Patents

Literature

46 results about "Hydronium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, hydronium is the common name for the aqueous cation H3O+, the type of oxonium ion produced by protonation of water. It is the positive ion present when an Arrhenius acid is dissolved in water, as Arrhenius acid molecules in solution give up a proton (a positive hydrogen ion, H+) to the surrounding water molecules (H2O).

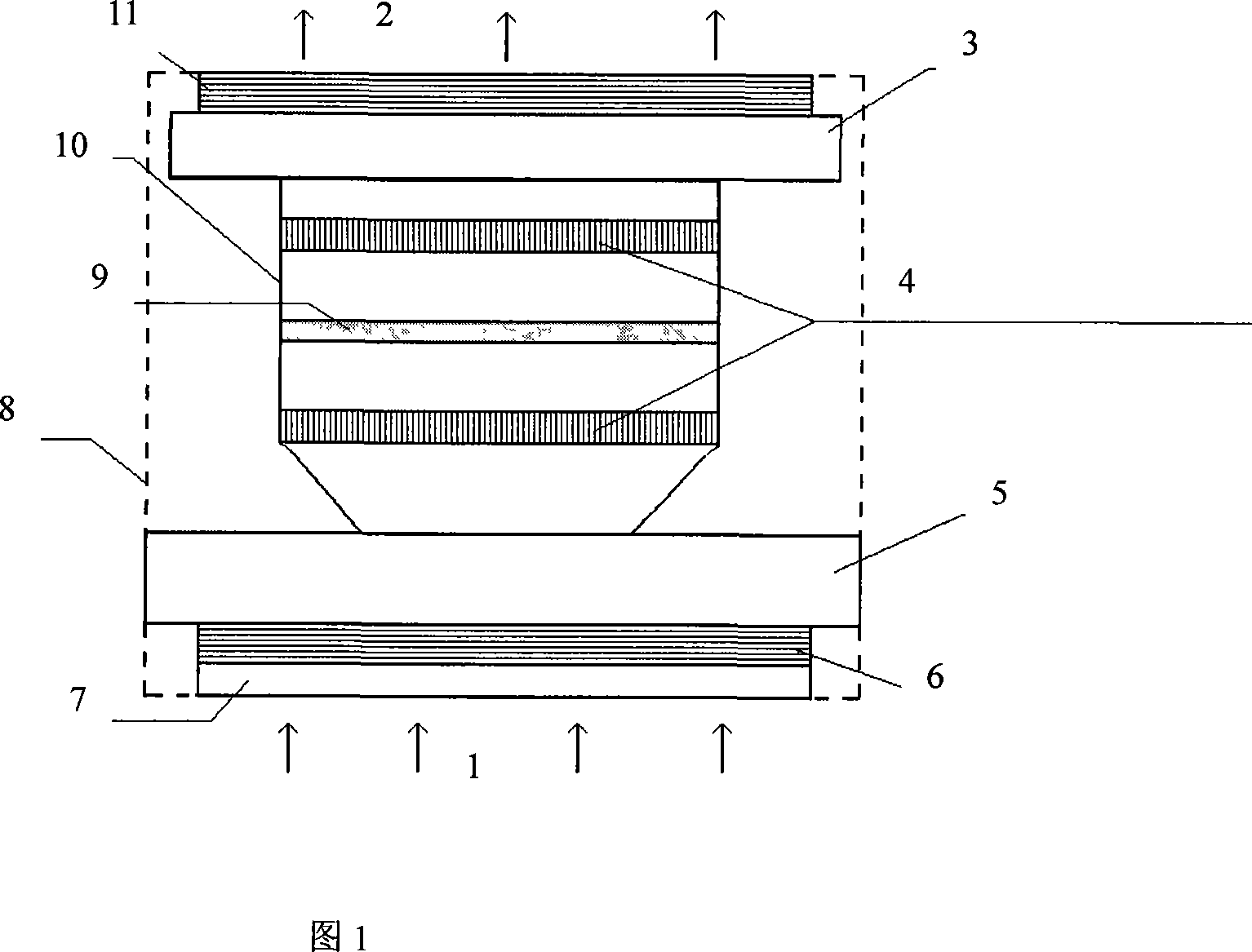

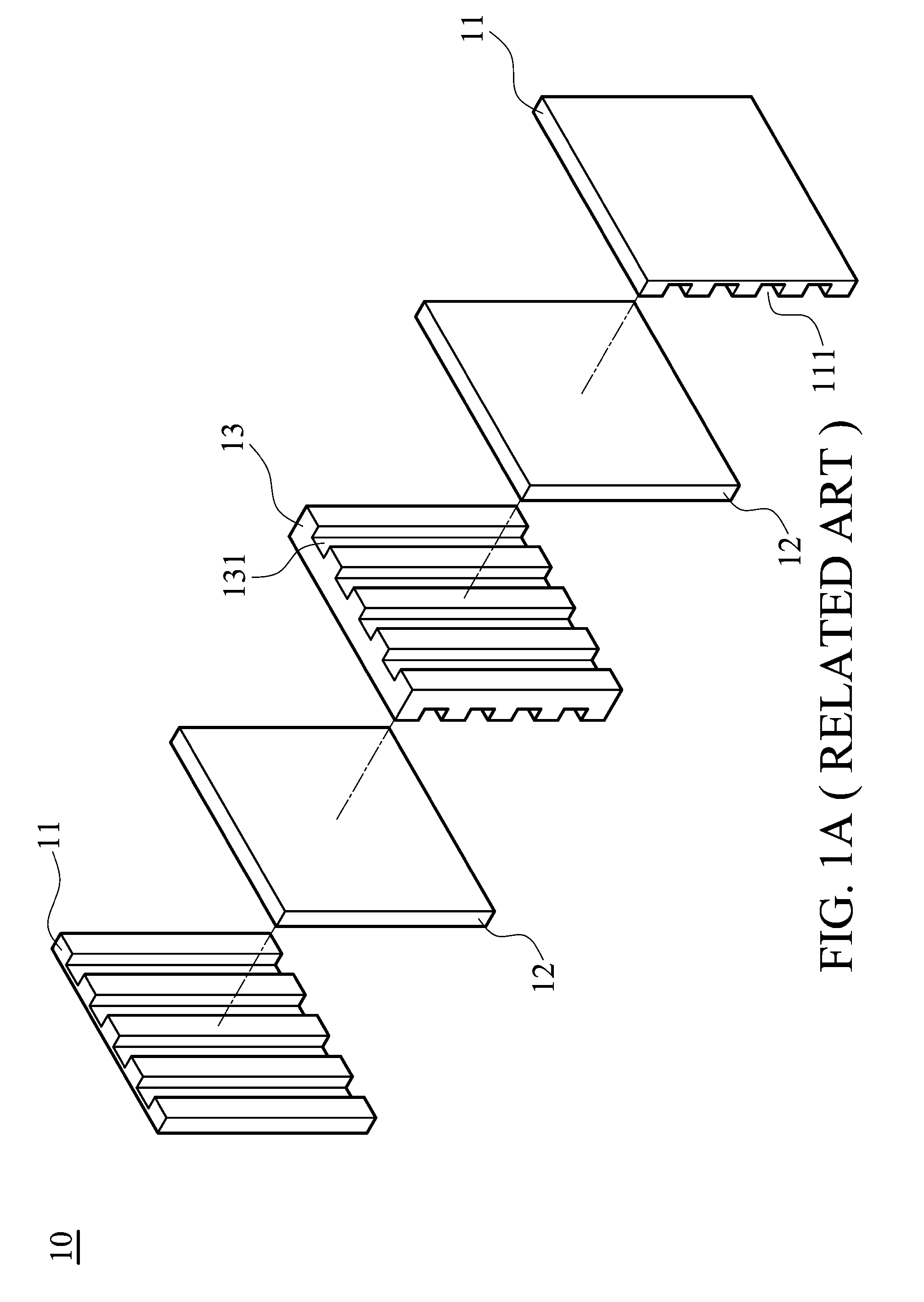

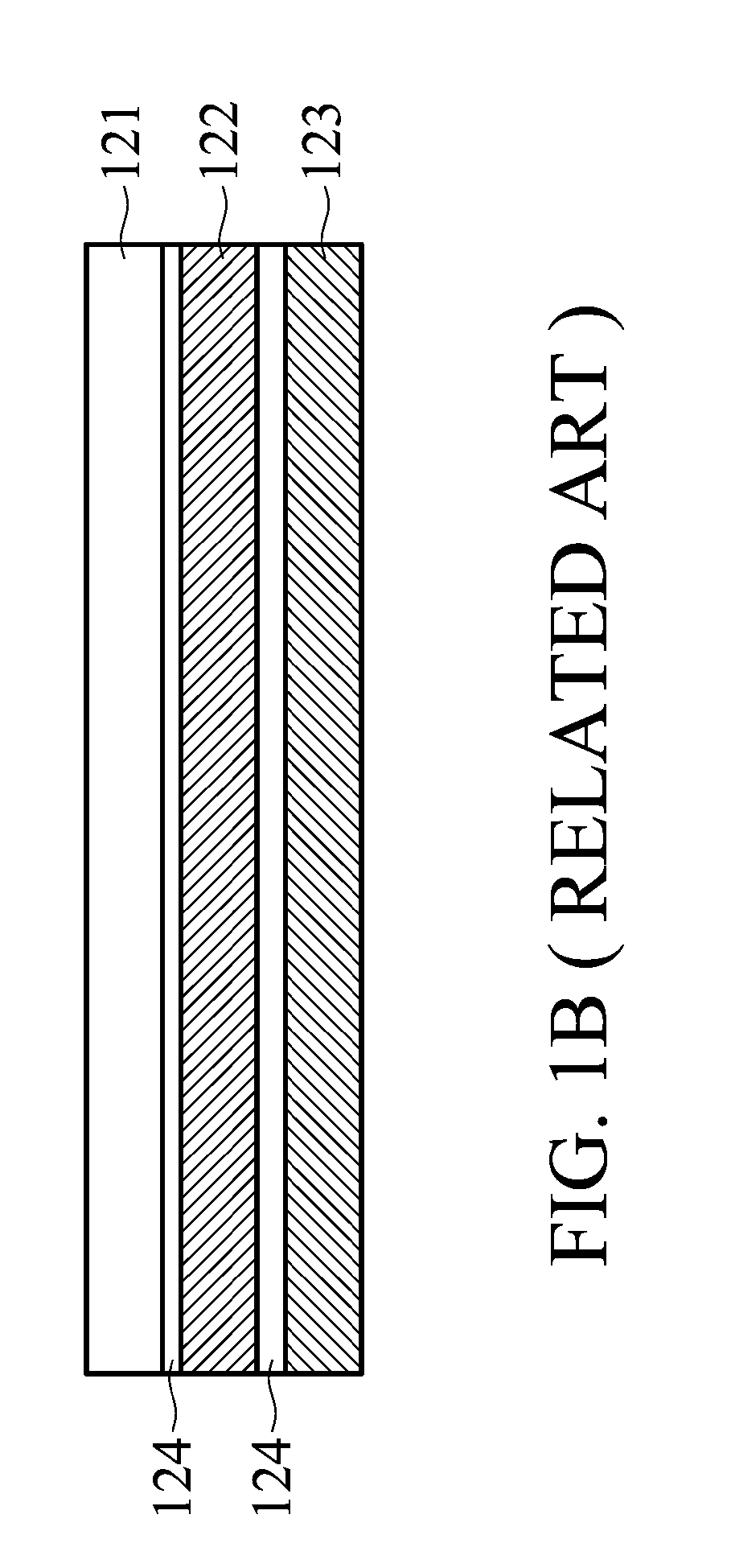

Photocatalysis air purifier

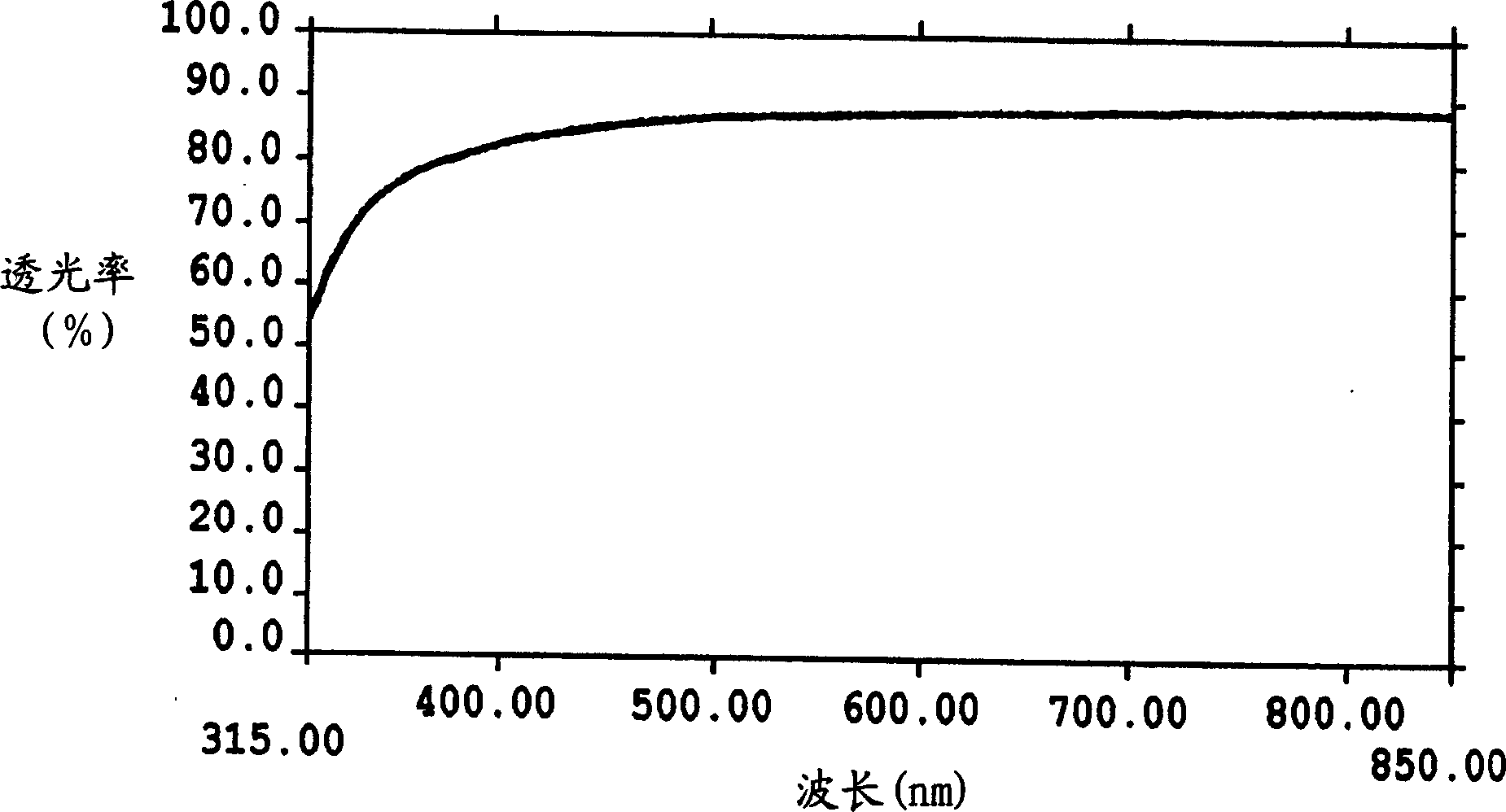

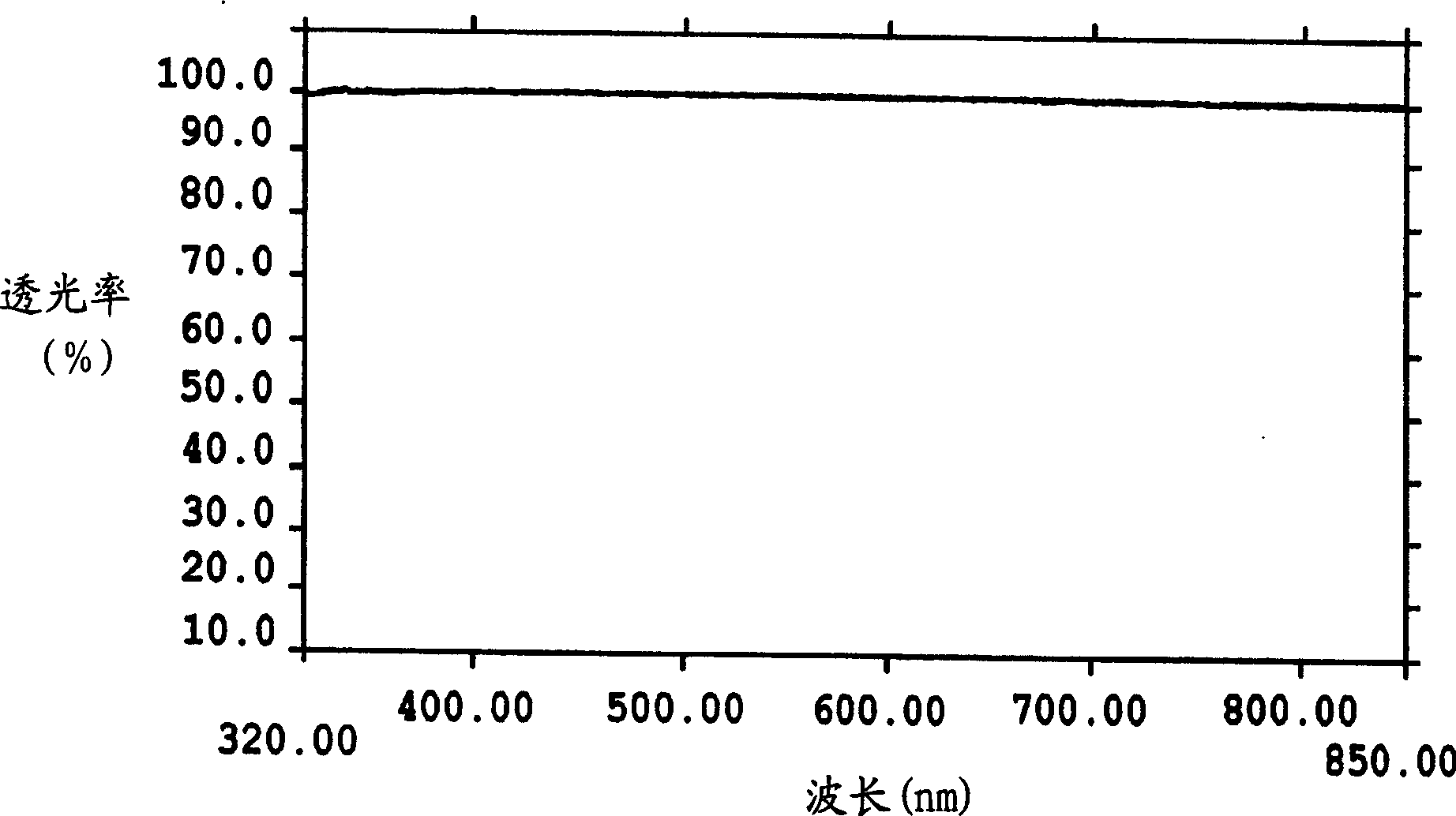

InactiveCN101121040ALarge specific surface areaGood light transmissionDeodrantsRadiationParticulatesPhotocatalytic reaction

The invention discloses an efficient photochemical catalysis air purifier, which consists of a machine box, a filtering device, a fan and a photochemical reacting room. The photochemical reacting room includes a three-dimensional honey comb ceramic halftone which loads a photocatalyst of nano-composite TiO2 and an ultraviolet radiation light which irradiates towards the honey comb ceramic halftone. The photocatalyst is TiO2 adulterated with little iron, lanthanum or cerium hydronium, and the quantity of the added hydronium is 0. 005 percent to 0.5 percent of the total weight. The three-dimensional honeycomb ceramic net of a photocatalyst carrier is a honeycomb ceramic, which is provided with 100 to 600 holes per square inch. The polluted air follows a wind inlet fan to go through the filtering device which consists of a primary filtering net and an active carbon filtering net, and granular articles are removed and volatile organic matters with peculiar smell are absorbed; the gas after primary purifying goes into the photochemical reacting room which is provided with the ultraviolet radiation light, the photocatalyst of nano-composite TiO2 and the three-dimensional honey comb ceramic net, and under an effect of a strong oxidizer which is produced by the reaction of the ultraviolet radiation and the photocatalyst, various organic pollutants in the air can be effectively decomposed.

