Composite doped modified lithium-ion battery anode material and its manufacture method

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of compound doped modified lithium-ion battery positive electrode materials and its preparation, can solve the problem of reducing the volume specific energy and volume specific power of materials, affecting the electrical properties of materials, and reducing the true density of materials, etc. Problems, to achieve the effect of strengthening ion conductivity and electronic conductivity, enhancing electronic conductivity, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is to mix 1mol lithium nitrate, 1mol phosphoric acid, 0.995mol ferrous acetate, 0.005mol yttrium acetate and 36.0g glucose, use 144.0g ethanol as a dispersant, and mix evenly through high-speed ball milling;

[0028] The second step is to place the mixed raw materials in a well-type furnace, pass through nitrogen as a protection, heat at 250°C for 20 hours, cool and grind to obtain PO 4 3- , Li + , Y 2+ , Fe 2+ and carbon black reaction precursor;

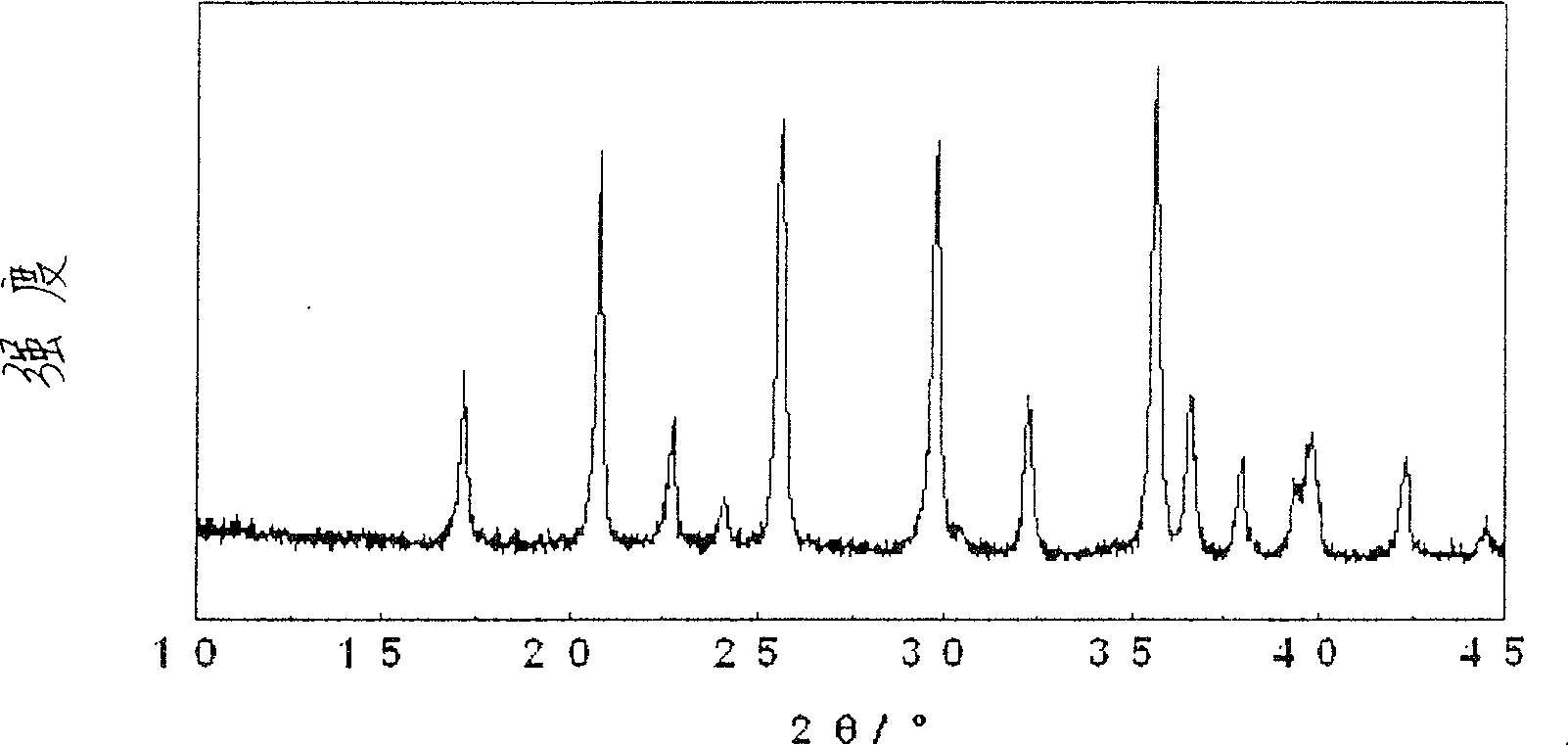

[0029] The third step is to put the reaction precursor into the reactor, place it in a well-type furnace, pass through nitrogen as a protection, and calcinate at 500°C for 10 hours, and then get LiFe after cooling with the furnace. 0.995 Y 0.005 PO 4 / C composite doping modified cathode material.

