Multilayer composite grid sound barrier and application of multilayer composite grid sound barrier

A multi-layer composite and sound insulation board technology, which is applied in the direction of sound insulation, sound generating equipment, hull paneling, etc., can solve the problems of poor heat insulation and sound attenuation, and can not meet the acoustic requirements, etc., to achieve excellent sound insulation performance and structure Simple and reasonable, the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

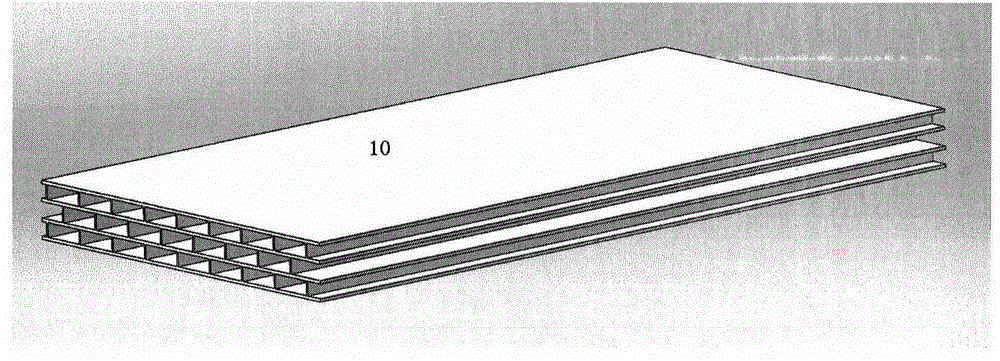

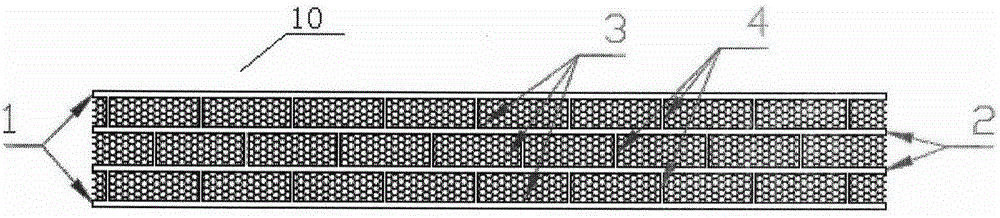

[0025] see figure 1 -2, the first embodiment of the present invention, a multi-layer composite grid sound insulation board 10, the multi-layer composite grid sound insulation board 10 is a multi-layer composite three-dimensional structure, including a surface layer 1, a middle sound insulation layer 2 , lightweight sandwich layer 3, and keel 4. The middle sound insulation layer 2 is two layers of flat plates, located between the surface layers 1 . The lightweight sandwich layer 3 is filled between the surface layer 1 and the middle sound insulation layer 2 and is located between the middle sound insulation layers 2 . The keel 4 connects the surface layer 1 and the middle sound insulation layer 2 and connects the middle sound insulation layer 2, and the extension line of the keel 4 on one side of the same middle sound insulation layer 2 is different from the extension line of the keel 4 on the other side of the middle sound insulation layer 2. Overlap occurs.

[0026] see...

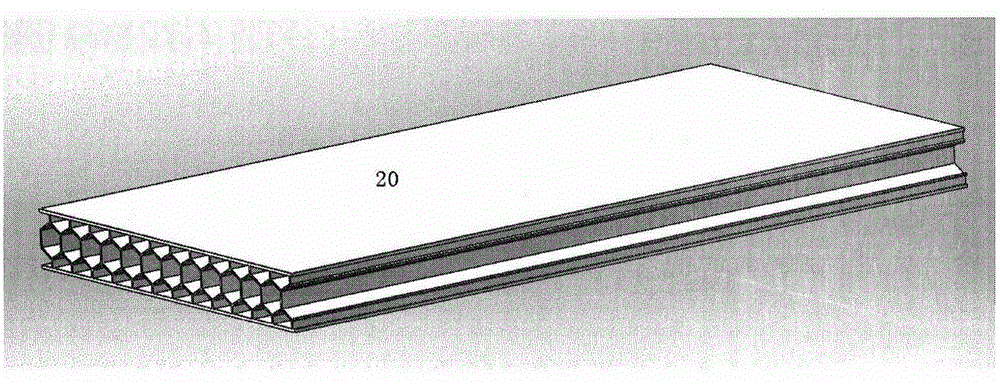

Embodiment approach

[0028] see Figure 5 , The third embodiment of the present invention, a multi-layer composite grid sound insulation board 30, including a surface layer 1, a middle sound insulation layer 2, a lightweight sandwich layer 3, and a keel 4. Different from the above embodiment, the multi-layer composite grid sound insulation board 30 has a middle sound insulation layer, and the keel 4 is discontinuous in the length direction of the composite grid sound insulation board. The keel set up in this way reduces the sound transmission of the structure, saves the use of keel materials, saves costs, and can also reduce the quality of the board itself, making the board lighter and reducing the weight of the structure.

[0029] see Figure 6 , the fourth embodiment of the present invention, a multi-layer composite grid sound insulation board 40 , including a surface layer 1 , a middle sound insulation layer 2 , a keel 4 and a support structure 5 . The support structure 5 is arranged to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com