Patents

Literature

41results about How to "Good vapor permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

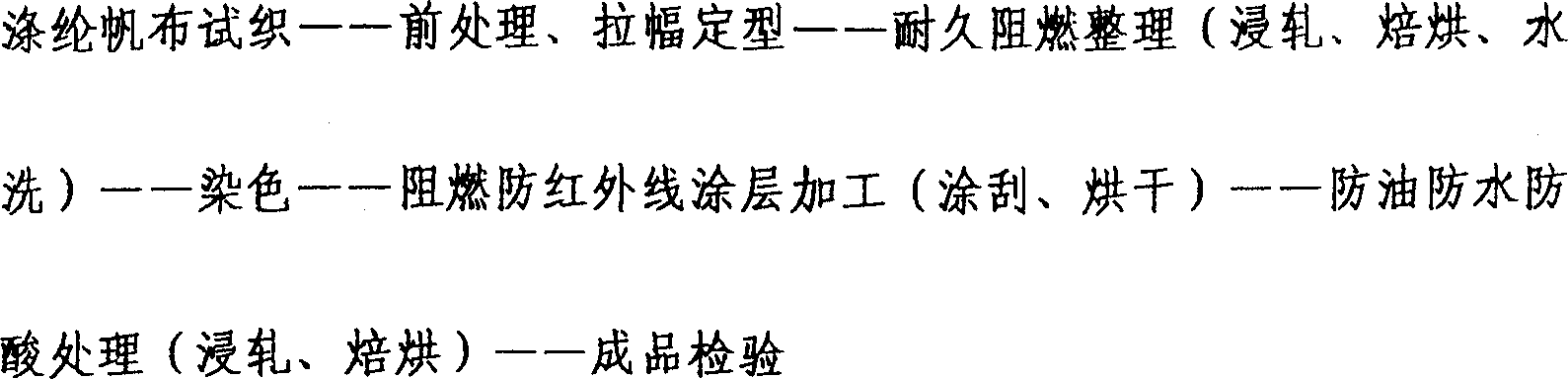

Production of ventilating, antiflame, oilproof, waterproof, acidproof, and antinear-infrared dacron tarpaulin

InactiveCN1888300AGood flame retardancyImprove low temperature performanceTextiles and paperPolyesterAdhesive

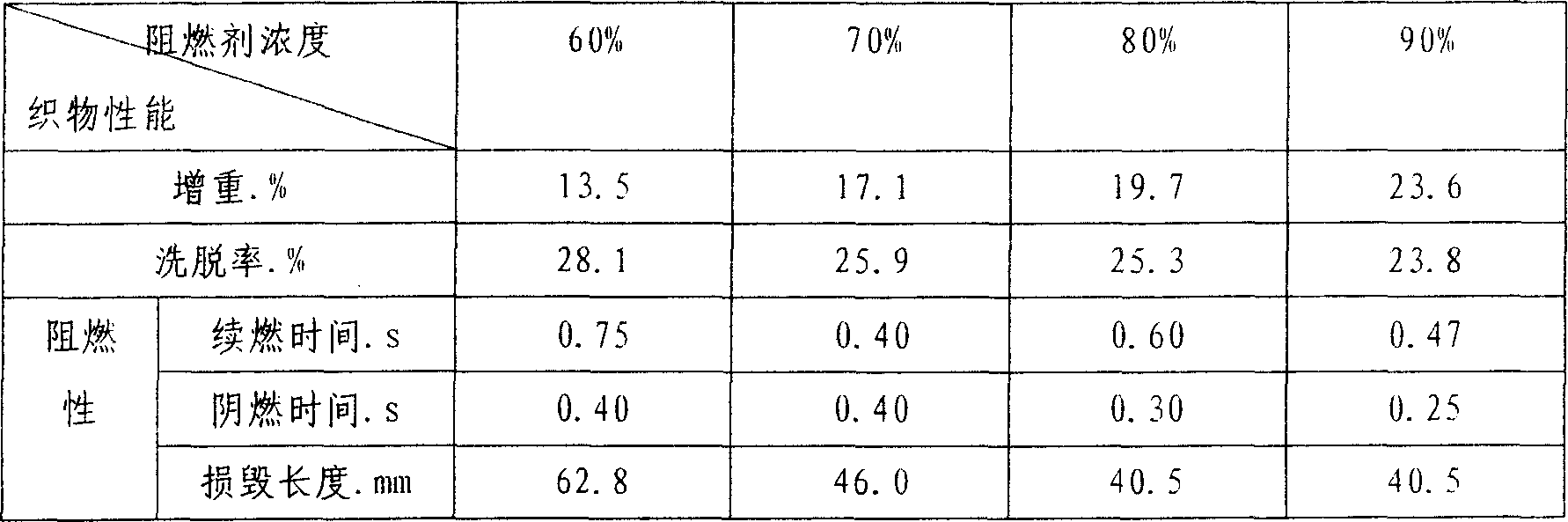

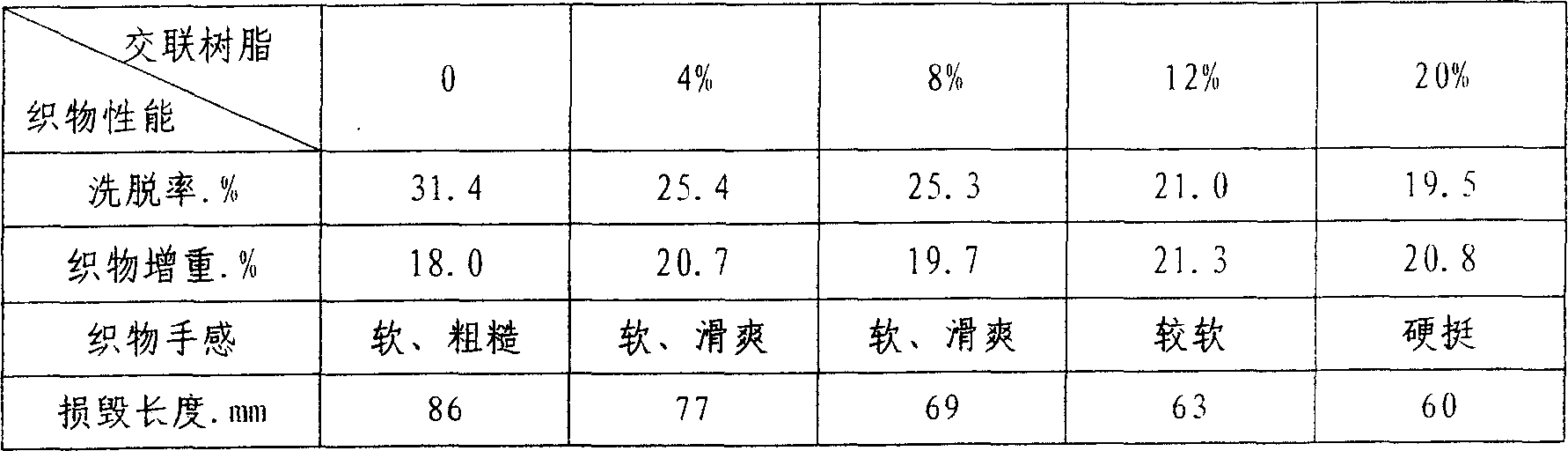

The present invention relates to a preparation process of breathable fire-retardant oil-proofing water-proofing acid-proofing and anti-near-infrared polyester sailcloth. Said preparation process includes the following several steps: firstly, making permanent flame retardant treatment of polyester sailcloth, said permanent flame retardant treatment includes padding and baking, baking temperature is 170 deg.C-200deg.C, baking time is 1-10 min, coating flame retardant PU coating adhesive, making water-proofing and acid-proofing treatment, drying and baking for 1-10 min, at 170-230 deg.C, then making permanent flame retardant of base cloth, dyeing, coating flame retardant PU coating adhesive, making water-proofing, oil-proofing and acid-proofing treatment.

