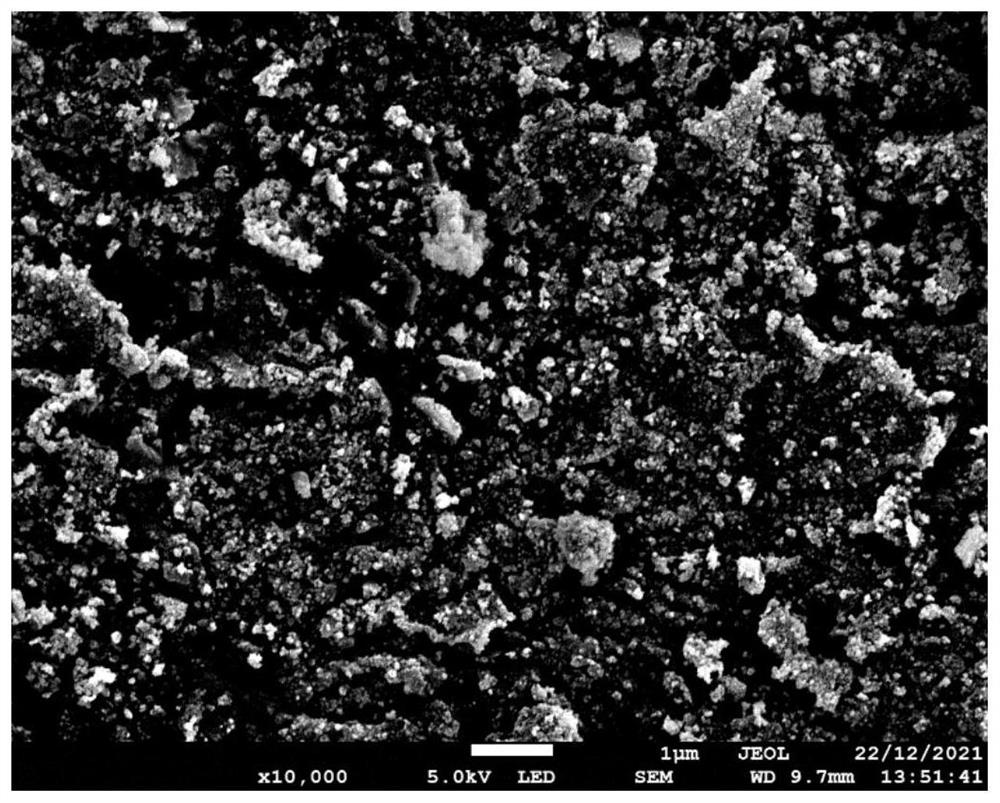

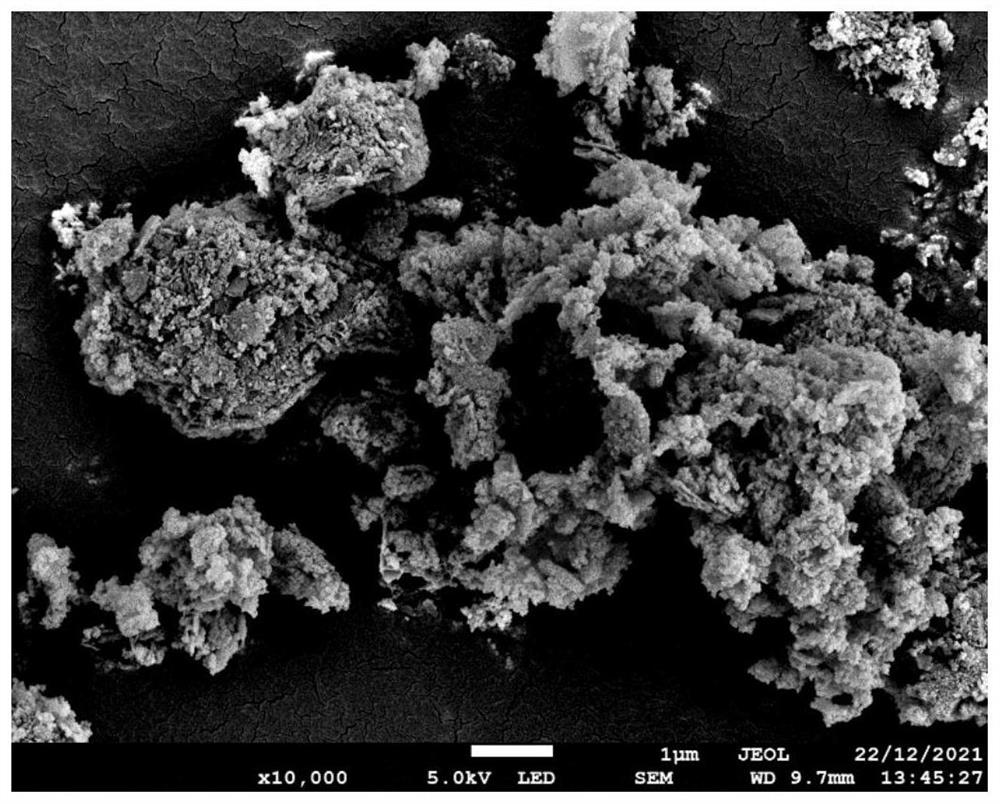

[0056] Get dolomite (magnesia content 20%), by calcination, digestion, adopt carbon dioxide carbonization to realize calcium and magnesium separation and obtain heavy magnesium water (containing magnesium bicarbonate 30g / L), add 1.5% aluminum nitrate (mass) in heavy magnesium water ratio) and 1% polyacrylamide (mass ratio), stirred evenly, pumped into the flash tank, under the action of high-speed rotation, the mixed solution was atomized, and in reverse contact with hot air heated to 200 ° C, quickly Dry to obtain composite powder. The composite powder is calcined in an electric furnace for 1 hour at a temperature of 600°C, and the carbon dioxide generated during the calcining process is further recovered. The antibacterial powder obtained by calcination is ball milled in a corundum ball mill tank at a speed of 400r / min for 1 hour to obtain a nano-magnesium-based active factor antibacterial material with a diameter of less than 50 nanometers.

[0057] Mix the above-mentioned...

Embodiment 2

[0064] Get dolomite (magnesia content 20%), by calcination, digestion, adopt carbon dioxide carbonization to realize calcium and magnesium separation and obtain heavy magnesium water (containing magnesium bicarbonate 30g / L), add 0.7% cerium nitrate (mass nitrate) in heavy magnesium water ratio) and 1% sodium silicate (mass ratio), stir evenly, pump into the flash tank, under the action of high-speed rotation, the mixed solution is atomized, and it is in reverse contact with hot air heated to 200°C, rapidly Dry to obtain composite powder. The composite powder was calcined in an electric furnace for 2 hours at a temperature of 550°C, and the carbon dioxide generated during the calcining process was further recovered. The antibacterial powder obtained by calcining is ball milled in a corundum ball mill tank at a speed of 400r / min for 2 hours to obtain a nano-magnesium-based active factor antibacterial material with a diameter below 50 nanometers.

[0065] Mix the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com