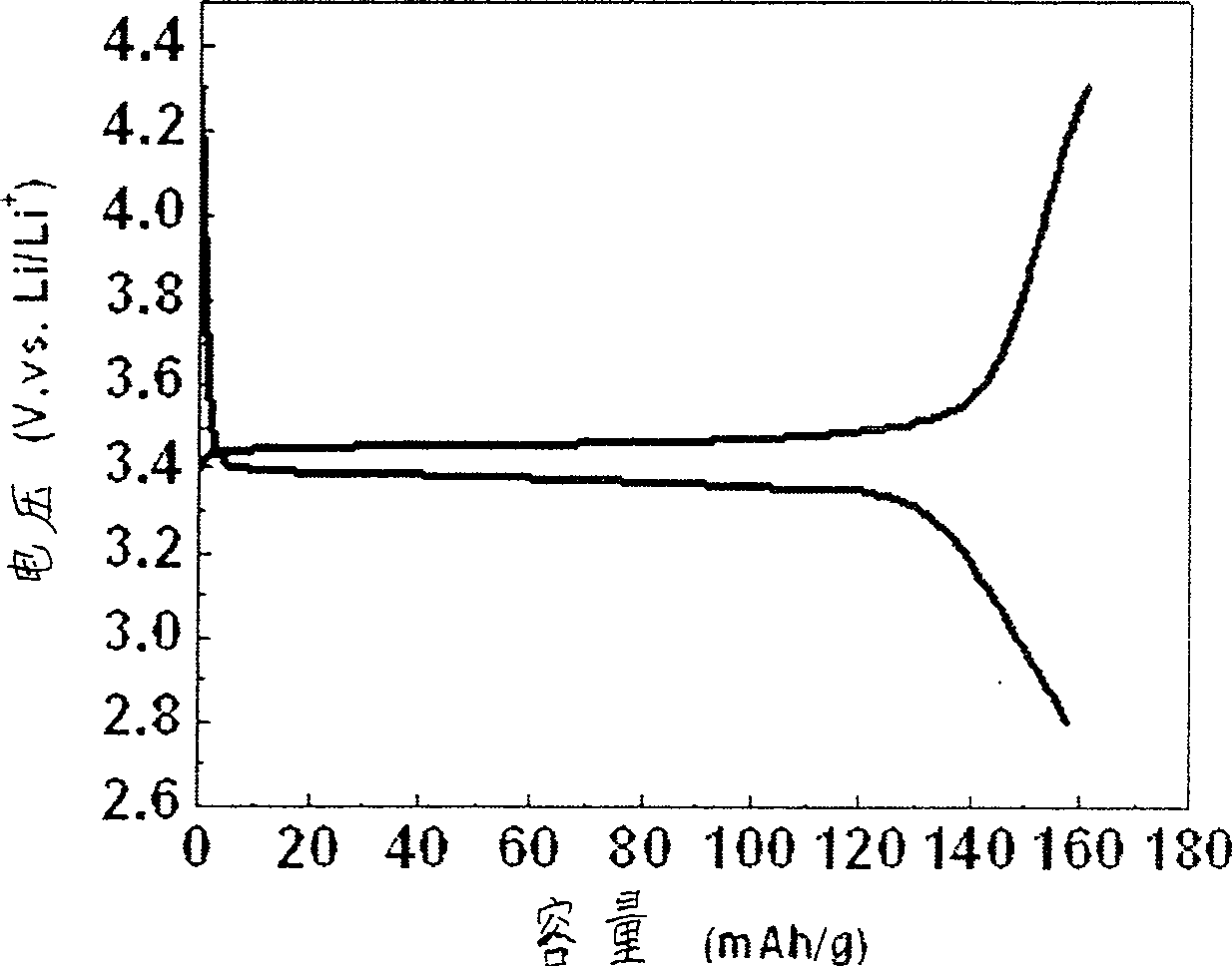

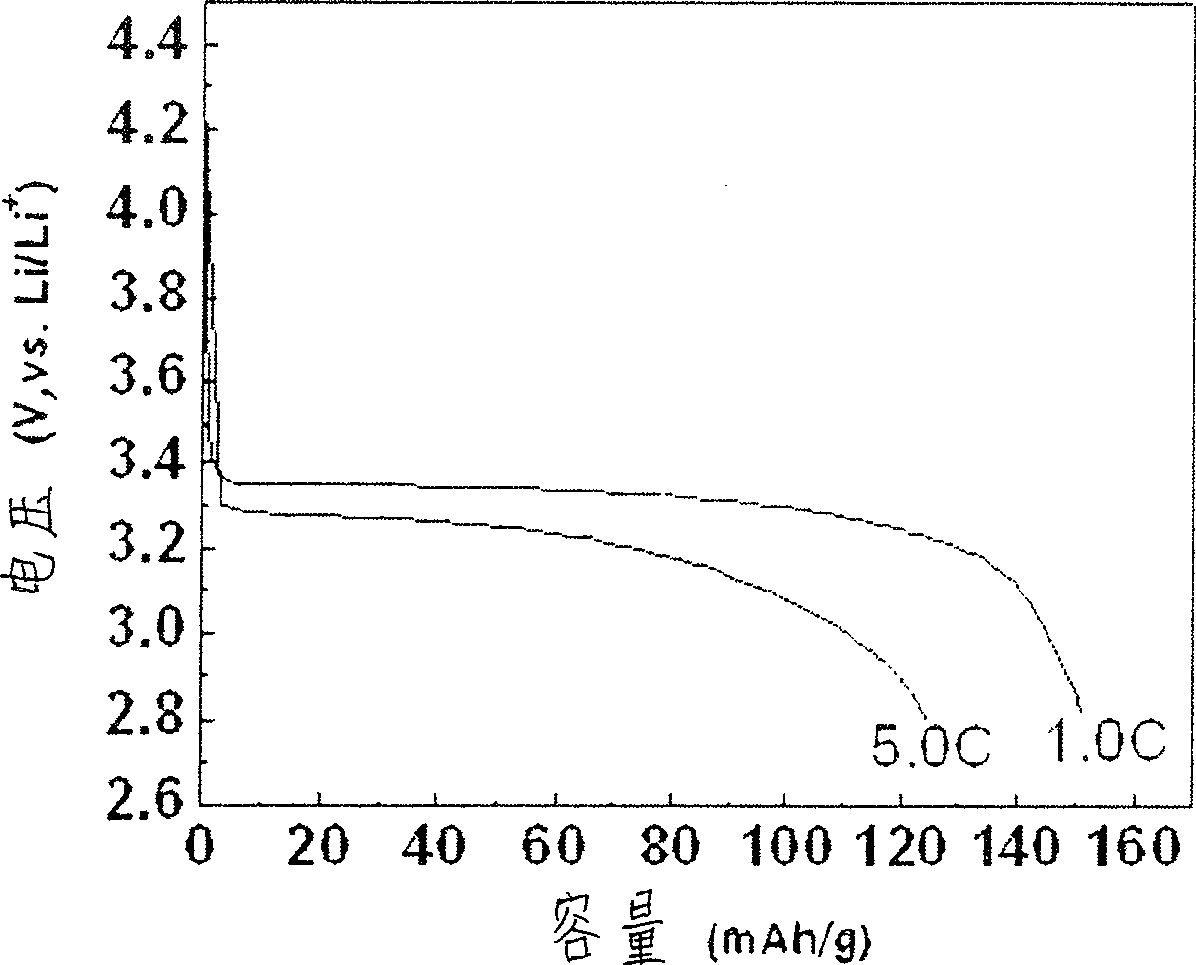

[0030] Adopt above-mentioned composite doping modification positive electrode material to make positive electrode film as positive electrode active material, the composition of positive electrode film is m 活...

Embodiment 2

[0032] The first step is to mix 0.5mol lithium carbonate, 1mol diammonium hydrogen phosphate, 0.99mol ferrous oxalate, 0.01mol lanthanum acetate and 8.0g epoxy resin, use 162.0g ethanol as a dispersant, and mix evenly through high-speed ball milling;

[0033] The second step is to place the mixed raw materials in a well-type furnace, pass through nitrogen as a protection, heat at 300°C for 10 hours, cool and grind to obtain PO 4 3- , Li + , La 2+ , Fe 2+ and carbon black reaction precursor;

[0034] The third step is to put the reaction precursor into the reactor, place it in a well-type furnace, pass through nitrogen as a protection, calcinate at 650°C for 24 hours, and obtain LiFe after cooling with the furnace. 0.99 La 0.01 PO 4 / C composite doping modified cathode material.

[0035] Adopt above-mentioned composite doping modification positive electrode material to make positive electrode film as positive electrode active material, the composition of positive electro...

Embodiment 3

[0037] The first step is to mix 0.5mol lithium carbonate, 1mol ammonium phosphate, 0.98mol ferrous acetate, 0.02mol neodymium acetate and 18g cellobiose, use 140.0g ethanol as a dispersant, and mix evenly through high-speed ball milling;

[0038] The second step is to place the mixed raw materials in a pit furnace, pass through nitrogen as a protection, heat at 350°C for 5 hours, cool and grind to obtain PO 4 3- , Li + 、Nd 2+ , Fe 2+ and carbon black reaction precursor;

[0039] The third step is to put the reaction precursor into the reactor, place it in a well-type furnace, pass through nitrogen as a protection, and calcinate at 700°C for 30 hours, and then get LiFe after cooling with the furnace. 0.98 Nd 0.02 PO 4 / C composite doping modified cathode material.

[0040] Adopt above-mentioned composite doping modification positive electrode material to make positive electrode film as positive electrode active material, the composition of positive electrode film is m 活...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com