Owner:南通东升艾克特种纺织防护面料有限公司

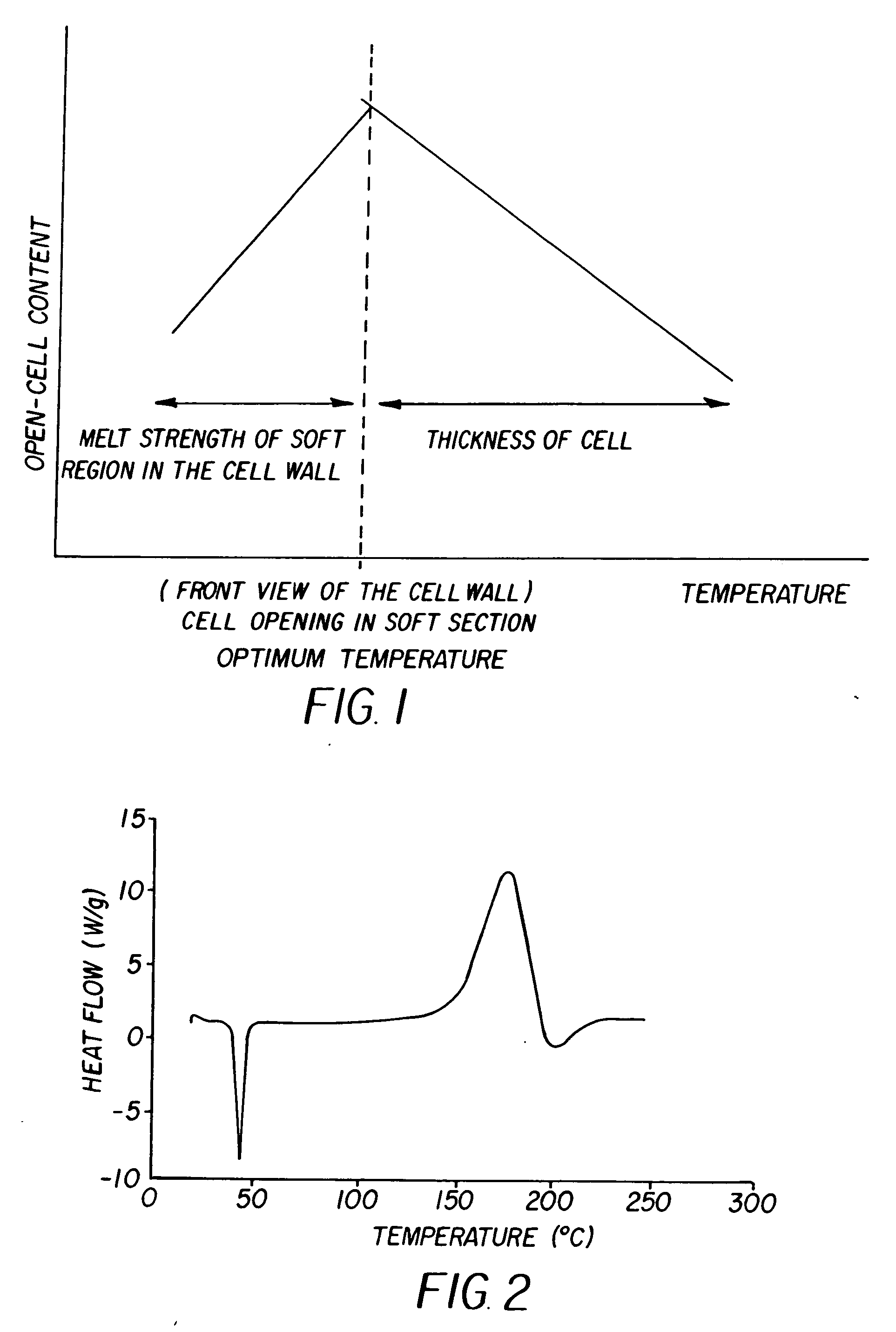

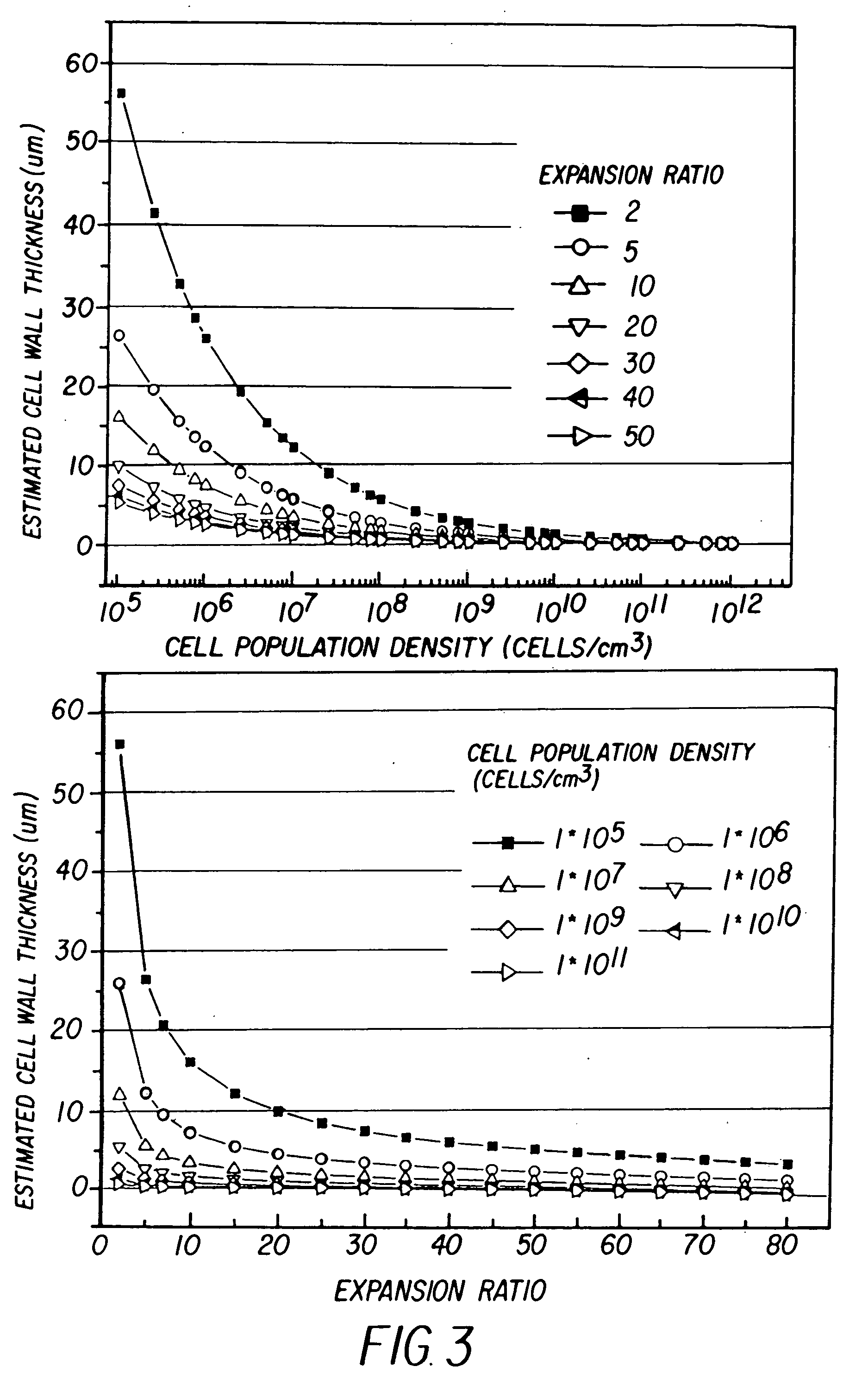

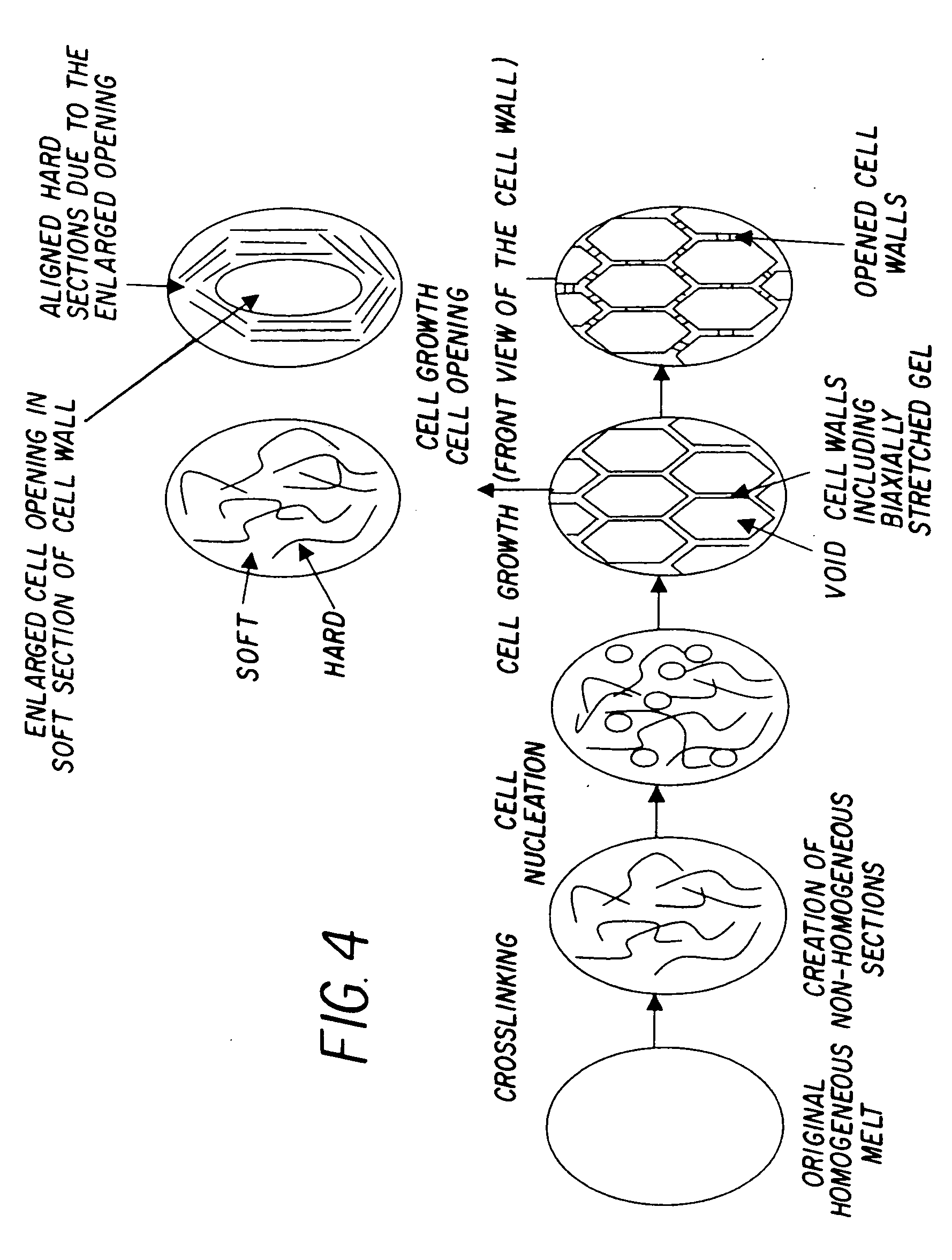

Manufacturing process for open celled microcellular foam

The present invention relates to a method for making an open celled microcellular foam comprising providing at least one foamable polymer and a crosslinking agent in an extruder, injecting at least one blowing agent into said at least one foamable polymer and said crosslinking agent in said extruder, blending said blowing agent injected into said at least one foamable polymer and said crosslinking agent in said extruder, feeding said blended blowing agent, at least one foamable polymer and said crosslinking agent in said extruder to a die, and depressurizing said blended blowing agent, said at least one foamable polymer and said crosslinking agent.

Owner:DONTULA NARASIMHARAO +6

Method for processing non-woven wall fabrics

InactiveCN103276534AHigh vapor permeabilityAvoid condensationNon-woven fabricsPolypropylenePolyester

The invention mainly discloses a method for processing non-woven wall fabrics. The method includes steps of firstly, processing polypropylene or polyester spun-bonded non-woven fabrics; secondly, printing design patterns on the polypropylene or polyester spun-bonded non-woven fabrics; and thirdly, coating movable gum on back surfaces of the spun-bonded non-woven fabrics by a coating technique by the aid of a scraper. A technique for processing the polypropylene or polyester spun-bonded non-woven fabrics includes adding environment-friendly polypropylene flame-retardant master batches with the mass percent of 0-10% into polypropylene or polyester processed raw materials; mixing the environment-friendly polypropylene flame-retardant master batches and the polypropylene or polyester processed raw materials to obtain mixtures, and performing melt extrusion on the mixtures by a large screw; filtering the extruded mixtures by a filter which is a metal screen with 600-1200 meshes to obtain melt; quantitatively outputting the melt at the speed of 80-400 liters per hour by a metering pump; spinning the melt to obtain fibers; cooling the fibers by air; drafting the fibers by air flows; and forming nets of net curtains. The method has the advantages that new products manufactured by the method are excellent in flame-retardant effect, high in vapor permeability, convenient to assemble and disassemble and low in cost, and the like.

