Preparation method of black porous zinc oxide photocatalyst

A technology of porous zinc oxide and photocatalyst, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, etc., can solve the problem of no black porous ZnO nanomaterial preparation method application report issues such as low biological toxicity and environmental toxicity, strong absorption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of black porous zinc oxide photocatalyst, comprises the steps:

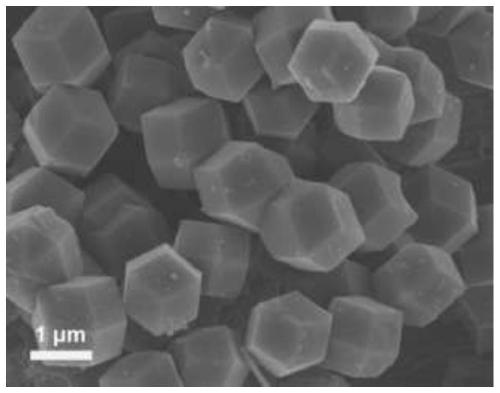

[0032] S1. Dissolve 0.89g of cobalt nitrate in 30mL of methanol, 0.98g of 2-methylimidazole in 10mL of methanol, mix and stir for 10min, add it to the hydrothermal reaction kettle, and place it in an oven at 100°C for 12h. After washing with water and ethanol three times each, the ZIF-8 precursor was obtained after vacuum drying at 60°C;

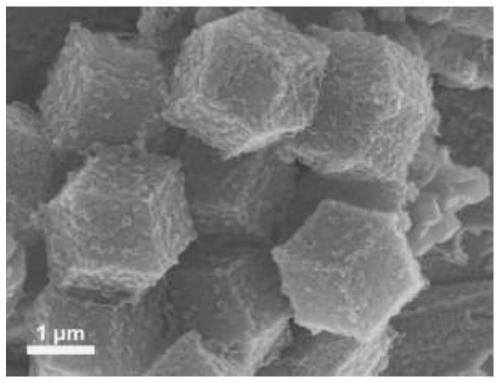

[0033] S2. Put 0.1 g of the ZIF-8 precursor in a muffle furnace, heat it to 600°C at a heating rate of 10°C / min, stop heating after 3 hours of heat preservation, and when the temperature in the furnace drops to room temperature, white porous ZnO is obtained powder;

[0034] S3, after putting 0.1 gram of white porous ZnO powder into the corundum ark, place it in a high-temperature tube furnace, and 2 Under the condition of / Ar (10% / 90%) atmosphere, after annealing treatment at a temperature of 400° C. for 2 hours, the black porous zinc oxide...

Embodiment 2

[0036] A kind of preparation method of black porous zinc oxide photocatalyst, comprises the steps:

[0037] S1. Dissolve 1.78 grams of cobalt nitrate in 30 mL of methanol, 1.96 grams of 2-methylimidazole in 10 mL of methanol, and mix and stir for 15 minutes, then add it to a hydrothermal reaction kettle, and place it in an oven at 120 ° C for 12 hours. After washing with water and ethanol three times each, the ZIF-8 precursor was obtained after vacuum drying at 60°C;

[0038] S2. Put 0.1 g of the ZIF-8 precursor in a muffle furnace, heat it to 600°C at a heating rate of 8°C / min, stop heating after 4 hours of heat preservation, and obtain white porous ZnO when the temperature in the furnace drops to room temperature powder;

[0039] S3, after putting 0.1 gram of white porous ZnO powder into the corundum ark, place it in a high-temperature tube furnace, and 2 Under the condition of / Ar (20% / 80%) atmosphere, after annealing treatment at a temperature of 400° C. for 3 hours, the...

Embodiment 3

[0041] A kind of preparation method of black porous zinc oxide photocatalyst, comprises the steps:

[0042] S1. Dissolve 5.9 grams of cobalt nitrate in 100 mL of methanol, and 7.8 grams of 2-methylimidazole in 50 mL of methanol. After mixing and stirring for 15 minutes, add it to a hydrothermal reaction kettle and place it in an oven at 120°C for 10 hours. After washing with water and ethanol three times each, the ZIF-8 precursor was obtained after vacuum drying at 60°C;

[0043] S2. Put the ZIF-8 precursor in a muffle furnace, heat it to 620° C. at a heating rate of 5° C. / min, and keep it warm for 2-4 hours to obtain a white porous ZnO powder;

[0044] S3, after putting the white porous ZnO powder into the corundum ark, put it in a high-temperature tube furnace, 2 / Ar (25% / 75%), after annealing at a temperature of 350° C. for 2.5 hours, the temperature in the furnace was lowered to room temperature to prepare a black porous zinc oxide photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com