Manufacture technology for compositing high-chromium alloy ceramic grain composite on surface of wear-proof machine part

A technology of high chromium alloy and ceramic particles, which is applied in the production process field of high chromium alloy ceramic particle composites on the surface of wear-resistant parts, to achieve the effects of long cycle, extended operating life and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A production process for compounding high-chromium alloy ceramic particle composites on the surface of wear-resistant parts, comprising the following steps in sequence:

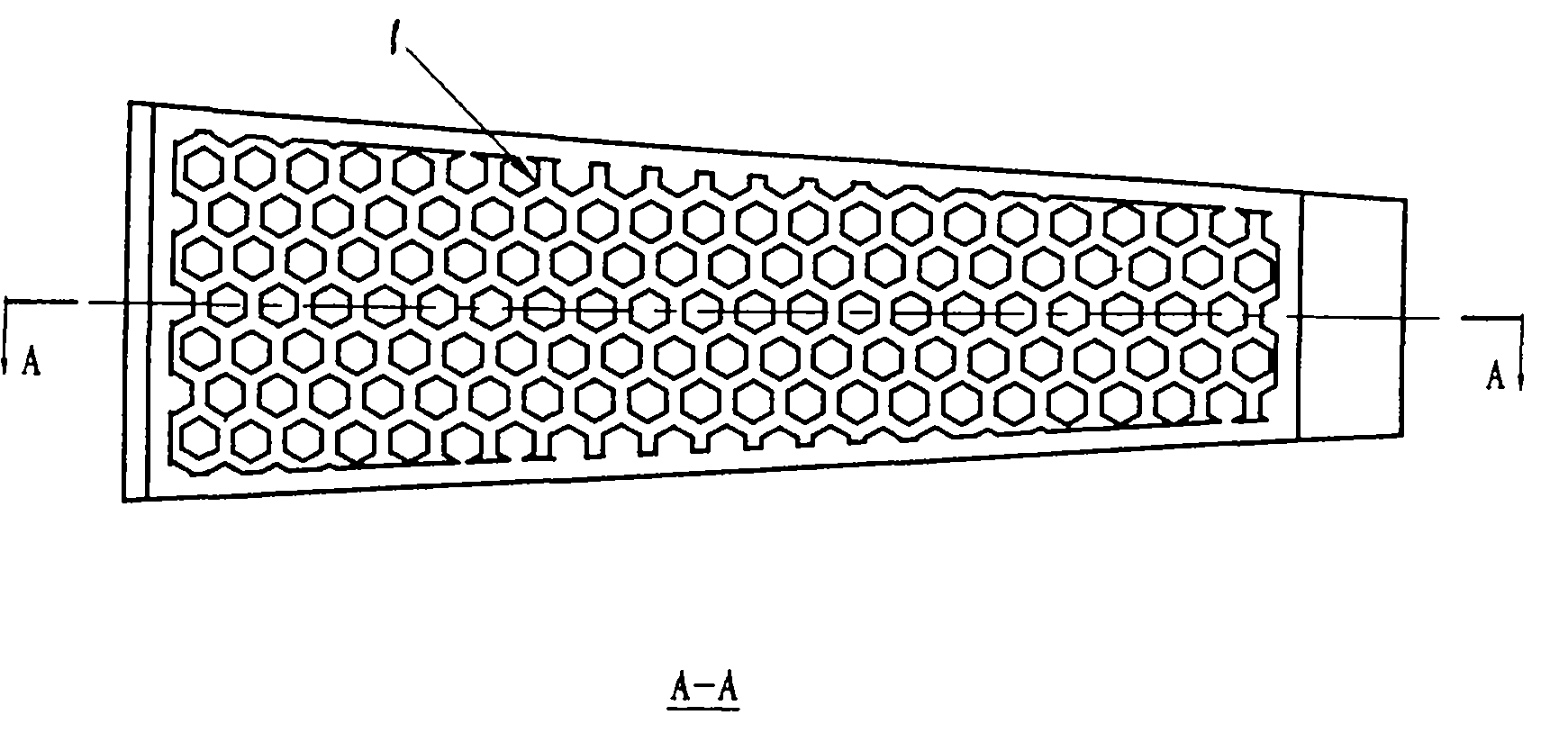

[0034] (1) Preparation of high chromium alloy ceramic particle composite grid:

