bt composite safety explosion-proof metallized film

A metallized film and composite technology, applied in the direction of film/thick film capacitors, fixed capacitor parts, fixed capacitor electrodes, etc., can solve the problem that the fuse cannot work, the capacitor core cannot be well adsorbed, and the capacitor is easy to attenuate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

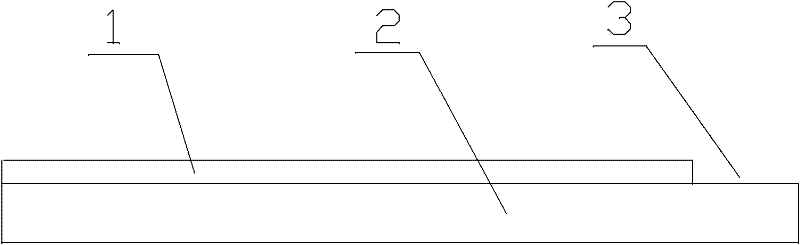

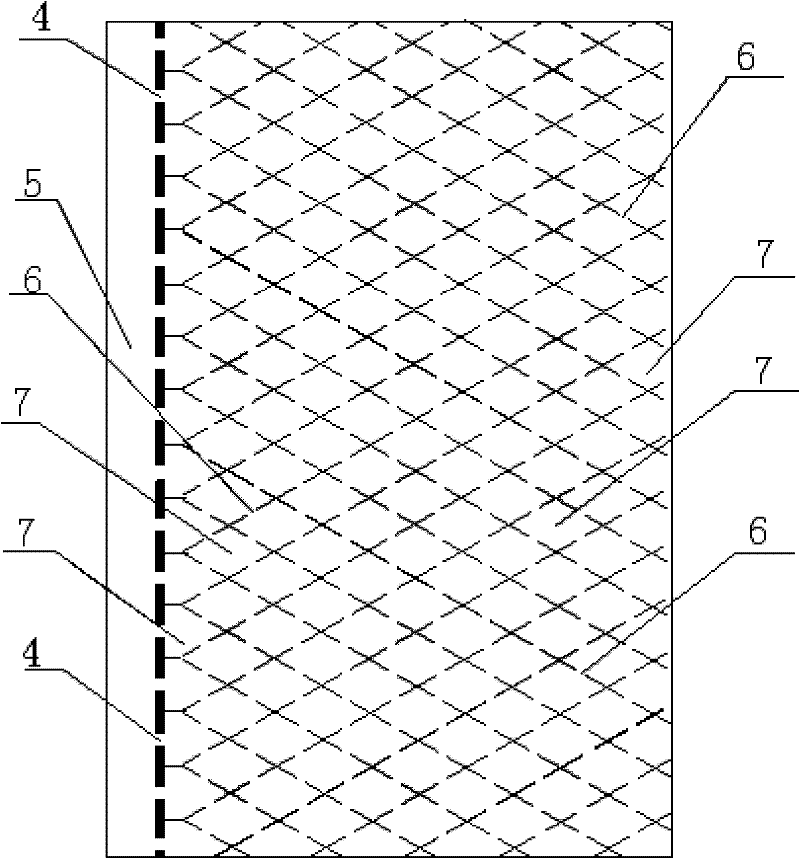

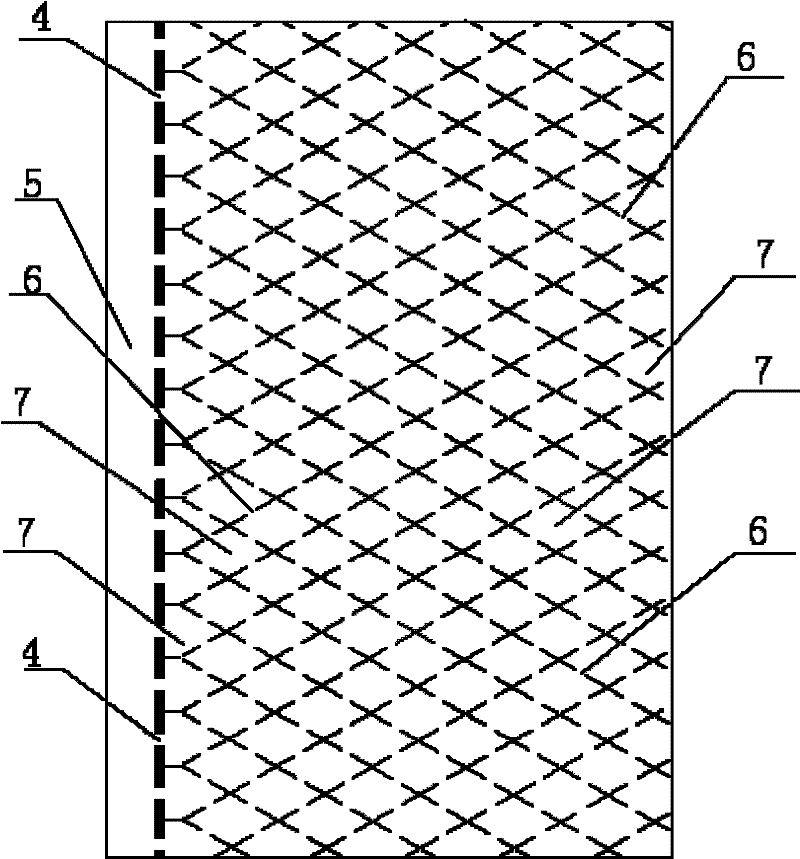

[0016] figure 1 , figure 2 A specific structure of the present invention is shown. The BT composite safety explosion-proof metallized film of the present invention is a kind of metallized film, and it comprises conductive metal layer 1 and insulating thin film dielectric layer 2, and metal layer 1 film is plated on thin film dielectric layer 2, on thin film dielectric A blank margin 3 with a certain width is reserved on one end side of the layer 2 along the longitudinal direction, and the metal layer 1 is a BT composite grid structure, including: a metal layer coated on the thin film dielectric layer 2 along the longitudinal direction A strip-shaped edge thickening area 5 with a certain width on the other end side; a metallized grid 7 that is continuously and regularly distributed between the edge thickening area 5 and the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com