Expanded graphite and nano-silicon composite material and preparation method thereof, electrode sheet, battery

A technology of expanded graphite and composite materials, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of low load, low tap density, low volume specific capacity, etc., achieve low energy consumption, high tap density, high The effect of volume to capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

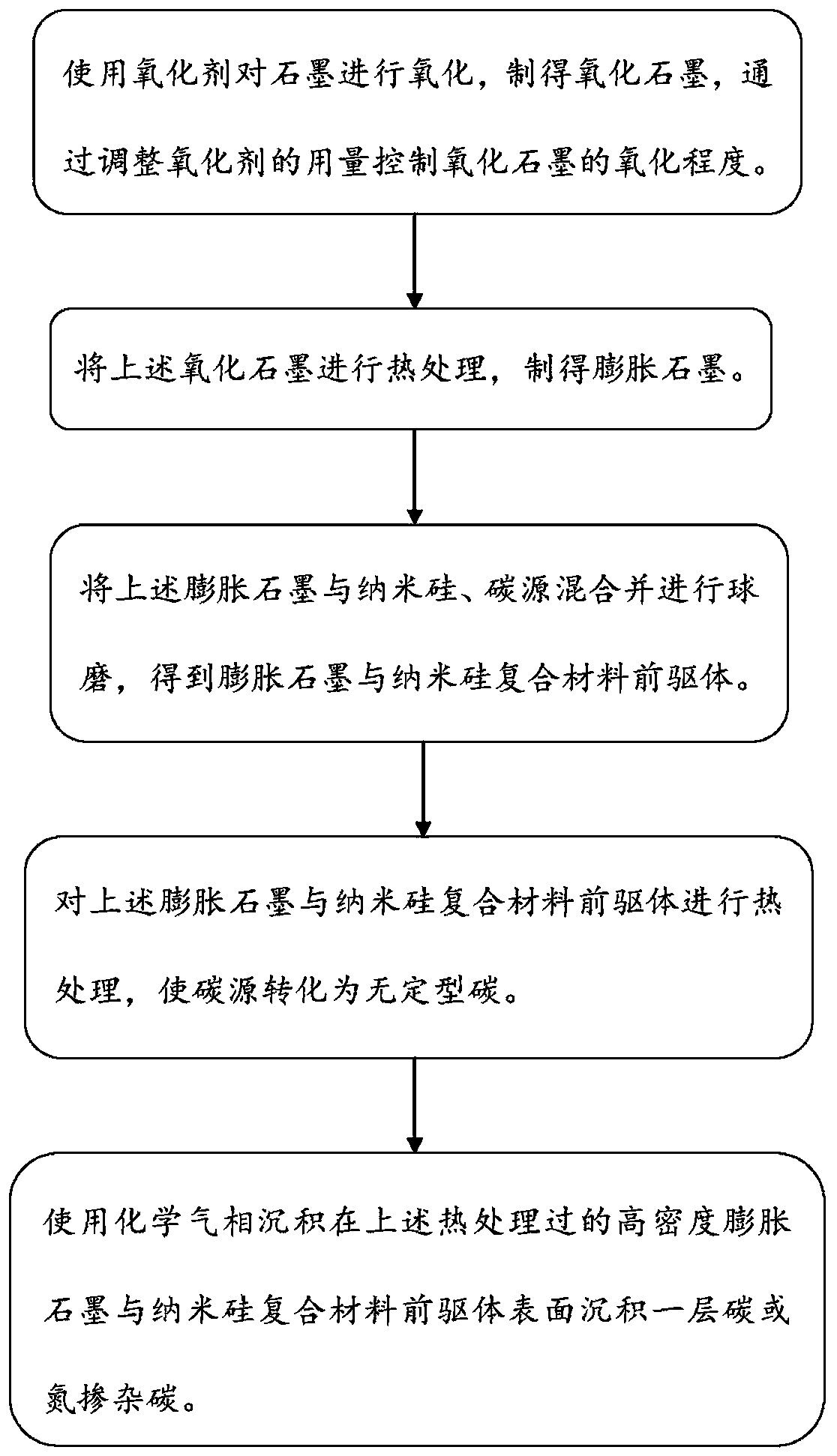

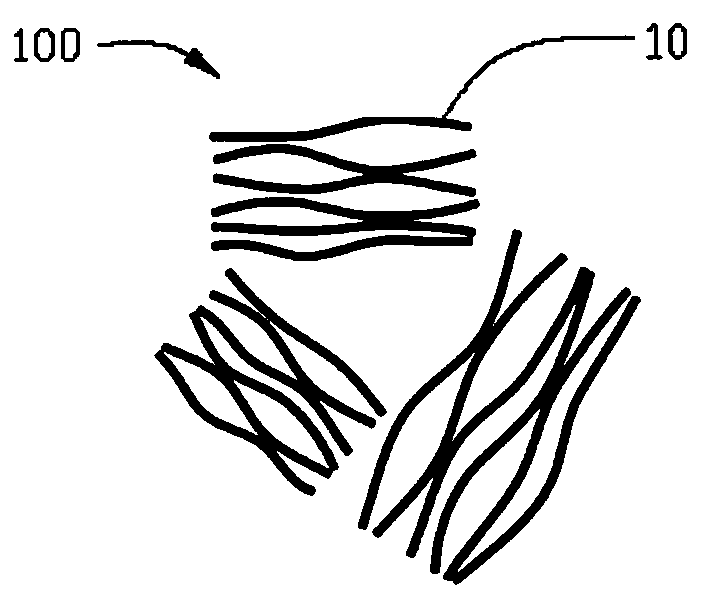

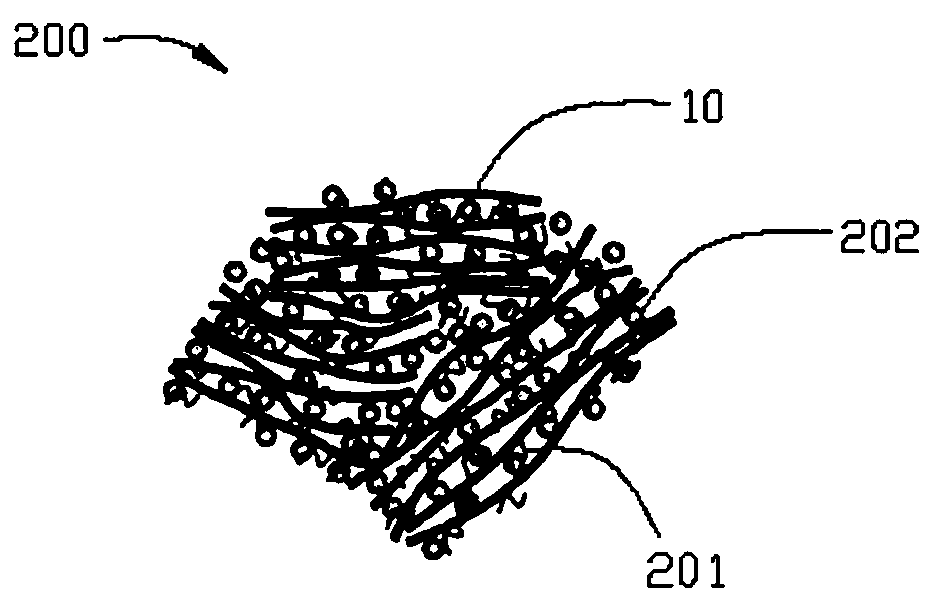

[0028] see figure 1 , the present invention provides a method for preparing a high-density expanded graphite and nano-silicon composite material 300, the high-density expanded graphite and nano-silicon composite material 300 can be applied to an electrode (not shown) of a lithium-ion battery, which includes the following steps .

[0029] In step S1, graphite is provided, and the graphite is oxidized by using concentrated sulfuric acid, potassium permanganate, and nitrate as an oxidizing agent to obtain graphite oxide, and the oxidation degree of graphite oxide is controlled by adjusting the amount of the oxidizing agent.

[0030] Specifically, the above step S1 includes the following steps.

[0031] Step S11, graphite, nitrate is added in the concentrated sulfuric acid according to certain proportion, at temperature T 1 Stir for a while 1 , to obtain a mixed solution.

[0032] Wherein the mass ratio of the graphite to the nitrate is 2:1, the mass ratio of the concentrated ...

Embodiment 1