Owner:绍兴聚能新材料科技有限公司

White mulberry bark fiber cospinning fubric and its production technology

InactiveCN1590615AGood vapor permeabilityFeel cool but softWeft knittingWoven fabricsYarnCotton fibre

Owner:四川省丝绸进出口集团有限公司 +1

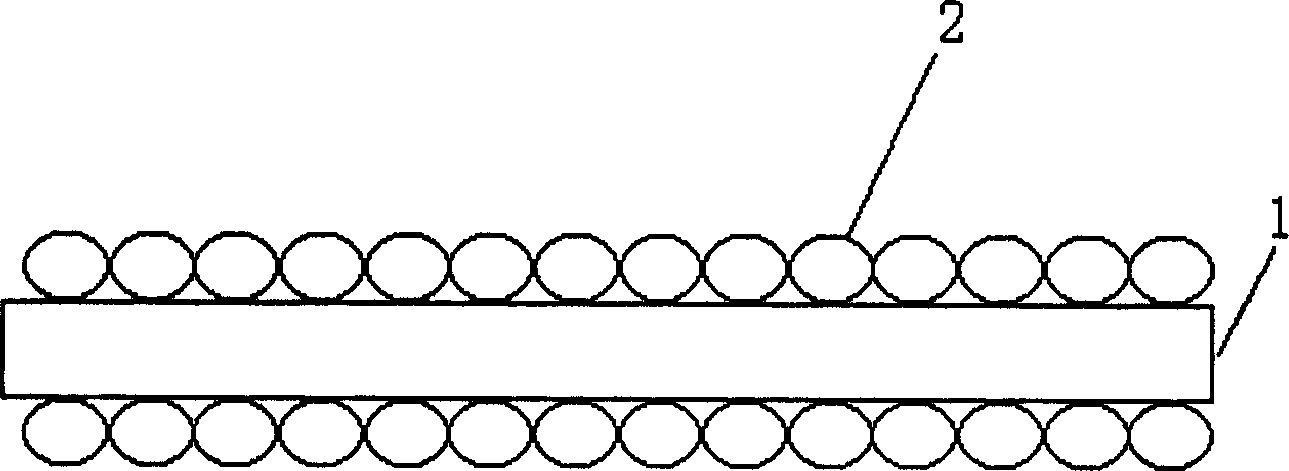

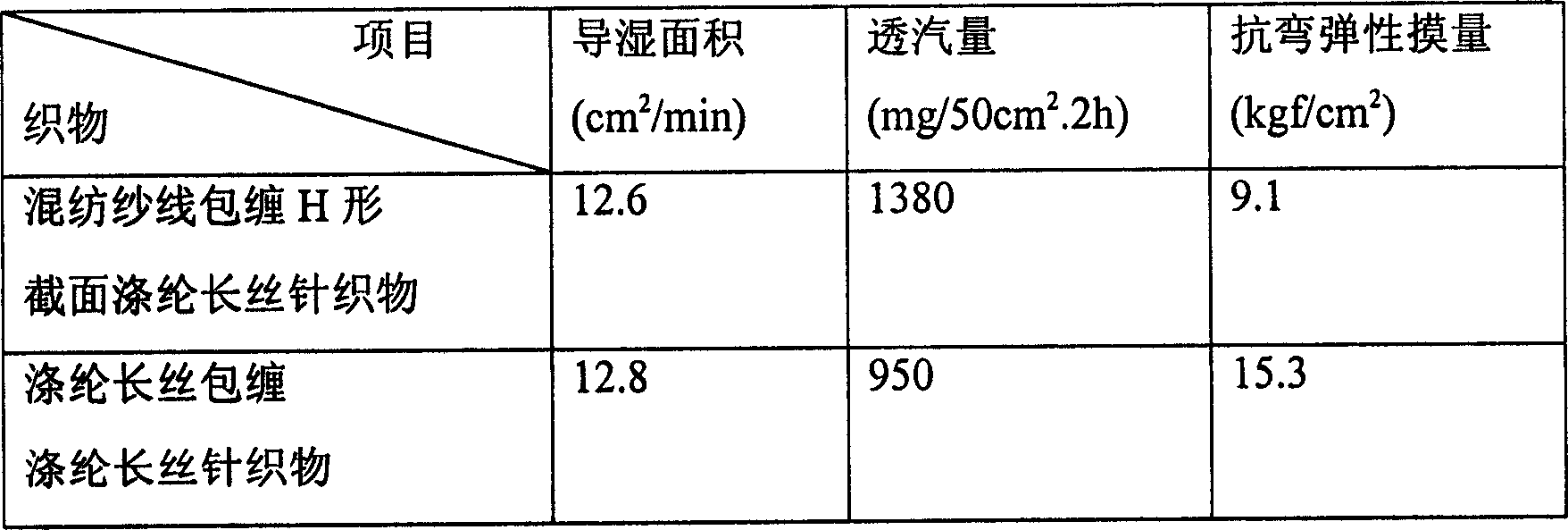

Yarn with high guiding moisture, permeability and contact confortable function

InactiveCN1560341AStrong moisture-wicking and comfortable functionalityGood vapor permeabilityYarnLiquid waterMoisture permeability

