Composite net-shaped grid manufacturing equipment for storage battery

A technology for manufacturing equipment and batteries, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of short battery life, poor corrosion resistance of sulfuric acid, damage to ecology, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and should not be used to limit the scope of protection of this patent.

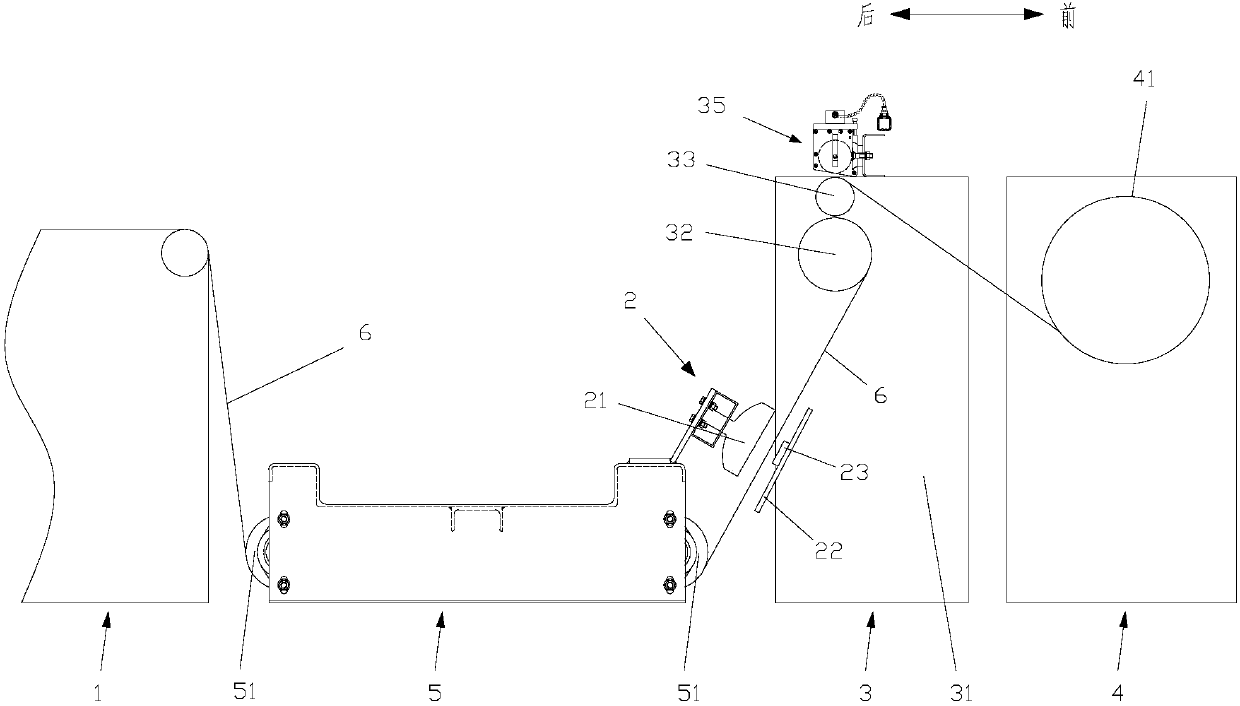

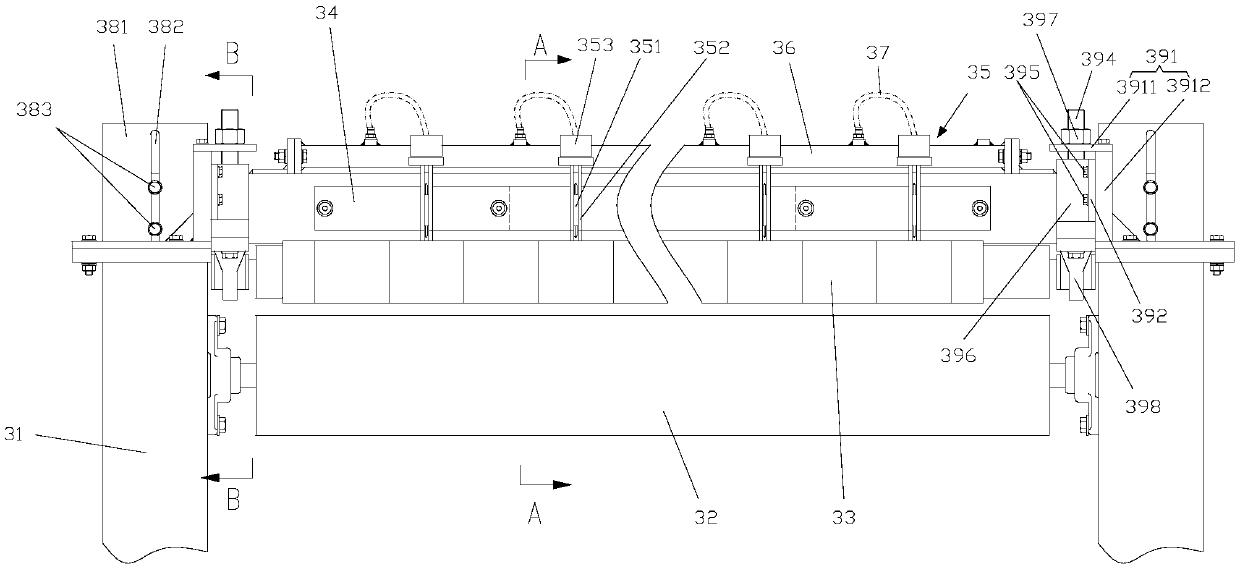

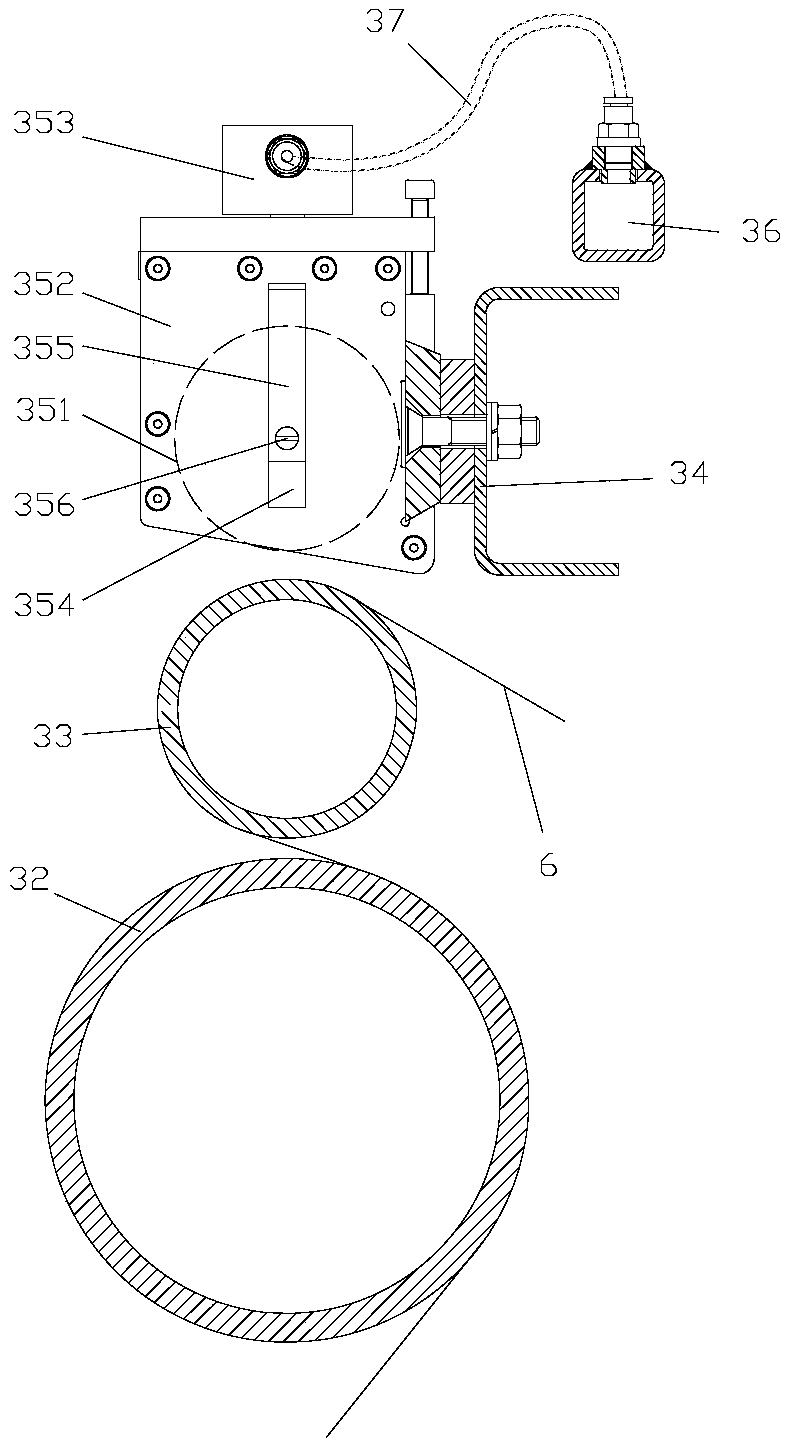

[0026] like Figure 1-Figure 5 As shown, the embodiment of the present invention provides a composite mesh grid manufacturing equipment for batteries, including: a braiding machine 1, used to weave the grid composite wire 61 and the hot-melt wire 62 into a composite grid 6, the The composite grid 6 is divided into several grid strips along the warp line according to the set width, and the edges of each grid strip both sides are woven with hot-melt lines 62 (such as Figure 5 shown in the thick solid line), in the present embodiment, the grid composite wire 61 can be a carbon fiber coaxial composite zinc wire or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com