Owner:JIANGSU GAOCHUN CERAMICS

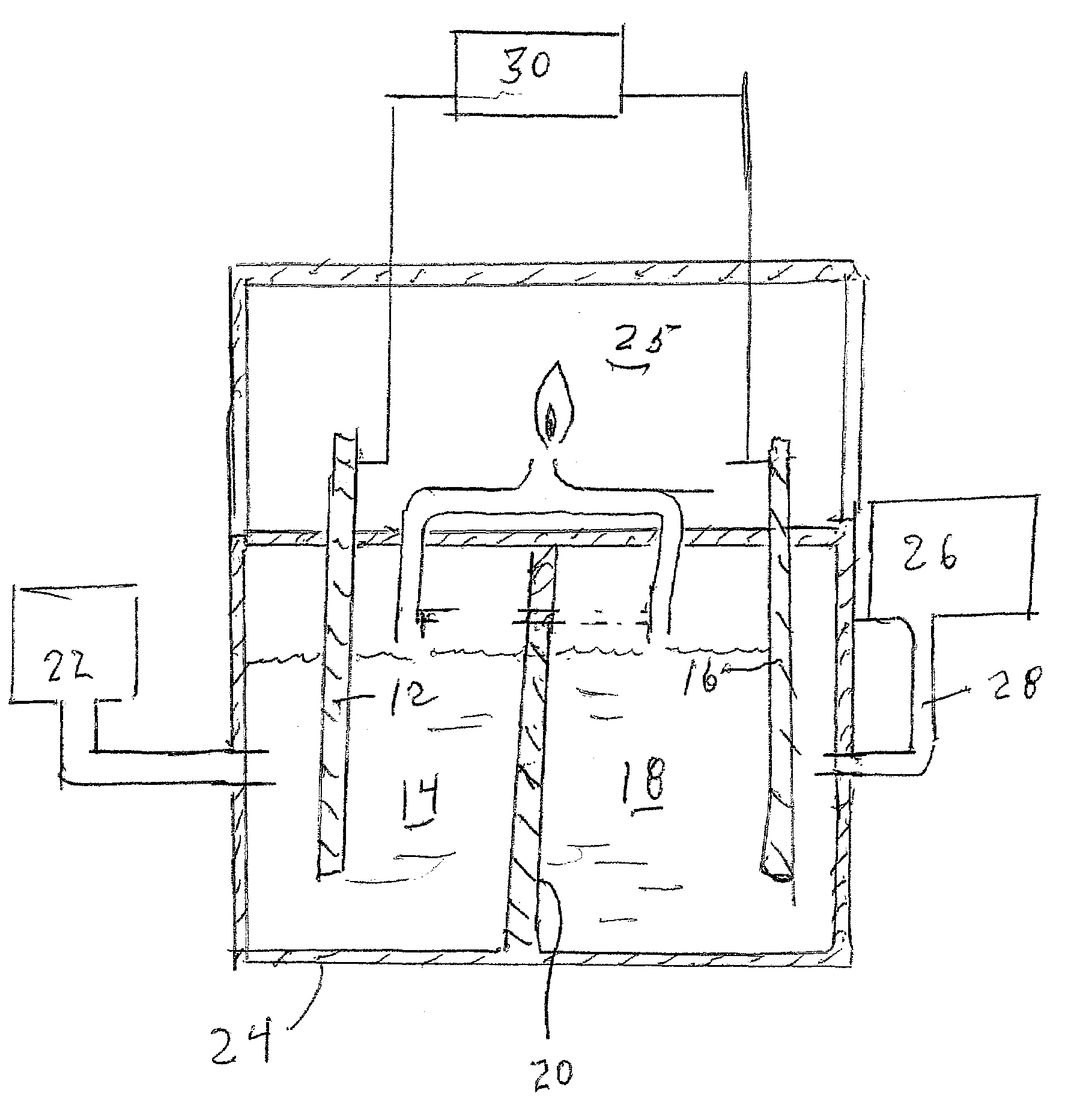

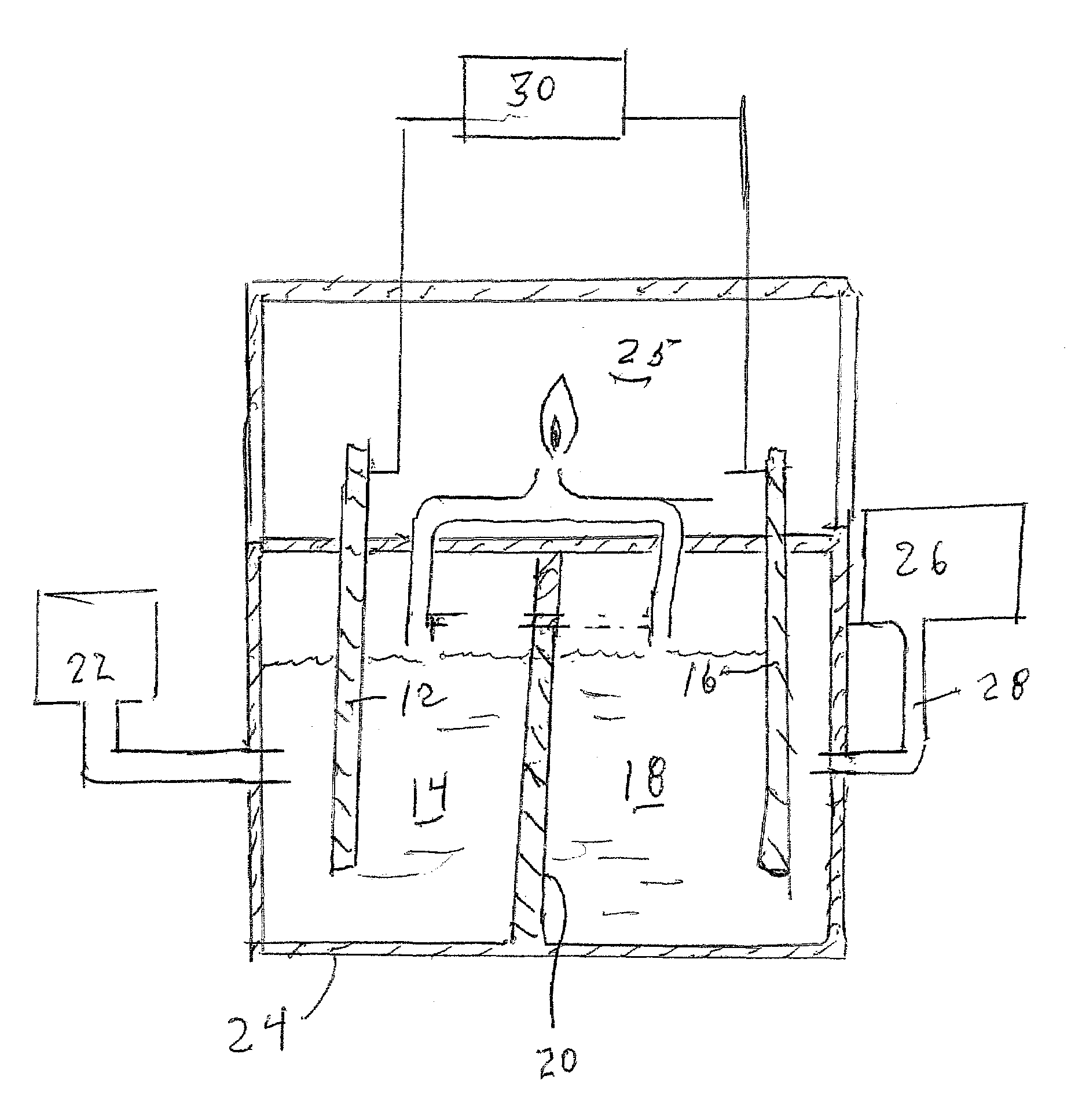

Hydronium-oxyanion energy cell

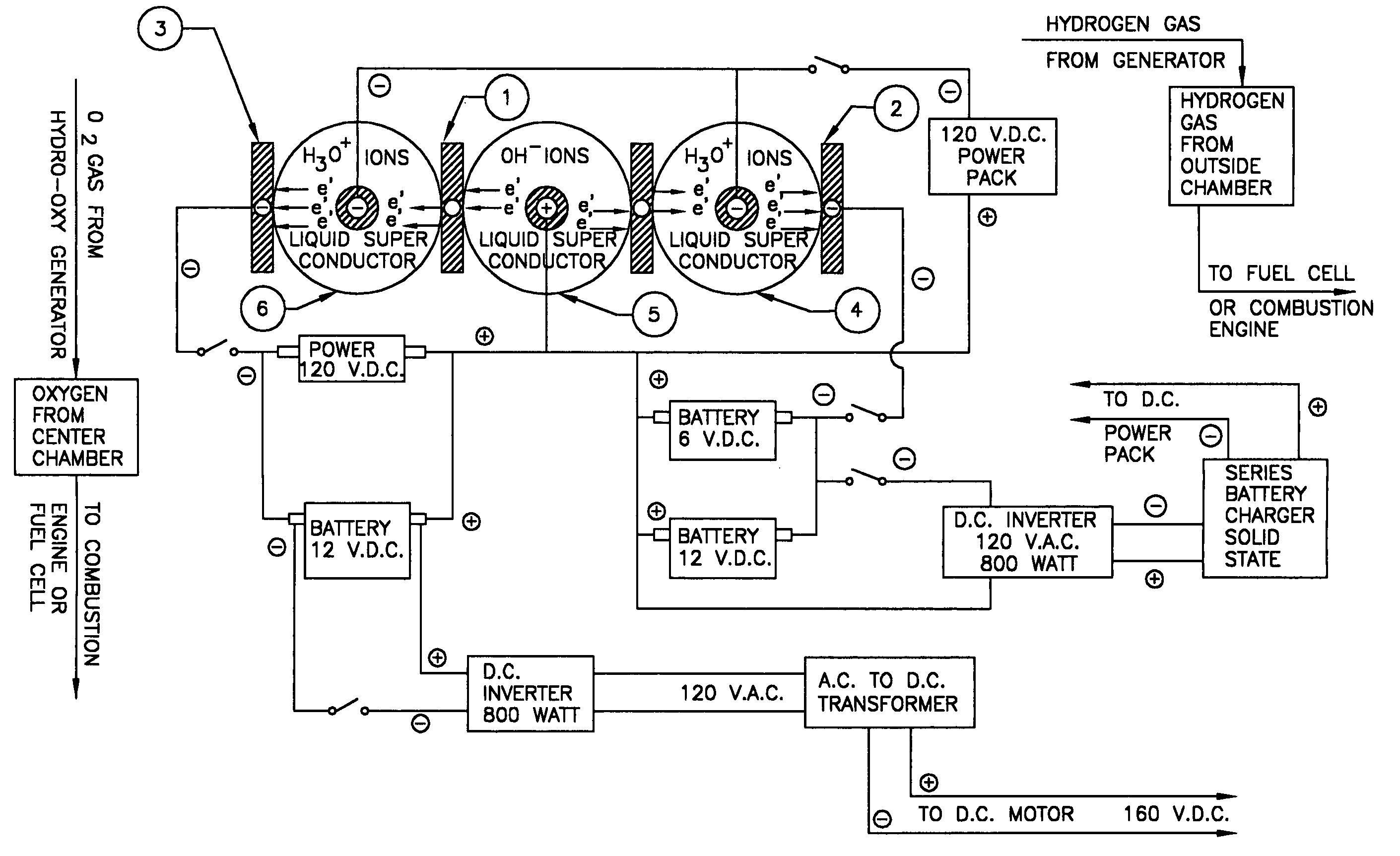

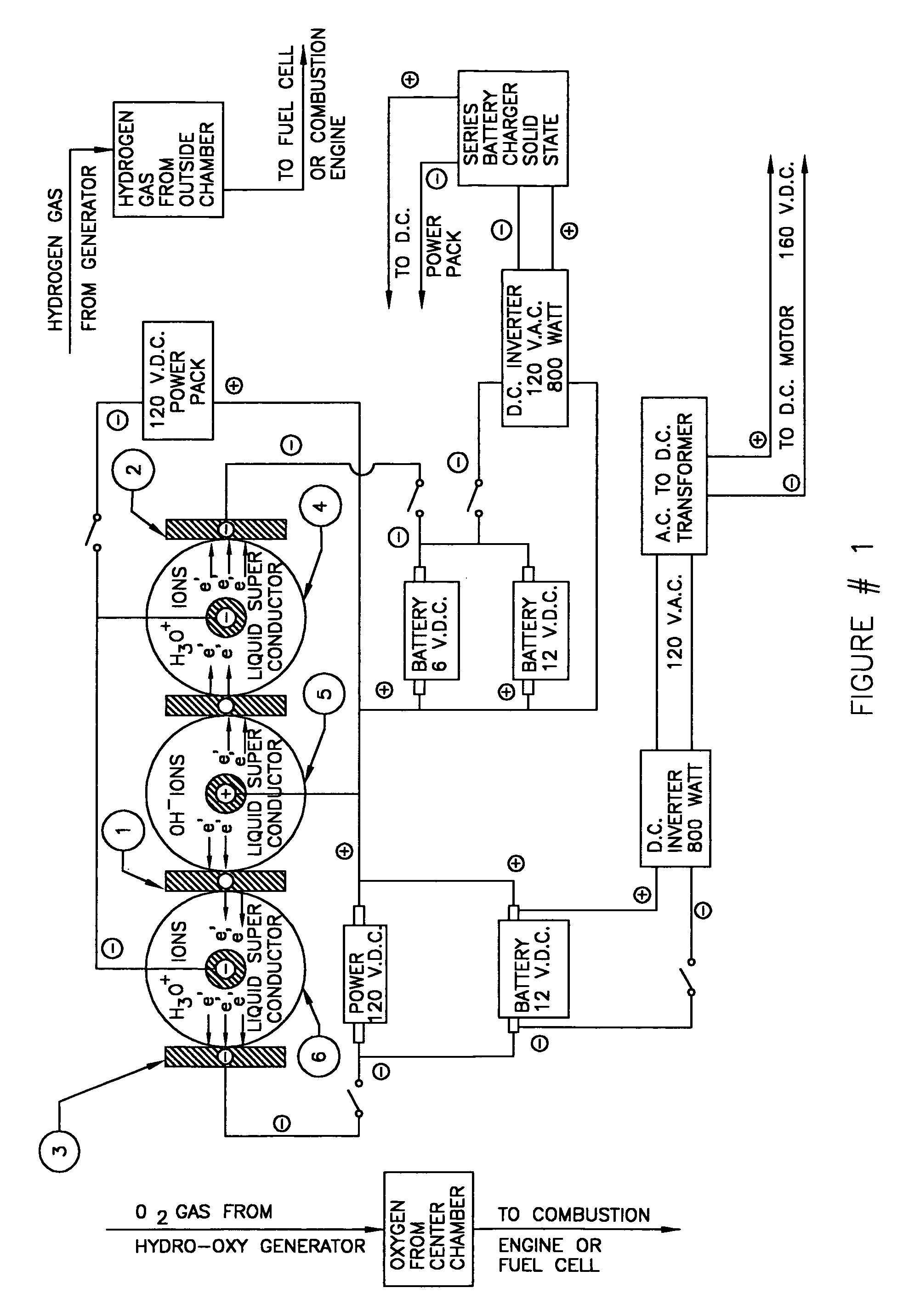

An energy cell for producing electrical energy and a fuel being a mixture of hydrogen and oxygen from aqueous solutions of hydronium and oxyanions. The aqueous solution of hydronium ions is delivered to a cathode in a cathode compartment where the ions are reduced by contact with a precious metal cathode. The aqueous solution of oxyanions is delivered to an anode in an anode compartment where the ions are reduced by contact with a precious metal cathode. Electrical potential between anode and cathode is available as a source of electrical energy. Hydrogen from the cathode department and oxygen from the anode compartment are combusted to provide heat in a combustion compartment.

Owner:WURZBURGER STEPHEN R

Binder compositions and membrane electrode assemblies employing the same

Binder composites for membrane electrode assemblies and membrane electrode assemblies employing the same are provided. The binder composition includes a solvent, a hyper-branched polymer and a polymer with high ion conductivity, wherein the hyper-branched polymer and the polymer with high conductivity of hydronium are distributed uniformly over the solvent, and the hyper-branched polymer has a DB (degree of branching) of more than 0.5.

Owner:IND TECH RES INST

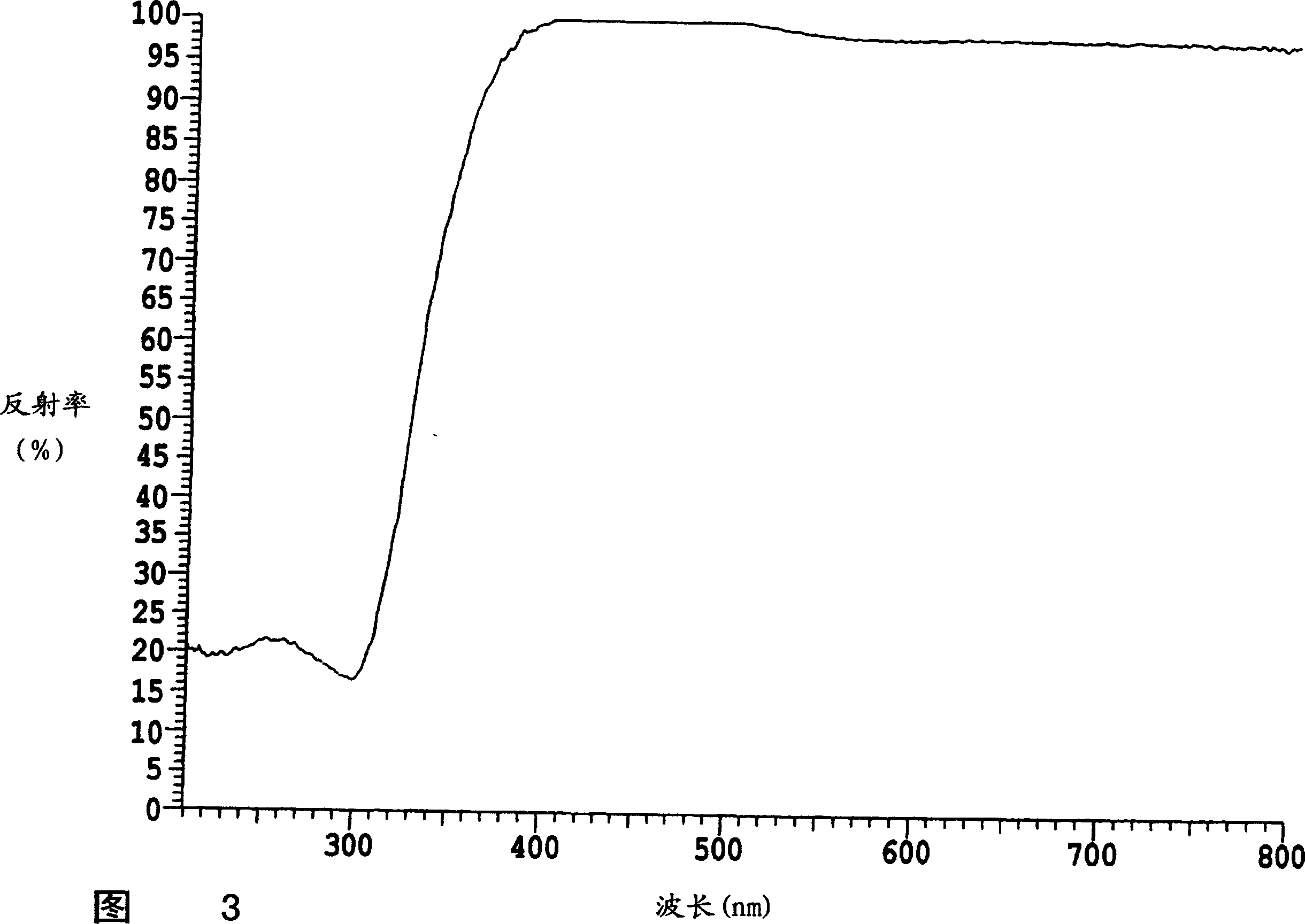

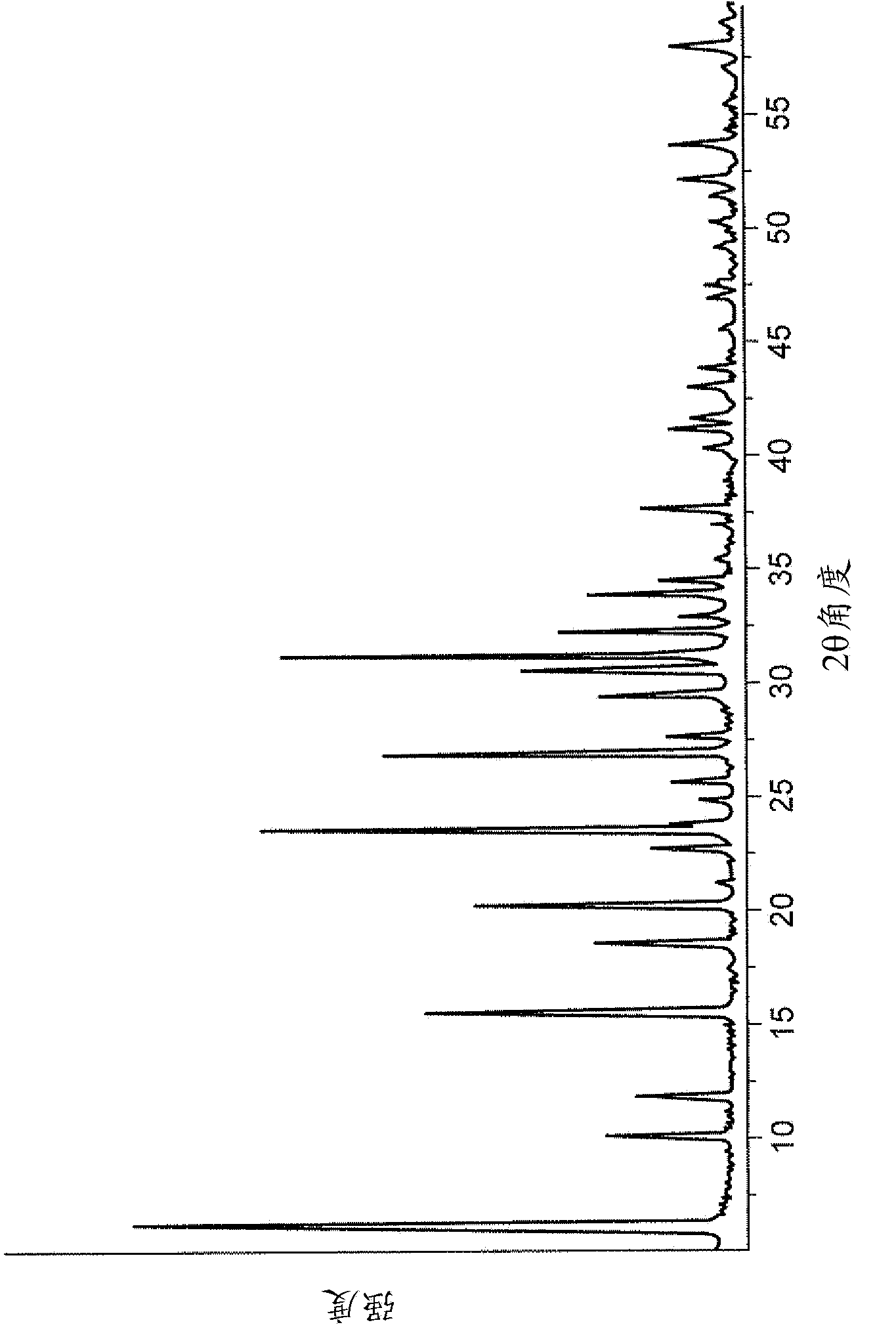

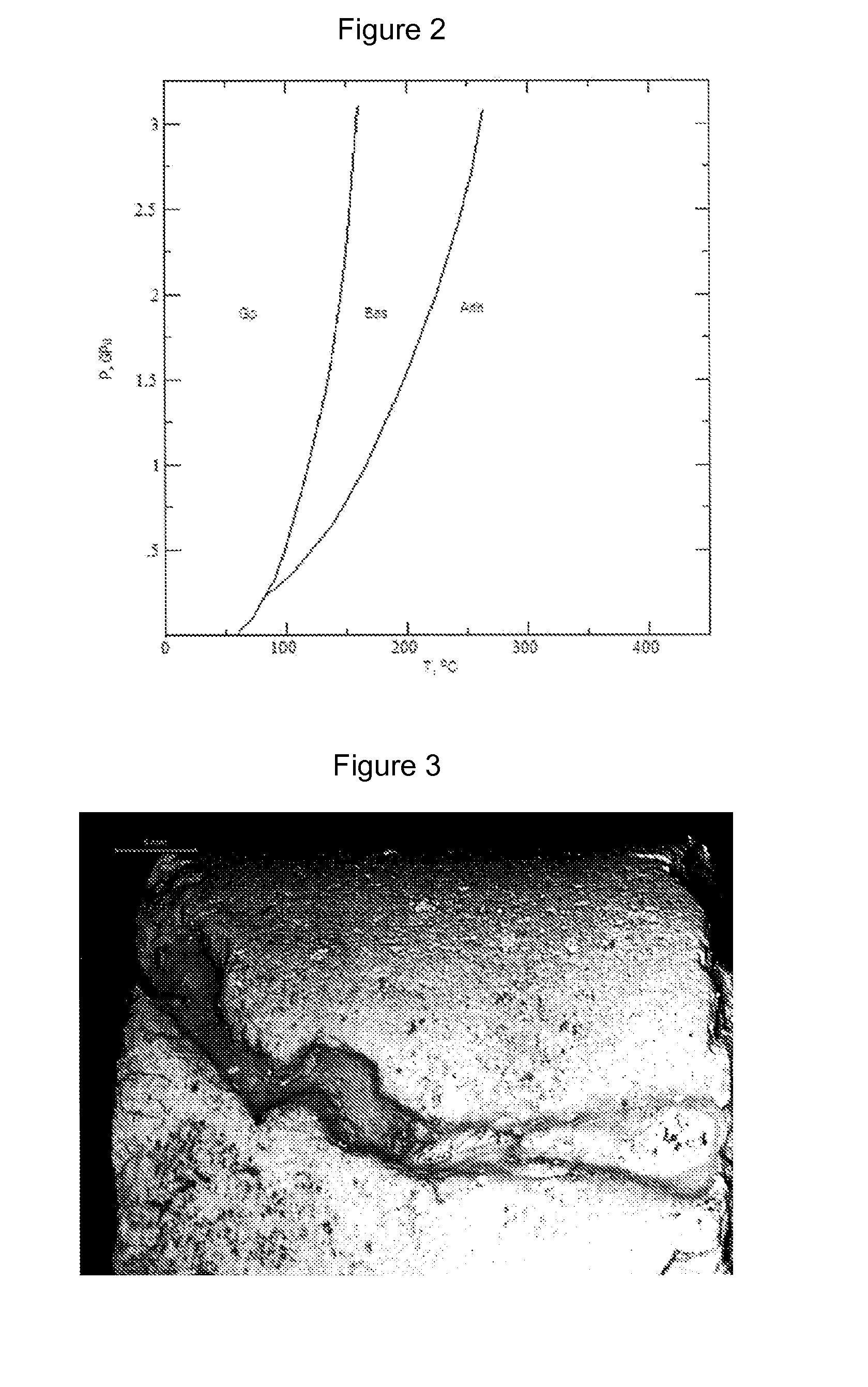

Layered titanic acid, lamellar titanic acid, lamellar titanium oxide and method for producing lamellar titanic acid

Owner:OTSUKA CHEM CO LTD

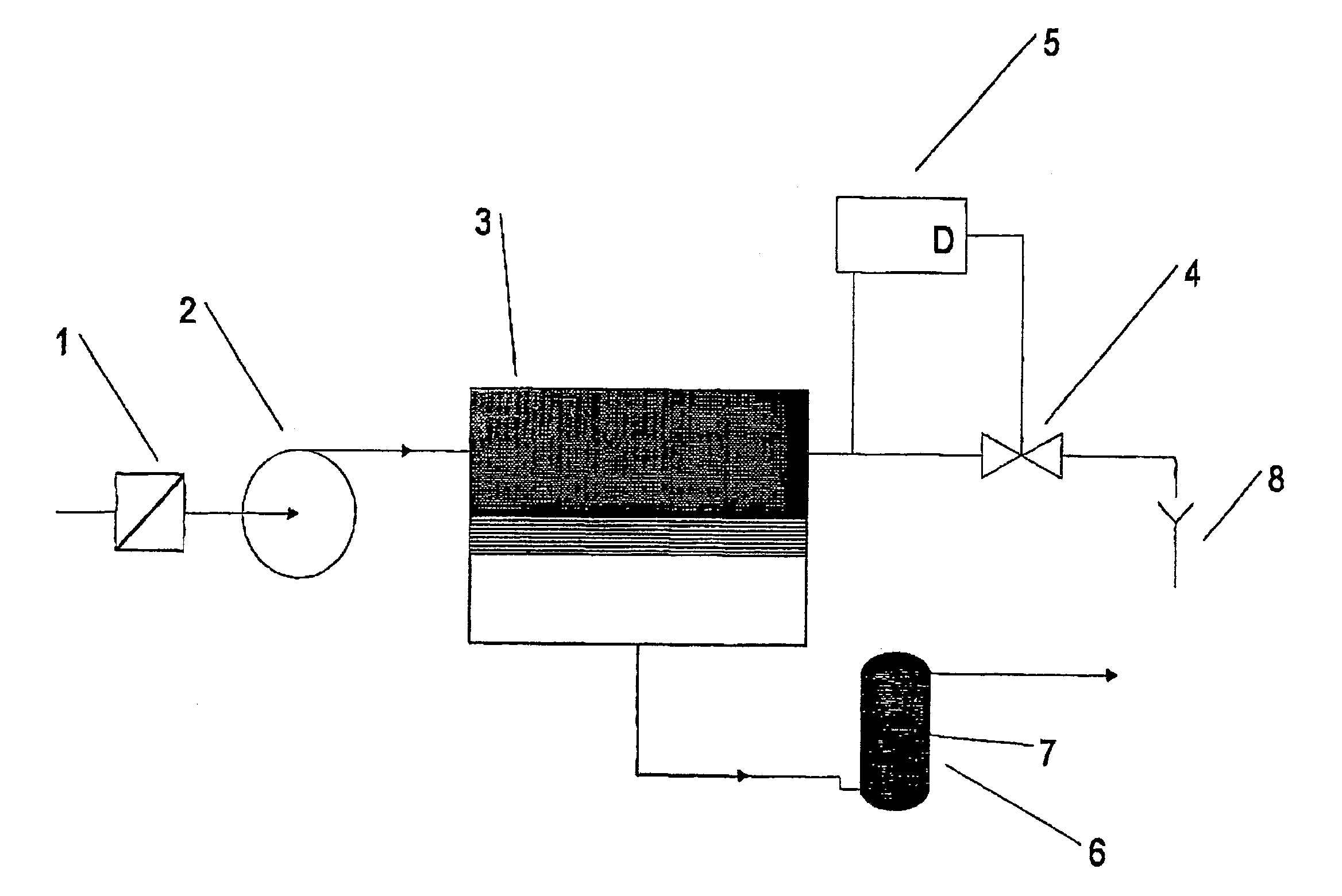

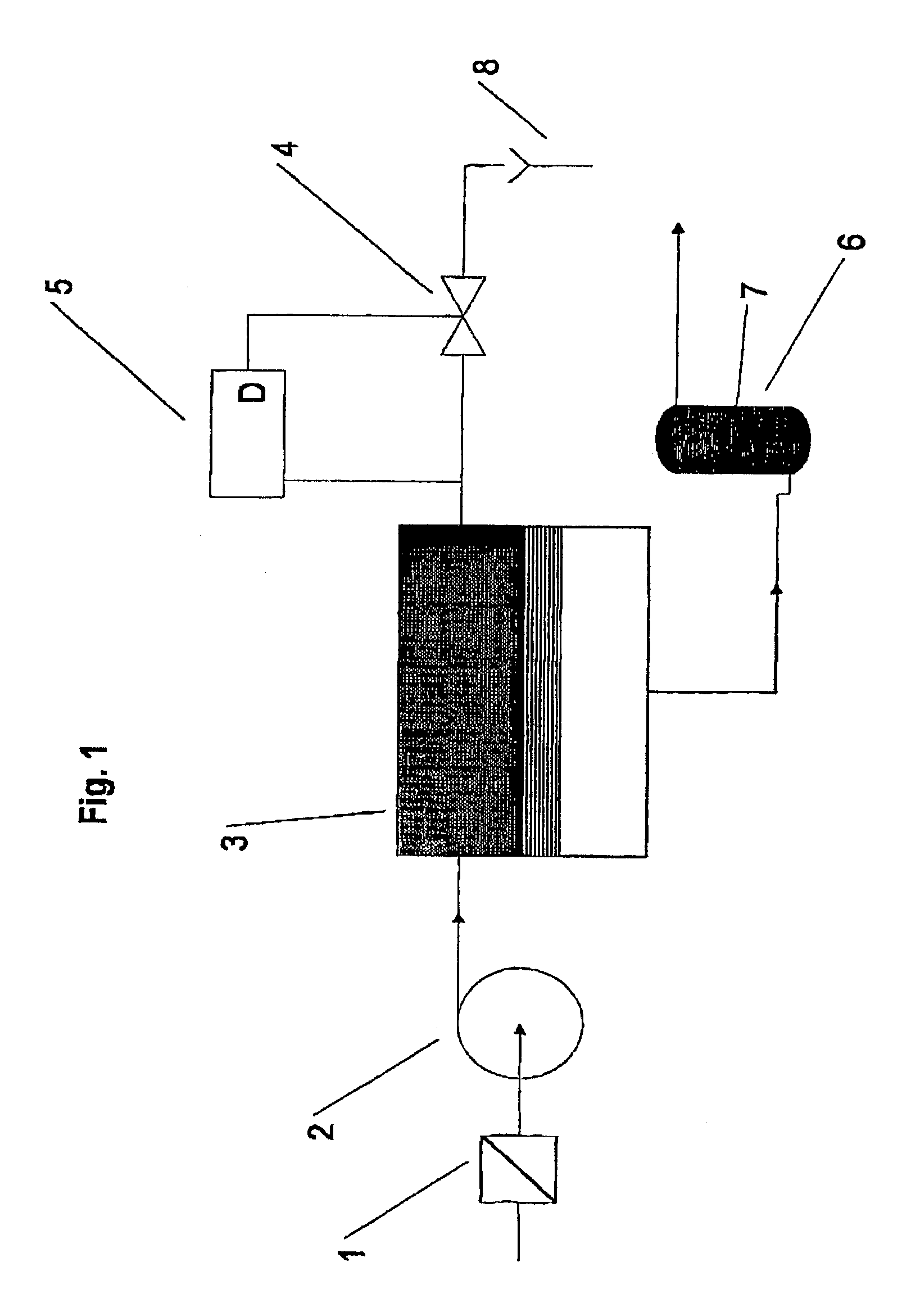

Method and device for reducing scale formation and/or corrosion in systems which conduct liquids

InactiveUS7273558B2Reduce foulingReduce corrosionSolid sorbent liquid separationWater/sewage treatment by ion-exchangePhosphatePotassium

The invention relates to a method and a device for reducing scale formation and / or corrosion in systems which conduct liquids or are in contact with liquids. According to the invention, this is achieved without reducing the quantity of hardness constituents contained in the liquid overall, without exchanging the hardness constituents in the liquid for other cations such as e.g. hydronium, sodium or potassium and without adding chemicals such as e.g. phosphates which inhibit scale formation to the liquid. Instead, scale formation is reduced by specifically shifting the molar distribution of the hardness constituents, especially the distribution proportions of the individual hardness constituents magnesium and calcium strontium and barium. According to the inventive method, proportions of the hardness constituents calcium, strontium and barium in the liquid are substituted with the proportions of the hardness constituent magnesium, In addition to efficiently reducing scale formation, the method inhibits corrosion processes in systems which conduct liquids or are in contact with liquids and reduces the extent of these processes.

