Dew formation-preventing building envelope structure for different thermal areas

An enclosure structure and anti-condensation technology, applied to building components, building structures, buildings, etc., can solve problems affecting human health, thermal performance damage, cracks in exterior wall finishes, etc., and achieve excellent waterproof insulation Steam performance, excellent waterproof performance, and the effect of reducing building energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

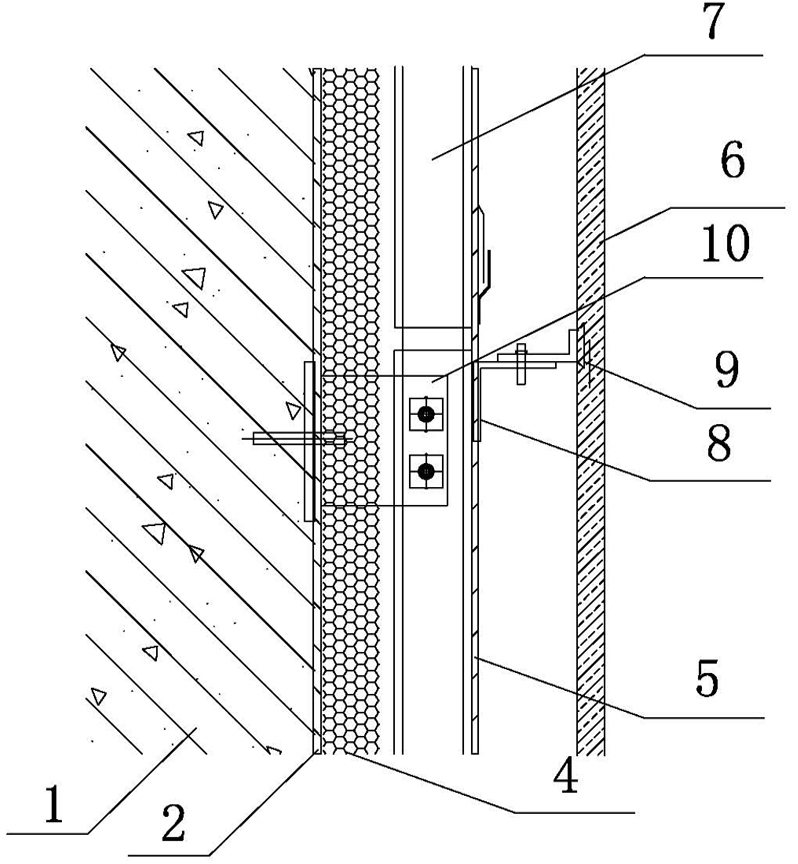

[0020] Such as figure 1 As shown, a building anti-condensation enclosure structure in different thermal areas includes an insulation layer 4, the inner side of the insulation layer 4 is provided with a metal-plated waterproof and vapor-proof coil 2, and the outer side of the insulation layer 4 is provided with a composite grid reinforcing rib waterproof and permeable Steam coil 5. The enclosure structure is suitable for a curtain wall structure. A keel structure composed of vertical keels 7 and horizontal keels 8 is connected to the base structure wall 1 through connectors 10, and the insulation layer 4 is arranged between the base structure wall 1 and the vertical keels 7. In between, a metal-plated waterproof and vapor-proof coil 2 is provided on the inner side of the insulation layer 4, and a composite grid reinforcing rib waterproof and vapor-permeable coil 5 is provided on the outer side of the vertical keel 7; It is the outer finish layer 6.

