flake g-c for bpa removal in water 3 no 4 /zif-8/agbr composite material and preparation method thereof

A technology of ZIF-8 and composite materials, which is applied in the direction of catalyst activation/preparation, water/sludge/sewage treatment, organic compound/hydride/coordination complex catalysts, etc., which can solve the problem of unsatisfactory degradation effect of composite materials, etc. , to achieve the effect of shortening the required time, high photocatalytic performance and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

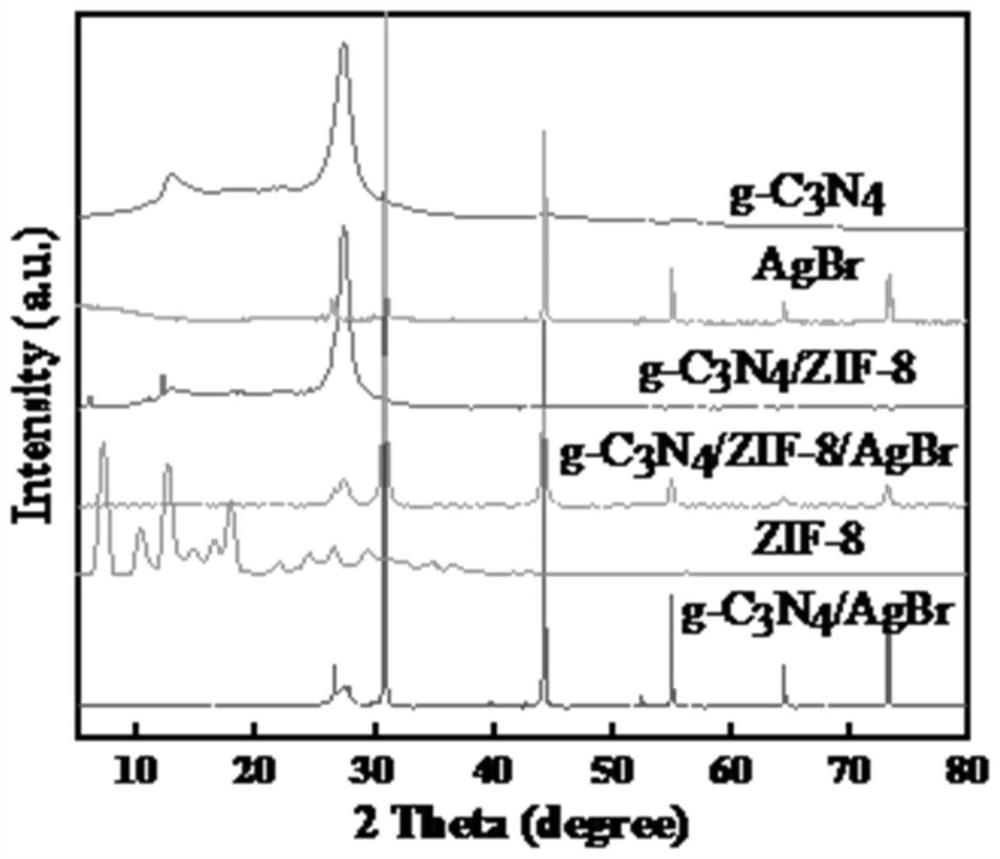

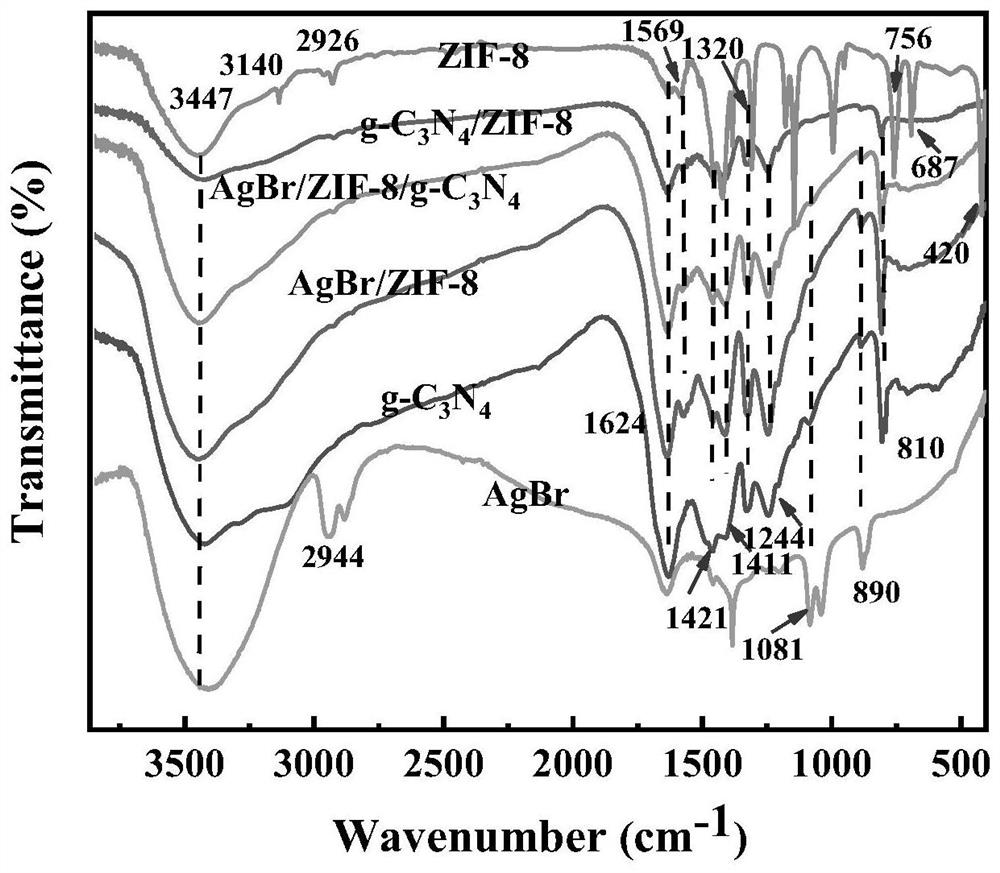

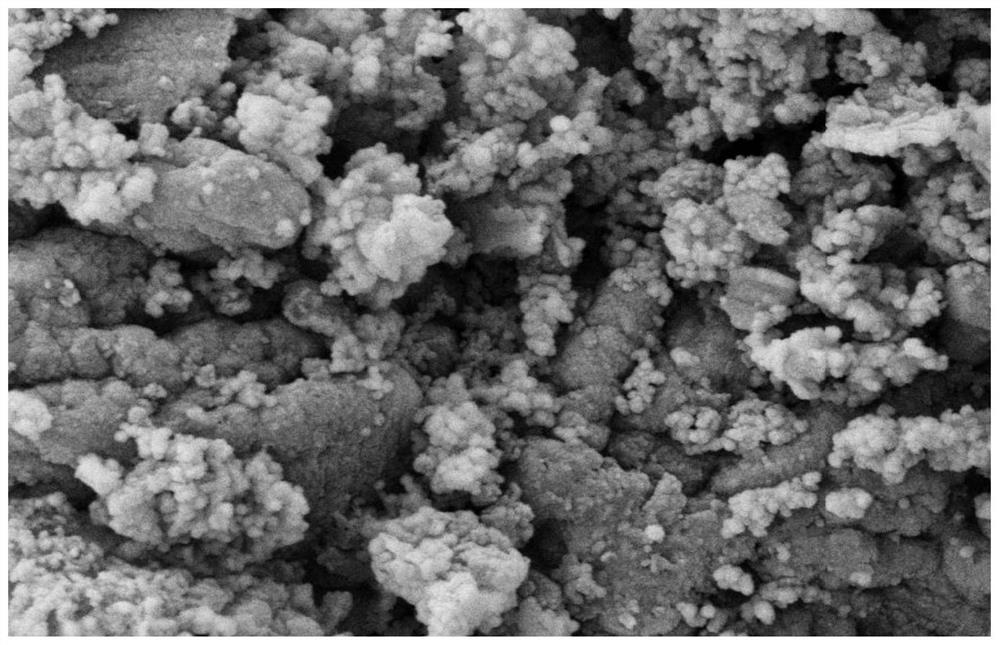

Image

Examples

Embodiment 1

[0031] (1) Preparation of g-C 3 N 4

[0032] Put melamine into an alumina crucible with a cover; heat to 550°C in a muffle furnace at a rate of 5°C / min, and keep at 550°C for 4h to obtain a yellow product;

[0033] Add 0.1 g of the product to 80 mL of concentrated H 2 SO 4 In, the protonated g-C 3 N 4 It is in the form of flakes, the specific surface area is increased, and hydronium ions are generated on the surface, which has strong oxidizing properties and can enhance the photocatalytic effect. It was stirred and sonicated for 8 h; g-C was collected by centrifugation 3 N 4 and washed several times with distilled water; the product was dried at 60°C for 24h to obtain the treated g-C 3 N 4 product.

[0034] (2) The general synthesis method of ZIF-8

[0035] A. Add 3g of Zn(NO 3 ) 2 ·6H 2 The 2-methylimidazole of 0 and 6.6g is added in the 200mL methanol solvent respectively;

[0036] B. The solution was vigorously stirred at room temperature for 1 h overnight; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com