[0054] Add 8g of phosphorus flake graphite and 4g of sodium nitrate into 200ml of concentrated sulfuric acid with a mass fraction of 98%, and stir at -5°C for 15 minutes to obtain a mixed solution; then slowly add 8g of potassium permanganate into the mixed solution, Stir at the temperature for 2 hours, then raise the temperature to 35°C, and continue to stir for 1 hour to obtain a precursor solution; add 400ml of water to the precursor solution, and raise the temperature to 98°C, stir for 2 hours, and then filter with suction to obtain an intercalated oxide graphite.

[0055] The above-mentioned graphite oxide with intercalation was heat-treated at 900° C. for 2 h under nitrogen protection atmosphere to obtain expanded graphite.

[0056] Weigh 100mg of the above-mentioned expanded graphite, 100mg of commercial nano-silicon, and 100mg of polyacrylonitrile into a ball mill jar, add 5g of grinding balls, then add 10ml of ethanol to wet the material, and ball mill at a speed of 4...

Embodiment 2

[0060] Add 8g of phosphorus flake graphite and 4g of sodium nitrate into 190ml of concentrated sulfuric acid with a mass fraction of 98%, and stir at -5°C for 15 minutes to obtain a mixed solution; then slowly add 16g of potassium permanganate into the mixed solution, Stir at the temperature for 1 hour, then raise the temperature to 35°C, and continue to stir for 1 hour to obtain a precursor solution; add 380ml of water to the precursor solution, raise the temperature to 98°C, stir for 2 hours, and then filter with suction to obtain an intercalated oxide graphite.

[0061] The above-mentioned graphite oxide with intercalation was heat-treated at 900° C. for 2 h under an argon protective atmosphere to obtain expanded graphite.

[0062] Weigh 200 mg of the above-mentioned expanded graphite, 100 mg of commercial nano-silicon, and 100 mg of polyacrylonitrile into a ball mill jar, add 8 g of grinding balls, then add 10 ml of ethanol to wet the material, and ball mill for 8 hours at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com