YVO4:Eu3/YPO4 core-shell structure nano-fluorescent powder and preparation method thereof

A technology of nano-fluorescent powder and core-shell structure, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low luminous efficiency and achieve simple production process, convenient operation, and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

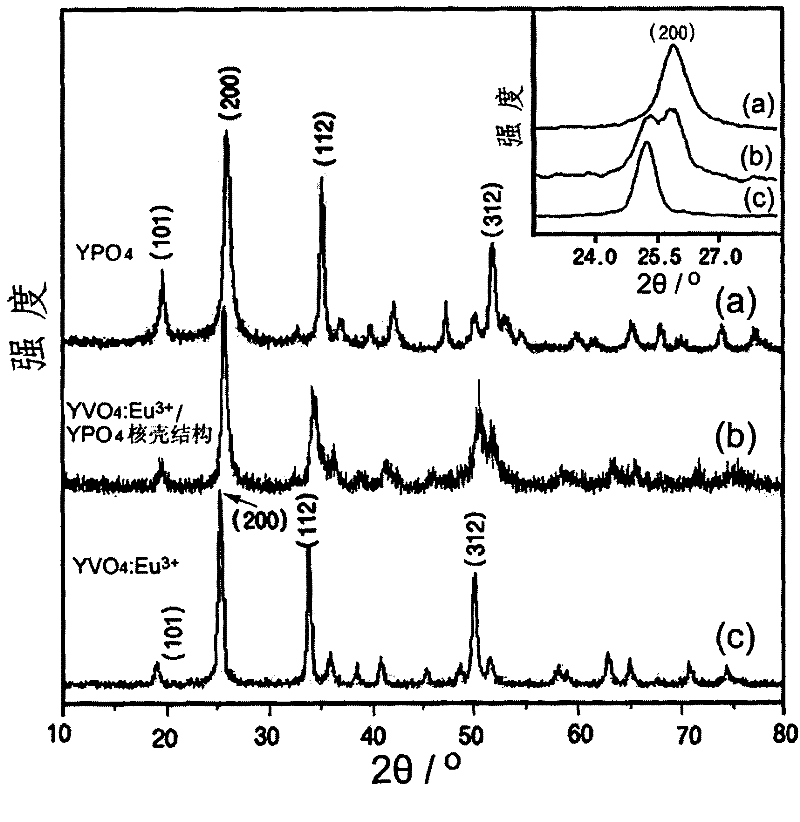

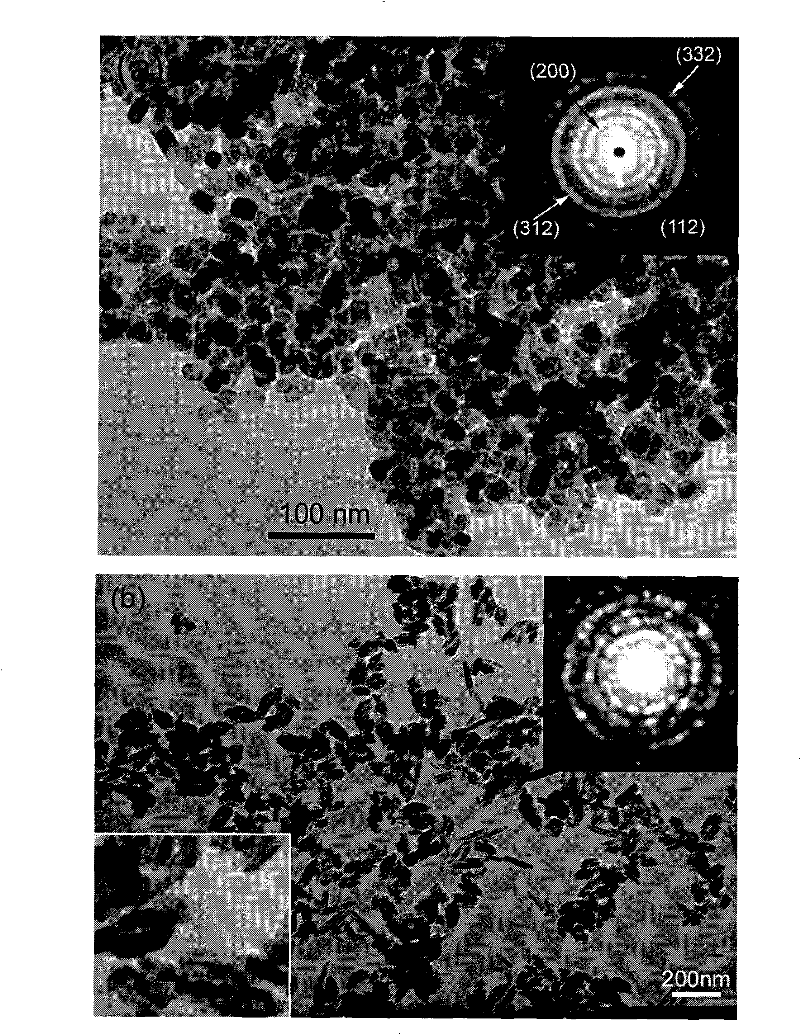

[0022] Preparation of YVO 4 :Eu 3+ / YPO 4 Nano fluorescent powder with core-shell structure, in which the doping concentration of europium is 8%, and the molar ratio of core-shell is 1:2, prepared by two-step hydrothermal method.

