A kind of environment-friendly composite material for preventing toxic gas and preparation method thereof

A composite material, toxic gas technology, applied in chemical instruments and methods, physical treatment, plant fibers, etc., can solve the problems of incomplete adsorption, high operating costs, slow adsorption speed, etc., to achieve good Ag loading effect, uniform distribution, The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

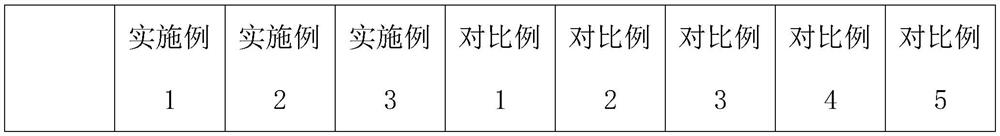

Examples

preparation example Construction

[0043] The preparation method of the environmental protection composite material comprises the following steps:

[0044] Step S1, using a flat vulcanizer to compound the skin-friendly layer and the outer cover layer on which the adsorption and degradation layer is deposited, with specific parameters: the compounding pressure is 5-6MPa, and the compounding temperature is 68-70°C;

[0045] In step S2, ultrasonic waves are used for two-pass compounding. A pair of engraved rolls are installed on the hot rolling mill. The size of the engraved rolls is 0.18cm*0.23cm, the distance between the rolling points is 3.5cm, and the inclination direction of the rolling points is the same as that of the hot rolling rolls. The included angle of the shaft center line is 45°, and the pressure of the hot roll is controlled at 50-60N / mm;

[0046] Step S3, put the material after two layers of compounding into the lemon essential oil steam for fumigation for 2-3 minutes, and after natural cooling, o...

Embodiment 1

[0049] An environmentally friendly composite material for preventing toxic gases, comprising an outer cover layer, an adsorption and degradation layer and a skin-friendly layer arranged in sequence, the outer cover layer is located at the outermost layer, and the outer cover layer is made of activated carbon cloth, which is formed on the inner surface of the activated carbon cloth by electrostatic spinning. An adsorption and degradation fiber film is deposited as an adsorption and degradation layer;

[0050] The environmentally friendly composite material is made by the following steps:

[0051] Step S1, using a flat vulcanizer to compound the skin-friendly layer and the outer cover layer on which the adsorption and degradation layer is deposited, with specific parameters: the compounding pressure is 5MPa, and the compounding temperature is 70°C;

[0052] In step S2, ultrasonic waves are used for two-pass compounding. A pair of engraved rolls are installed on the hot rolling m...

Embodiment 2

[0055] An environmentally friendly composite material for preventing toxic gases, comprising an outer cover layer, an adsorption and degradation layer and a skin-friendly layer arranged in sequence, the outer cover layer is located at the outermost layer, and the outer cover layer is made of activated carbon cloth, which is formed on the inner surface of the activated carbon cloth by electrostatic spinning. An adsorption and degradation fiber film is deposited as an adsorption and degradation layer;

[0056] The environmentally friendly composite material is made by the following steps:

[0057] Step S1, using a flat vulcanizer to composite the skin-friendly layer and the outer cover layer on which the adsorption and degradation layer is deposited, with specific parameters: the composite pressure is 5.5MPa, and the composite temperature is 69°C;

[0058] In step S2, ultrasonic waves are used for two-pass compounding. A pair of engraved rolls are installed on the hot rolling mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com