Preparation method of defect-rich metal oxide (sulfide)/graphene oxide composite material

A composite material and defect-rich technology, applied in the field of preparation of defect-rich metal oxide/graphene oxide composite materials, can solve the problems of harsh production conditions, high production cost, unreported semiconductor materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

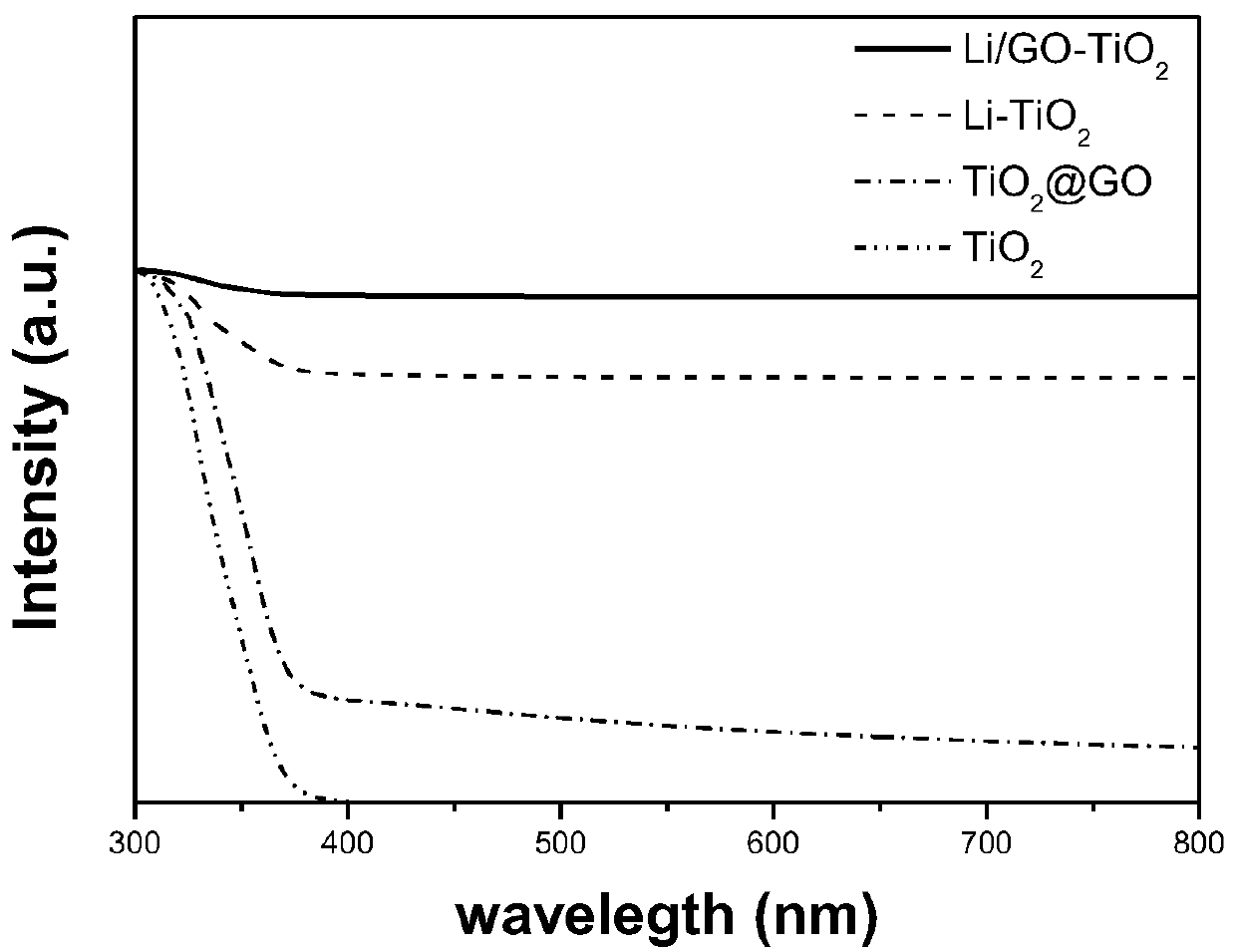

Image

Examples

Embodiment 1

[0021] Preparation of lithium-reduced GO@MoS proposed by the present invention 2 The material can be implemented by the following methods, and the specific preparation method includes the following steps:

[0022] (1) 100~600mg dry MoS 2 Pour the nanoparticles into a beaker, add 20-40ml EDA and 1-3mL graphene oxide gel, and add magnetons.

[0023] (2) 12-36mg lithium metal foil is dissolved in the above solution, sealed and magnetically stirred.

[0024] (3) After fully reacting, gradually add hydrochloric acid dropwise and stir to extinguish excess lithium flakes and form lithium salt to remove residual lithium metal.

[0025] (4) The precipitate obtained after the reaction was washed with deionized water and absolute ethanol, and then freeze-dried.

Embodiment 2

[0027] The preparation of the lithium-reduced GO@ZnO material proposed by the present invention can be implemented by the following method, and the specific preparation method includes the following steps:

[0028] (1) Pour 100-600mg of dry ZnO nanoparticles into a beaker, add 20-40ml of EDA and 1-3mL of graphene oxide gel, and add magnetons.

[0029] (2) 12-36mg lithium metal foil is dissolved in the above solution, sealed and magnetically stirred.

[0030] (3) After fully reacting, gradually add hydrochloric acid dropwise and stir to extinguish excess lithium flakes and form lithium salt to remove residual lithium metal.

[0031] (4) The precipitate obtained after the reaction was washed with deionized water and absolute ethanol, and then freeze-dried.

Embodiment 3

[0033] Preparation of lithium-reduced GO@MoO proposed by the present invention 3 The material can be implemented by the following methods, and the specific preparation method includes the following steps:

[0034] (1) 100~600mg dry MoO 3 Pour the nanoparticles into a beaker, add 20-40ml EDA and 1-3mL graphene oxide gel, and add magnetons.

[0035] (2) 12-36mg lithium metal foil is dissolved in the above solution, sealed and magnetically stirred.

[0036] (3) After fully reacting, hydrochloric acid was gradually added dropwise and stirred to extinguish excess lithium flakes and form lithium salt to remove residual lithium metal.

[0037] (4) The precipitate obtained after the reaction was washed with deionized water and absolute ethanol, and then freeze-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com