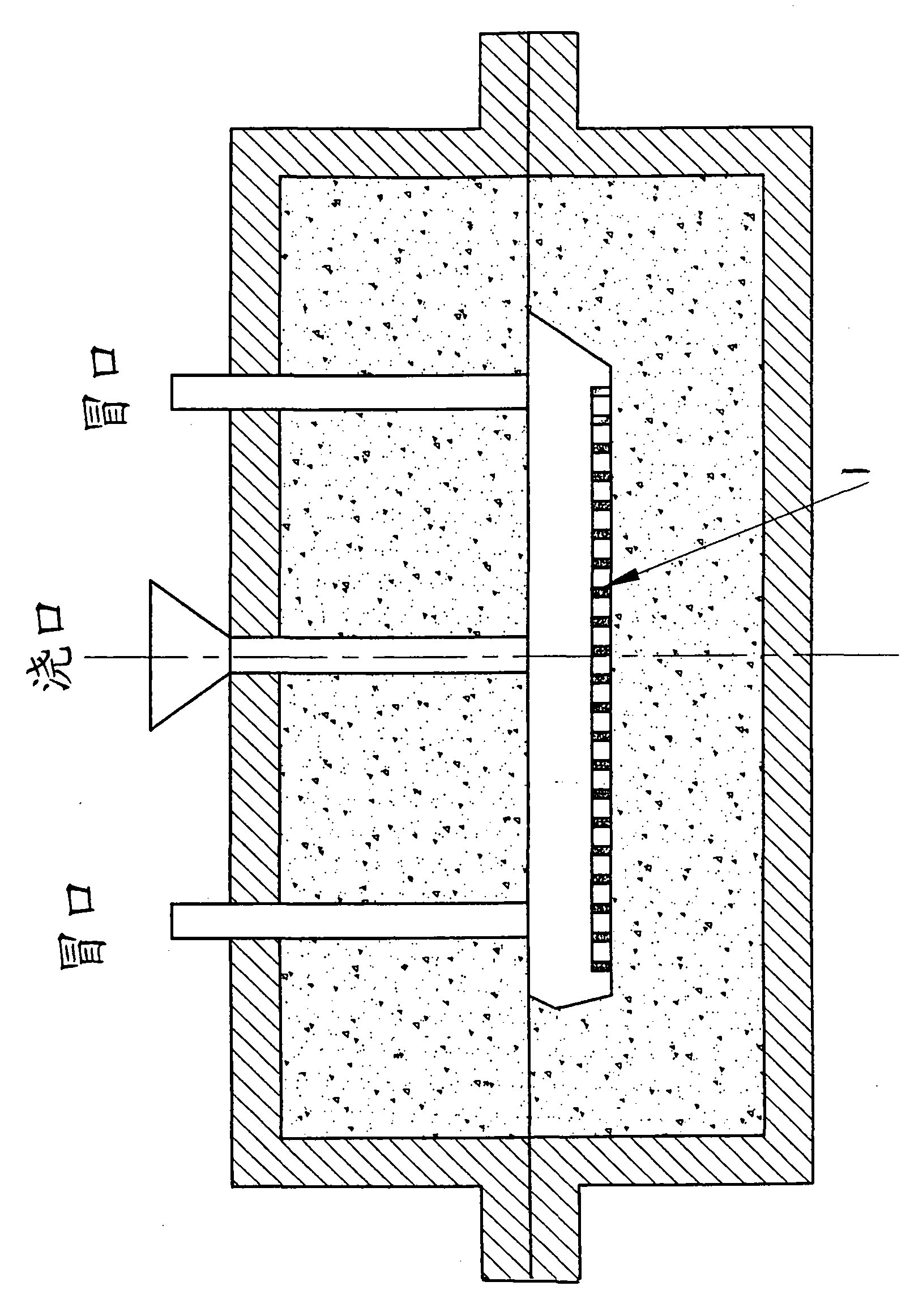

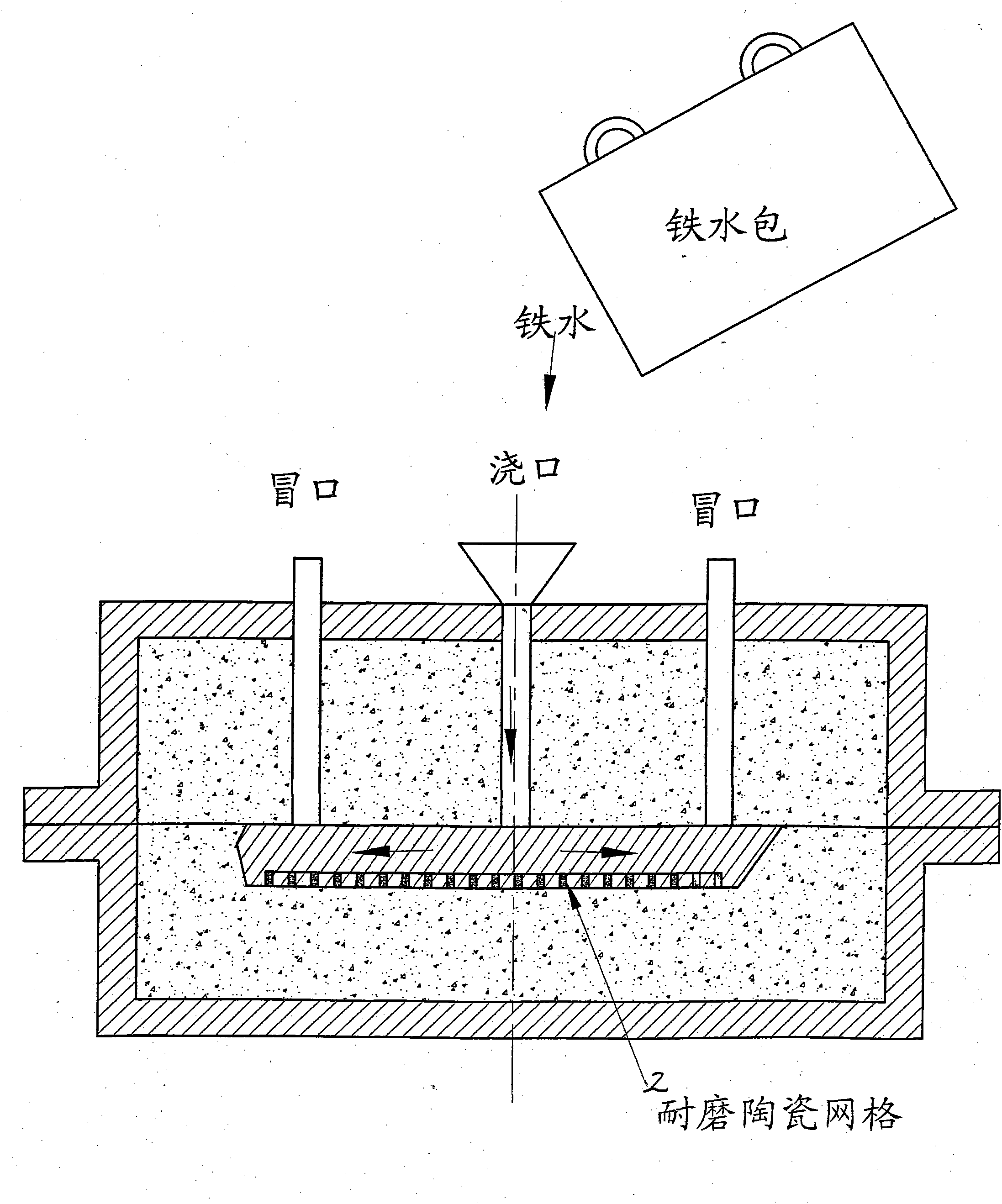

[0035] Melt the high chromium alloy and place it in the ladle, add sintered and crushed alumina and / or zirconia particles with a particle size of 80 to 100 mesh in the ladle, stir and mix, inject the mixture into the grid sand mold, and then Cooling and taking out to obtain a high chromium alloy ceramic particle composite grid 1;

[0036] (2) Fix the high-chromium alloy ceramic particle composite grid 1 on the modeling surface, and cast the machine part, so that the high-chromium alloy ceramic particle composite grid is fixed on the machine part surface.

[0037] The added amount of the alumina and / or zirconia particles is 30%-40% by volume.

[0038] The alumina and zirconia particles are particles with a content of 95% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com