Preparation and application of ZnO thin film with flexible substrate suede structure

A flexible substrate and suede technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of high growth temperature, small crystal grains, and difficulty in forming light scattering, so as to facilitate light scattering and material Inexpensive and convenient for large-scale production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

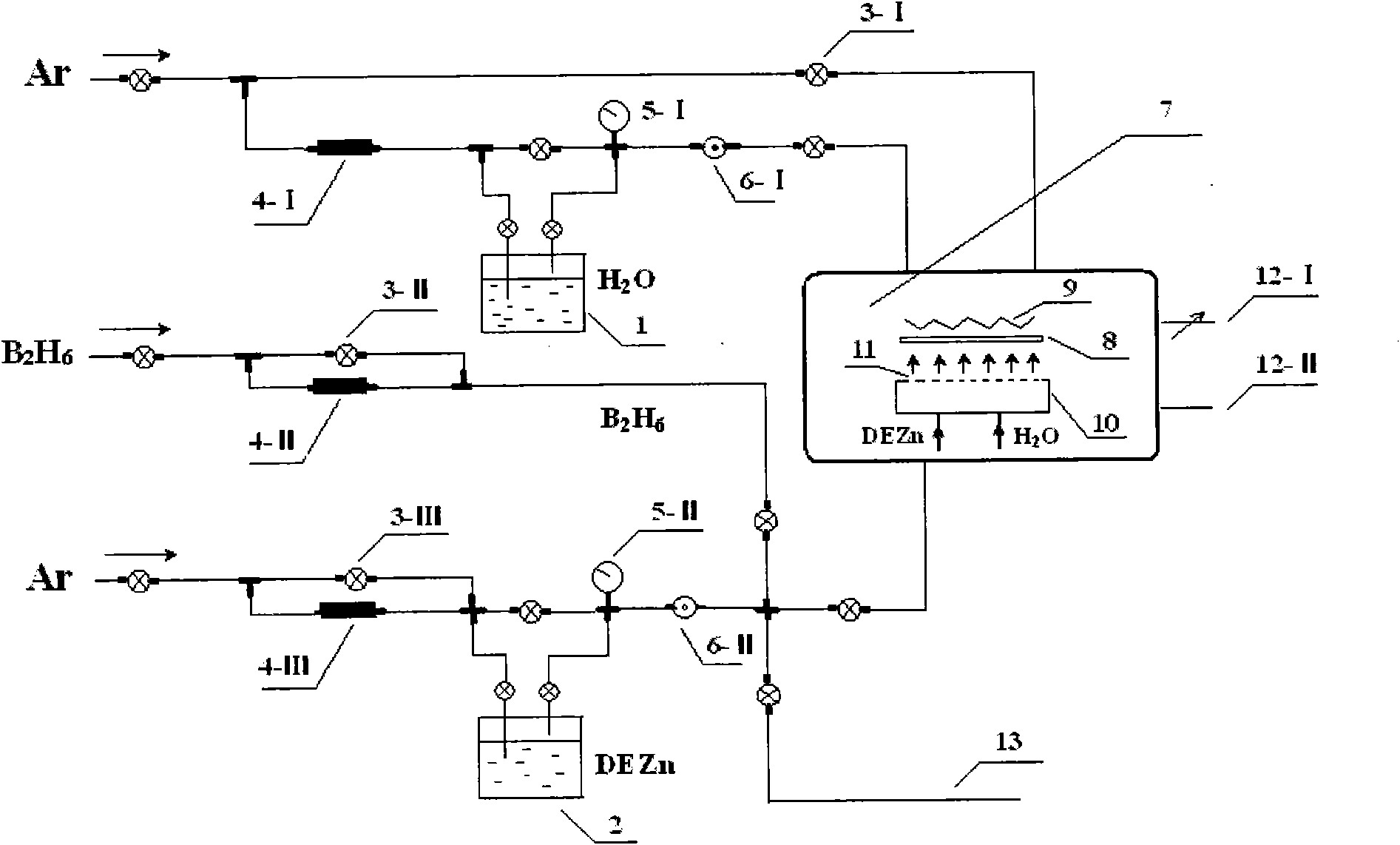

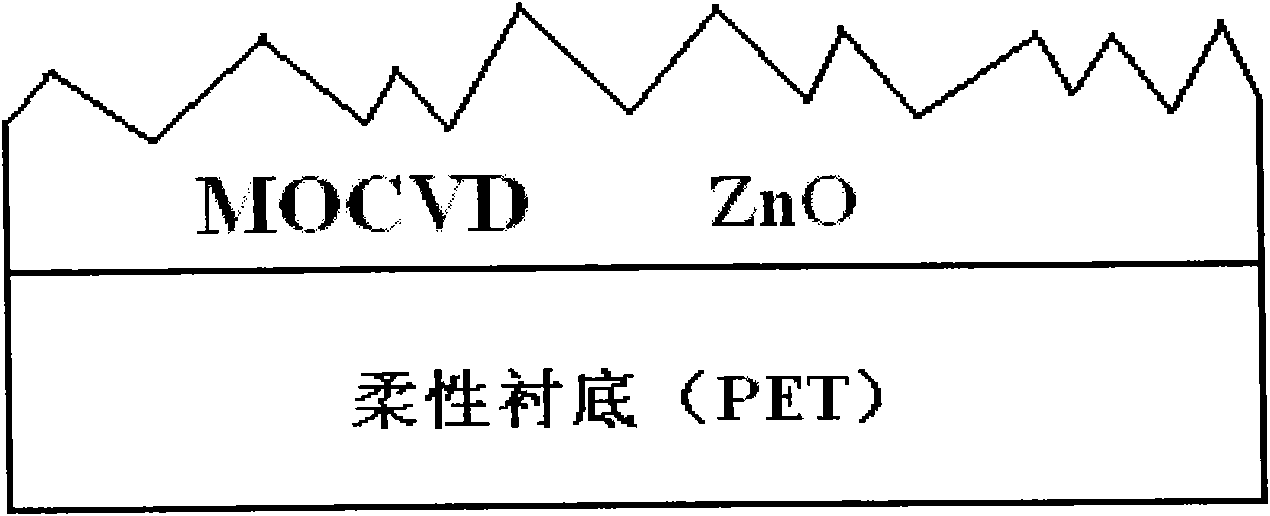

[0024] 1. Using the above figure 1 The MOCVD system in, with the help of high-purity DEZn (purity: 99.995%) and water as source material, B 2 h 6 As a doping gas, a textured ZnO film was grown on a PET flexible substrate, the substrate temperature was 145°C, the coating reaction pressure was 130Pa, and the thickness of the film obtained by the test was 1200nm.

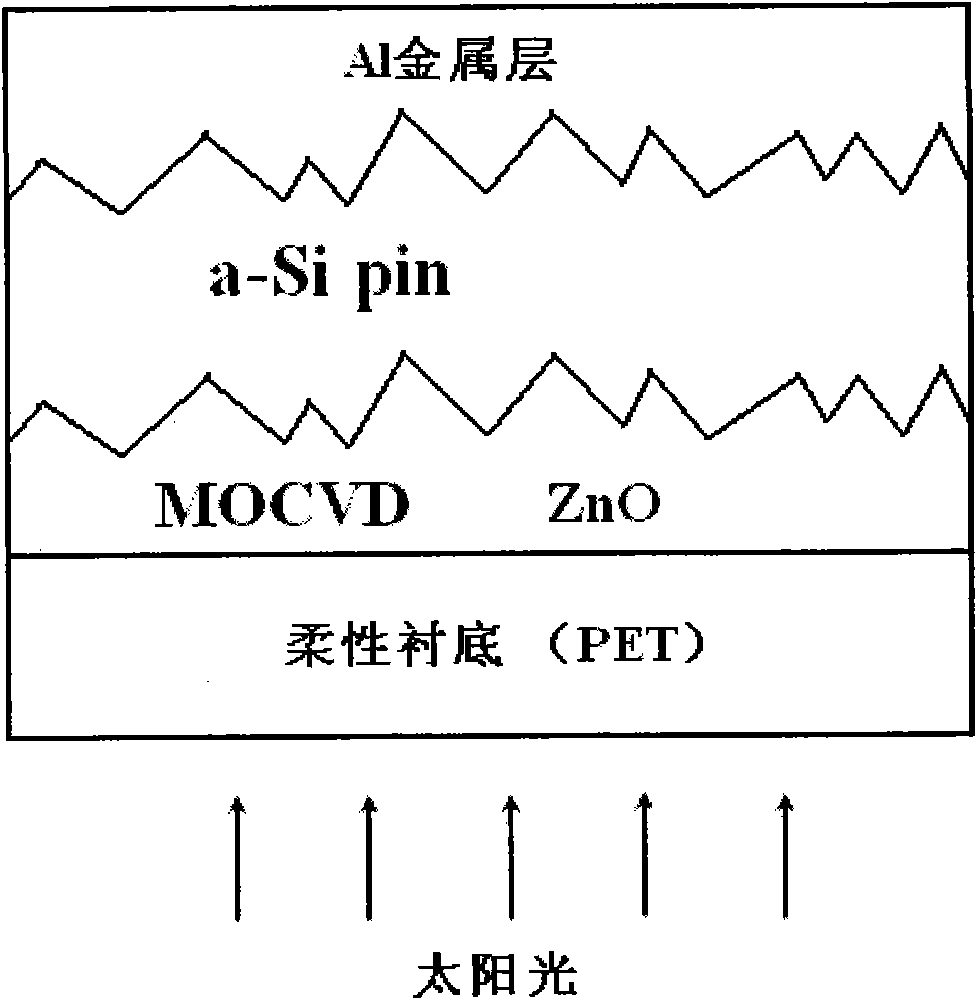

[0025] 2. Apply the textured structure PET / ZnO film to the pin type a-Si thin film solar cell. Such as image 3 As shown, the PET / ZnO film is plated, and then p, i, n three layers of a-Si film are grown, and finally the Al metal layer is plated. The photoelectric conversion efficiency of 6.3% is obtained through the current-voltage characteristic test.

Embodiment 2

[0027] 1. Using the above figure 1 The MOCVD system in, with the help of high-purity DEZn (purity: 99.995%) and water as source material, B 2 h 6 As a doping gas, a textured ZnO film was grown on a PET flexible substrate, the substrate temperature was 145°C, the coating reaction pressure was 260Pa, and the thickness of the film obtained by testing was 1500nm.

[0028] 2. Apply the textured structure PET / ZnO film to the pin type a-Si / a-Si laminated thin film solar cell. Such as Figure 4 As shown, the PET / ZnO film is plated, and then p, i, n and p, i, n six layers of a-Si film are grown, and finally the Al metal layer is plated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com