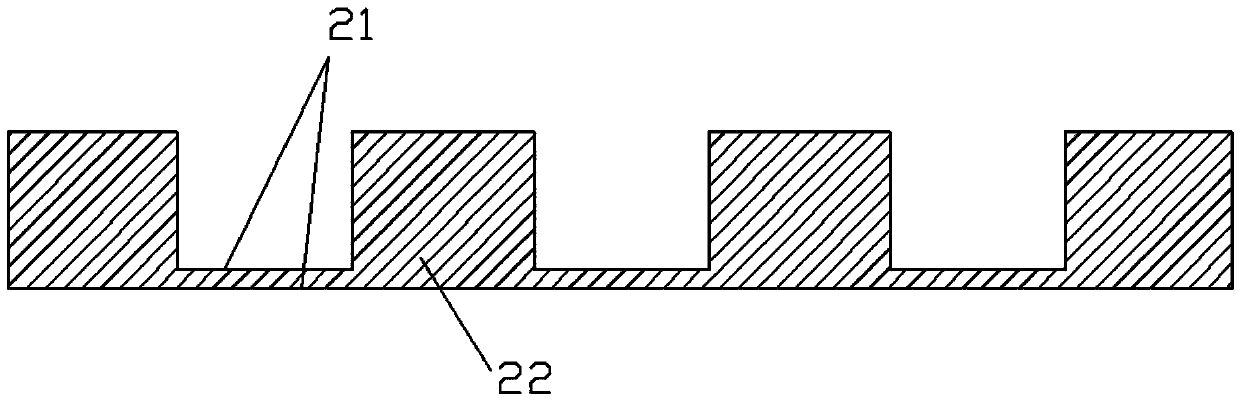

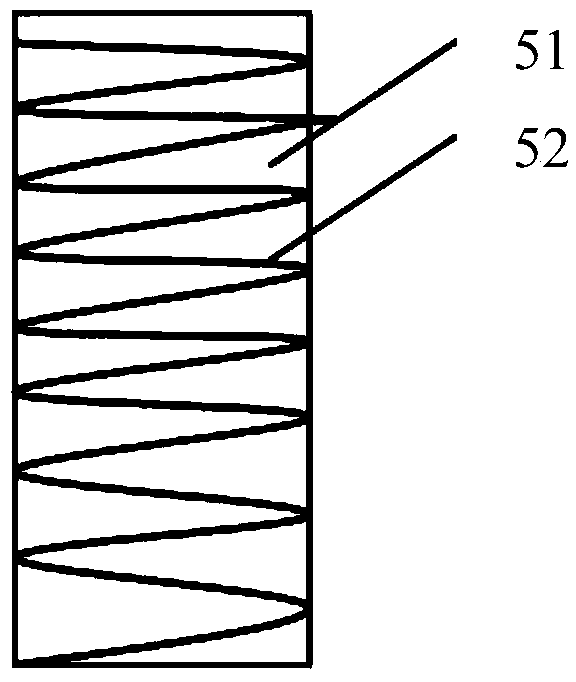

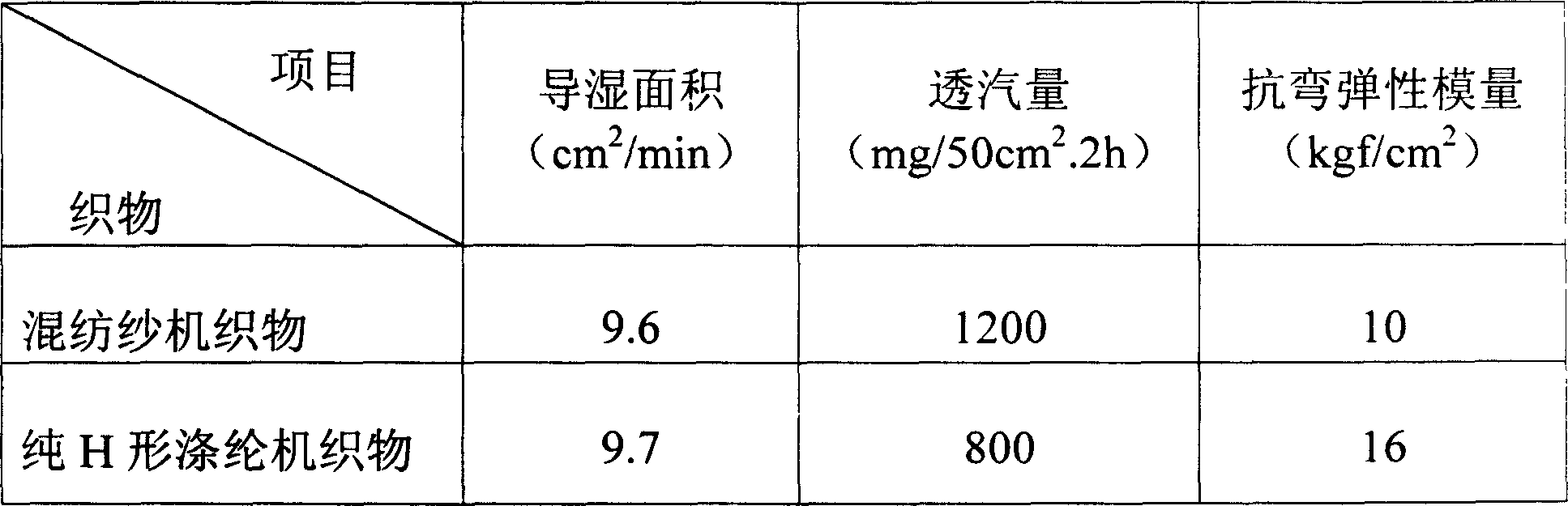

The invention is a moisture-permeable, vapor-transmitting, comfortable yarn, composed of a core layer and a winding layer outside the core layer, and its characteristic: the winding layer adopts a fabric of circular-section terylene and viscose rayon; the core layer adopts a H-shaped section terylene filament yarn. It has strong liquid water-conductivity and moisture-permeability comfort functions, and improves the vapor transmission and has strong vapor-transmission comfort functions, and thus the knitted fabrics by it are quickly dried, and worn dry-smoothly and comfortably; because bending elastic modulus is small, the yarn is soft and chemical fibre feeling is reduced, the feeling comfort property of the knitted fabrics by it is improved. The knitted fabrics by it can meet the requirements of work clothes and sport suits on conditions of plenties of sports and largely sweating, and be used in sportswear, and their moisture-permeable and vapor-transmitting comfort functions and feeling comfort functions are all completely good, and it has wide application prospect.

