Method for rapidly curing nuclides at low temperature with assistance of electric field

A rapid curing and electric field assisted technology, applied in nuclear engineering, radioactive purification, etc., can solve the problems of high calcination temperature and long time, and achieve the effect of increasing defect concentration and curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for quickly solidifying nuclide at low temperature under the assistance of an electric field, the specific steps are as follows:

[0029] a) Sample preparation:

[0030] Gadolinium oxide, neodymium oxide and zirconium oxide powders (molar ratio 1:4:5) are uniformly mixed by ball milling, and then molded.

[0031] b) Solid phase synthesis:

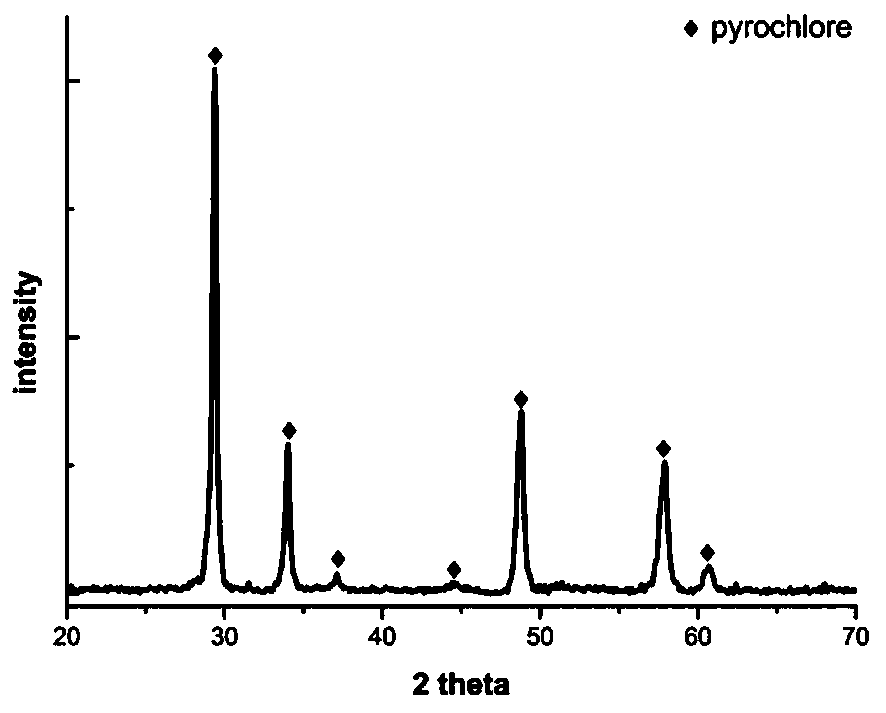

[0032] Put the prepared sample into the sintering furnace, and apply a voltage of 1000V (electric field strength E=1500V / cm) to the sample at 600°C through an external DC power supply to make the current reach 0.6A (current density j=100mA / mm 2 ), and kept for 5s, gadolinium oxide, neodymium oxide and zirconium oxide were solid-dissolved into one phase under the action of an electric field, and a pyrochlore structure (Gd 0.2 Nd 0.8 ) 2 Zr 2 o 7 , to achieve rapid solidification of nuclides at low temperatures, and to form stable pyrochlore-structured ceramics.

Embodiment 2

[0034] a) Sample preparation:

[0035] Gadolinium oxide, neodymium oxide and zirconium oxide powder (mole ratio is 4:1:5) are uniformly mixed by ball milling, and then molded.

[0036] b) Solid phase reaction:

