Thin-layer asphalt pavement overlaid with old cement concrete suitable for heavy-duty coal transportation traffic

A technology of old cement and concrete, which is applied to cohesive pavement, roads, roads and other directions paved on site, can solve the problems of short operation observation time, few projects for adding asphalt surface, and no design method, etc. Achieve excellent bearing capacity and high temperature stability, good crack resistance and waterproof performance, excellent anti-reflection crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

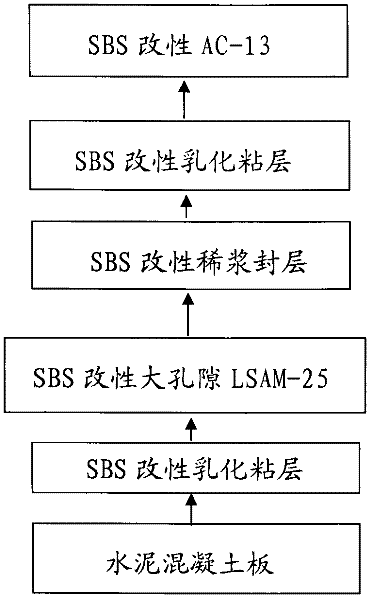

[0014] The original pavement of a main coal transportation line was made of cement concrete. Due to the heavy load, the cement pavement was severely damaged and needed to be rebuilt with "white plus black". The proportion of large trucks in the traffic composition of the main coal transportation line accounts for 40% to 50%, and through the survey of axle loads, it is found that the designed axle loads of single axle, double axle and three axles and double wheels are all 1.8 to 2.0 times the legal axle load. load limit. The axle load conversion is carried out according to the asphalt pavement, and the accumulated equivalent axle times within the design period of the lane are 3.5×107 times / lane. The pavement is paved in the following form: the cement concrete slab is provided with a rubber mastic high elastic stress absorption belt, and the rubber mastic high elastic stress absorption belt is provided with a SBS modified rubber with a content of 5% and a thickness of 6mm. Poro...

Embodiment 2

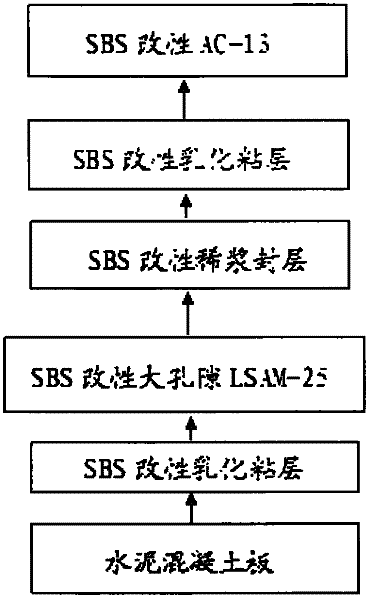

[0016] The original pavement of a main coal transportation line was made of cement concrete. Due to the heavy load, the cement pavement was severely damaged and needed to be rebuilt with "white plus black". The proportion of large trucks in the traffic composition of the main coal transportation line accounts for 50% to 60%, and through the survey of axle loads, it is found that the designed axle loads of single axle, double axle and three axles and double wheels are all 2.0 to 2.2 times the legal axle load. load limit. The axle load conversion is carried out according to the asphalt pavement, and the accumulated equivalent axle times within the design period of the lane are 9×107 times / lane. The following forms are used to overlay the pavement: the cement concrete slab is provided with a rubber mastic high elastic stress absorption belt, and the rubber mastic high elastic stress absorption belt is provided with a SBS modified rubber with a content of 5% and a thickness of 7mm...

Embodiment 3

[0018] The original pavement of a main coal transportation line was made of cement concrete. Due to the heavy load, the cement pavement was severely damaged and needed to be rebuilt with "white plus black". The proportion of large trucks in the traffic composition of the main coal transportation line accounts for 60% to 70%, and through the investigation of axle loads, it is found that the designed axle loads of single axle, double axle and three axles and double wheels are all 2.2 to 2.5 times the legal axle load. load limit. The axle load conversion is carried out according to the asphalt pavement, and the accumulated equivalent axle times within the design period of the lane are 2×108 times / lane. The pavement is paved in the following form: the cement concrete slab is provided with a rubber mastic high elastic stress absorption belt, and the rubber mastic high elastic stress absorption belt is provided with a SBS modified rubber with a content of 5% and a thickness of 8mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com