Method for improving electrochemical performance of lithium battery positive electrode coating material

A coating material and cathode material technology, applied in the field of lithium ion battery cathode material preparation, can solve problems such as affecting battery specific capacity, affecting lithium ion transmission, losing protection effect, etc., to improve cycle life, improve charge and discharge efficiency, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

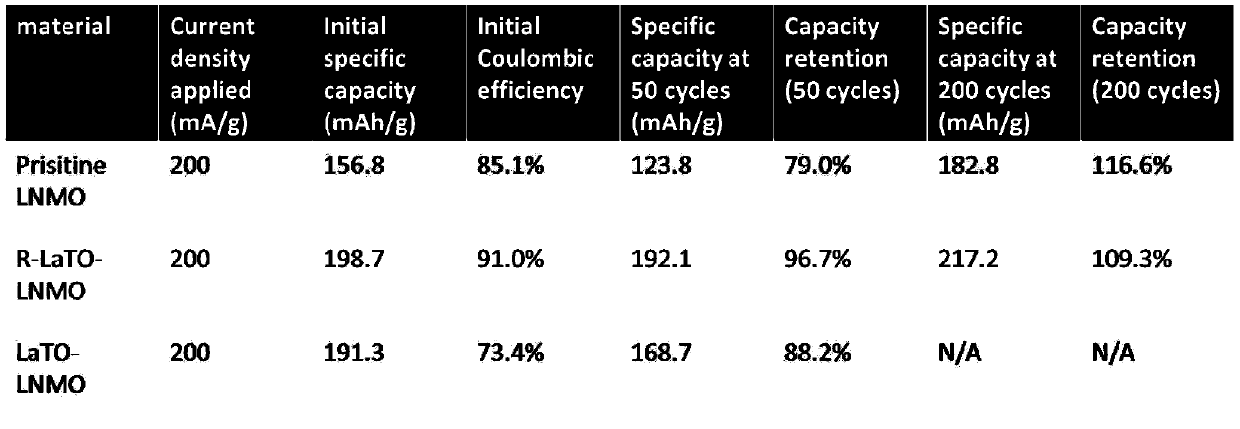

Examples

Embodiment 1

[0029] A preparation method of a conductively enhanced lanthanum titanate-coated lithium nickel manganese oxide positive electrode material, comprising the following steps:

[0030] (1) take by weighing lanthanum hydroxide and titanium tetrachloride by the mol ratio of 1:1;

[0031] (2) Dissolving lanthanum hydroxide and tetrabutyl titanate in triethylene glycol, heating to 60° C., and fully dissolving them to obtain a mixed solution A;

[0032] (3) Under the condition that the temperature of the mixed solution A is 60°C and the rotational speed of the mixer is 200r / min, mechanically stir for 30 minutes to obtain the mixed suspension B;

[0033] (4) Add ammonia water to the mixed suspension B at 60° C. under mechanical stirring at 300 r / min. The amount of ammonia water is 5 times the weight of lanthanum hydroxide.

[0034] (5) Continue stirring the mixed suspension in step (4) at 160° C. and 300 r / min for 4 hours to obtain a lanthanum titanate sol.

[0035] (6) According to ...

Embodiment 2

[0038] A preparation method containing a conductive zinc oxide coating nickel manganese oxide lithium positive electrode material, comprising the following steps:

[0039] (1) take sodium hydroxide and zinc acetate by the mol ratio of 1:1;

[0040] (2) Dissolving zinc acetate in methanol, heating to 60° C. to fully dissolve it, to obtain solution A; dissolving sodium hydroxide in methanol, stirring to obtain solution B;

[0041] (3) Under the condition that the temperature of the mixed solution A is 60°C and the rotational speed of the mixer is 200r / min, the solution B is slowly added to the solution A, and mechanically stirred for 30 minutes to obtain a zinc oxide sol;

[0042] (4) At room temperature, under the mechanical stirring condition of 200r / min, according to the concentration of zinc oxide sol, the powder of lithium nickel manganese oxide is weighed in the ratio of 0.5:9.5 by the molar ratio of zinc oxide: lithium nickel manganese oxide, and Add the powder to the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com