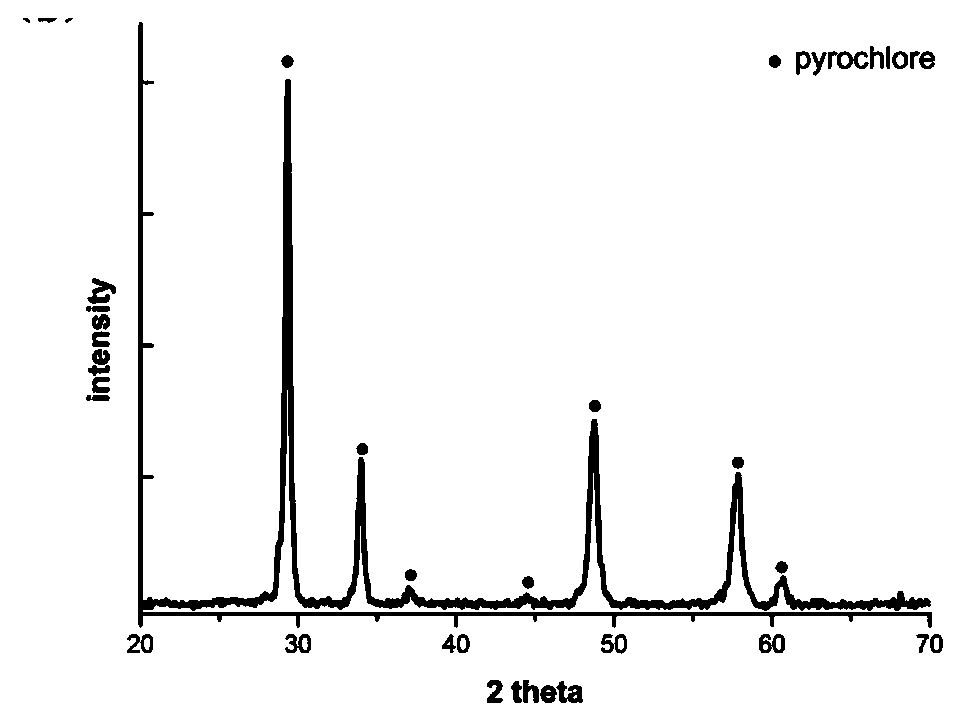

[0037] Put the prepared sample into a sintering furnace, and apply a voltage of 400V (electric field strength E=500V / cm) to the sample at 800°C through an external DC power supply to make the current reach 0.30A (current density j=50mA / mm 2 ), and kept for 10s, gadolinium oxide, neodymium oxide and zirconium oxide were solid-dissolved into one phase under the action of an electric field, and a pyrochlore structure (Gd 0.8 Nd 0.2 ) 2 Zr 2 o 7 .

Embodiment 3

[0039] a) Sample preparation:

[0040] Gadolinium oxide, neodymium oxide and zirconium oxide powders (molar ratio 3:2:5) are uniformly mixed by ball milling, and then molded.

[0041] b) Solid phase reaction:

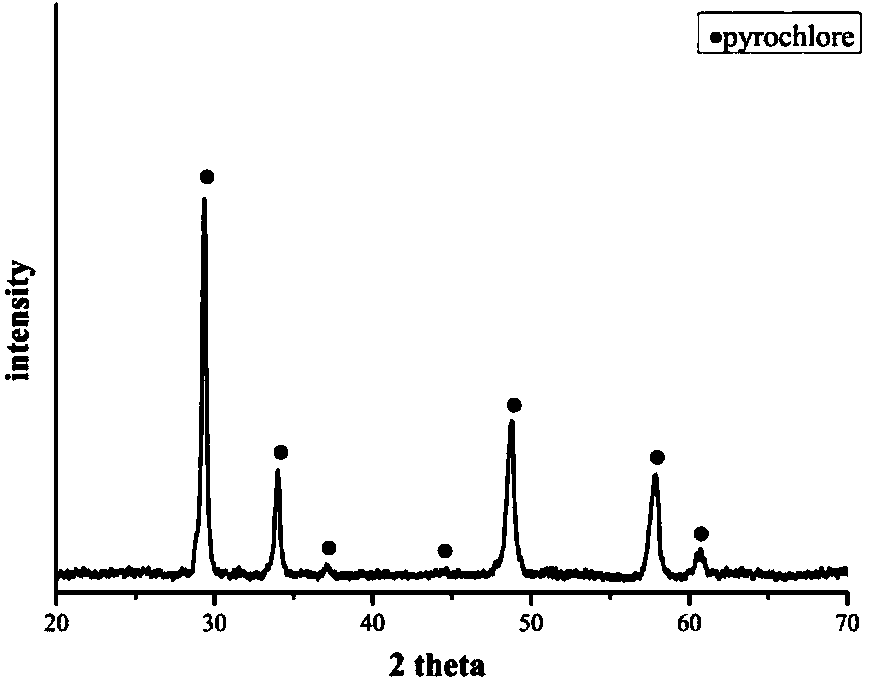

[0042] Put the prepared sample into a sintering furnace, and apply an 80V voltage (electric field strength E=100V / cm) to the sample at 1000°C through an external AC power supply (frequency 100Hz), so that the current reaches 1.20A (current density j=200mA / cm mm 2 ), and kept for 1s, gadolinium oxide, neodymium oxide and zirconium oxide were solid-dissolved into one phase under the action of an electric field, and a pyrochlore structure (Gd 0.6 Nd 0.4 ) 2 Zr 2 o 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com