Method for manufacturing filtering material with far infrared energy by non-built-in mode

A far-infrared, non-implanted technology, used in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as uneven mixing, reduced use efficiency, and separation of far-infrared particles and polymer materials, and achieve catalytic effects. Excellent, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

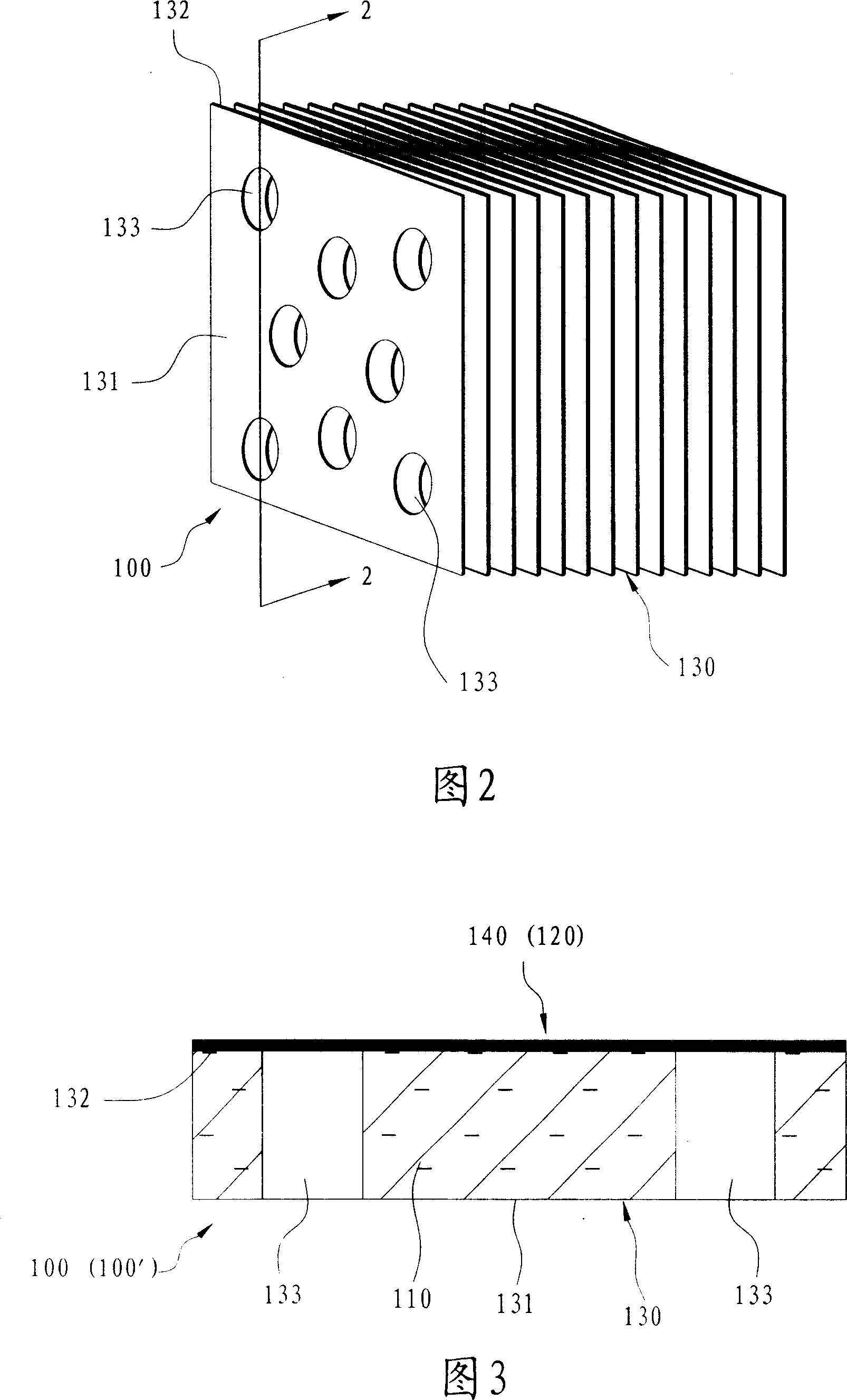

