Lithium iron phosphate composite modified lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve complex operation steps, increase the contact area between material particles, reduce material tap density, volume specific capacity and volume specific power To achieve the effect of improving electronic conductivity and lithium ion conductivity, enhancing ion conductivity and electronic conductivity, and improving high-rate discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the first step, add 0.51mol of lithium carbonate, 1mol of diammonium hydrogen phosphate, 0.057mol of iron citrate, 0.216mol of ferric oxide, and 0.01mol of samarium oxide into dehydrated alcohol accounting for 100% of the mass of the mixture as a dispersant. Ball mill ball mill mixing (speed 300r / min);

[0038] In the second step, the mixed raw materials are placed in a well-type heating furnace, nitrogen gas is introduced as a protective gas, the temperature is raised to 350°C, and the temperature is kept constant for 10 hours. After cooling, the reaction precursor is obtained by grinding;

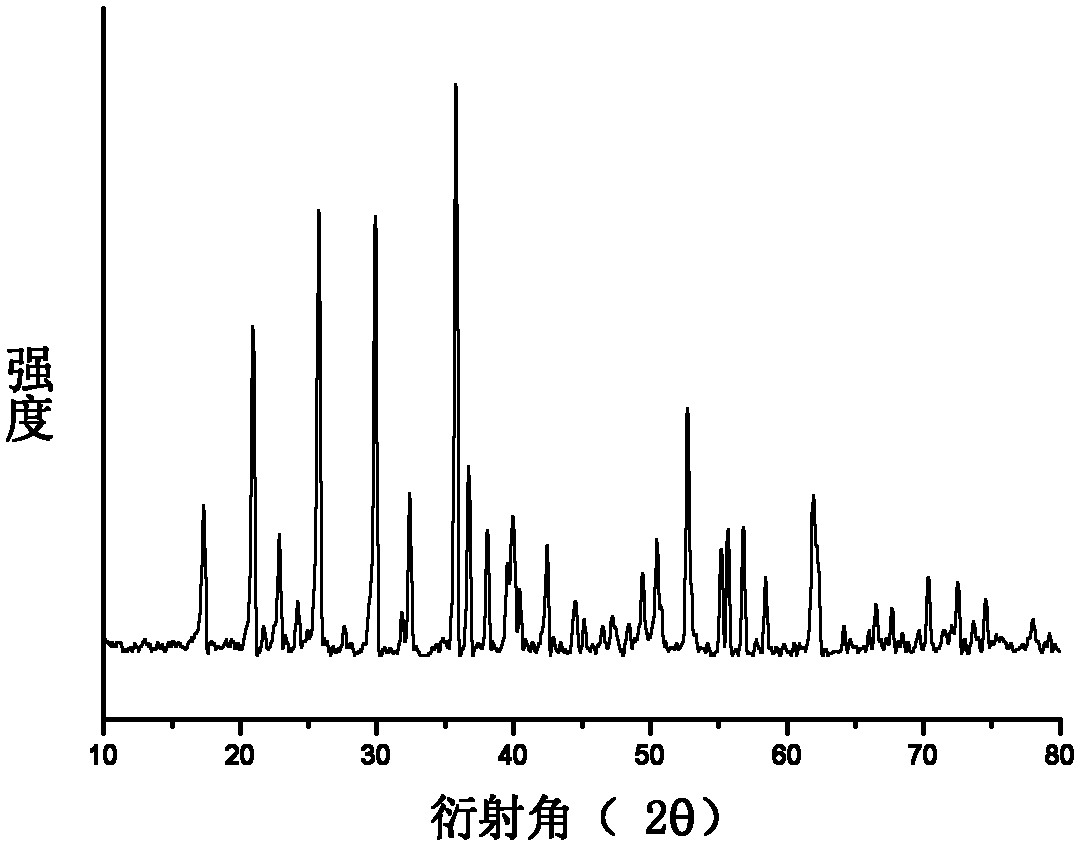

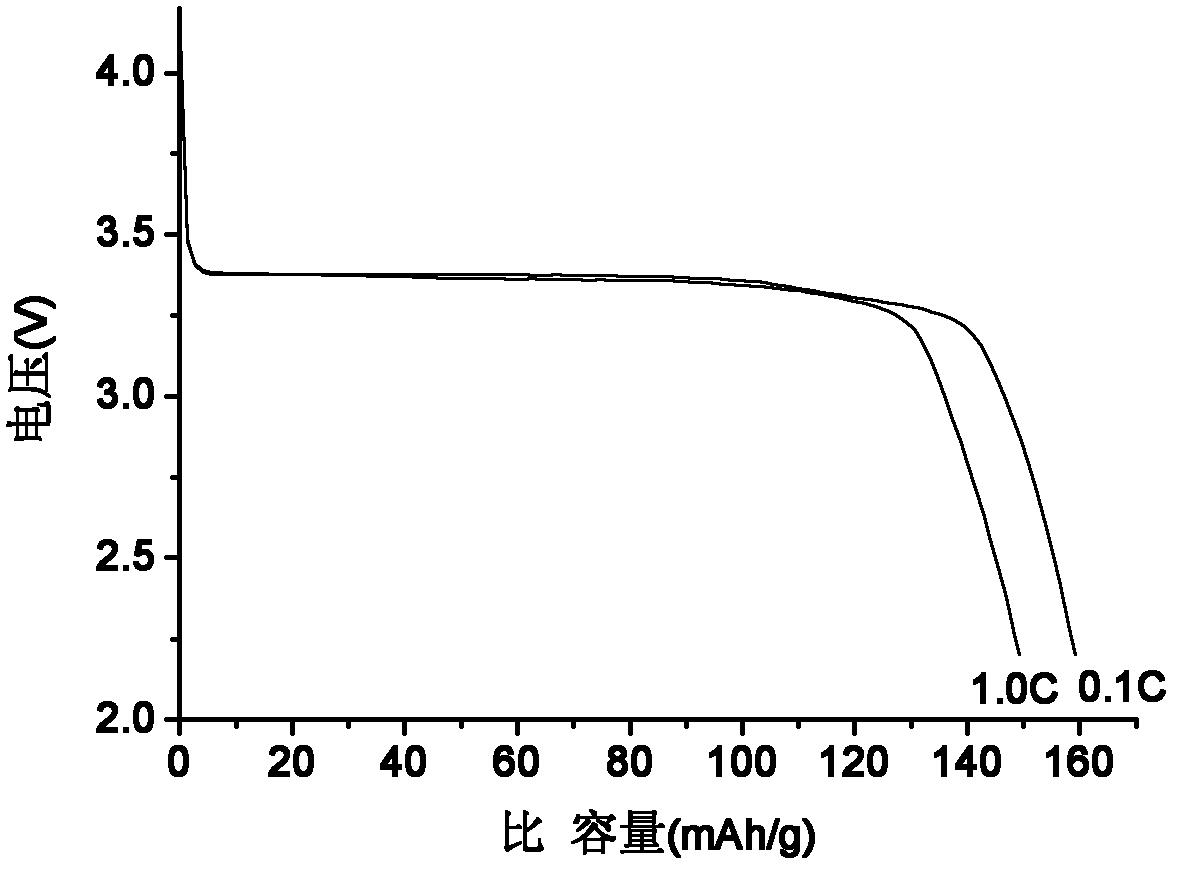

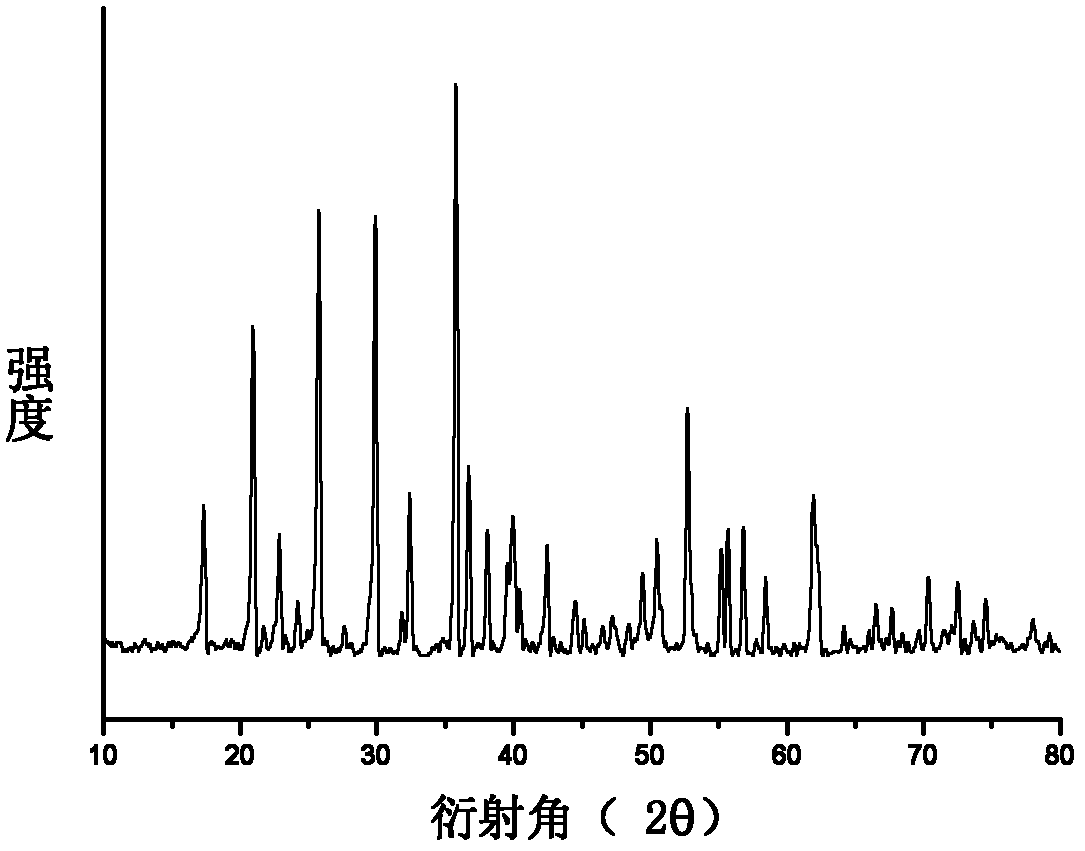