Owner:DONGHUA UNIV

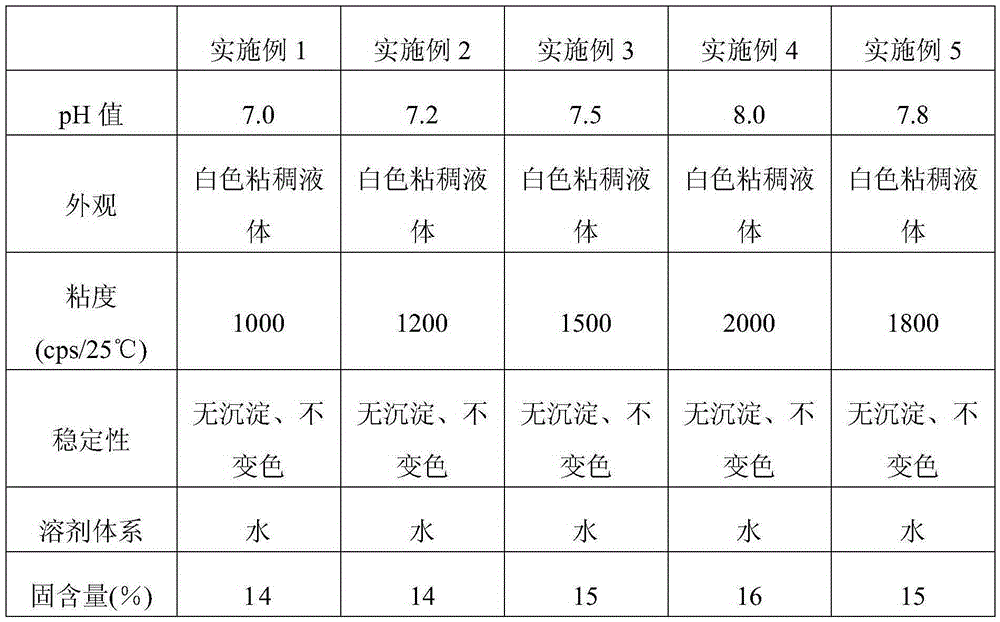

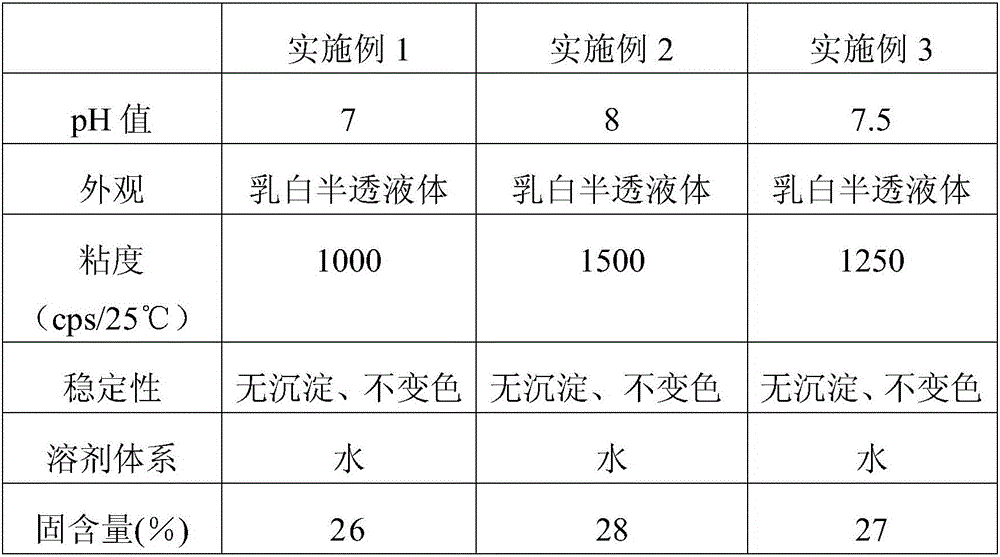

Water-based super-fogging super-blackening treating agent for synthetic leather and preparation method thereof

The invention relates to a water-based super-fogging super-blackening treating agent for synthetic leather, and the water-based super-fogging super-blackening treating agent is applied to a later period technology of the synthetic leather. The water-based super-fogging super-blackening treating agent is prepared from water-based resin, a water-based dispersing agent, a defoaming agent, silicon dioxide matting powder, a wetting agent, a Deuchem thickening agent and water. The invention further relates to a preparation method of the water-based super-fogging super-blackening treating agent for the synthetic leather. According to the water-based super-fogging super-blackening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster, better in color developing and excellent in comprehensive effect, meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based super-fogging super-blackening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

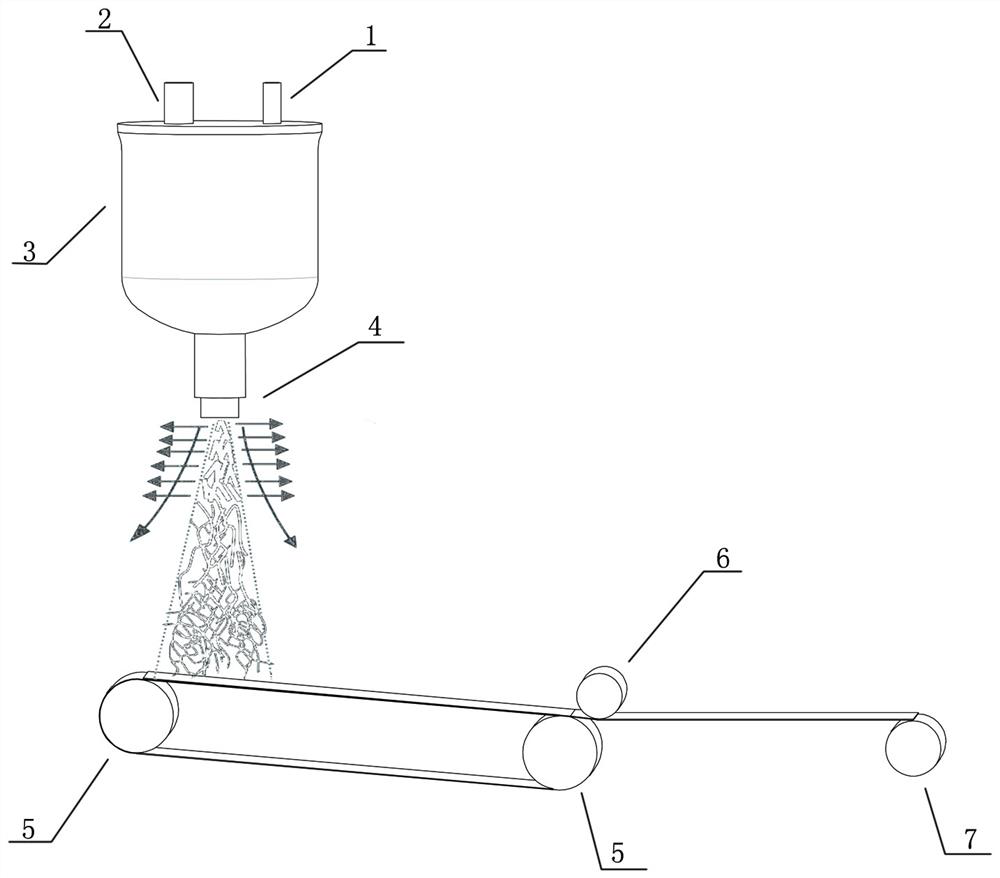

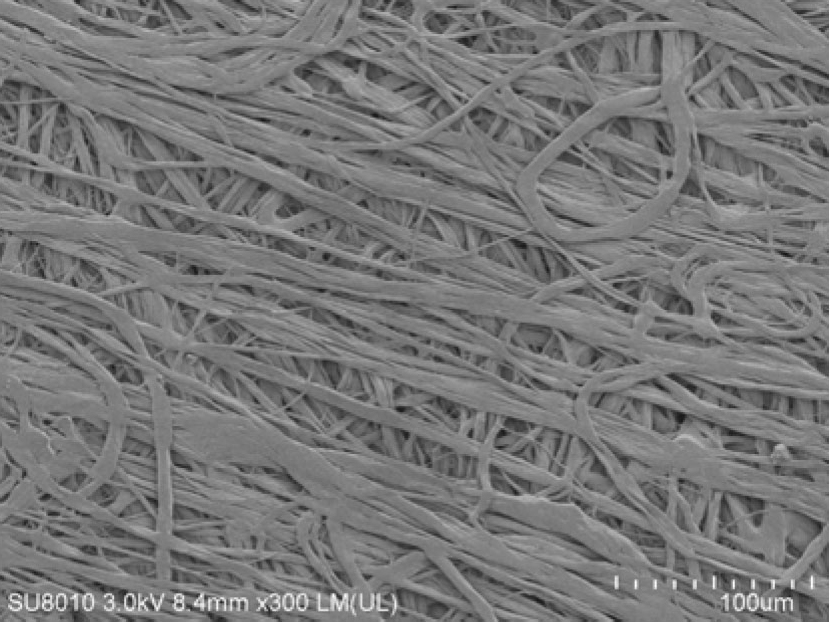

Instantaneous pressure-relief spinning method based high polymer fiber, preparation method thereof and application