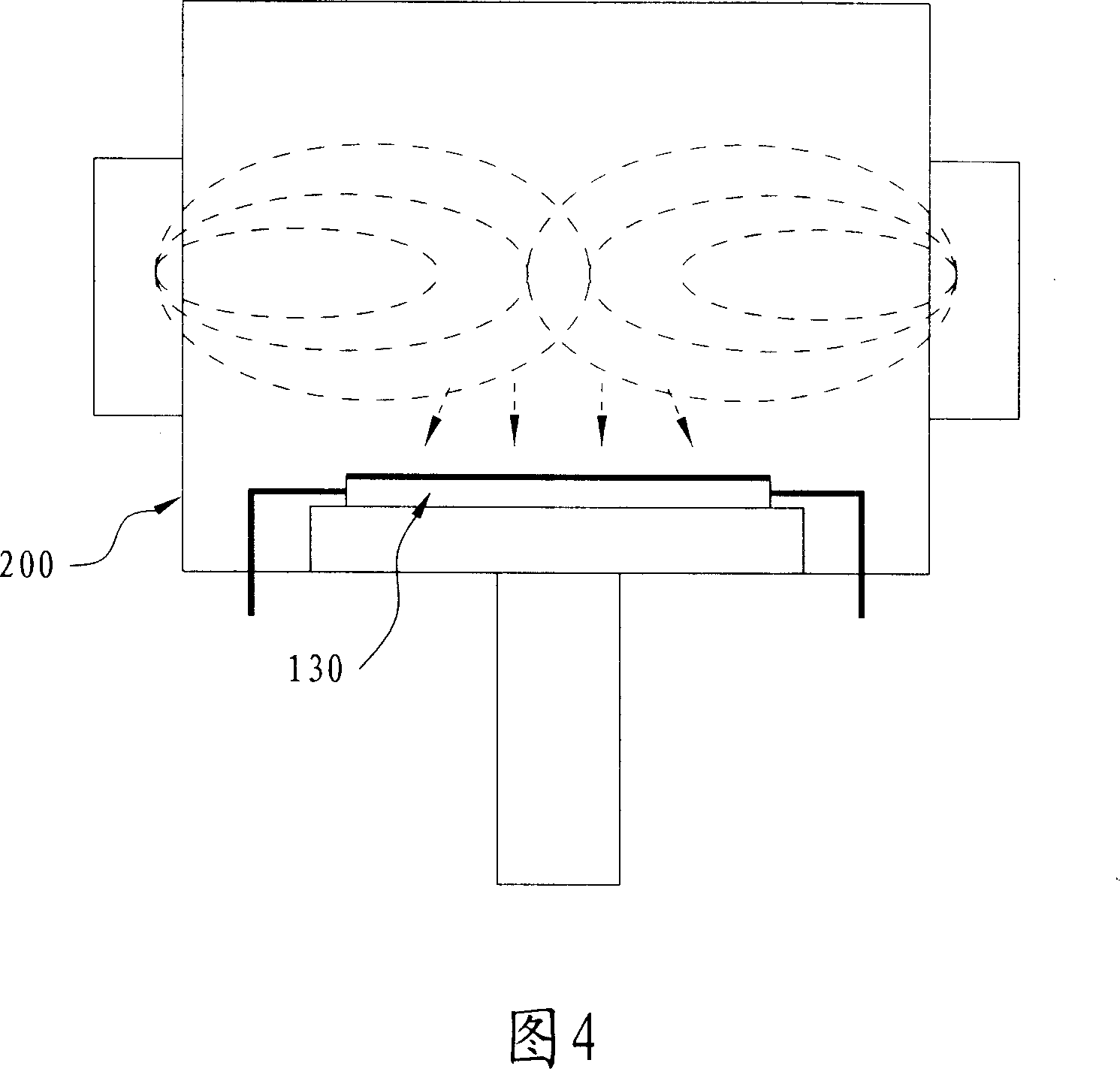

[0044] For further elaborating the technical means and the effect that the present invention takes for reaching the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the method for the far-infrared ray energy filter material that proposes according to the present invention with non-implantation The specific embodiment, manufacturing method, steps, features and effects thereof are described in detail below.