Owner:PITTWAY SARL

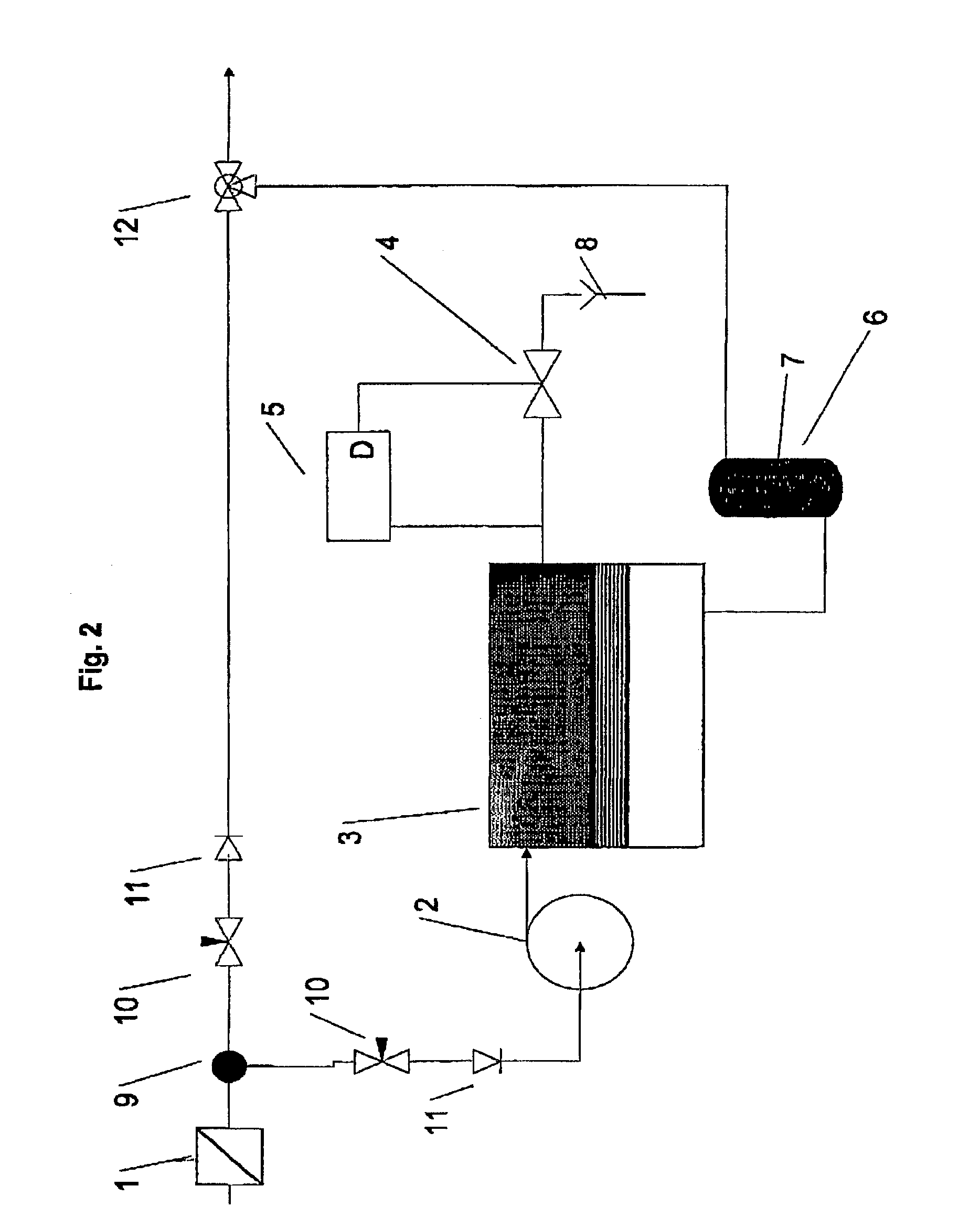

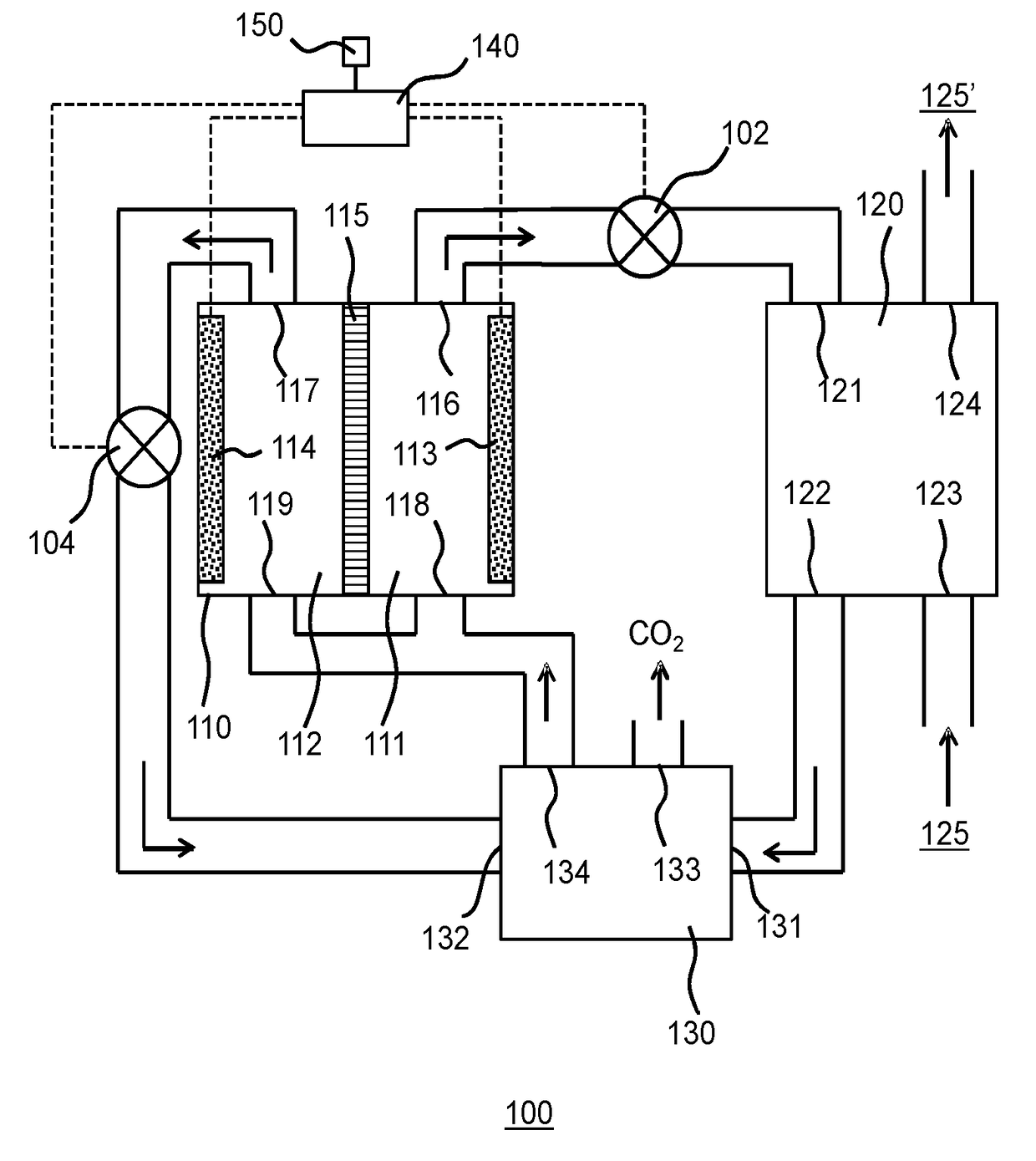

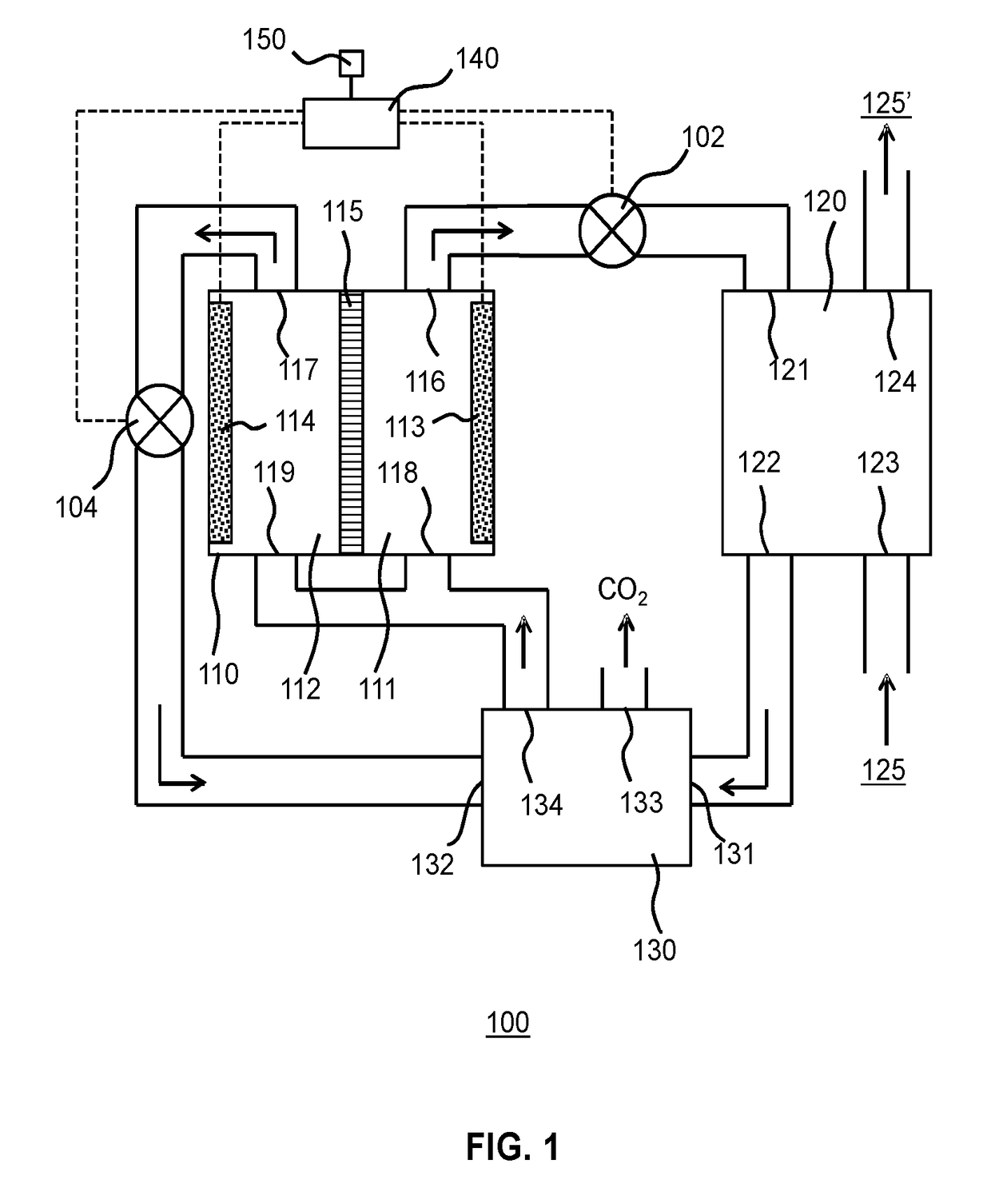

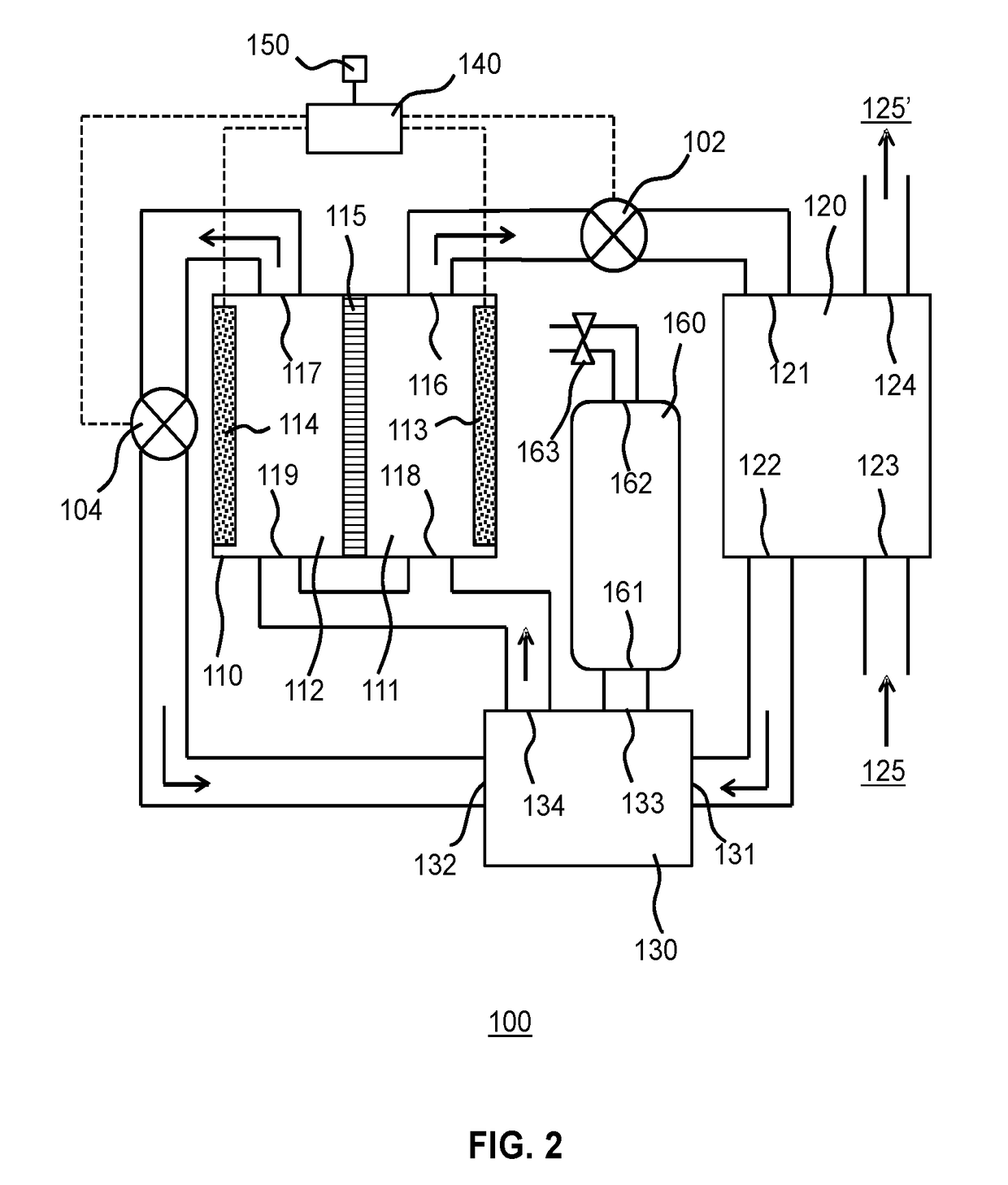

Gas capture apparatus and method

ActiveUS20170326497A1Promote growthReduce complexityWater treatment parameter controlProductsHydronium ionElectrolysis

A capture device for capturing a target gas from a gas flow is disclosed that can be continuously used without requiring consumption of target gas binding salts. To this end, the device is arranged to generate separate acidic and alkaline streams of fluid by electrolyzing water, binding the target gas to the hydroxide ions in the alkaline fluid stream or the hydronium ions in the acidic stream, and recombining the generated streams to release the bound target gas and regenerating part of the electrolyzed water for further electrolysis. Such a capture device may for instance be used in a gas purification system, e.g. an air purification system for controlling target gas levels in a confined space such as a vehicle cabin, domestic dwelling or office space, a target gas generation system or a target gas enrichment system, e.g. for creating target gas-rich air for horticultural purposes. A method for capturing target gas from a gas flow and optionally utilizing the captured target gas is also disclosed.

Owner:KONINKLJIJKE PHILIPS NV

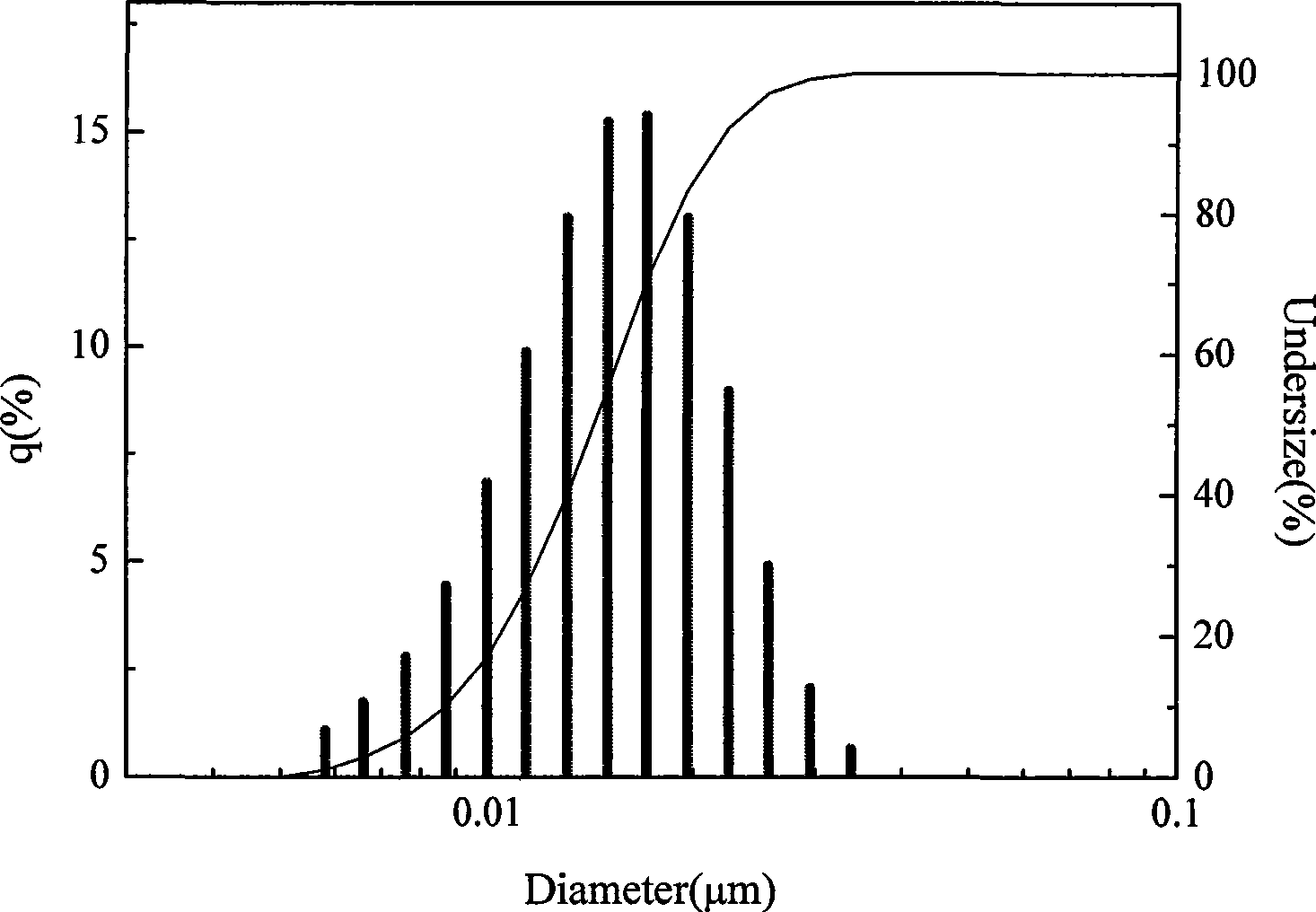

Suspension containing hydronium stabilized colloidal silicic acid nanoparticles, formulation obtained from the said dilutesuspension, powder obtained from the said de-hydrated suspension, compositions obtained from the said powder, preparation and use

ActiveUS20110064798A1Reduce polymerization timeFaster rateCosmetic preparationsBiocideHydronium ionHydrogen

The present invention relates to hydronium stabilized silicic acid nanoparticles, to the formulation obtained from the said diluted suspension, to the powder obtained from the said dehydrated suspension and to the preparation or dosage form obtained from the said suspension, formulation or powder, to their preparation and their use in all kinds of applications in the domains of food, medicine, pharmaceutics, cosmetics. The present invention provides a stable suspension of colloidal silicic acid nanoparticles having a pH lower than 0.9, a molar silicon concentration between 0.035 and 0.65, a free water concentration of at least 30% (w / v) and a ratio between hydronium ion and Si molar concentrations higher than 2 and preferably inferior to 4. The present invention further provides a method for preparing a stable suspension of colloidal silicic acid nanoparticles, which comprises the steps of providing an aqueous inorganic or organic silicon solution and quick mixing said aqueous inorganic or organic silicon solution with water containing a strong acidic compound at a temperature inferior at 30° C., preferably comprised between 1 and 25° C., to form a suspension of colloidal silicic acid nanoparticles having a pH lower than 0.9, stabilized by hydronium ions, the ratio between hydronium ions and Si molar concentrations being higher than 2 and preferably inferior to 4, for a molar silicon concentration between 0.035 and 0.65 and a free water concentration of at least 30% (w / v).

Owner:AQUARIUS INVESTHLDG +1

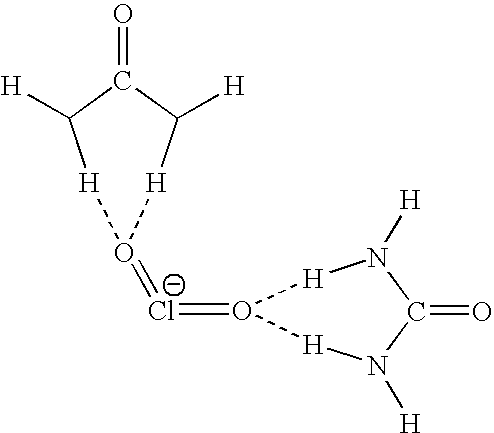

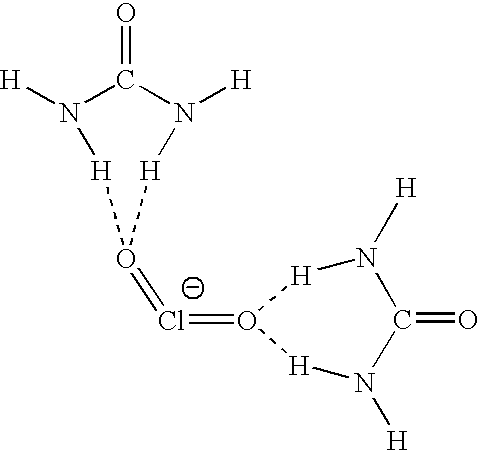

Stabilized Chlorine Dioxide and Hypochlorous Acid in a Liquid Biocide

InactiveUS20080226748A1Reduce formationProcess stabilityBiocideAntisepticsHydronium ionChlorine dioxide

A liquid biocide containing stabilized chlorine dioxide and hypochlorous acid for various uses, including use as a teat dip or dairy animals. The stable, prophylactic biocide consists essentially of 0.10-20.0% by weight of a chlorite salt, 0.1-3.0% by weight of an acid, 0.10-2.0% by weight of an alkaline agent, and the balance water. Chlorite salt reacts with the acid to form germicidal chlorine dioxide and hypochlorous acid. The acid constituency and the alkaline agent constituency regulate the pH of the solution such that the biocide is stable when mixed for a period greater than two months. The present disclosure also includes a method of producing a stable, prophylactic biocide for dairy cattle, the method comprising 0.10-20.0% by weight of a chlorite salt, 0.10-3.0% by weight of an acid, 0.10-2.0% by weight of an alkaline agent, and the balance water in a container, and sealing the container. In the method, the acid and alkaline agent constituencies regulate the pH of the solution such that the formation of hydronium ions from the acid is correspondingly regulated to stabilize the solution for a period greater than two months from the date of sealing.

