Aluminum-doped lithium vanadium fluorophosphate/phosphatized graphene oxide composite material and preparation method thereof, and application in lithium ion battery

A technology of vanadium lithium fluorophosphate and composite materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrical conductivity, and achieve the effects of improved electrical conductivity, high phase purity, and good crystal morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

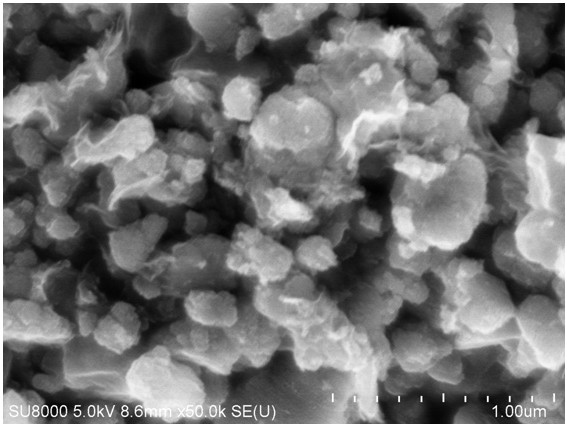

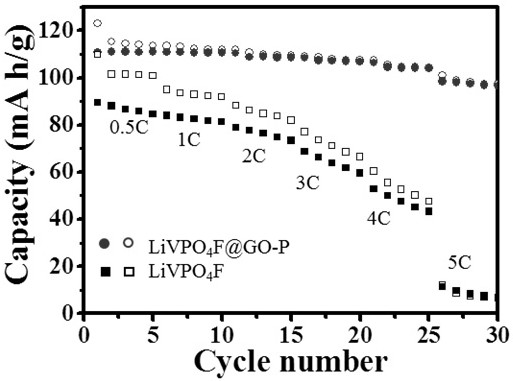

Image

Examples

Embodiment 1

[0024] A preparation of vanadium lithium fluorophosphate composite positive electrode material and its application in lithium ion batteries, comprising the following steps:

[0025] 1) Add the graphene-containing suspension into DMF, and sequentially add lithium source, vanadium source, phosphorus source and aluminum source to 60 ml of graphene suspension in a stoichiometric ratio of 1:1:1:0.2 , after stirring with a magnetic stirrer for 15 min, the mixed solution was transferred to a polytetrafluoroethylene liner and heated in a microwave at 350 °C for 30 min;

[0026] 2) After the reaction, the solution was centrifuged and washed, and the precipitate was collected and dried in a drying oven;

[0027] 3) Mix and grind the lithium vanadium phosphate / graphene precursor, fluorine source, phosphorus source, and molten salt at a mass ratio of 1:1:1:10, and calcinate at 350 °C for 2 h in an inert gas atmosphere, then 750 °C Calcination at ℃ for 5 h;

[0028] 4) The collected prod...

Embodiment 2

[0032] A preparation of vanadium lithium fluorophosphate composite positive electrode material and its application in lithium ion batteries, comprising the following steps:

[0033] 1) Add the graphene-containing suspension into DMF, and sequentially add lithium source, vanadium source, phosphorus source and aluminum source to 70 ml of graphene suspension in a stoichiometric ratio of 1:1:1:0.5 , after stirring with a magnetic stirrer for 25 min, the mixed solution was transferred to a polytetrafluoroethylene liner and heated in a microwave at 250 °C for 45 min;

[0034] 2) After the reaction, the solution was centrifuged and washed, and the precipitate was collected and dried in a drying oven;

[0035] 3) Mix and grind the lithium vanadium phosphate / graphene precursor, fluorine source, phosphorus source, and molten salt at a mass ratio of 1:1:2:20, and calcinate at 400 °C for 2 h in an inert gas atmosphere, then 800 °C Calcination at ℃ for 3 h;

[0036] 4) The collected prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com