Near-infrared high-afterglow material and preparation method thereof

A near-infrared and afterglow technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of short afterglow time and weak afterglow intensity, and achieve the effect of enhanced afterglow intensity, uniform distribution, and improved afterglow performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

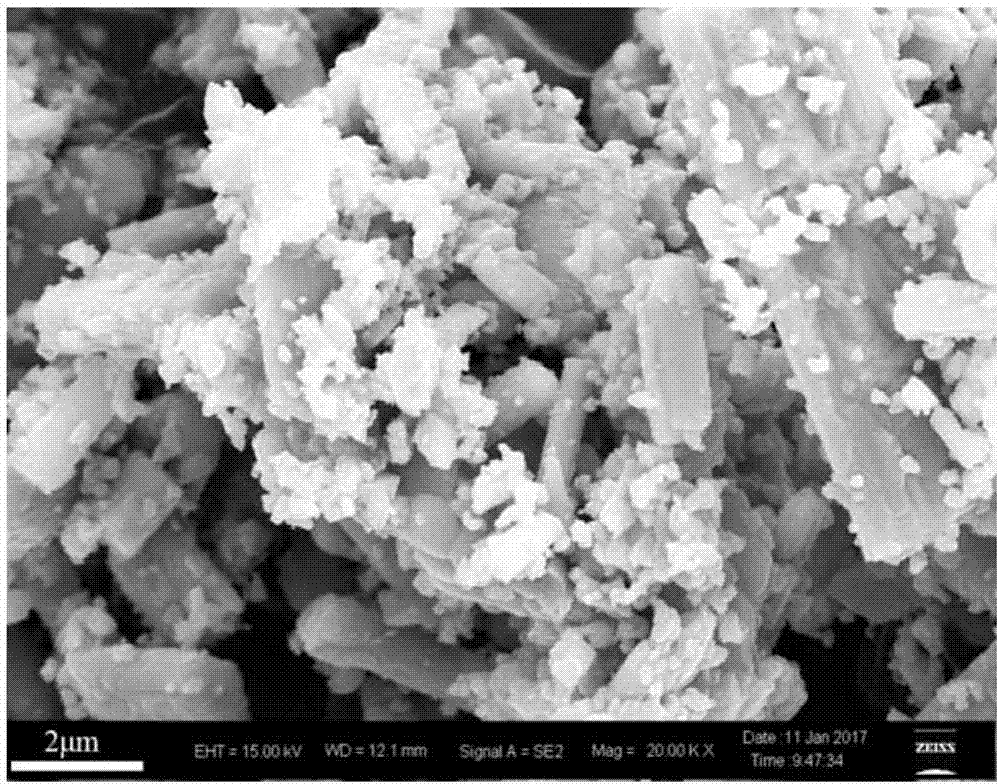

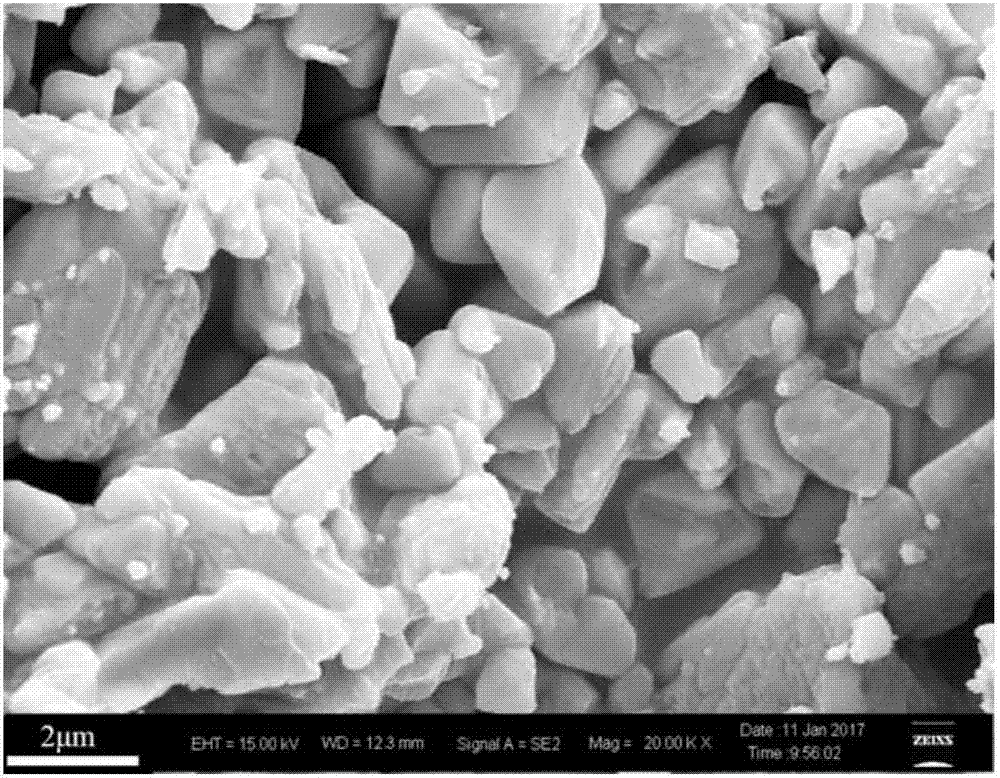

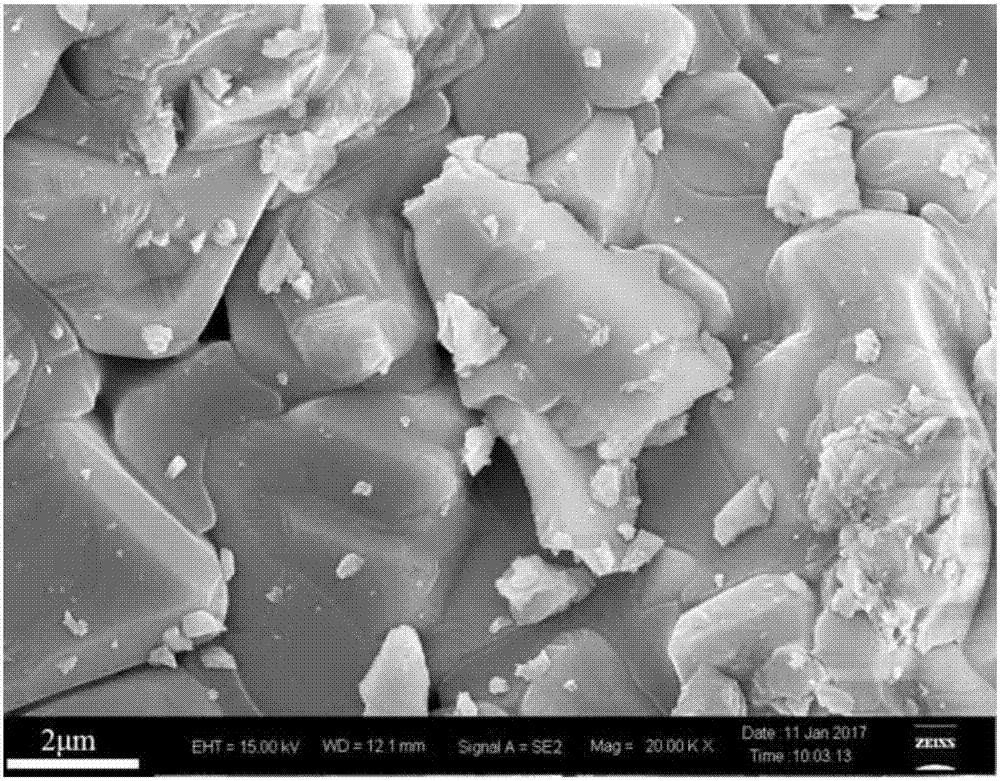

[0020] Specific embodiment one: the molecular formula of the near-infrared high afterglow material of this specific embodiment is (Zn 1-x Ca x ) 3 (Ga 0.995 Cr 0.005 ) 2 Ge 2 o 10 , where 0.01≤x≤0.03.

specific Embodiment approach 2

[0021] Embodiment 2: The preparation method of the near-infrared high afterglow material described in Embodiment 1 is carried out in the following steps:

[0022] 1. Mix zinc oxide, calcium oxide, gallium oxide, chromium oxide and germanium oxide according to the molar ratio of (3-3x): 3x: 0.995: 0.005: 2 to obtain a mixture; wherein 0.01≤x≤0.03;

[0023] 2. After adding the mixture into water and heating to boiling, add nitric acid with a mass percentage concentration of 65% dropwise under stirring until all solid particles in the solution disappear, and cool to room temperature to obtain an oxide solution;

[0024] 3. Take water, ethanol and oleic acid according to the volume ratio of 1: (4-5): (3-5), first mix the water and ethanol evenly, then add oleic acid and mix evenly to obtain a mixed solvent; The oxide solution is added to the mixed solvent, and mixed evenly to obtain a mixed solution;

[0025] 4. Add the mixed solution obtained in step 3 into the hydrothermal kett...

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the total mass percent concentration of oxides in the oxide solution in Step 2 is 30%-41%; other aspects are the same as Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com