Owner:BOU MATIC TECH

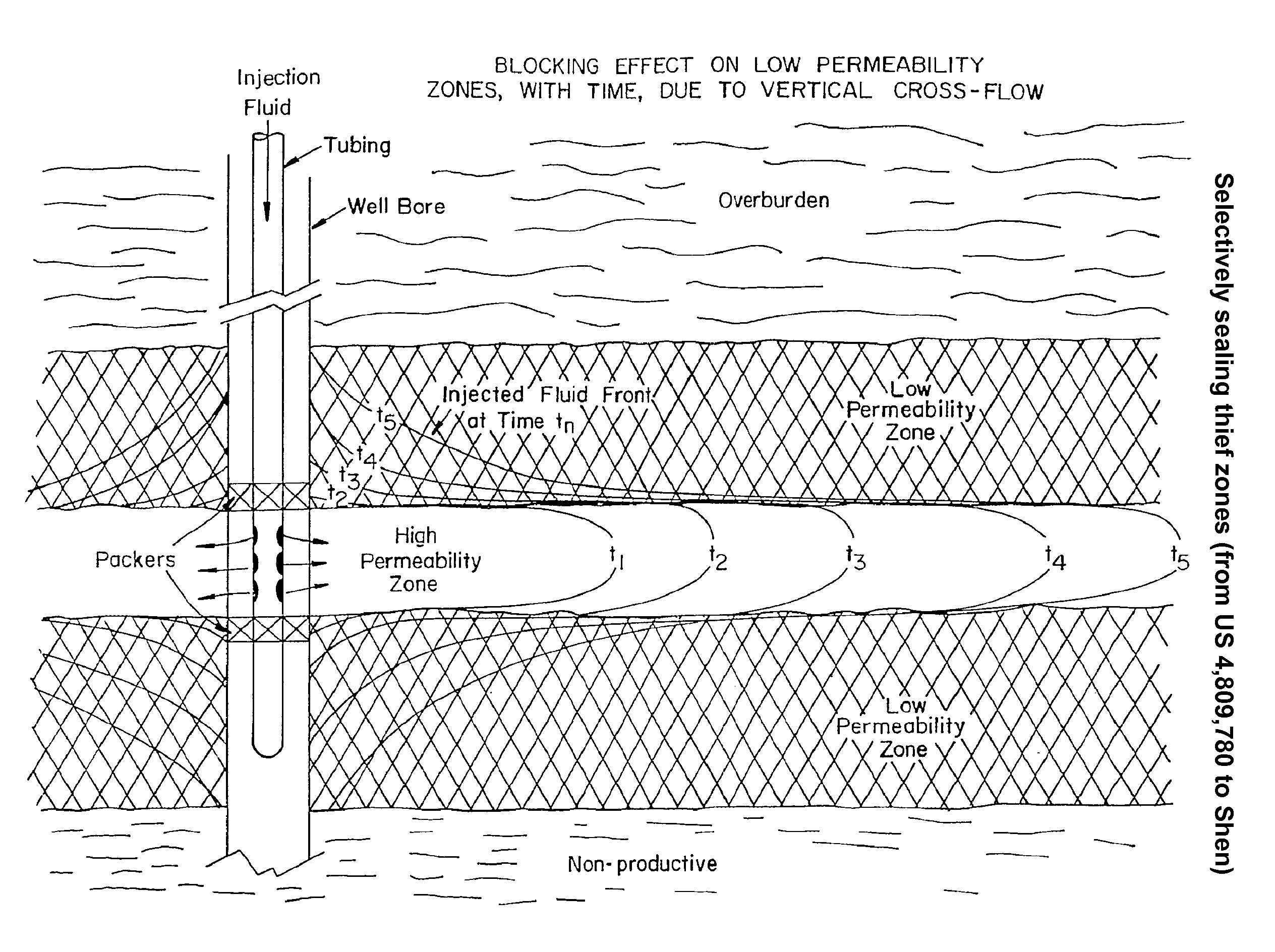

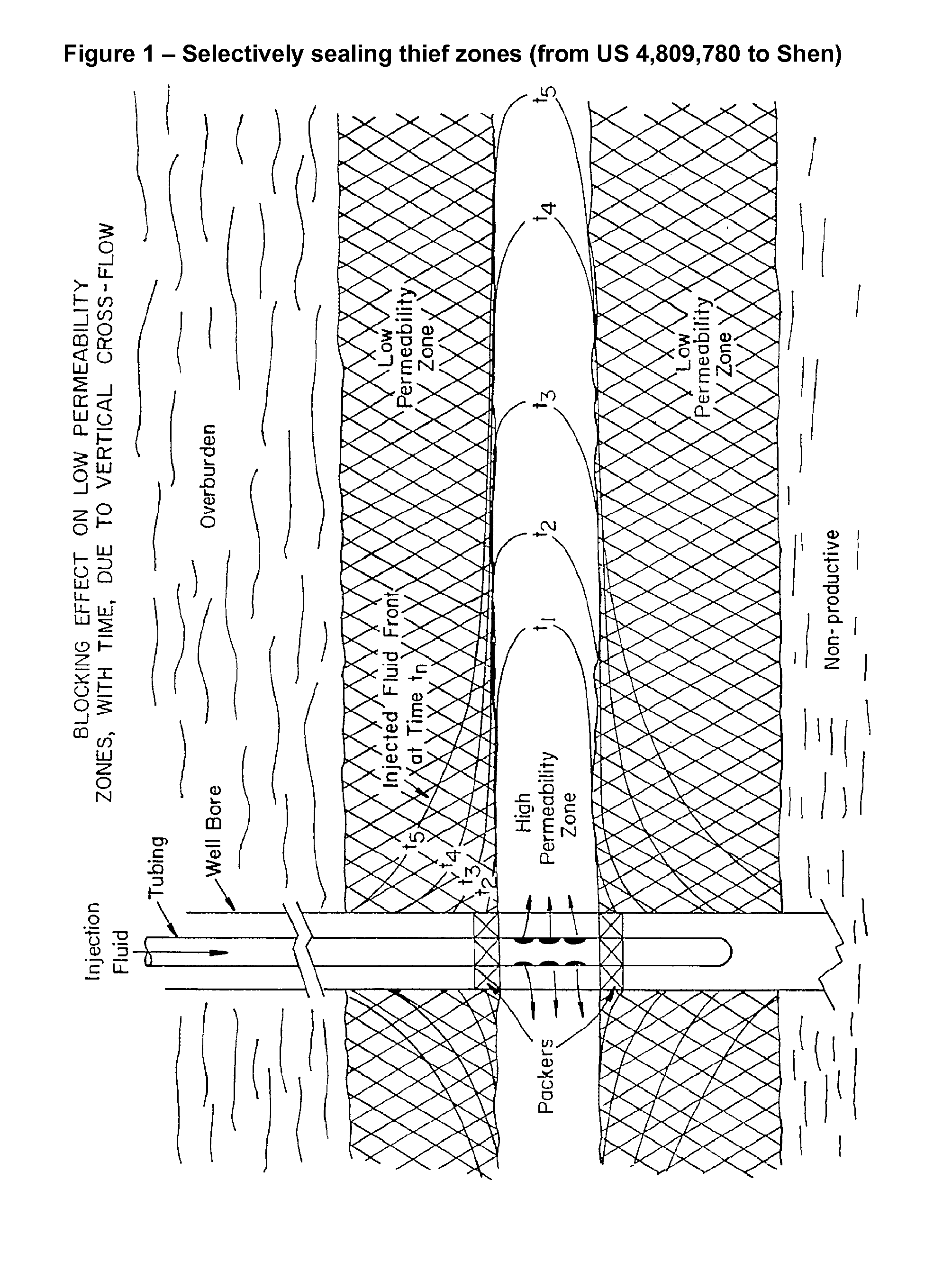

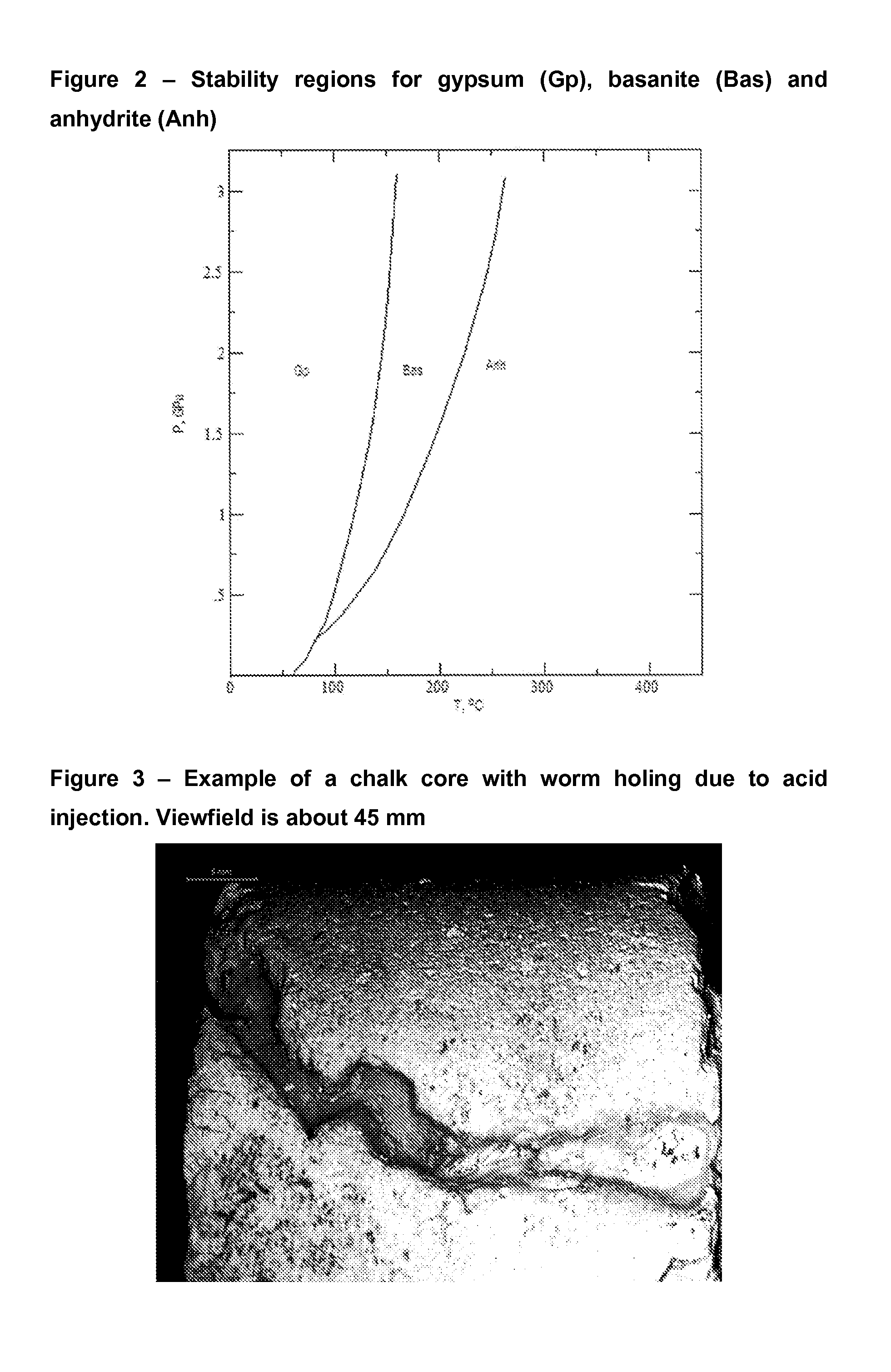

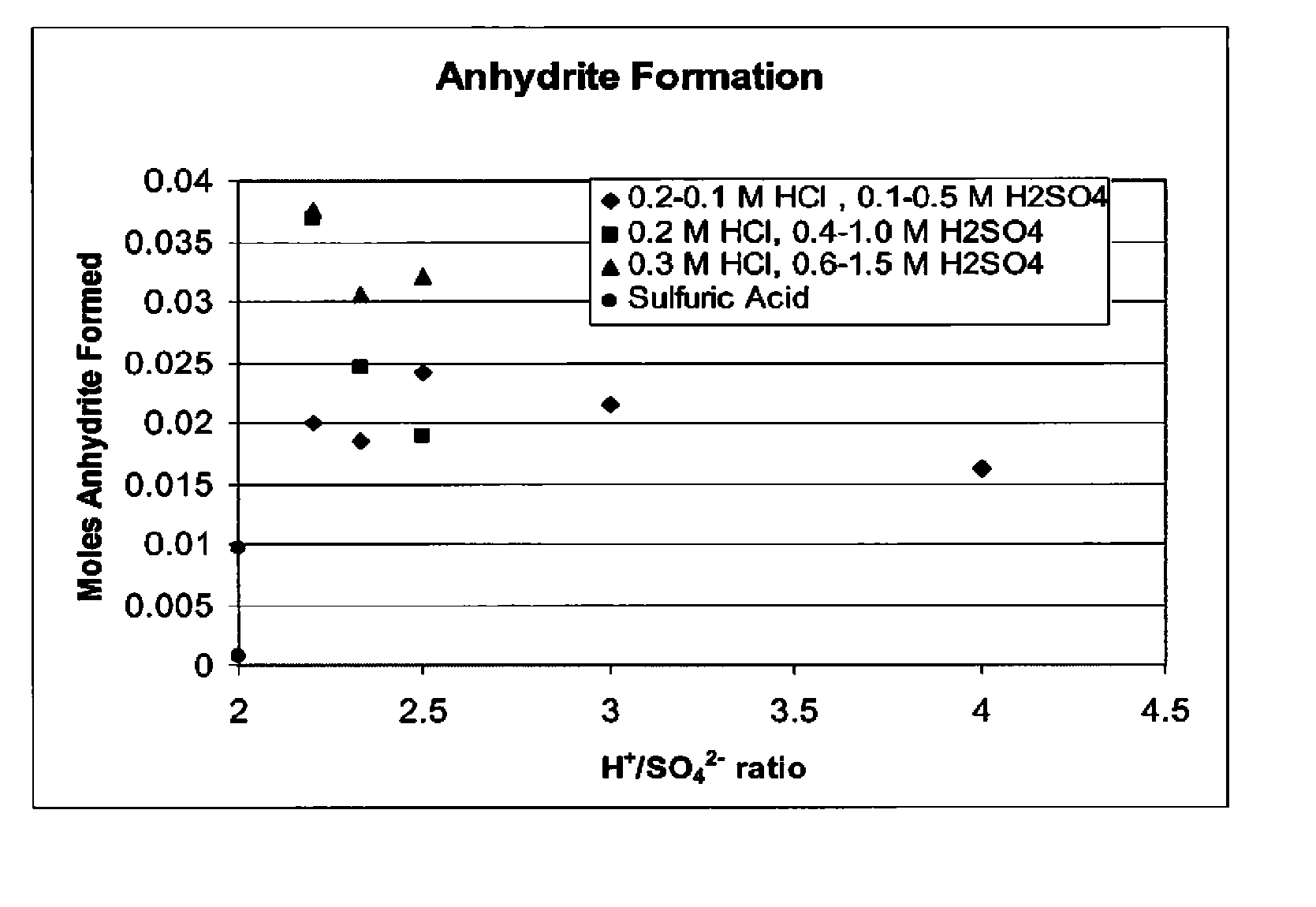

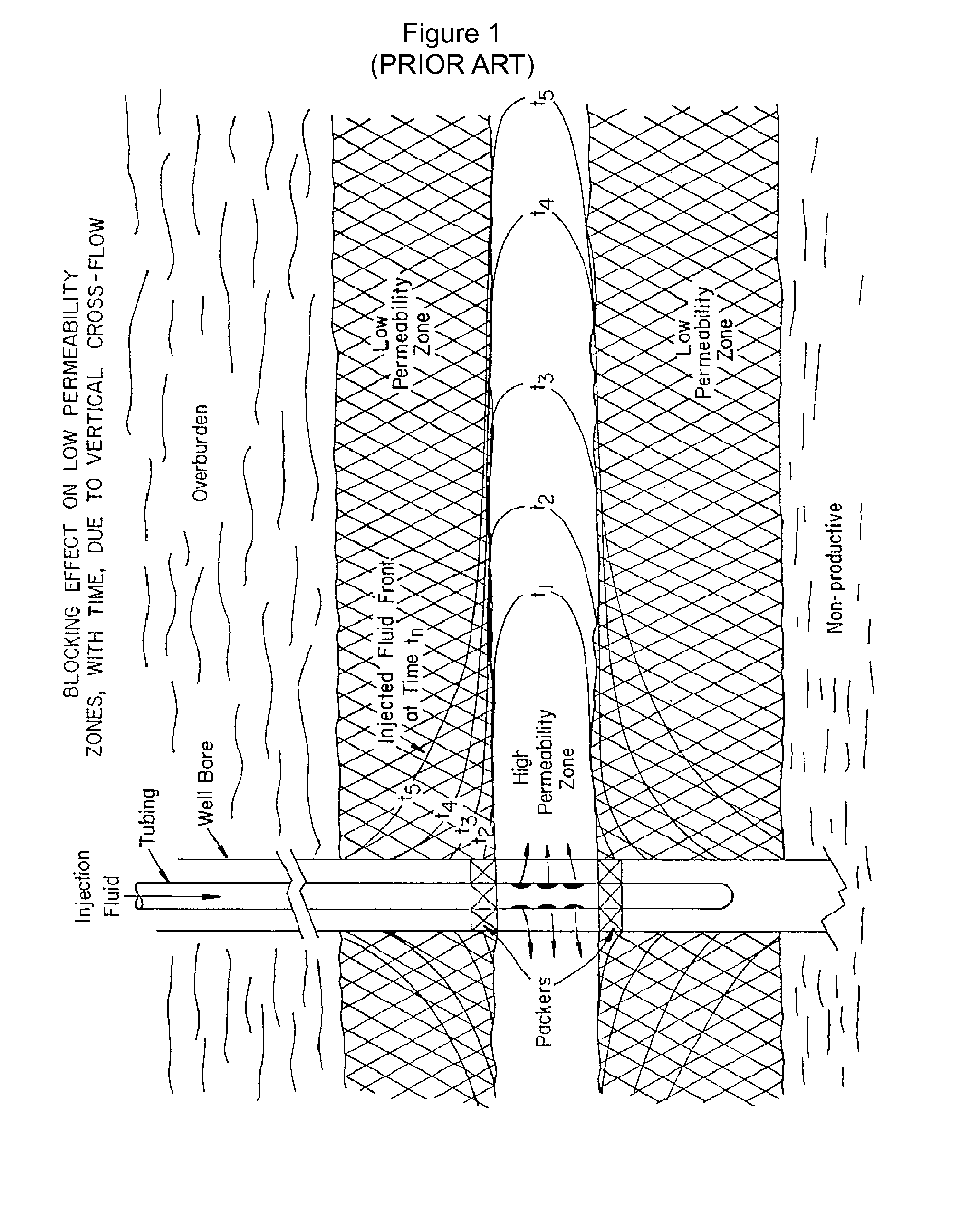

Sealing of thief zones

ActiveUS20120061082A1Simple methodIncrease ionic strengthFluid removalFlushingHydronium ionSULFATE ION

The present invention provides a method for selectively sealing a thief zone in a hydrocarbon reservoir located in a calcium-rich formation and penetrated by a borehole comprising injecting into the thief zone a sealing fluid comprising a mixture of and hydronium ions (H+) and a source of sulfate ions (SO42−) which mixture can provide precipitation of a designated calcium sulfate compound.

Owner:MAERSK OLIE & GAS AS

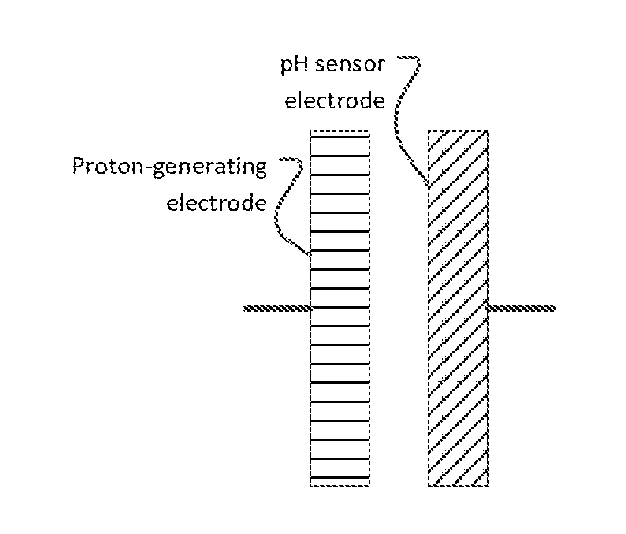

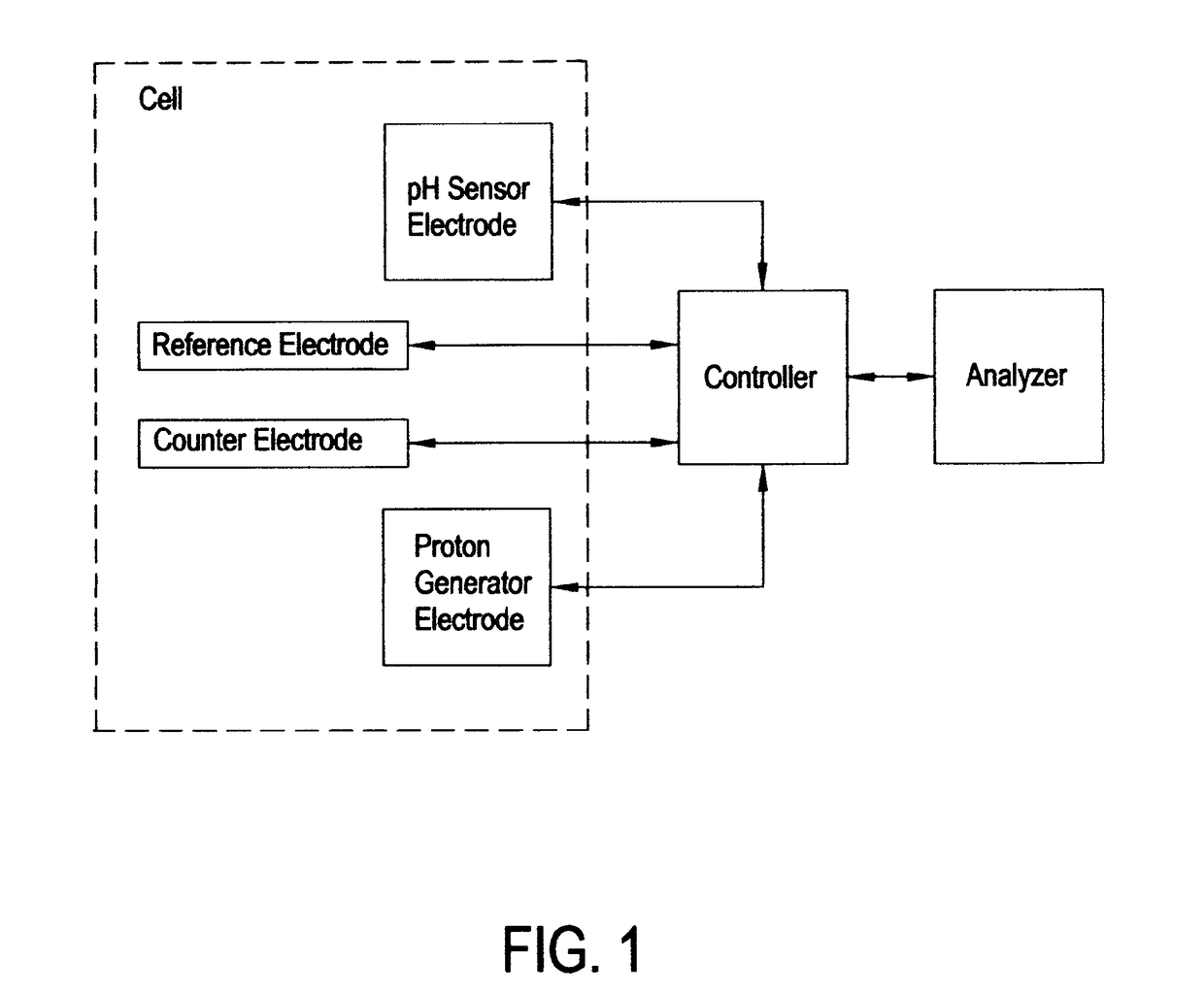

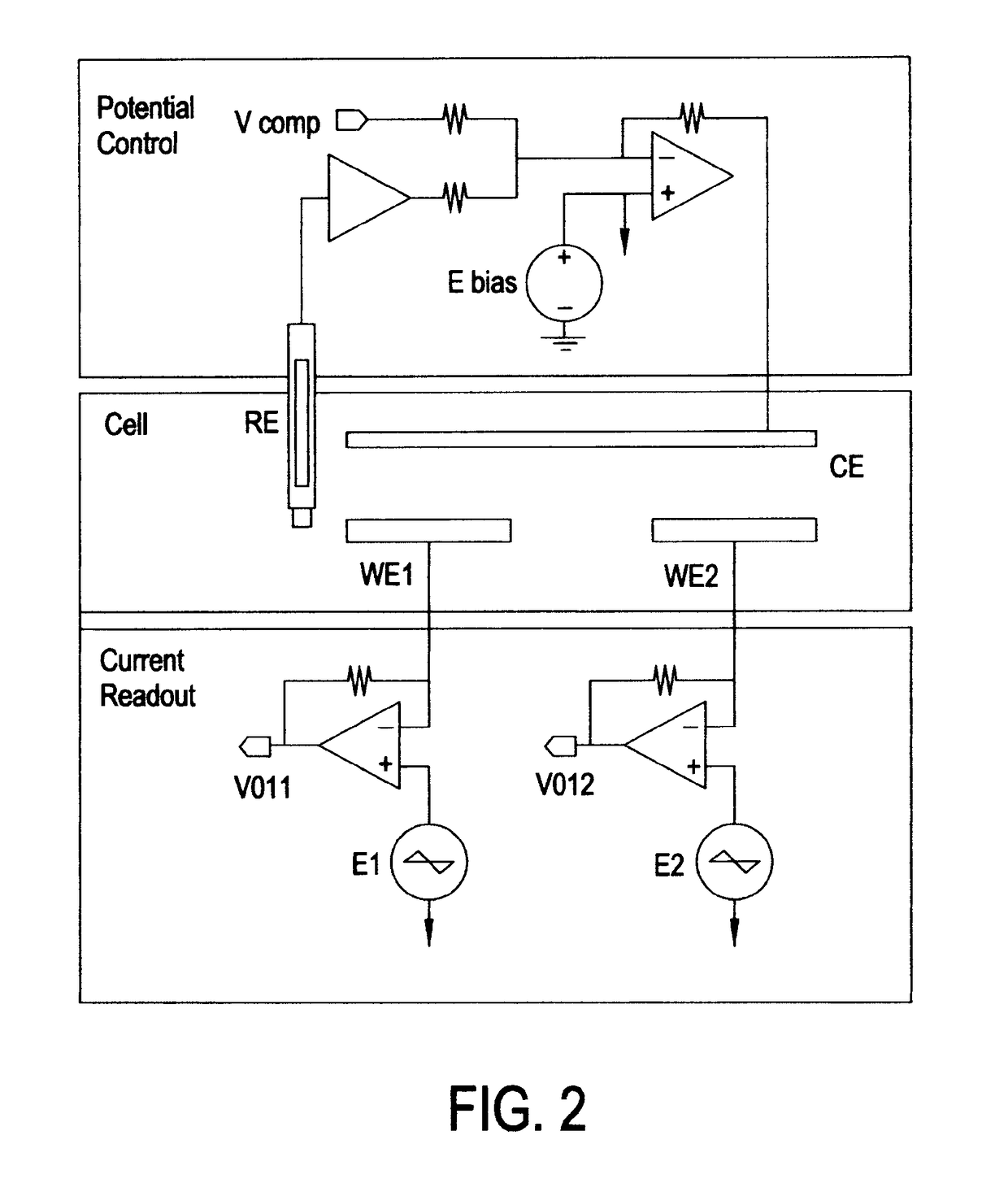

Alkalinity sensor

An embodiment provides a method for determining the alkalinity of an aqueous sample using an alkalinity sensor, including: monitoring the pH of an aqueous sample using a pH sensor in a sample cell, the pH sensor including a pH sensor electrode made of boron-doped diamond; generating hydronium ions, using a hydronium generator, in the aqueous sample in the sample cell, the hydronium generator including a hydronium-generating electrode; changing the pH of the aqueous sample by causing the hydronium generator to generate an amount of hydronium ions in the aqueous sample; quantifying and converting a current or charge to the number of hydronium ions produced to an end point of the electrochemical titration, the end point correlating to the alkalinity of a sample; and analyzing the alkalinity of the aqueous sample based on the generated amount of hydronium ions and the resulting change in pH monitored by the pH sensor.