ActiveCN111691060AReduce recyclingEasy to handleFilament/thread formingFilament-forming treatmentPolymer scienceSpinning

The invention discloses a preparation method for instantaneous pressure-relief spinning method based high polymer fiber. The preparation method comprises the following steps: metering and conveying high polymer and plastifying auxiliaries into a supercritical kettle, guiding in supercritical carbon dioxide under a stirring state, forming supercritical spinning fluid after stirring is stable, separating and converting supercritical spinning fluid into carbon dioxide gas, the plastifying auxiliaries and cured high polymer in open atmospheric environment instantaneously released through a spinning spray head, and enabling the cured high polymer to form high polymer fibers under action of replacement of the plastifying auxiliaries and instantaneous pressure-relief differential-pressure drawing. The invention further discloses a high polymer fiber prepared by the method and application thereof. The preparation method provided by the invention can obtain higher spinning pressure difference and spinning spray speed relative to a flash evaporation method, and further can avoid recycling and treatment of the organic solvent; and the prepared high polymer fiber has a diameter of 0.5-5 [mu]m.The preparation method belongs to the technical field of high polymer non-woven fabric preparation, and is suitable for the field of finite medical protective clothing.

Owner:DONGHUA UNIV +1

Temperature-adjustable thermostatic pad warm in winter and cool in summer

The invention discloses a temperature-adjustable thermostatic pad warm in winter and cool in summer. The thermostatic pad comprises a substrate and a temperature adjusting pad, wherein the temperature adjusting pad is a grooved three-dimensional fabric; one or more uniformly arranged grooves are formed in the bottom of the temperature adjusting pad; phase change material bags are placed in the grooves, and are sealed and packaged by adopting a high-strength flexible material; heating units are arranged at the bottoms of the phase change material bags. According to the thermostatic pad, a phase change material can change between a high-energy state and a low-energy state in the presence of the heating units and an air conditioner, so that the micro-climatic environment around a human body can be kept within a relatively constant and proper temperature range in different environments through the thermostatic pad, the requirement of the human body on comfort is met, and the thermostatic pad has warm keeping and cooling functions; necessary elasticity and support force are provided by a high-bending rigidity fiber layer of the raised part in the three-dimensional fabric, so that good pressure spreading effects are achieved, and the phase change material bags in the grooves can be protected; sufficient pores are formed in the raised part of the grooved three-dimensional fabric, so that high air permeability is ensured.

Owner:SUZHOU UNIV

Textile compounding technology

The invention relates to a textile compounding technology, which is characterized by taking a textile as a base material, and adopting non-woven fabric, a sponge, leather or a film as an auxiliary base material. The method comprises the steps of: 1) selecting a hot melt adhesive or thermoplastic resin and conducting heating to 130-200DEG C to melt it, controlling the viscosity at 3000-200000mpas; 2) spreading the base material and the auxiliary base material; 3) coating the base material or the auxiliary base material with the molten hot melt adhesive or thermoplastic resin through a fiber coater, and keeping the coating weight at 3-40g / m<2>; 4) subjecting the base material and the auxiliary base material to lamination fusion; and 5) cooling the laminated and fused product and conducting coiling. The composite laminated textile involved in the invention has soft, comfortable and smooth handfeel, good waterproofness and vapor permeability, high strength and good flexibility, resistance to hydraulic impact, strong low temperature adaptability, good dry cleaning performance, and can prevent oil stain, dust pollution and wind and keep warm. With the characteristics of bacterial resistance and easy cleaning, the product has wide application.

Owner:HUZHOU JINTADI TEXTILE MILL

Yarn possessing guiding moisture, ventilate and contact comfort effects

InactiveCN1563533ASuperior Yarn PerformanceLiquid water conduction ability is strongYarnYarnMoisture

This invention relates to a yarn which has the function of wet conduction and permeability and comfortable contact function and its production method includs adopting blend spinning of round section terylene, cotton fiber or viscose fiber and H section terylene to produce blend yarns, specifications of the raw materials and the optimum weight ratio are : 9 - 11 dtex fine round terylene 15 - 20% cotton or viscose fibers 10 -30%, 17 - 22 dtex, H section terylens fibers 55 - 70%.

Owner:DONGHUA UNIV

Water-based polishing treatment agent for synthetic leather and preparation method of agent

InactiveCN105442323ASmall smellProcess safetyHeat resistant fibresGrip property fibresDefoaming AgentsChemistry

The invention relates to a water-based polishing treatment agent for synthetic leather. The water-based polishing treatment agent is applied to the back-end process of the synthetic leather and comprises components as follows: water-based resin, a water-based dispersing agent, a defoaming agent, silica matting powder, a water-based brightener, a wetting agent, a Deuchem thickening agent and water. The invention further relates to a preparation method of the water-based polishing treatment agent for the synthetic leather. All components of the water-based polishing treatment agent coordinate with one another and have the combined action, the synthetic leather is unique in hand feeling after treatment and has the advantages of avoidance of cracking during baking at the high temperature and the like, meanwhile, a prepared spraying diluted solution has the good storage stability, a pigment does not deposit easily, and the leather treated with the treatment agent has the natural gloss, the clear color, the good color developing property and the good comprehensive effect. The water-based polishing treatment agent for the synthetic leather is a novel material for back-end treatment and can be applied to an existing synthetic leather production line, the process is simple, production equipment is not required to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

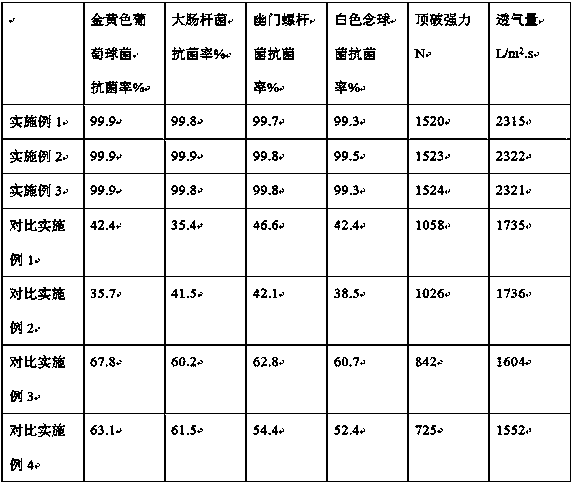

Medical bandage with hydrogel antibacterial layer

InactiveCN108939126AGood antibacterial and anti-inflammatory effectAvoid infectionNon-adhesive dressingsAbsorbent padsBandageMechanical property