Embodiment 2

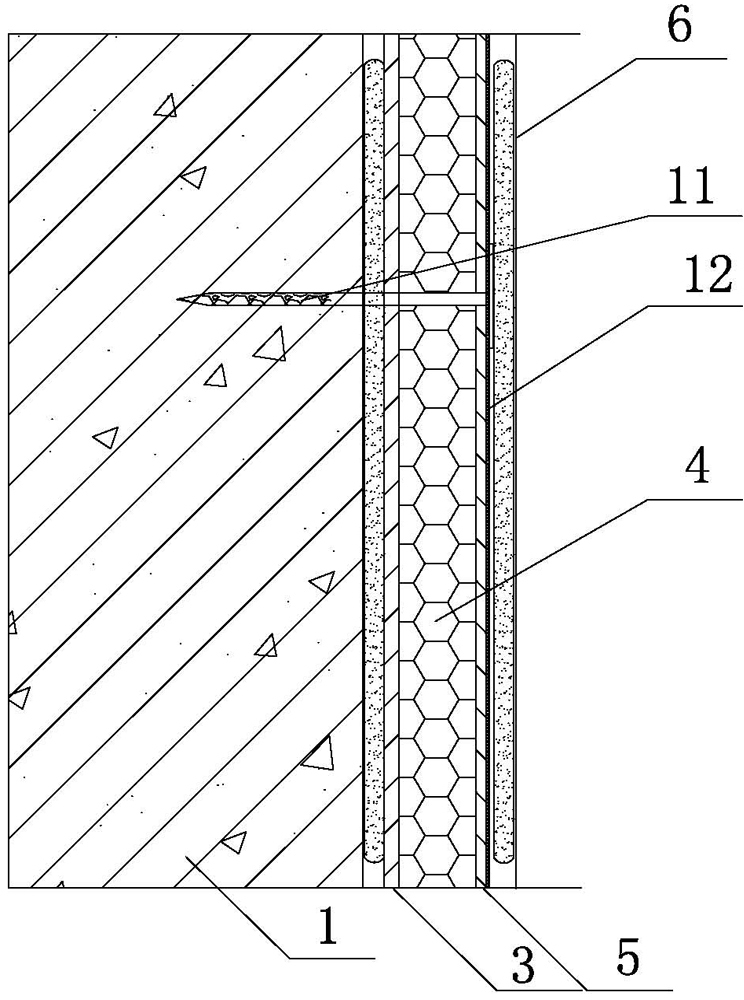

[0022] Such as figure 2 As shown, a building anti-condensation enclosure structure in different thermal areas, including an insulation layer 4, a non-woven composite waterproof and vapor-proof membrane coil 3 with an adhesive surface on the inner side of the insulation layer 4, and a composite grid on the outside of the insulation layer 4 Rib waterproof and vapor-permeable coil 5. The enclosure structure is suitable for solid veneer bricks or paint exterior walls, and the surface non-woven composite waterproof and vapor-proof membrane coiled material 3 inside the insulation layer 4 of the enclosure structure is fixed on the base structure wall 1 by adhesives and seedling bolts 11 On the outside of the insulation layer 4, there is a glass fiber mesh 12 on the outside of the composite grid stiffener waterproof and vapor-permeable coil 5, and the glass fiber mesh 12 is fixed to the exterior wall 6 by an adhesive.

Embodiment 3

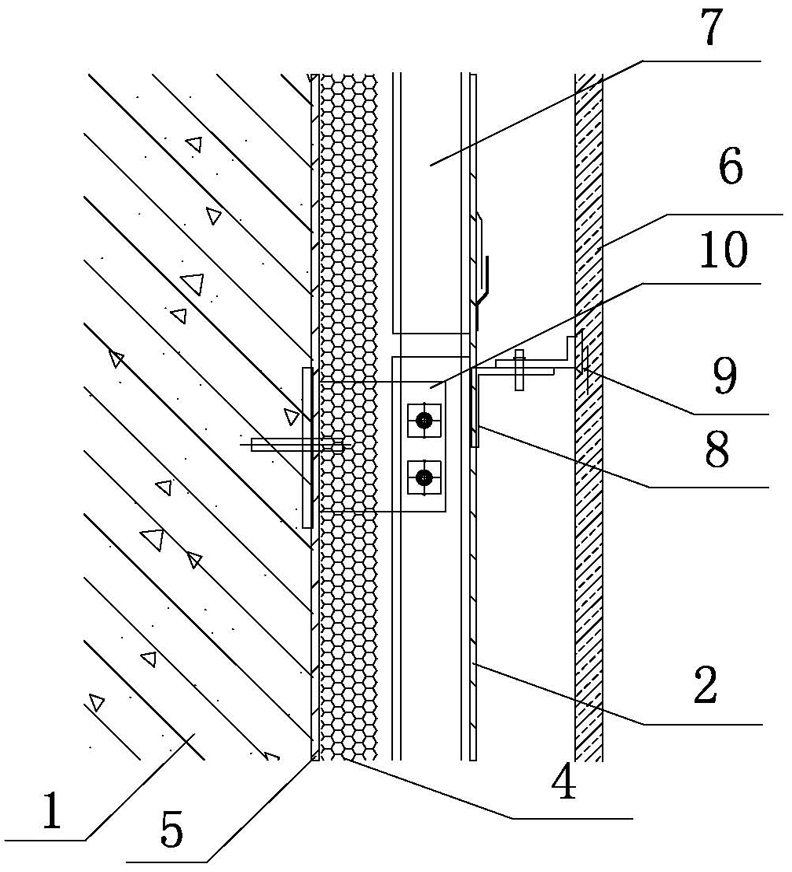

[0024] Such as image 3 As shown, a building anti-condensation enclosure structure in different thermal areas includes an insulation layer 4, a composite grid reinforcing rib waterproof and vapor-permeable coil 5 is provided on the inside of the insulation layer 4, and a metal-plated waterproof insulation layer is provided on the outside of the insulation layer 4. Steam coil 2. The enclosure structure is suitable for a curtain wall structure. A keel structure composed of vertical keels 7 and horizontal keels 8 is connected to the base structure wall 1 through connectors 10, and the insulation layer 4 is arranged between the base structure wall 1 and the vertical keels 7. Between, on the inner side of the insulation layer 4, there is a composite grid reinforcement waterproof and vapor-permeable coil 5, and on the outer side of the vertical keel 7, there is a metal-plated waterproof and vapor-proof coil 2; It is the outer finish layer 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com