[0039] The third step is to put the obtained reaction precursor into the reactor, put it in the pit furnace, pass nitrogen gas as the protective gas, raise the temperature to 700°C, keep the temperature at a constant temperature for 24 hours, and after cooling with the furnace, grind and sieve, the obtained powder is ready for LiFe 1-x RE x PO 4 -REPO 4 / (C+Fe 2 P) Composit...

Embodiment 2

[0043] The first step with 1.02mol lithium nitrate, 0.068mol ammonium hydrogen phosphate, 0.028mol ferric citrate, 0.932mol ferric phosphate, 0.05mol lanthanum oxide, the amount of adding ethanol is 200% of mixture quality, mixes through high-speed ball mill ball milling (rotating speed 400r / min);

[0044] In the second step, the mixed raw materials are placed in a well-type furnace, and argon is introduced as a protective gas, and the temperature is raised to 250 ° C, and the temperature is kept constant for 10 hours, and the reaction precursor is obtained after cooling and grinding;

[0045] The third step is to put the reaction precursor into the reactor, put it in the pit furnace, pass nitrogen gas as the protective gas, raise the temperature to 800°C, and calcine at constant temperature for 32 hours. After cooling with the furnace, grinding, and sieving, the powder obtained is LiFe 1-x RE x PO 4 -REPO 4 / (C+Fe 2 P) Composite doping modified cathode material with a ta...

Embodiment 3

[0048] In the first step, 1mol lithium phosphate, 0.127mol ferric citrate, 0.281mol ferric oxide, 0.04mol neodymium oxide, the amount of ethanol added is 200% of the mass of the mixture, and mixed by ball milling in a high-speed ball mill (rotating speed 400r / min);

[0049] In the second step, the mixed raw materials are placed in a well-type heating furnace, nitrogen gas is introduced as a protective gas, the temperature is raised to 400°C, and the temperature is kept constant for 5 hours. After cooling, the reaction precursor is obtained by grinding;

[0050]The third step is to put the obtained reaction precursor into the reactor, put it in the pit furnace, pass nitrogen gas as the protective gas, raise the temperature to 500°C, keep the temperature for 40 hours, cool down with the furnace, grind and sieve the obtained powder. LiFe 1-x RE x PO 4 -REPO 4 / (C+Fe 2 P) Composite doping modified cathode material with a tap density of 1.2g / cm 3 .

[0051] The above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com