Owner:HACH CO

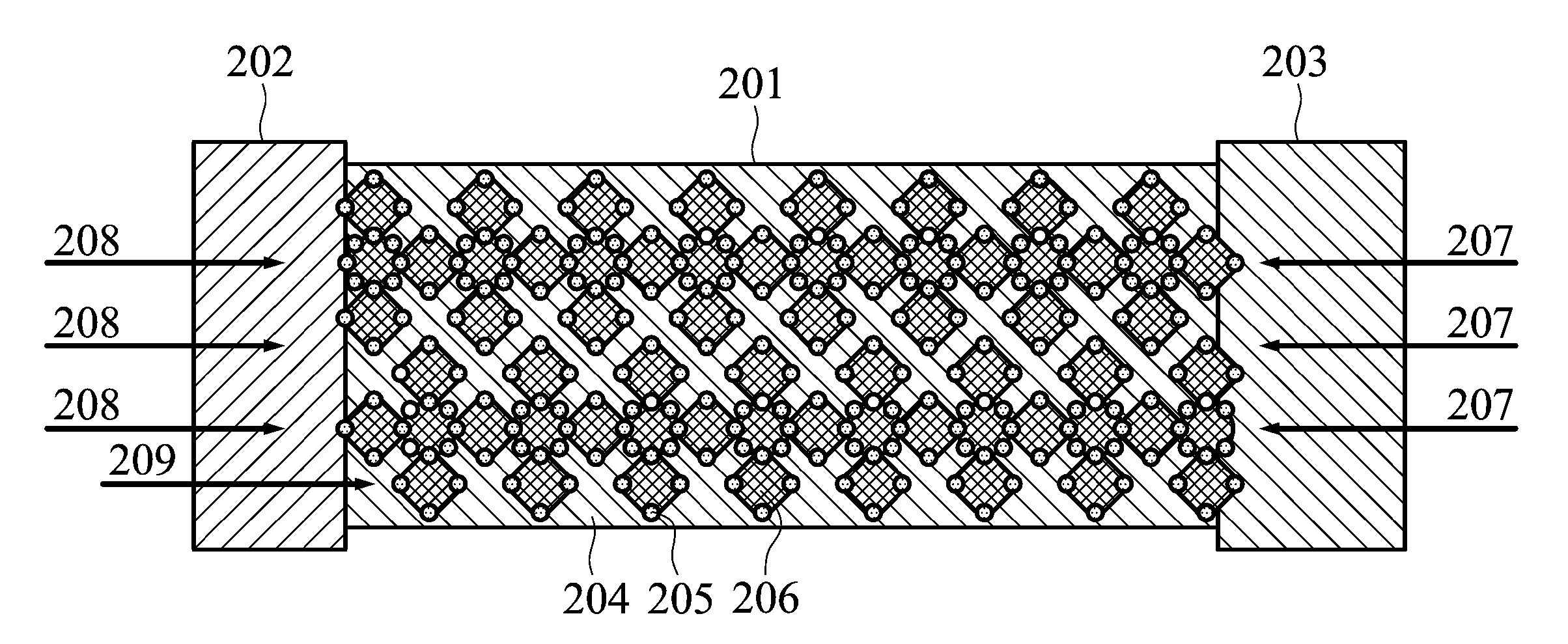

Oxide nanotube composite carbon-based electrode material and preparation method thereof

InactiveCN1755851AHigh capacity densityLower internal resistanceElectrode manufacturing processesHybrid capacitor electrodesFiberHigh rate

The invention relates to an oxide nanometer pipe composite carbon base electrode material of super capacitor and it's preparing method. Wherein the electrode material comprises following components: the metal oxide nanometer pipe in 0.1-20 mass%, the conductive carbon black in 0.1-15 mass%, the nanometer metal in 0.1-8 mass%, the activated carbon in 0.1-99 mass%, and the nanometer activated carbon fiber in 0.1-99 mass%. Based on the activated carbon with high rate of surface area and the nanometer activated carbon fiber, said electrode material utilizes the metal oxide nanometer pipe and three-dimensional network cage construction formed by said metal oxide nanometer pipe to supply the transmission channel of hydronium of electrolyte, which can markedly improve the effective rate of surface area of electrode activated material to improve the capacity density of said electrode material, to attain the super capacitor with high energy density. And The invention has lower cost and supports the commercial application.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

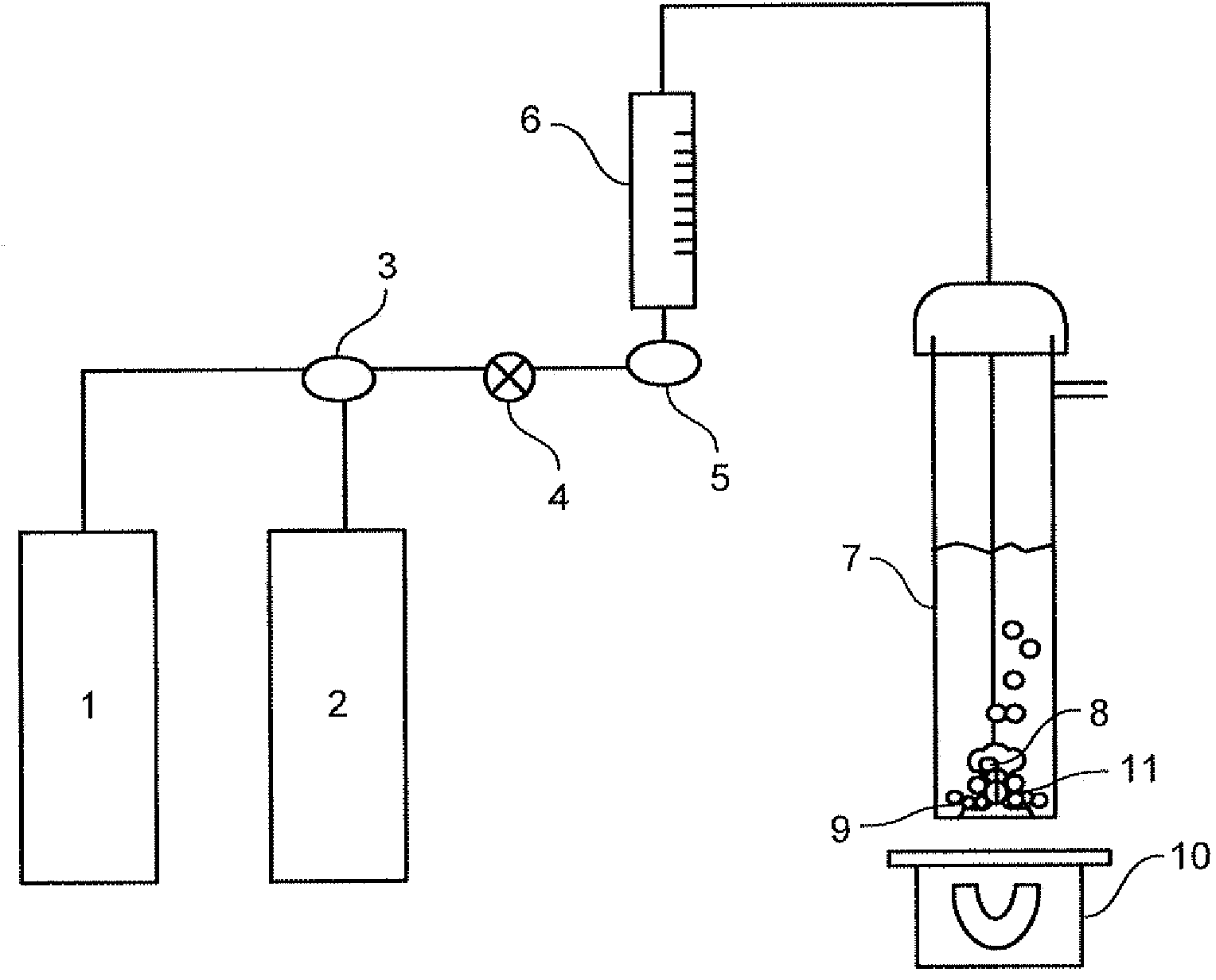

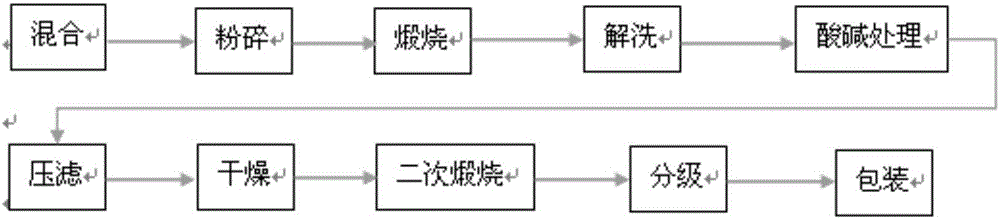

Nanometer zirconia sol and preparation method thereof

InactiveCN101544402ANarrow and stable particle size distributionLow reaction temperatureZirconium compoundsWater bathsEmulsion

The invention relates to a nanometer zirconia sol and a preparation method thereof. The proposal comprises the following steps that: firstly, an industrial zirconium oxychloride solution with a concentration of between 0.1 to 3 mol / L and ammonia water with a concentration of between 1 and 3.5 mol / L are slowly dripped into an ammonium chloride buffer solution with a concentration of between 0.1 and 1.5 mol / L at a temperature of between 25 and 35DEG C under stirring conditions, the pH value of the mixed solution is controlled to be between 8 and 10, and the mixed solution is continuously stirred for 0.5 to 1 hour to obtain a precursor, namely a zirconium hydroxide hydrate precipitate; then the zirconium hydroxide hydrate precipitate is scrubbed and carried out suction filtration for 2 to 4 times to obtain a filter cake; then the filter cake is dispersed into water according to the mol ratio that the zirconium hydroxide hydrate to nitric acid solution to the water is 1: 0.8-1.5: 40-200, and the nitric acid solution is dripped during the stirring to obtain an emulsion; and finally, a surfactant which accounts for 0.1 to 1.5 percent of the volume of the emulsion and a complexing agent which accounts for 0.5 to 3 percent of the volume of the emulsion are added into the emulsion respectively, the mixture is continuously stirred for 0.25 to 0.5 hour, and the mixture is heated for 6 to 20 hours in water bath at a temperature of between 85 and 90 DEG C to obtain the nanometer zirconia sol. The nanometer zirconia sol and the method have the characteristics of low cost, energy conservation, simple process, low equipment requirement and broad application range.

Owner:WUHAN UNIV OF SCI & TECH

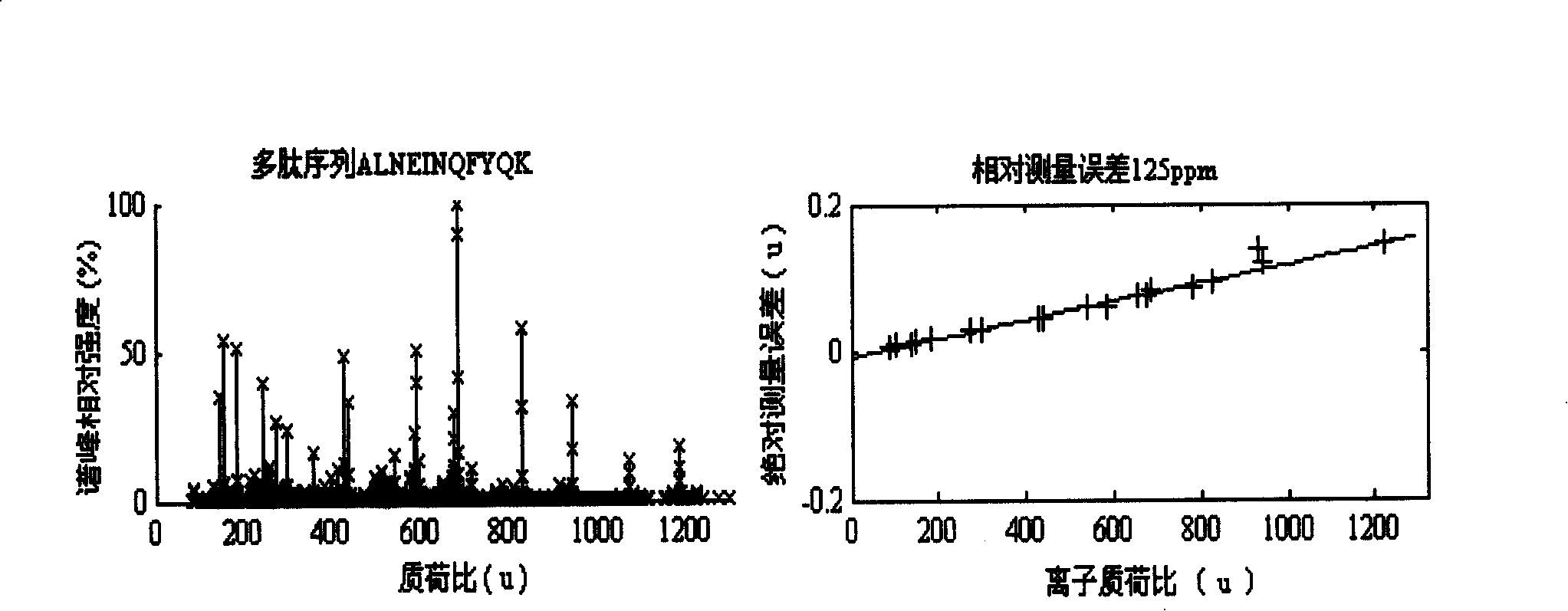

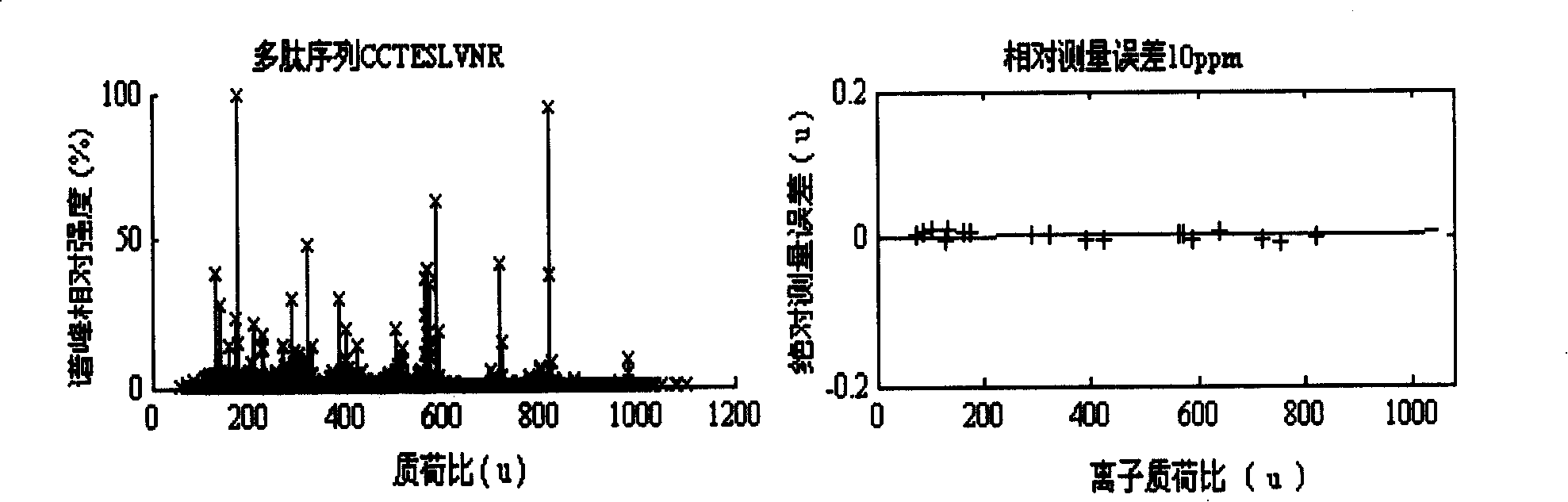

Method for predicting mass spectrum mass measurement error

InactiveCN101196498AForecast Error SituationForecast error distributionComponent separationObservational errorDistillation

The invention discloses a prediction method of the inaccuracy of measurement of the mass spectrum quality, which comprises the following steps: first, resolve the inaccuracy of measurement of the substance into the system error and the random error; second, calculate the inaccuracy of measurement of the sample point in the mass spectrum, wherein the sample point comprises the hydronium, sum of the hydronium or difference of the hydronium; third, select the maximum value and minimum value of the objective function in random error to determine the parameter value of the distillation function in system error. The inaccuracy of measurement of the sample point calculated in the mass spectrum is gained by predicting the molecular formula of the hydronium. The advantages of the invention are that: no extra internal or external standards required as the reference; no pre-identification is needed; both the error condition of individual mass spectrum and the error distribution condition of all mass spectrum of the whole samples; high predicting accuracy.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

Highly protonated hydronium and carbamide as a skin sanitizing and wound healing solution

A water-based, alcohol-free, skin sanitizing and wound healing solution with a natural skin softener, where the nature of the biocidal enhancer used in the process of making the solution significantly increases efficacy while simultaneously enabling much more economical manufacturing, processing and transportation of the product. As the present solution is water-based, no further moisturizing additives are required, and those with sensitive skin, diabetes, allergies or religious beliefs are able to use the product without concern.

Owner:APHEX BIOCLEANSE SYST

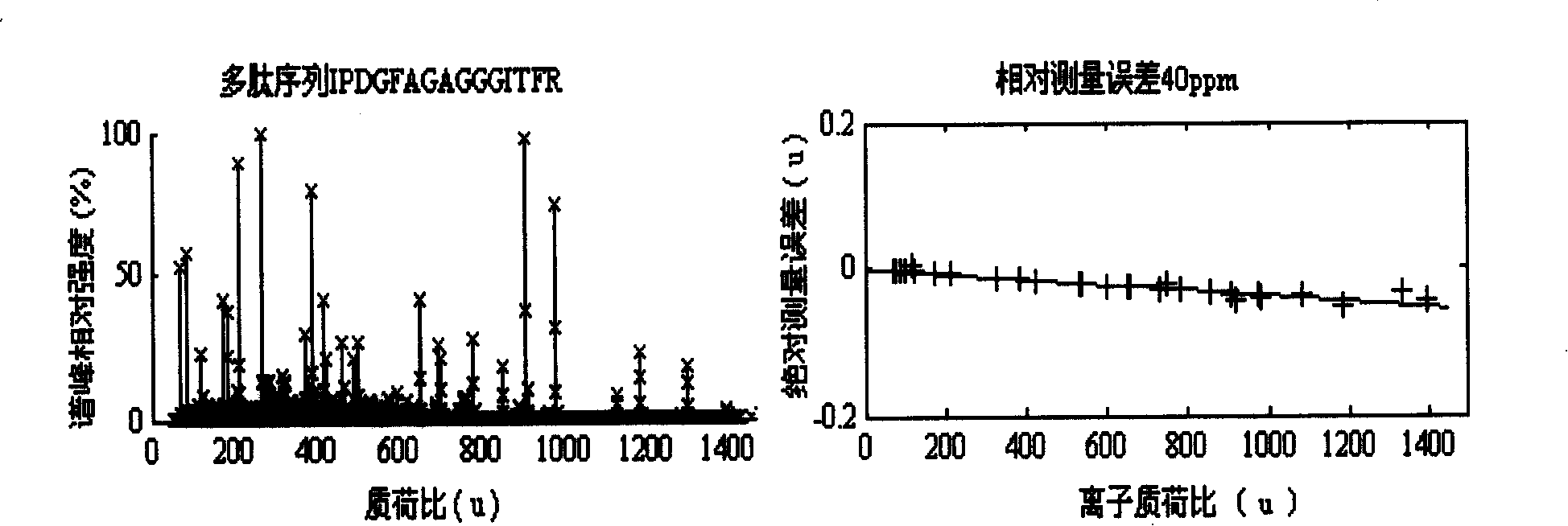

Method for removing magnesium ion and calcium ion in middle-degree brine in salt-field

InactiveCN101139101APotassium chloride content increasedReduce evaporation resistanceAlkali metal chloridesPotassiumSea salt

The present invention relates to a method to wipe off magnesium hydronium and calcium hydronium by the moderate brine of salt field so as to improve sodium chloride output and quality in a sea salt production zone. When the brine of salt field reaches to 10 to 18 degrees Be', the magnesium hydronium is wiped off by electric lime waste residues. The amount ratio of the electric lime to the brine is 1 : 2.5 to 1 : 4. When the concentration of the electric lime reaches to 30 to 60 g / l, the pH value of the brine in the magnesium wiping off process keeps on 11 to 12.5. When the brine approaches to saturation, mirabilite and a few sodium carbonates are added in the brine to wipe off rest calcium hydronium. The invention leads the composition of beach field brine to generate qualitative change and reduces vaporizing impedance. The brine salt producing amount of unit volume and the potassium chloride content in the salt producing mother liquor have been improved greatly. The invention has not only reduced crystallization area, improved salt quality, but also simplified salinization technics. Under the same output and irrigating pool depth, the invention can save 21 percent beach field area. The production can be increased by 10 percent under the same production area.

Owner:ENG TECH INST CO LTD OF CNSIC

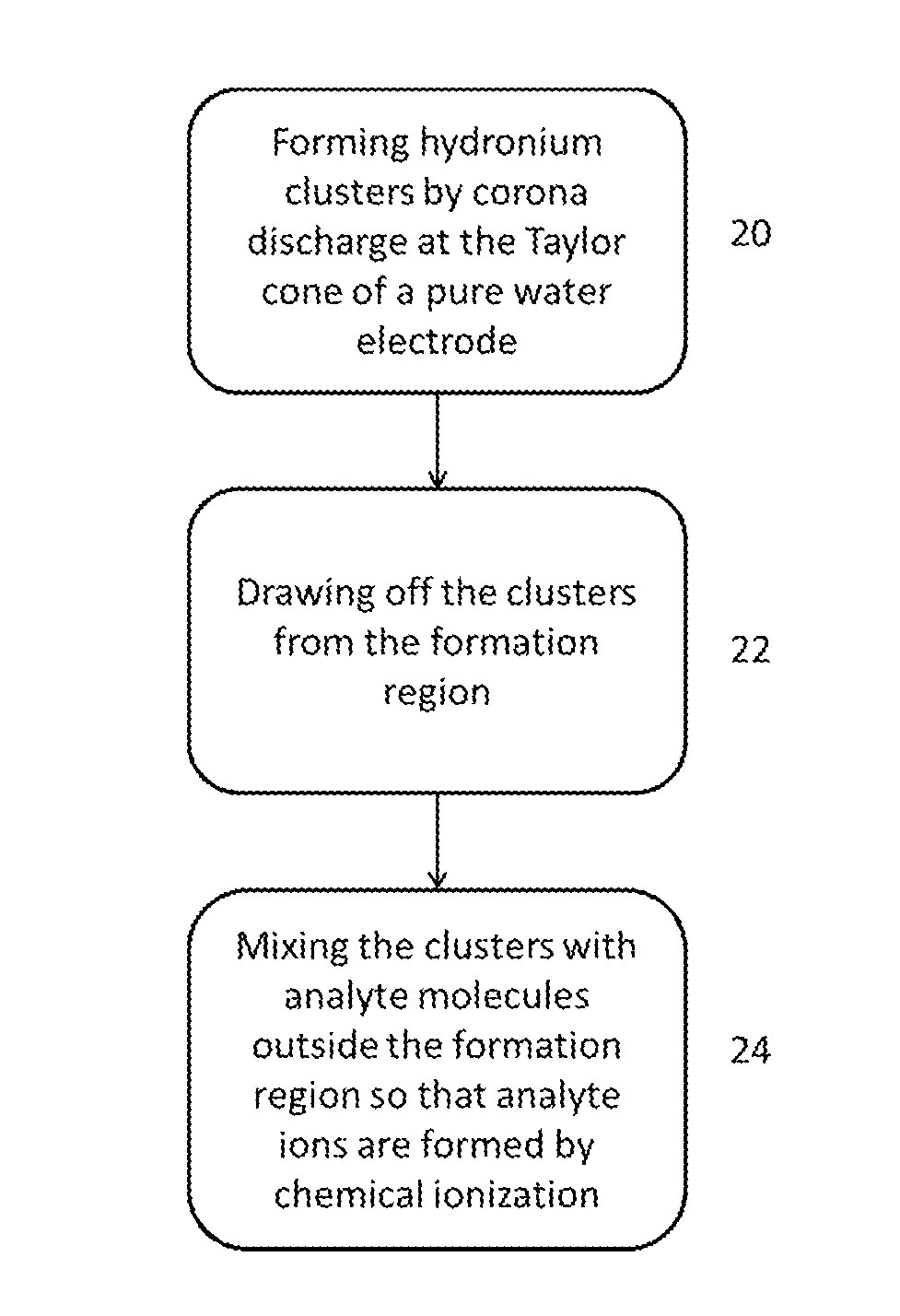

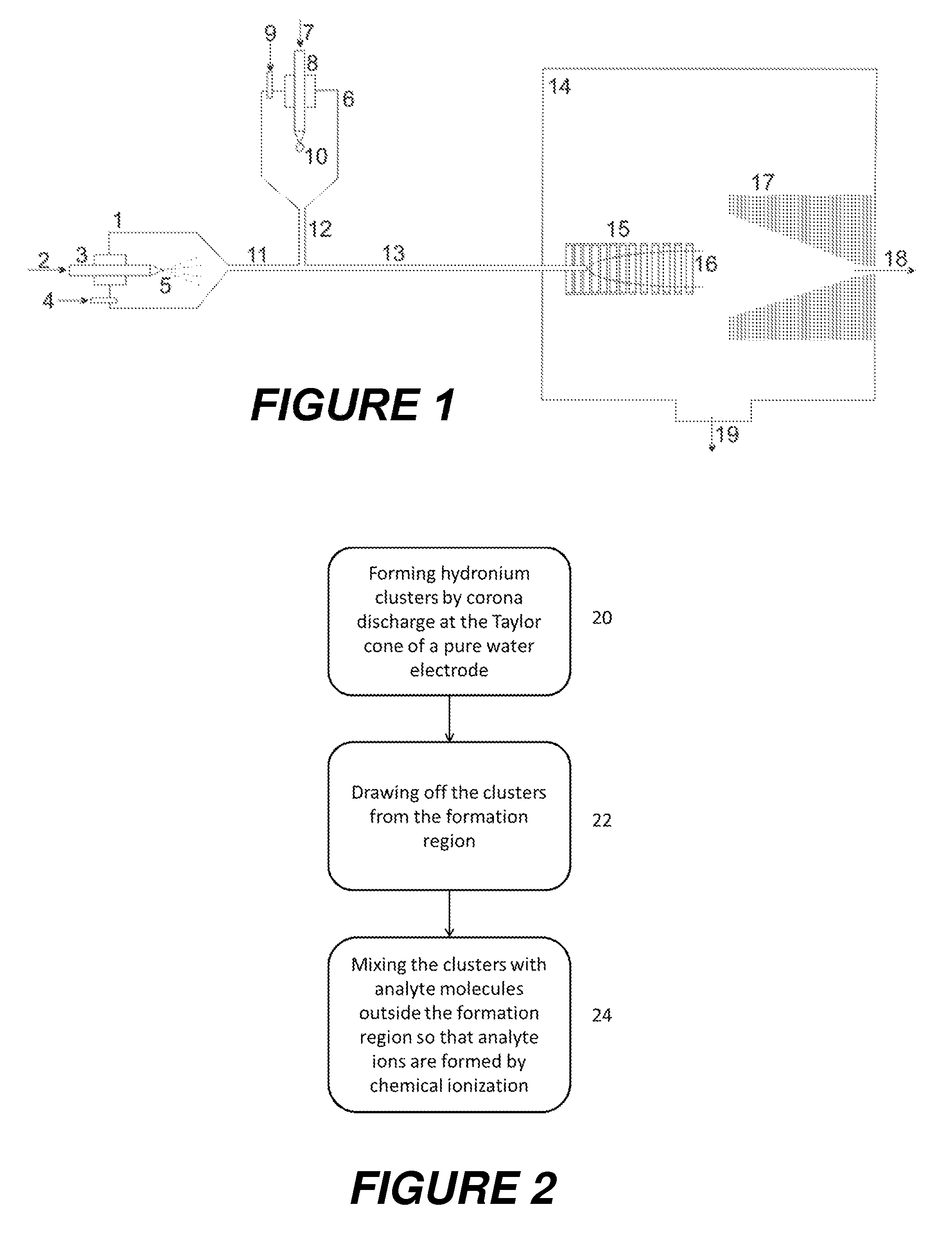

Chemical ionization with reactant ion formation at atmospheric pressure in a mass spectrometer

ActiveUS20140314660A1Long life timeParticle separator tubesPreparing sample for investigationIon hydrationIonization chamber

The invention relates to the production of water cluster ions (“hydronium clusters”) at atmospheric pressure for the chemical ionization of analyte molecules. It is proposed that a corona discharge at the Taylor cone of an aqueous liquid, preferably pure or slightly acidified pure water, is used instead of corona discharges on metal tips, which have been the usual method up to now. The hydronium clusters of the form [H(H2O)n]+ can be produced in a discharge chamber, which is separate from the ionization chamber, and introduced into the ionization chamber through a capillary. In the ionization chamber, the hydronium clusters can be heated and reduced in size by means of electrical acceleration and gas collisions, and thus made more reactive in order that analyte molecules of low proton affinity can also be ionized.