[0023] The first step, hydrothermal preparation of YVO 4 :Eu 3+ Core, the specific process is as follows: 1) 2.678 grams of yttrium nitrate Y (NO 3 ) 3 ·6H 2 O (7.0 mmol) and 0.271 g of europium nitrate Eu (NO 3 ) 3 ·6H 2 O (0.6 mmol) was dissolved in 190 mL deionized water. Now, europium ions account for 8% of rare earth ions, and the total molar concentration of rare earth ions is 0.040 moles / liter; 2) add 1.200 grams of sodium metavanadate NaVO in the above solution 3 2H 2 O (7.6 mmol); 3) the above solution is poured into an autoclave with a volume of 200 milliliters, and the degree of filling is 95%. After the autoclave is hydrothermally treated at 150° C. for 120 hours, it is cooled to room temperature; 4) the The final solution wa...

Embodiment 2

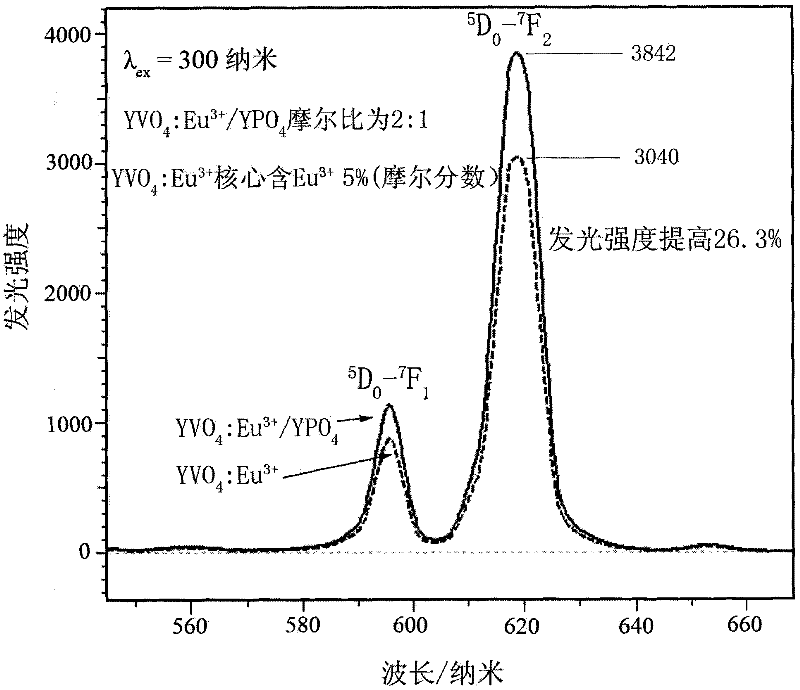

[0027] Preparation of YVO 4 :Eu 3+ / YPO 4 Nano fluorescent powder with core-shell structure, in which the doping concentration of europium is 5%, and the molar ratio of core-shell is 2:1, prepared by two-step hydrothermal method.

[0028] The first step, hydrothermal preparation of YVO 4 :Eu 3+ Core, the specific process is as follows: 1) 6.550 grams of Y (NO 3 ) 3 ·6H 2 O (17.1 mmol) and 0.401 g Eu (NO 3 ) 3 ·6H 2 O (0.9 mmol) was dissolved in 180 milliliters of deionized water, at this time, europium ions accounted for 5% of the total rare earth ions, and the total molar concentration of rare earth nitrates was 0.100 mol / liter; 2) 2.106 grams of metavanadic acid were added to the above solution Ammonia NH 4 VO 3 (18.0 mmol), stirring; 3) put the final prepared solution into an autoclave with a volume of 200 milliliters, and the filling degree is 90%. After the autoclave is hydrothermally treated at 180° C. for 100 hours, it is cooled to room temperature ; 4) Cent...

Embodiment 3

[0032] Preparation of YVO 4 :Eu 3+ / YPO 4 Nano fluorescent powder with core-shell structure, wherein the doping concentration of europium is 3%, and the molar ratio of core-shell is 4:1, prepared by two-step hydrothermal method.

[0033] The first step, hydrothermal preparation of YVO 4 :Eu 3+ Core, the specific process is as follows: 1) 14.861 grams of Y (NO 3 ) 3 ·6H 2 O (38.8 mmol) and 0.535 g Eu (NO 3 ) 3 ·6H 2 O (1.2 millimoles) was dissolved in 160 milliliters of deionized water. At this time, europium ions accounted for 3% of the total rare earth ions, and the total molar concentration of rare earth nitrates was 0.250 mol / liter; 2) Add 5.522 grams of metavanadate to the above solution Potassium KVO 3 (40.0 mmol), stirring; 3) Pour the prepared solution into a 200 ml autoclave with a filling degree of 80%. After the autoclave was hydrothermally treated at 200°C for 60 hours, it was cooled to room temperature; 4) the processed The solution was centrifuged and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com