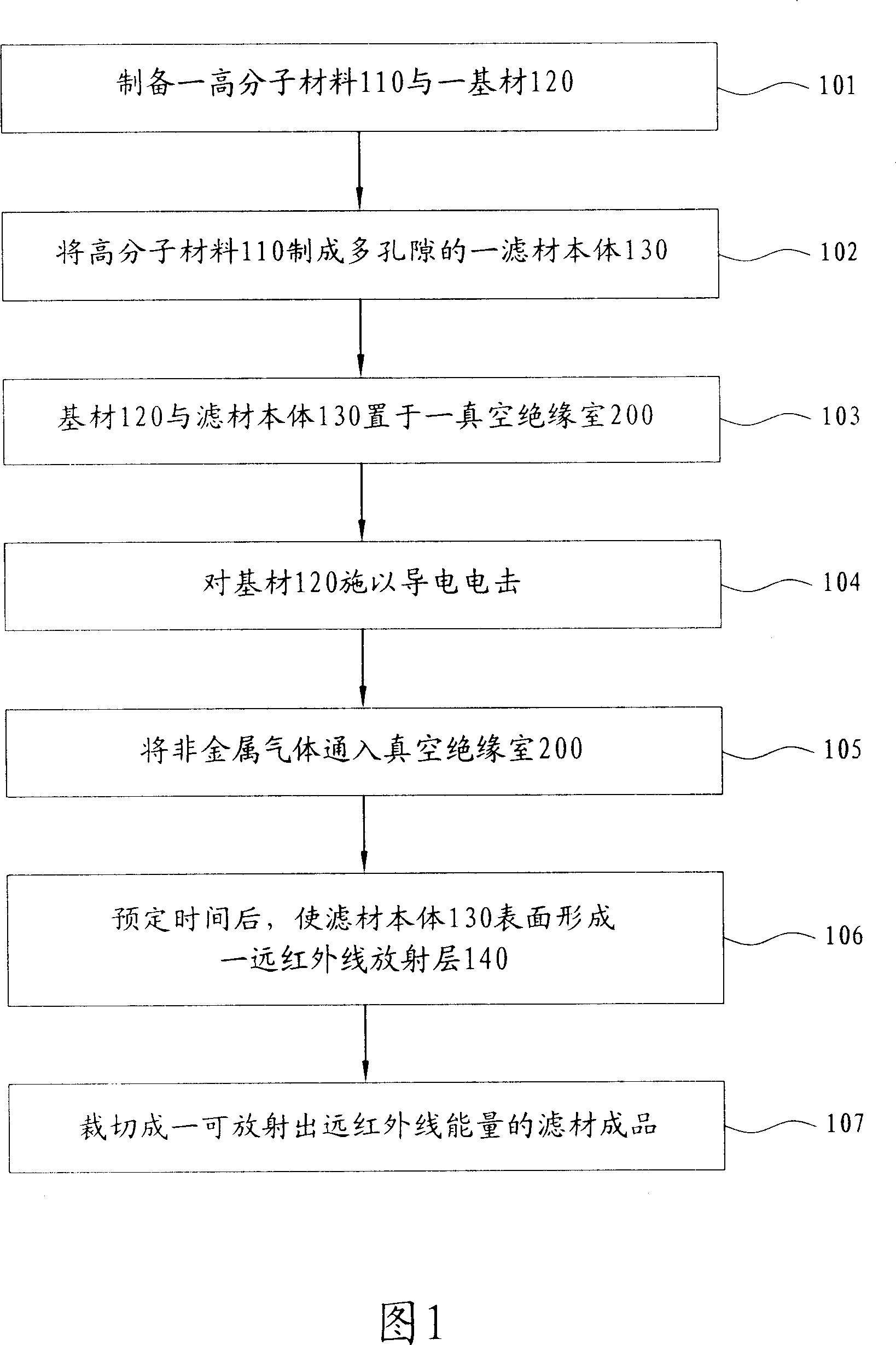

[0045] Please refer to FIG. 1 , which shows a manufacturing flow chart of the first embodiment of the present invention.

[0046] The present invention is the first embodiment of the method for making tool far-infrared energy filter material with non-implantation type, and this filter material mainly is to make air cleaner filter element 100, and at least comprises the following steps:

[0047] Step 1: As in process 101, prepare a polymer material 110 and at least one substrate 120, the polymer material 110 can be fibro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com