Owner:BRUKER DALTONIK GMBH & CO KG

Stabilized Chlorine Dioxide and Hypochlorous Acid in a Liquid Biocide

InactiveUS20090110754A1Prevent proliferationIncrease milk productionBiocideAntisepticsHydronium ionChlorine dioxide

A liquid biocide containing stabilized chlorine dioxide and hypochlorous acid for various uses, including use as a teat dip or dairy animals. The stable, prophylactic biocide consists essentially of 0.10-20.0% by weight of a chlorite salt, 0.1-3.0% by weight of an acid, 0.10-2.0% by weight of an alkaline agent, and the balance water. Chlorite salt reacts with the acid to form germicidal chlorine dioxide and hypochlorous acid. The acid constituency and the alkaline agent constituency regulate the pH of the solution such that the biocide is stable when mixed for a period greater than two months. The present disclosure also includes a method of producing a stable, prophylactic biocide for dairy cattle, the method comprising 0.10-20.0% by weight of a chlorite salt, 0.10-3.0% by weight of an acid, 0.10-2.0% by weight of an alkaline agent, and the balance water in a container, and sealing the container. In the method, the acid and alkaline agent constituencies regulate the pH of the solution such that the formation of hydronium ions from the acid is correspondingly regulated to stabilize the solution for a period greater than two months from the date of sealing.

Owner:STEVENSON RANDAL D

Conversion of gaseous carbon dioxide into aqueous alkaline and/or alkaline earth bicarbonate solutions

InactiveCN103930372AHigh yieldCalcium/strontium/barium carbonatesBicarbonate preparationLe Chatelier's principleAlkaline earth metal

A material with cationic exchanger properties is introduced into aqueous media, where the equilibriums of carbon dioxide dissolution take place. A cationic exchanger material x / nMw E,- is used to capture hydronium cations (H3O<+>) according to: x / nM<+n>Ex<->(s) + xH3O<+>(aq) = xH3O<+>Ex<->(s) + x / nM<+n>(aq) where "x" stands for molar amount of the anionic centers of charge of the cationic exchanger material E<x-> balanced by x / n molar amount of metal M, "n" stands for the metal valence, and M is selected from the group consisting of 1A and / or 2A of the periodic table of elements. This capture of the hydronium cations, H3O<+>, shifts certain reaction equilibriums to the right, according to Le Chatelier's principle, producing more bicarbonate, HCO3<->, and / or carbonate, CO3<=>, than would otherwise be obtained.

Owner:SILICA DE PANAMA

Water filter material and preparation process thereof as well as corresponding water filter device

InactiveCN102898120AIncrease calcium ion contentImprove the immunityWater/sewage treatment by neutralisationWater/sewage treatment by substance additionHuman bodyWater filter

The invention belongs to the technical field of daily life, and particularly designs a drinking water filter material and a preparation process thereof as well as a corresponding water filter device. The water filter material is prepared by sintering a filter component powder substance and a clay powder substance, wherein the filter component at least comprises a substance which can generate atomic groups with positive electricity and negative electricity. Due to adopting the technical scheme, the pH value of pure water is adjusted to be weakly alkaline, a sterilization function is achieved, macroelements such as potassium, sodium, calcium, magnesium, phosphorus and trace elements such as zinc, iron, selenium, strontium, iodine, fluorine, metasilicic acid and the like, which are beneficial to the human body, are released, two negative ions such as hydroxidion and hydronium ions are produced, immunity and natural healing capacity of the human body for harmful substances can be improved, the water molecular groups can be reduced by utilizing the produced negative ions, and the water molecules and trace elements can be conveniently absorbed by the human body.

Owner:BEIJING TIANTIANYIQUAN WATER PURIFICATION EQUIP

Conversion of gaseous carbon dioxide into aqueous alkaline and/or alkaline earth bicarbonate solutions

ActiveUS8828338B2Good effectLow costCalcium/strontium/barium carbonatesBicarbonate preparationLe Chatelier's principleAlkaline earth metal

A material with cationic exchanger properties is introduced into aqueous media, where the equilibriums of carbon dioxide dissolution take place. A cationic exchanger material x / nM+nEx− is used to capture hydronium cations (H3O+) according to:x / nM+nEx−(s)+xH3O+(aq)=xH3O+Ex−(s)+x / nM+n(aq)where “x” stands for molar amount of the anionic centers of charge of the cationic exchanger material Ex− balanced by x / n molar amount of metal M, “n” stands for the metal valence, and M is selected from the group consisting of 1A and / or 2A of the periodic table of elements. This capture of the hydronium cations, H3O+, shifts certain reaction equilibriums to the right, according to Le Chatelier's principle, producing more bicarbonate, HCO3−, and / or carbonate, CO3=, than would otherwise be obtained.

Owner:SILICA DE PANAMA

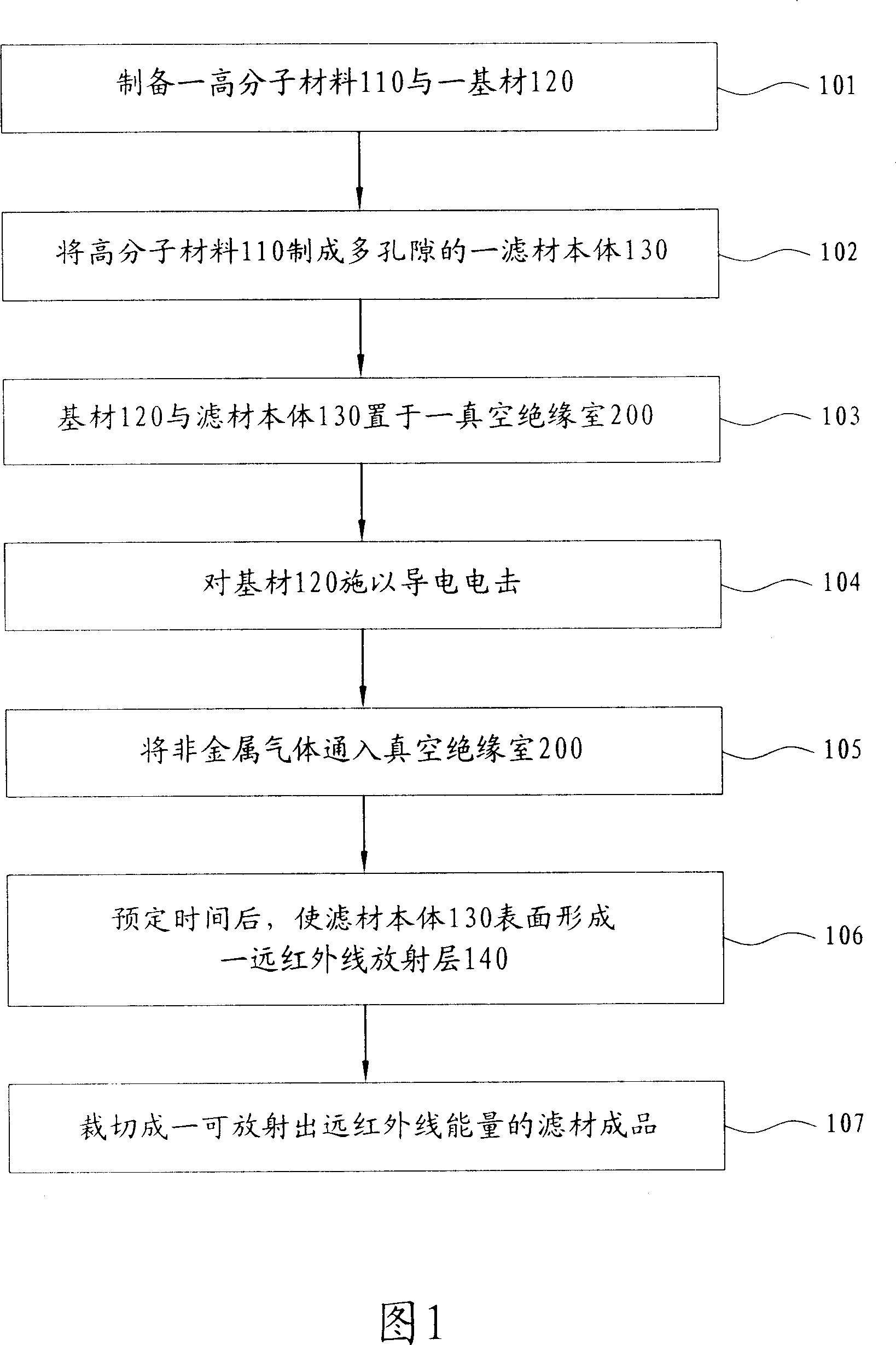

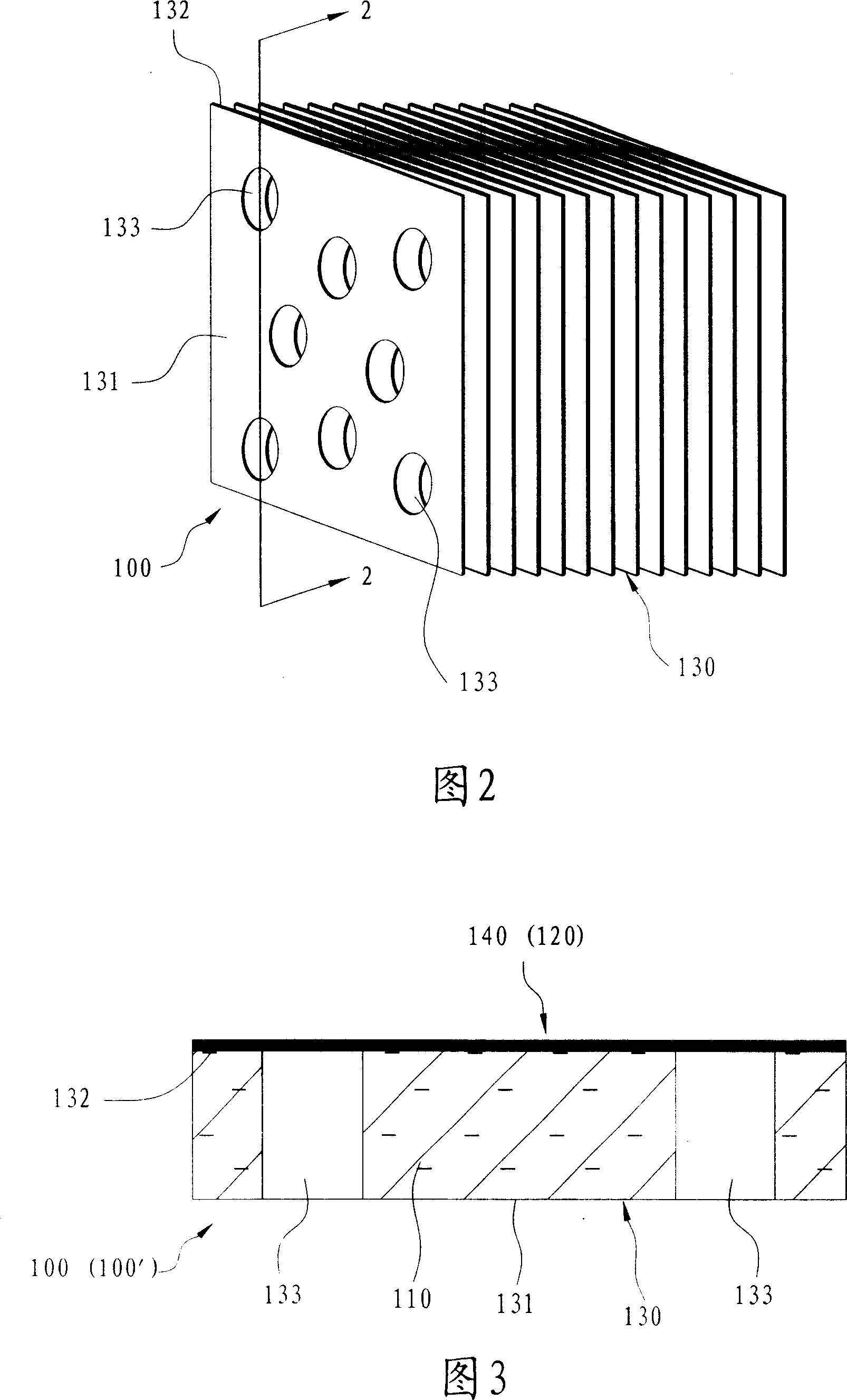

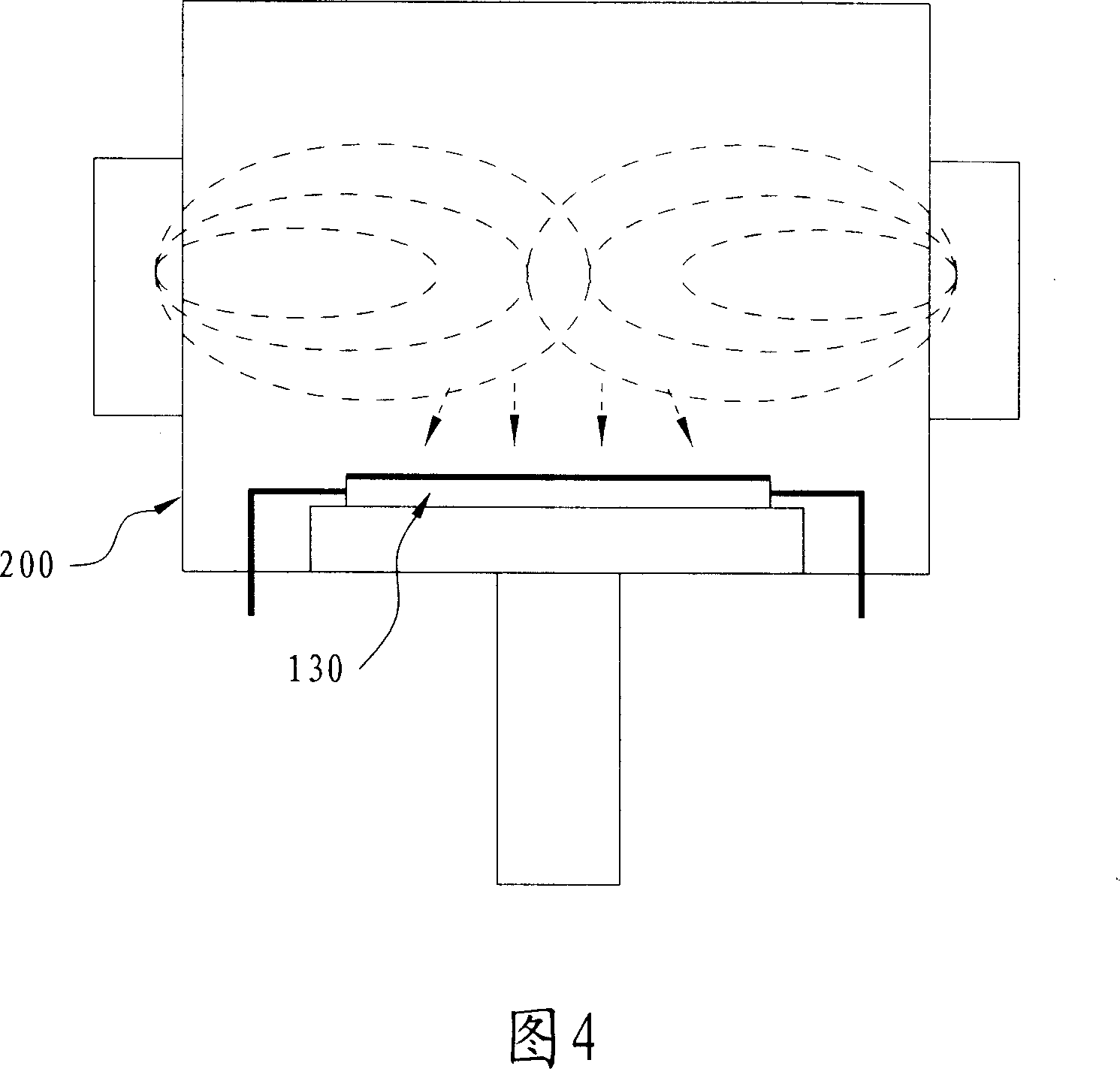

Method for manufacturing filtering material with far infrared energy by non-built-in mode

InactiveCN101121086AIon particle size is smallImprove adhesion strengthDispersed particle filtrationCombustion-air/fuel-air treatmentAir filterEngineering

A manufacturing method of a filtrating material with far infrared energy in a non-implanted manner is that a macromolecule material and at least a base material are placed inside a closed vacuum and insulated room, and subsequently a conductive electric shock is brought to the base material to make the base material produce static hydroniums and make the ionized base material produce mixture in the vacuum circumstance. After the scheduled time, the ionized base material is coagulate and gathered on the surface of the macromolecule material to make the macromolecule material form a far infrared radiating layer. Finally, the macromolecule material is taken out from the vacuum and insulated room to obtain a filtrating material, which can radiate far infrared energy. The far infrared radiating layer material of the filtrating material of the present invention does not producing stripping. The base material can fully mix with the macromolecule material. The present invention is used in an air filter and that an efficacy of a better catalytic effect is achieved.

Owner:SUNSHINE SUNDRY INT

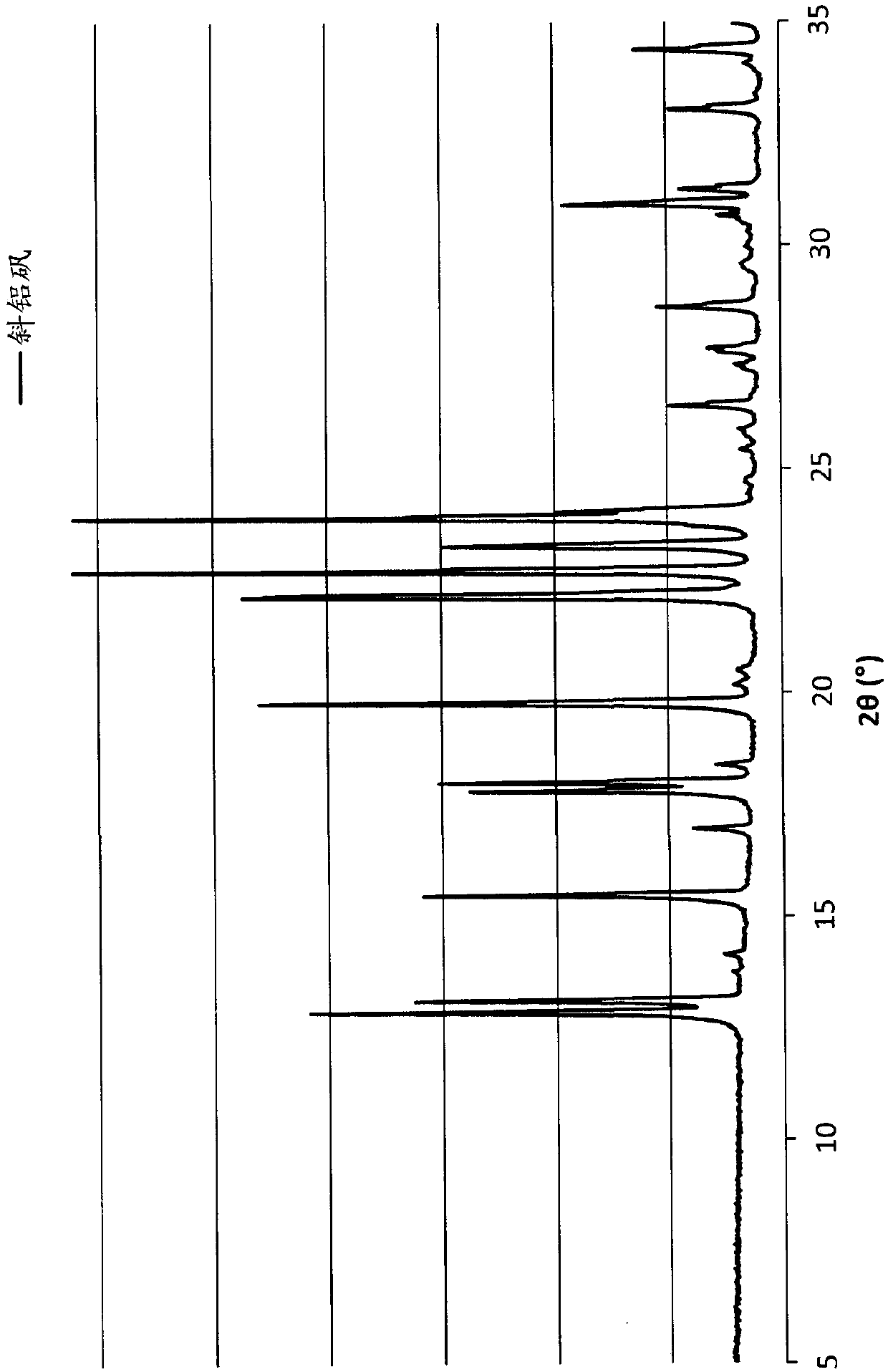

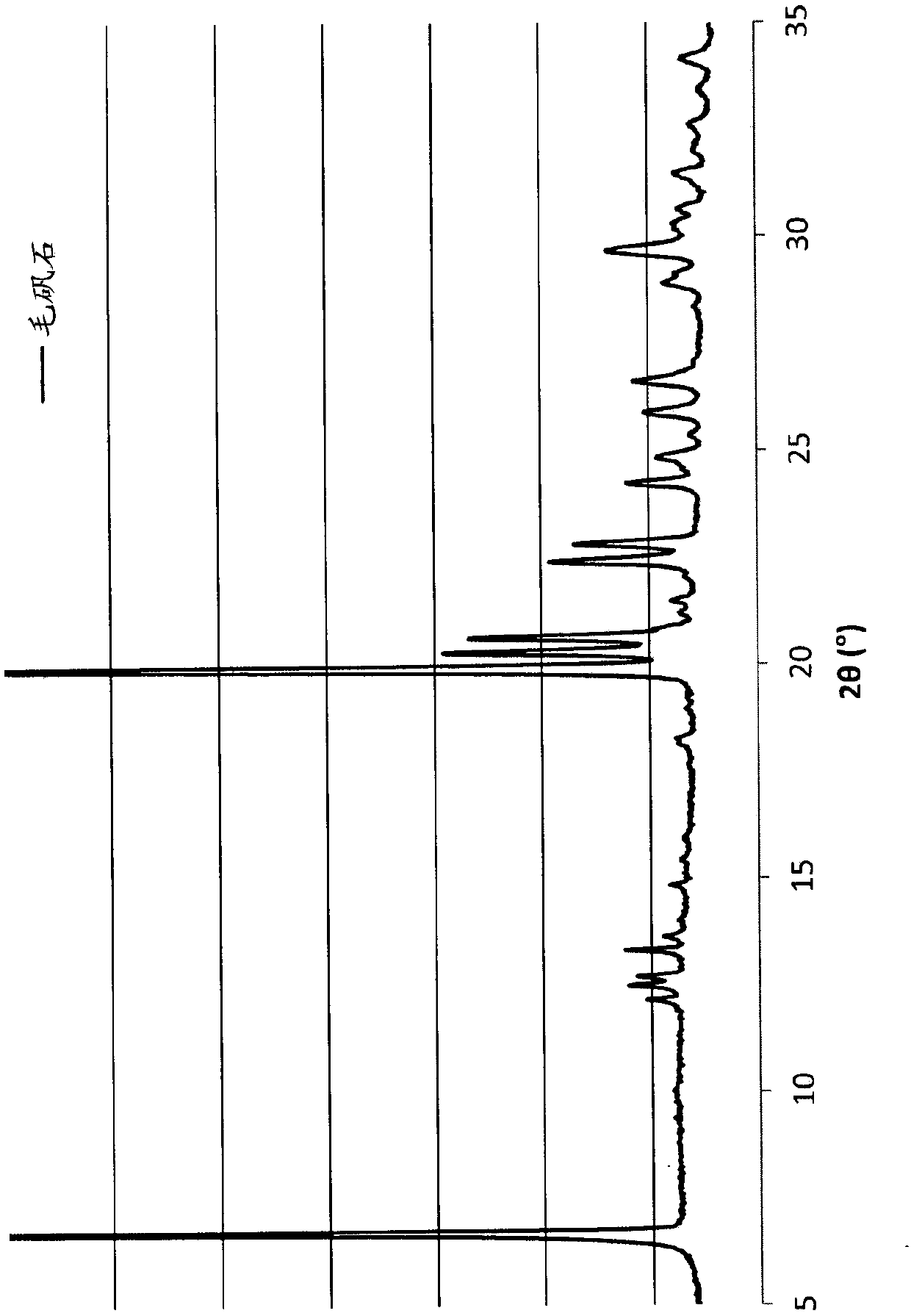

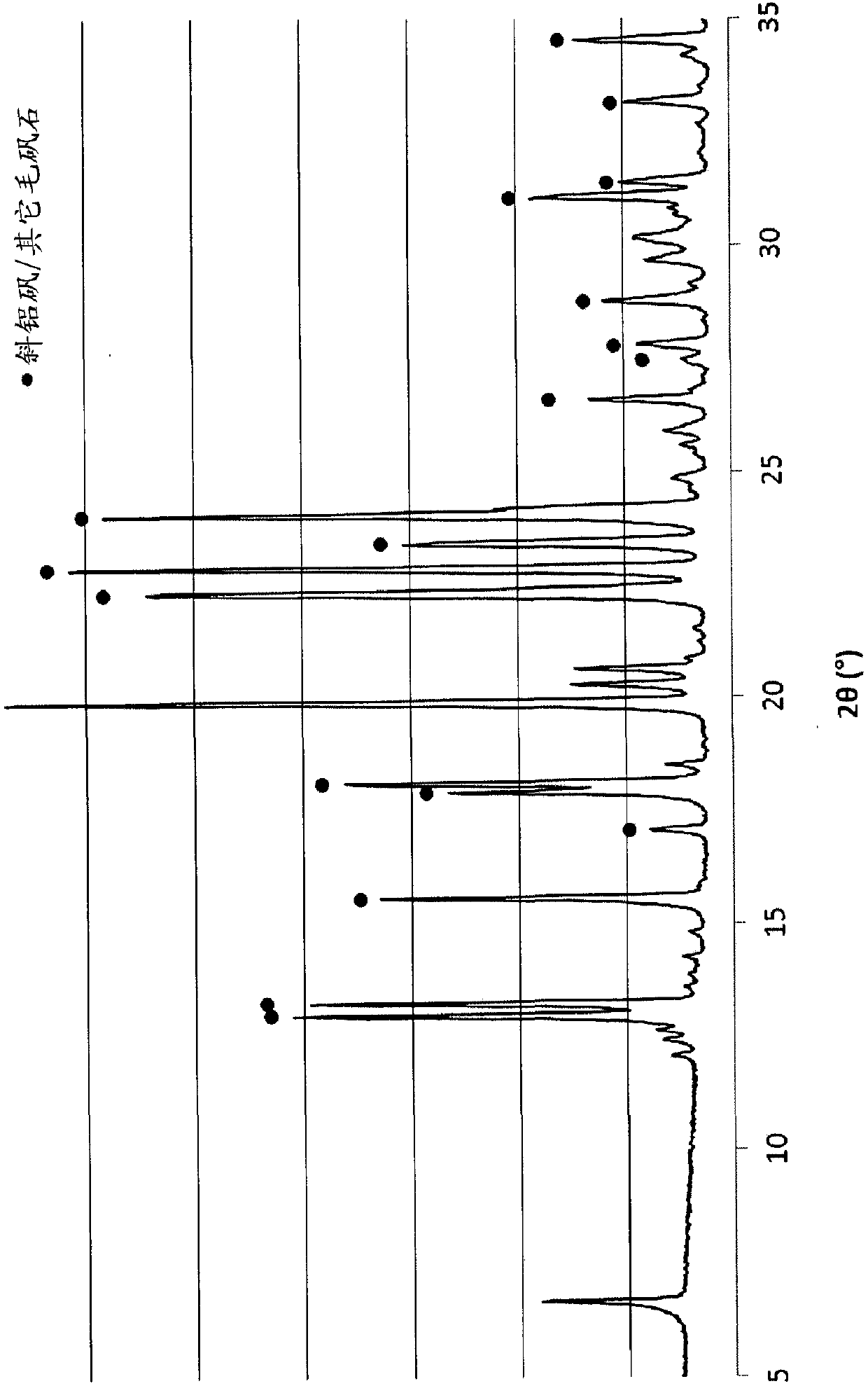

Alkali free aluminate sulfate based shotcrete accelerator as stable suspension or redispersible solid

Described is a shotcrete accelerator which is a solid comprising at least one of jurbanite and hydronium alunite or an aqueous suspension or slurry of the solid, and a method of producing the shotcrete accelerator as a solid. The solid shotcrete accelerator is redispersible in water yielding stable aqueous dispersions or slurries. Extended shelf life of the solids and aqueous dispersions and reduced transport costs are the main advantages compared to existing technologies.

