Novel water erosion resistant composite coating structure

A composite coating, a new type of technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems affecting the thermal economy and safety reliability of large units, to prolong the incubation period of water corrosion, improve Combining Strength and Toughness, Harmonizing Effects of Strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described

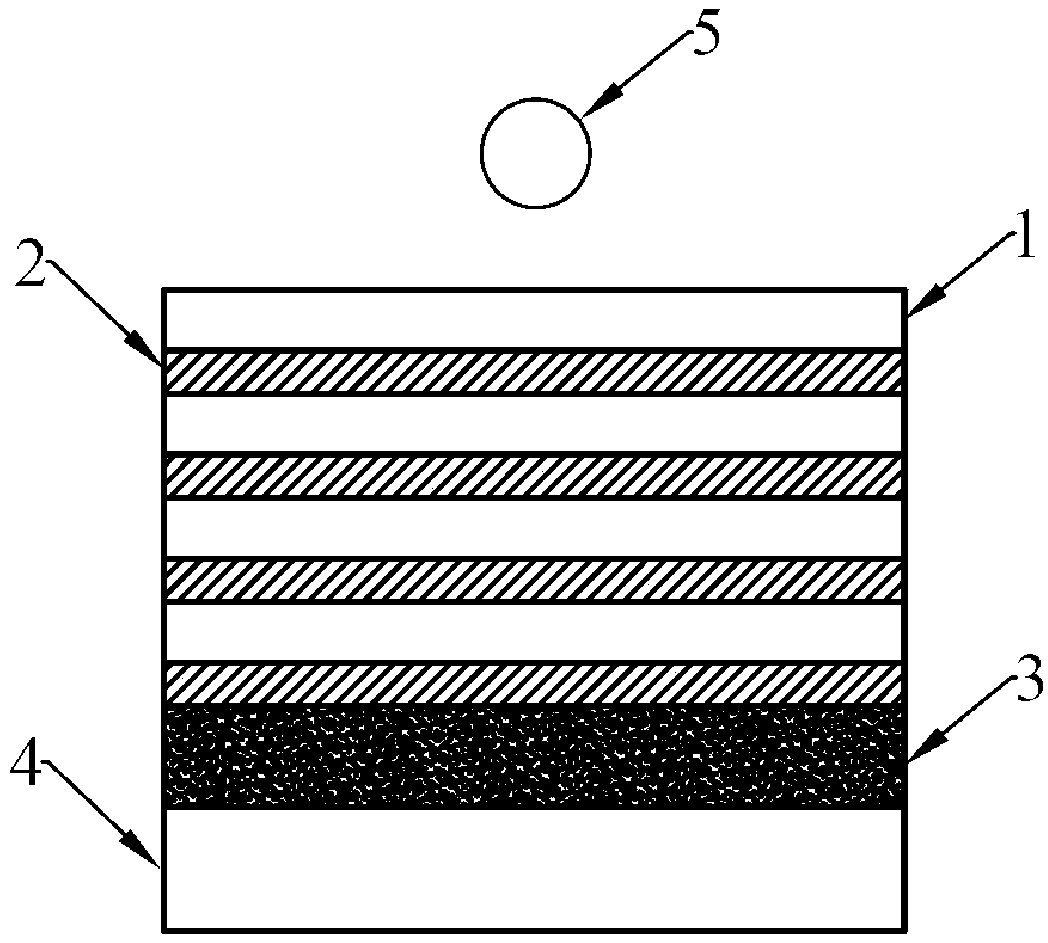

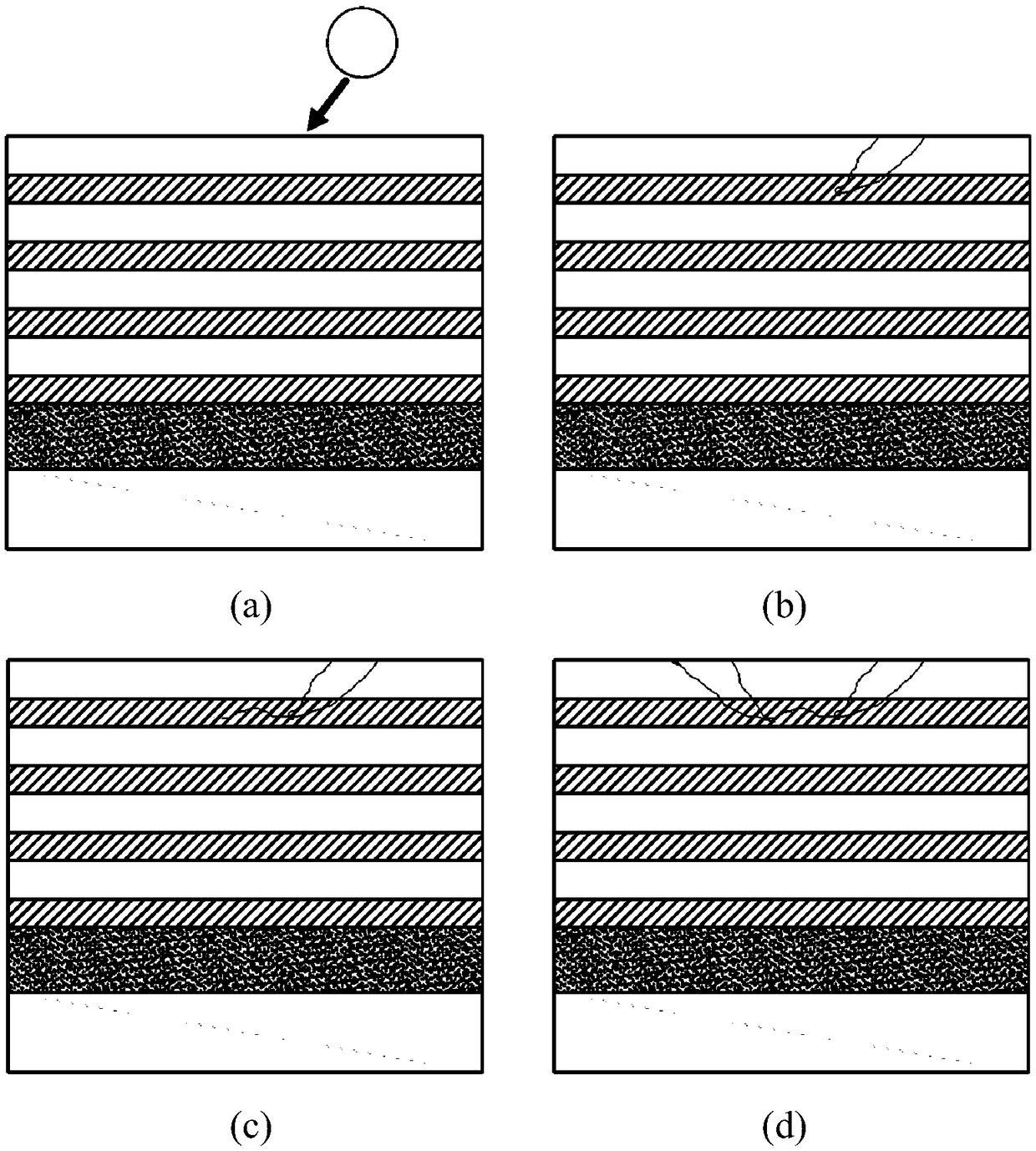

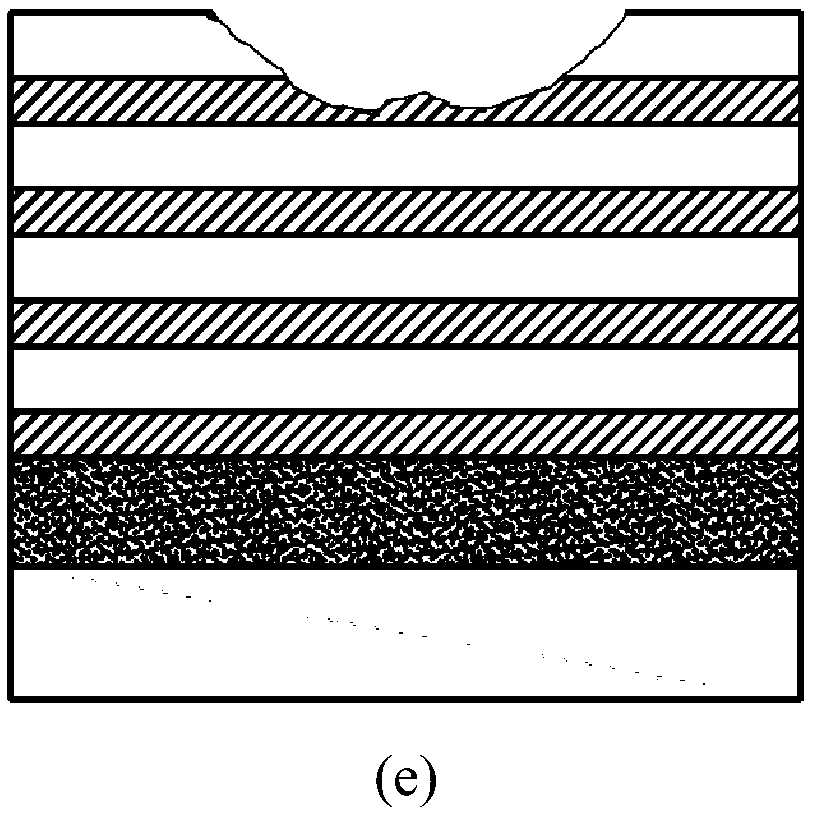

[0026] see Figure 1 to Figure 3 , a new anti-corrosion composite coating structure provided by the present invention, comprising a plurality of metal nitride MeN hard layers 1 and metal Me soft layers 2 arranged at intervals, a layer of metal nitride MeN hard layers 1 and metal Me soft layers 2 A cycle can be repeated according to actual needs. The thickness of each thin layer is generally a few microns. The metal element Me here can be selected from Ti, V, Zr, Cr, Mo, Nb, Ta and other elements according to the actual situation. , if two or more metal elements are to be selected to prepare binary and multi-component composite coatings, it is necessary to ensure that the chemical properties of the selected metal elements and the deposition process are roughly similar in order to ensure a good bonding force between the layers, while the multi-component The advantage of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com