Owner:SIKA TECH AG

Suspension containing hydronium stabilized colloidal silicic acid nanoparticles, formulation obtained from the said diluted suspension, powder obtained from the said de-hydrated suspension, compositions obtained from the said powder, preparation and use

The present invention relates to hydronium stabilized silicic acid nanoparticles, to the formulation obtained from the said diluted suspension, to the powder obtained from the said dehydrated suspension and to the preparation or dosage form obtained from the said suspension, formulation or powder, to their preparation and their use in all kinds of applications in the domains of food, medicine, pharmaceutics, cosmetics. The present invention provides a stable suspension of colloidal silicic acid nanoparticles having a pH lower than 0.9, a molar silicon concentration between 0.035 and 0.65, a free water concentration of at least 30% (w / v) and a ratio between hydronium ion and Si molar concentrations higher than 2 and preferably inferior to 4. The present invention further provides a method for preparing a stable suspension of colloidal silicic acid nanoparticles, which comprises the steps of providing an aqueous inorganic or organic silicon solution and quick mixing said aqueous inorganic or organic silicon solution with water containing a strong acidic compound at a temperature inferior at 30° C., preferably comprised between 1 and 25° C., to form a suspension of colloidal silicic acid nanoparticles having a pH lower than 0.9, stabilized by hydronium ions, the ratio between hydronium ions and Si molar concentrations being higher than 2 and preferably inferior to 4, for a molar silicon concentration between 0.035 and 0.65 and a free water concentration of at least 30% (w / v).

Owner:AQUARIUS INVESTHLDG +1

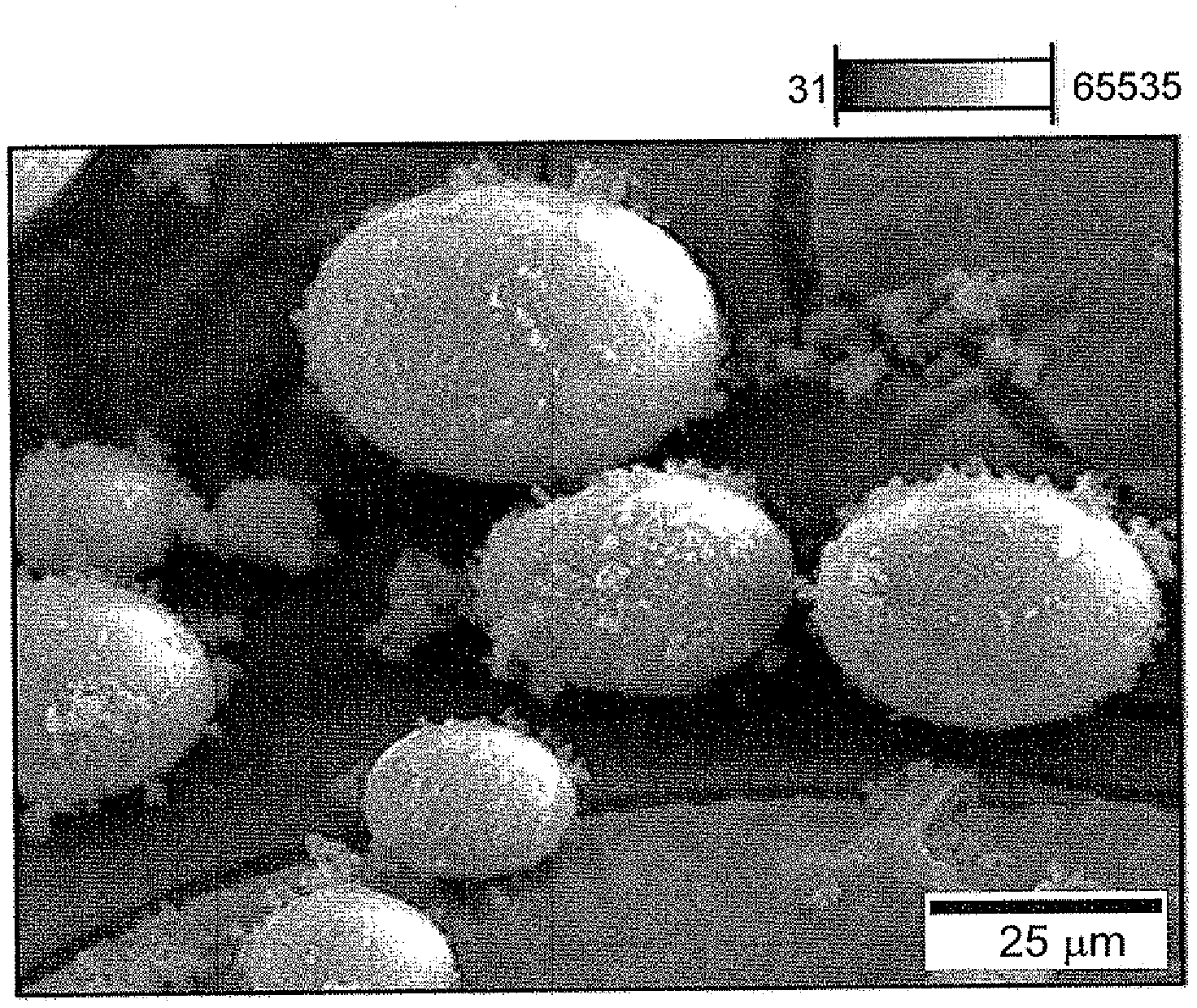

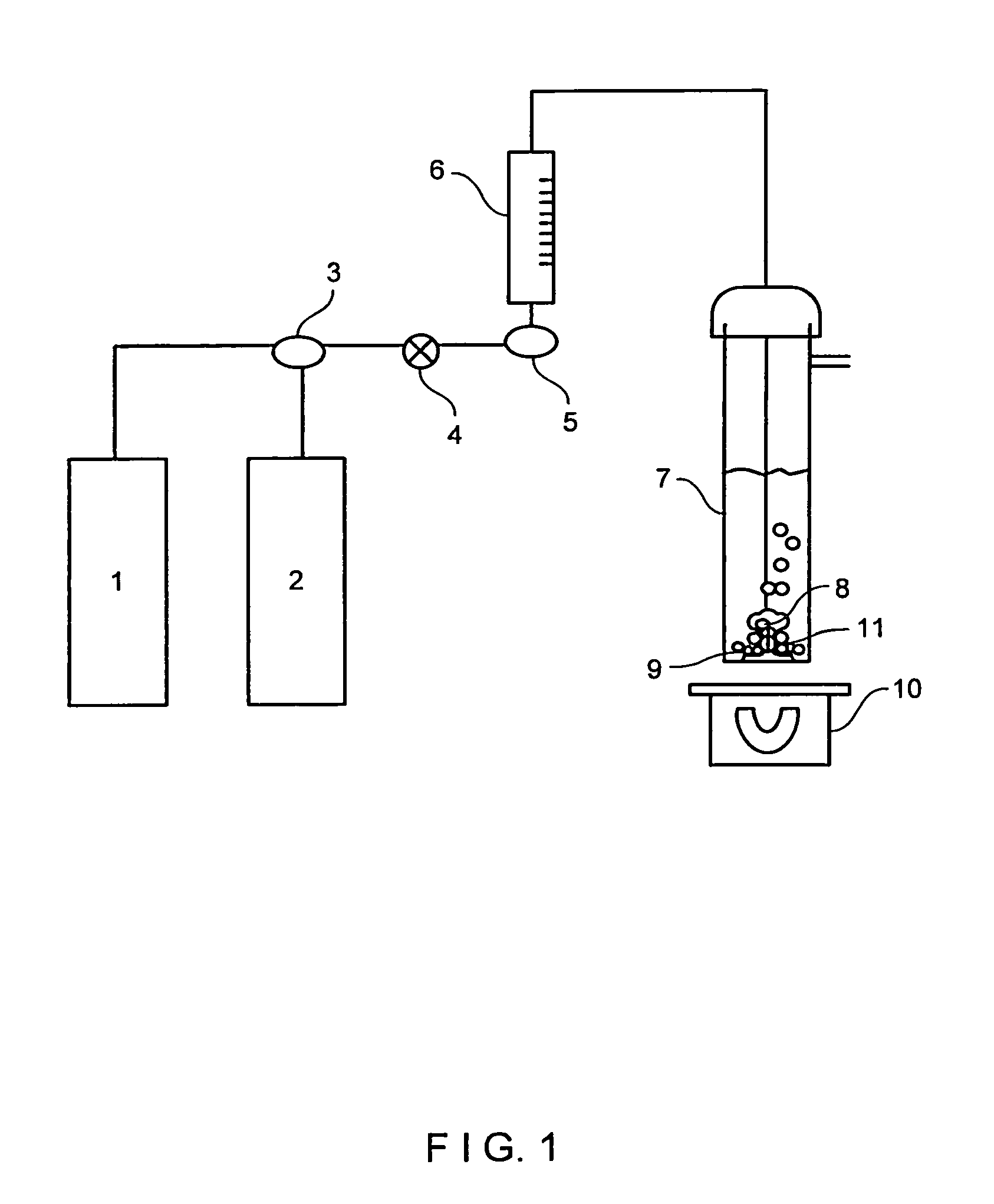

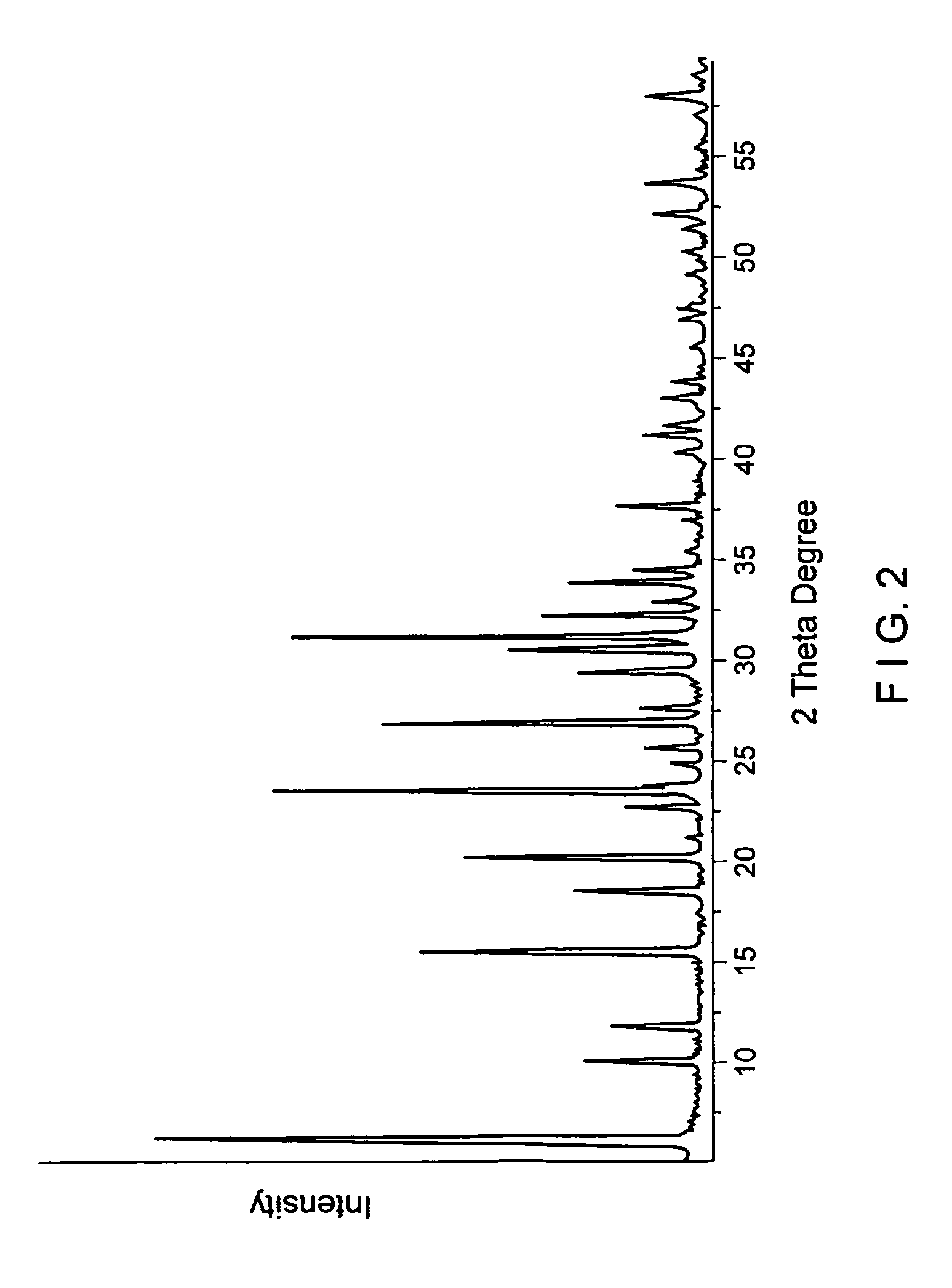

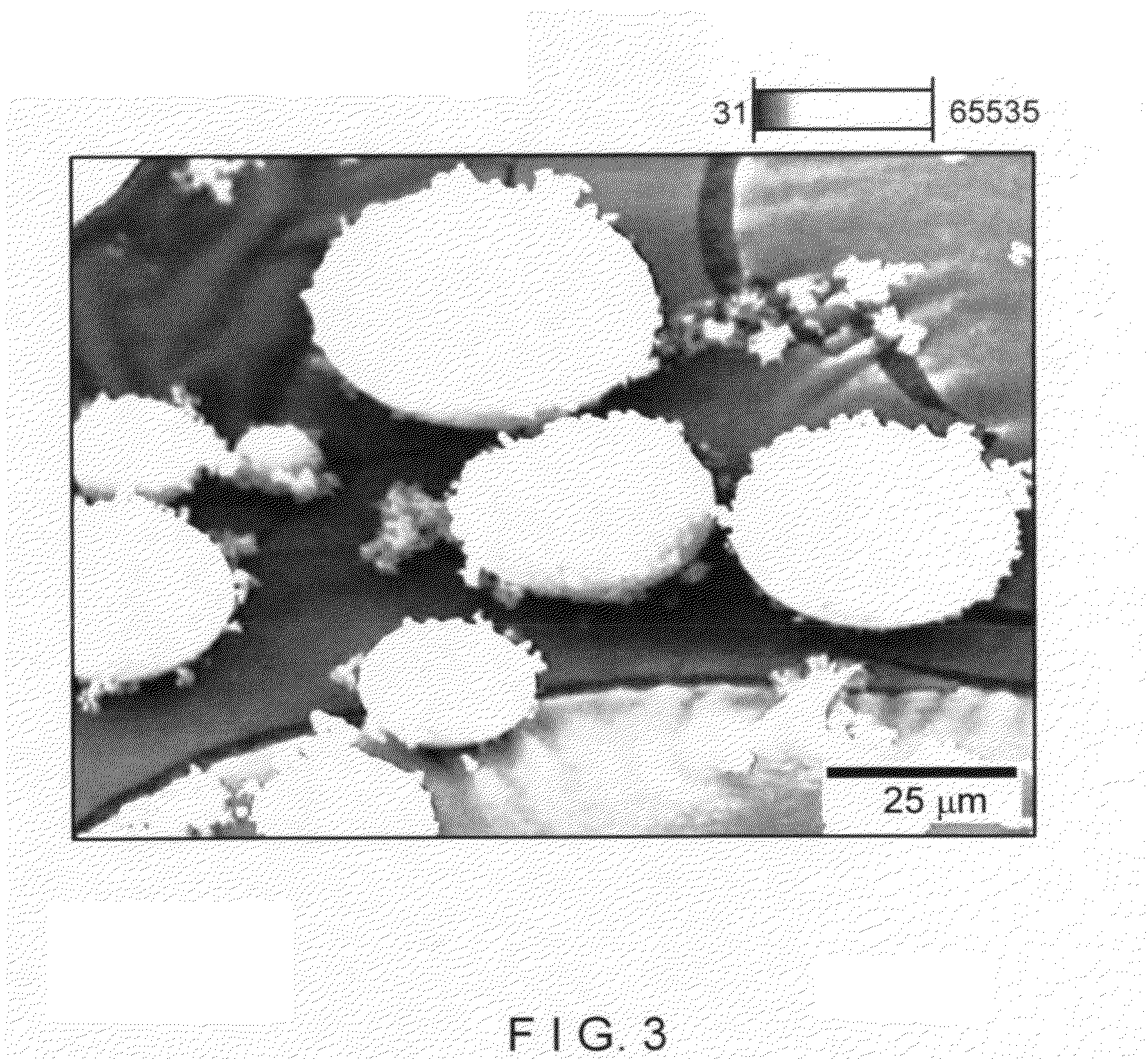

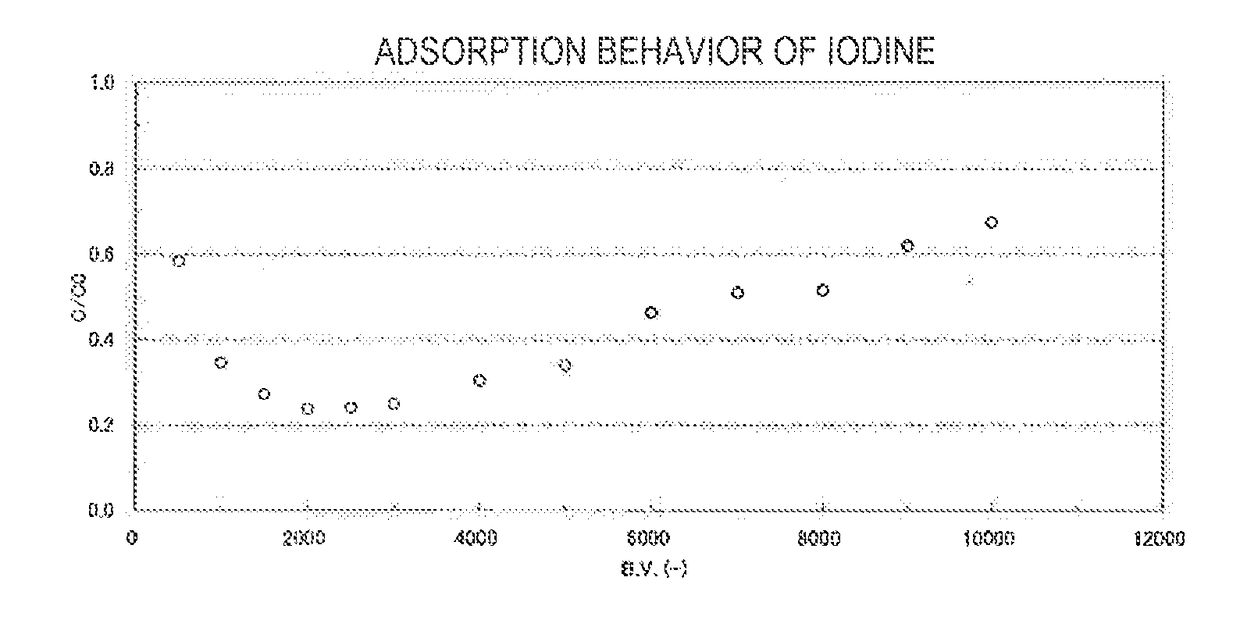

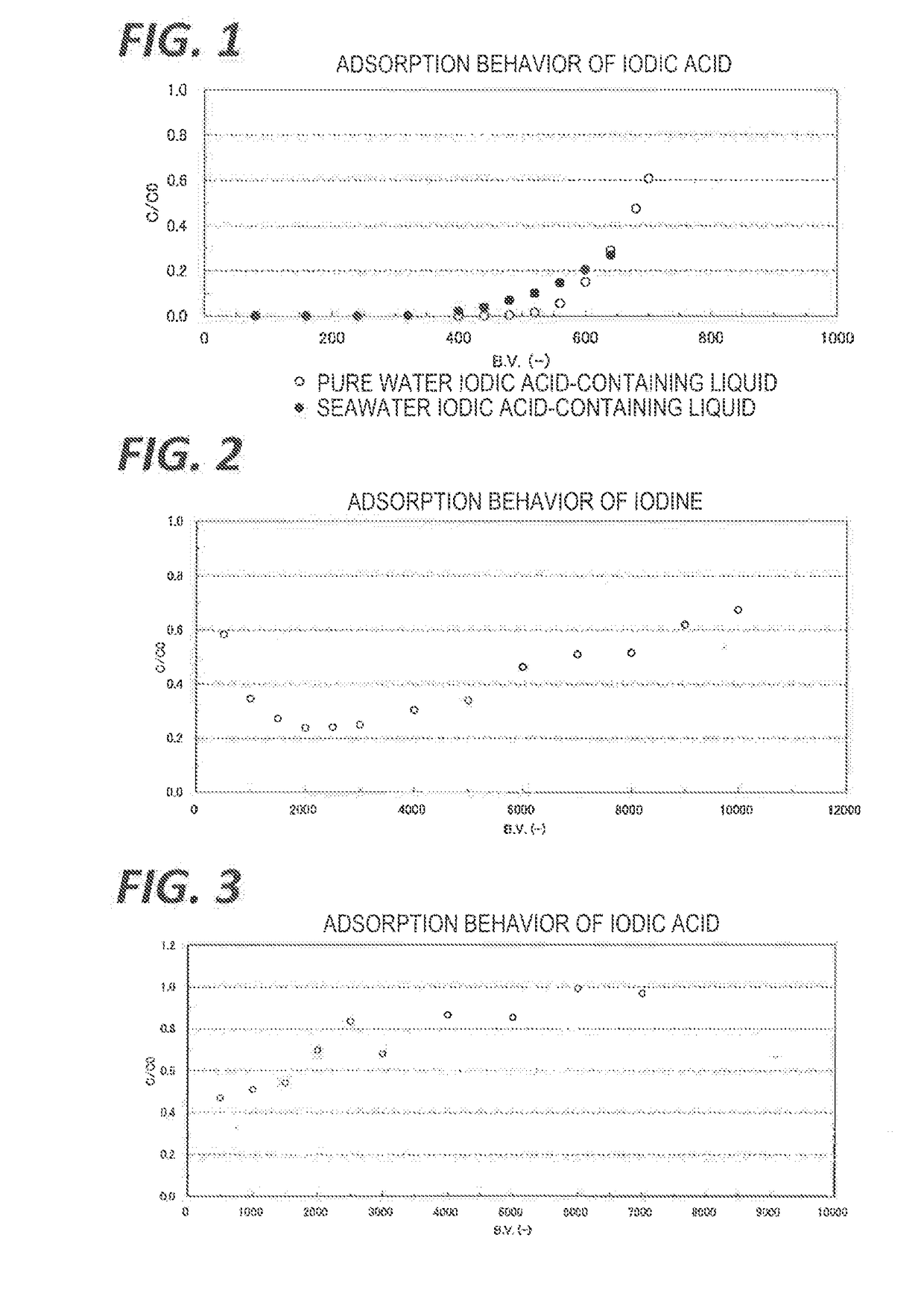

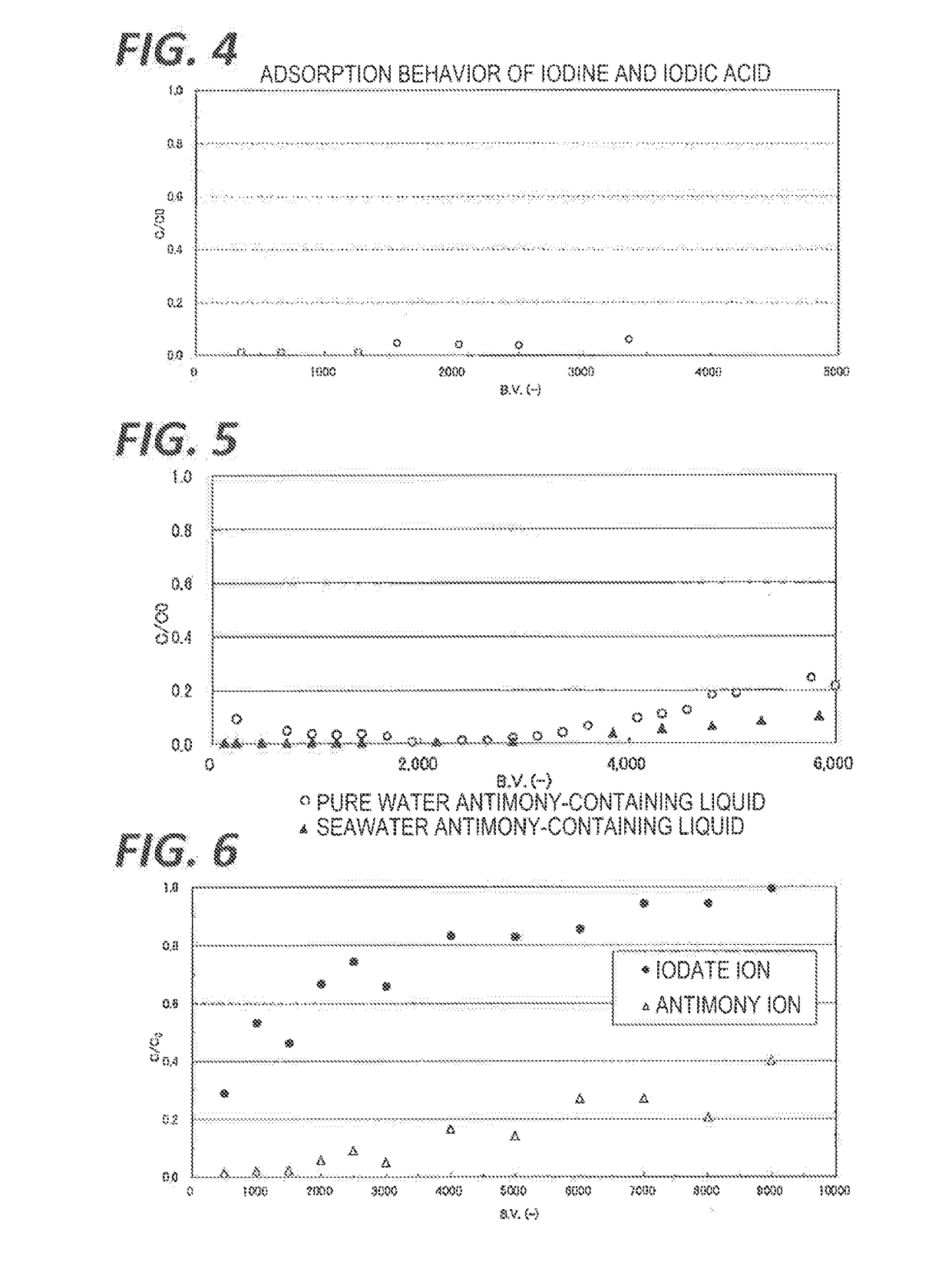

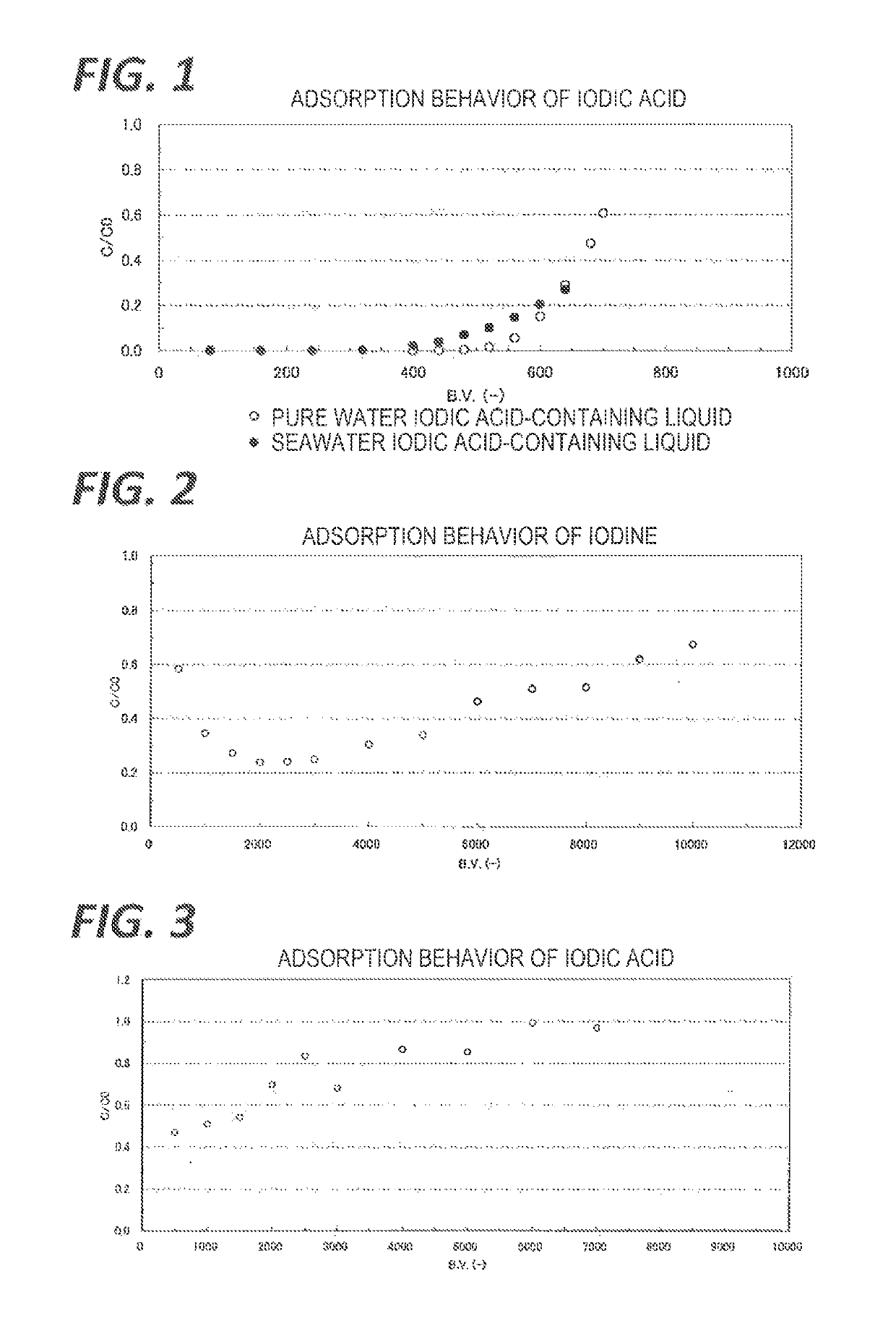

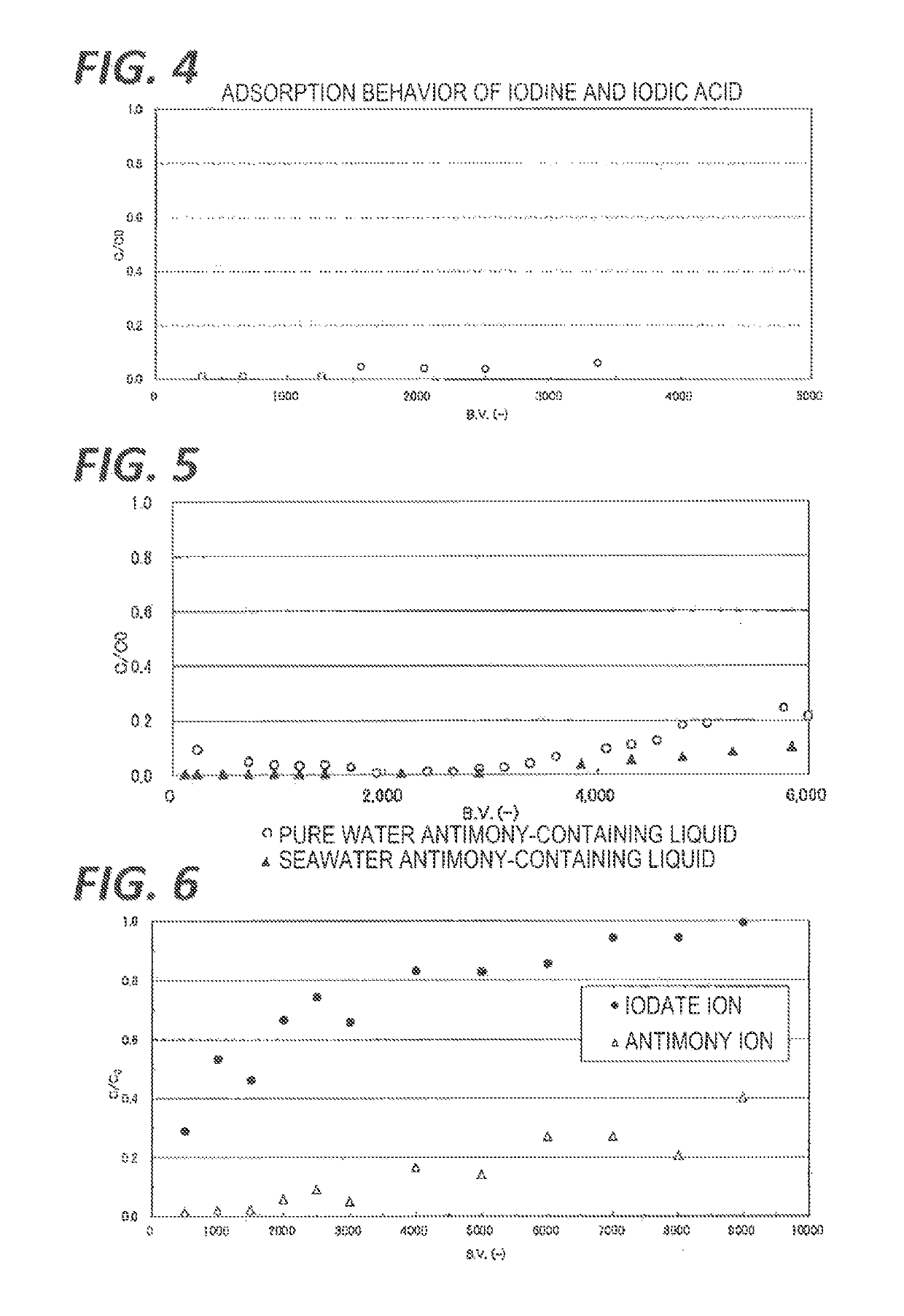

Adsorbent for adsorbing iodine compounds and/or antimony, method for preparing said adsorbent, and method and apparatus for treating radioactive waste liquid by using said adsorbent

ActiveUS20180158558A1Excellent economic feasibilityGood adsorption performanceCation exchanger materialsOrganic anion exchangersIodine compoundsRare-earth element

Provided are an adsorbent capable of removing radioactive water liquid including iodine compounds and / or antimony by means of a water passing treatment, and a method and an apparatus for treating radioactive waste liquid by using the adsorbent. The adsorbent includes a polymer resin and 10 parts by weight or more of a hydrous hydroxide of a rare earth element based on 100 parts by weight of the polymer resin, in which the hydrous hydroxide of the rare earth element has a water content of 1 part by weight to 30 parts by weight based on 100 parts by weight of a dry product thereof, and adsorbs iodine compounds and / or antimony.

Owner:EBARA CORP +1

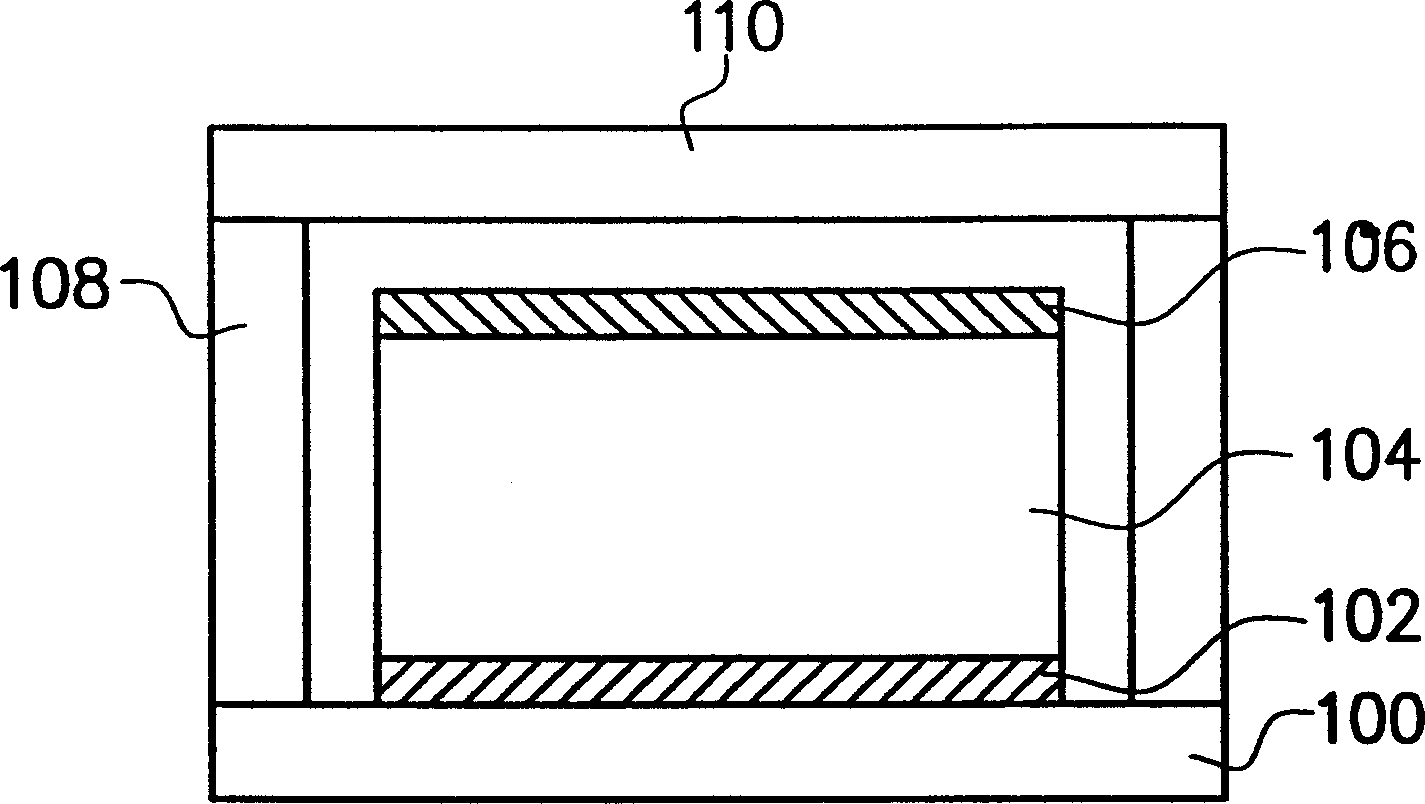

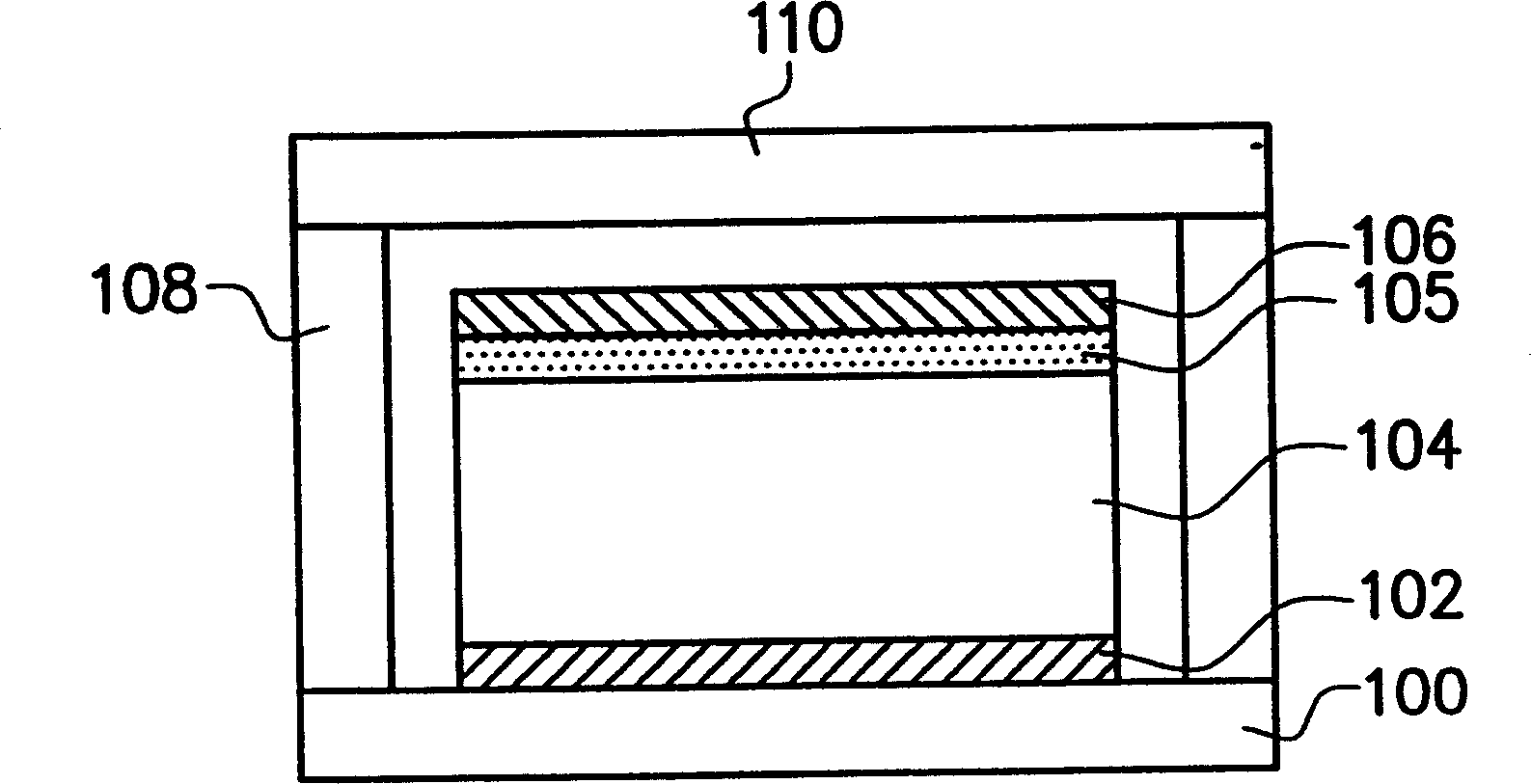

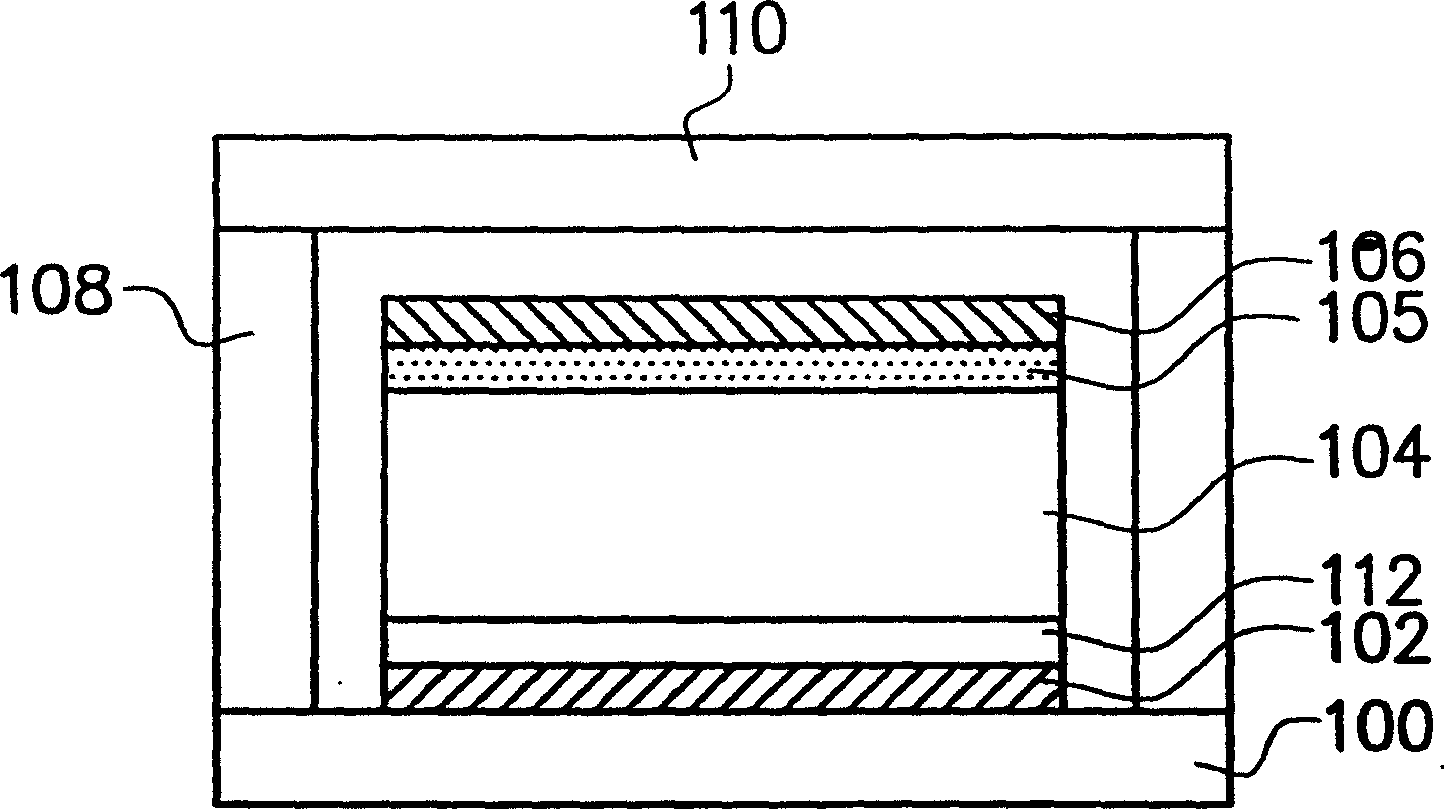

Organic electroluminescent assembly and manufacturing method thereof

InactiveCN1568108AReduce riskImprove cathode processElectrical apparatusElectroluminescent light sourcesOptoelectronicsImpurity

The invention supplies a method to make organic electric-promoted component. The component includes: a base plate, a anode on the plate, a light emitting layer on the plate, a cathode on the layer, and a hydronium layer of impurities. And the hydronium layer of impurities adds 0.1%~10% LiClO4 or other hydronium compound to Alq3.

Owner:RITDISPLAY

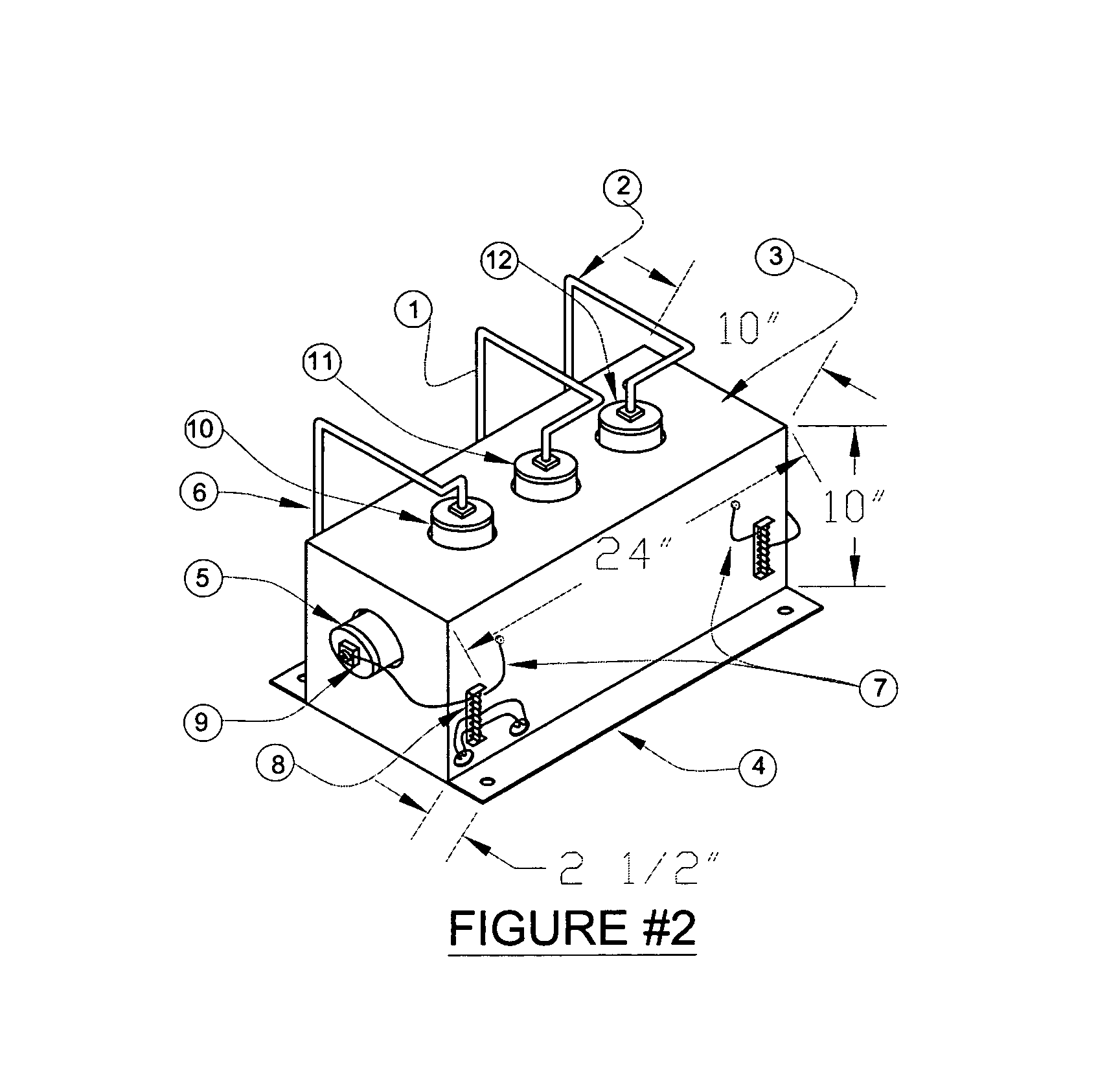

Hydro-oxy fuel generator

InactiveUS7914934B2Good adhesionReduce dependenceCellsPhotography auxillary processesHydronium ionHydrogen

Owner:FOSTER JESSE

Sealing of thief zones

ActiveUS8733441B2Increase ionic strengthReduce solubilityFluid removalFlushingHydronium ionSULFATE ION

The present invention provides a method for selectively sealing a thief zone in a hydrocarbon reservoir located in a calcium-rich formation and penetrated by a borehole comprising injecting into the thief zone a sealing fluid comprising a mixture of and hydronium ions (H+) and a source of sulfate ions (SO42−) which mixture can provide precipitation of a designated calcium sulfate compound.

Owner:MAERSK OLIE & GAS AS

Chemical ionization with reactant ion formation at atmospheric pressure in a mass spectrometer

ActiveUS9228926B2Long life timePreparing sample for investigationIon sources/gunsWater clusterCorona discharge

The invention relates to the production of water cluster ions (“hydronium clusters”) at atmospheric pressure for the chemical ionization of analyte molecules. It is proposed that a corona discharge at the Taylor cone of an aqueous liquid, preferably pure or slightly acidified pure water, is used instead of corona discharges on metal tips, which have been the usual method up to now. The hydronium clusters of the form [H(H2O)n]+ can be produced in a discharge chamber, which is separate from the ionization chamber, and introduced into the ionization chamber through a capillary. In the ionization chamber, the hydronium clusters can be heated and reduced in size by means of electrical acceleration and gas collisions, and thus made more reactive in order that analyte molecules of low proton affinity can also be ionized.

Owner:BRUKER DALTONIK GMBH & CO KG

Scale-like potassium titanate preparation method and brake pad

InactiveCN106745208AOvercoming heat recessionOvercome the disadvantages of poor high temperature wearAlkali titanatesFriction liningWear resistantPotassium

Owner:ZHANGJIAGANG OTSUKA CHEM

Adsorbent for adsorbing iodine compounds and/or antimony, method for preparing said adsorbent, and method and apparatus for treating radioactive waste liquid by using said absorbent

InactiveUS10388419B2Good economic viabilityImprove adsorption capacityCation exchanger materialsOrganic anion exchangersRare-earth elementPolymer resin

Provided are an adsorbent capable of removing radioactive water liquid including iodine compounds and / or antimony by means of a water passing treatment, and a method and an apparatus for treating radioactive waste liquid by using the adsorbent. The adsorbent includes a polymer resin and 10 parts by weight or more of a hydrous hydroxide of a rare earth element based on 100 parts by weight of the polymer resin, in which the hydrous hydroxide of the rare earth element has a water content of 1 part by weight to 30 parts by weight based on 100 parts by weight of a dry product thereof, and adsorbs iodine compounds and / or antimony.

Owner:EBARA CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com