The invention discloses a medical bandage with a hydrogel antibacterial layer. The medical bandage is provided with three layers. The lower surface layer is made of hydrogel, fits the skin and can sterilize and dry a wound. The middle layer contains modified bamboo charcoal fibers, has good permeability, improves the use comfort of a patient, synergizes with the hydrogel layer, and has excellent antibacterial effect. The upper surface layer is a medical pressure sensitive adhesive, is convenient in bonding and avoid troubles caused by knotting. Berberine and aloe vera gel are added into the hydrogel layer so as to improve the antibacterial and anti-inflammatory effects of the hydrogel and effectively prevent the wound from infection and inflammation. Nanometer titanium dioxide and grapheneoxide are used to modify the bamboo charcoal fibers, and so the compatibility between the bamboo charcoal fibers and a base fabric substrate is enhanced, the mechanical properties and vapor permeability of the bandage are enhanced, and the hydrogel antibacterial layer is synergized to against bacteria from inside to outside, which makes the antibacterial effect remarkable.

Owner:安徽玉然经编科技有限公司

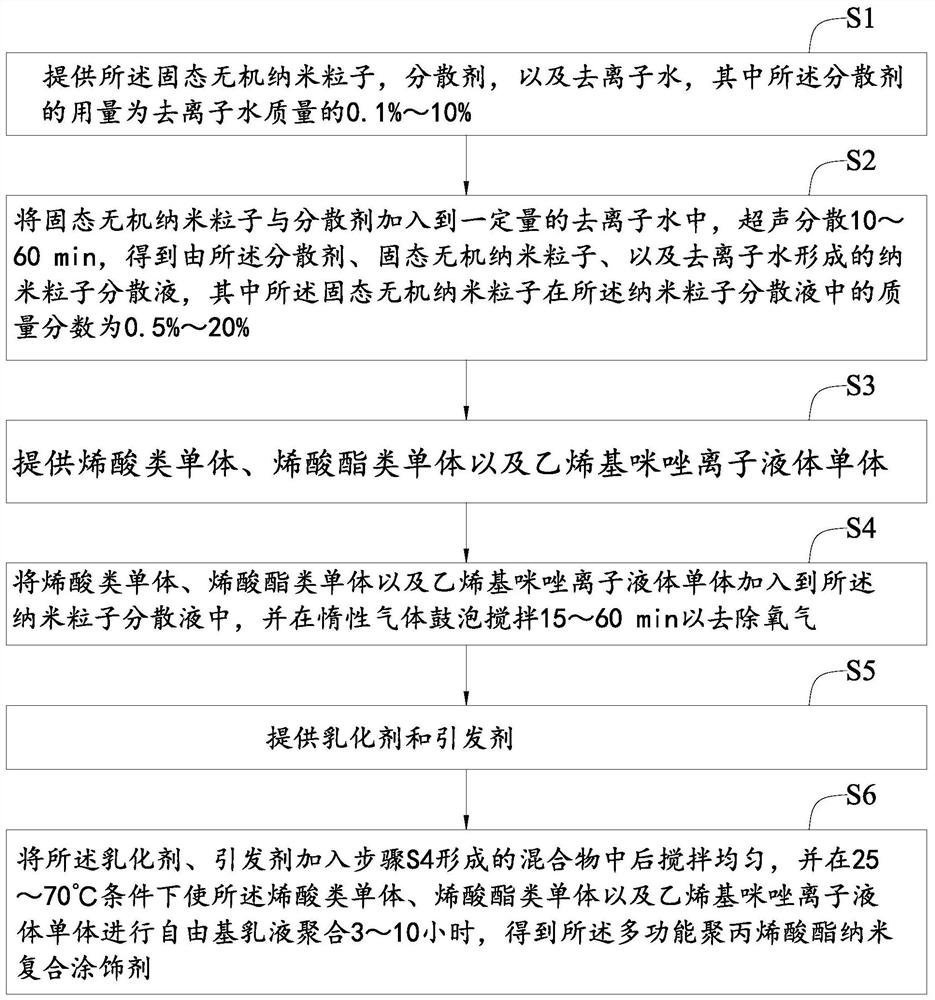

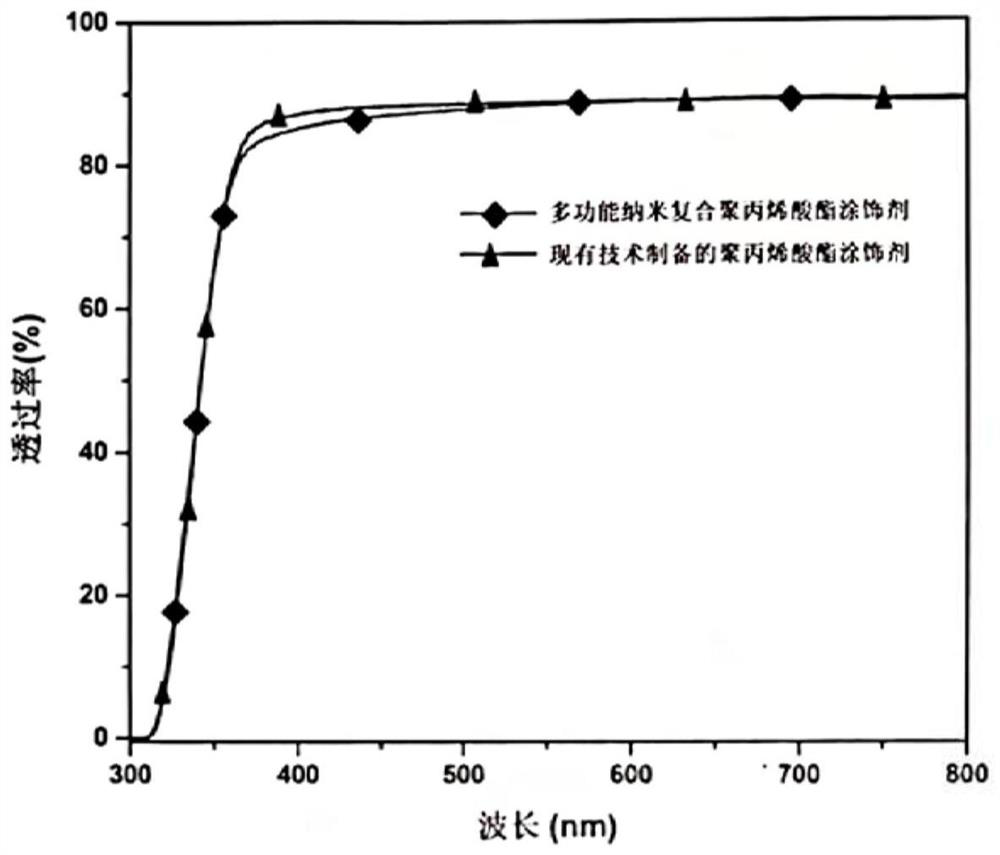

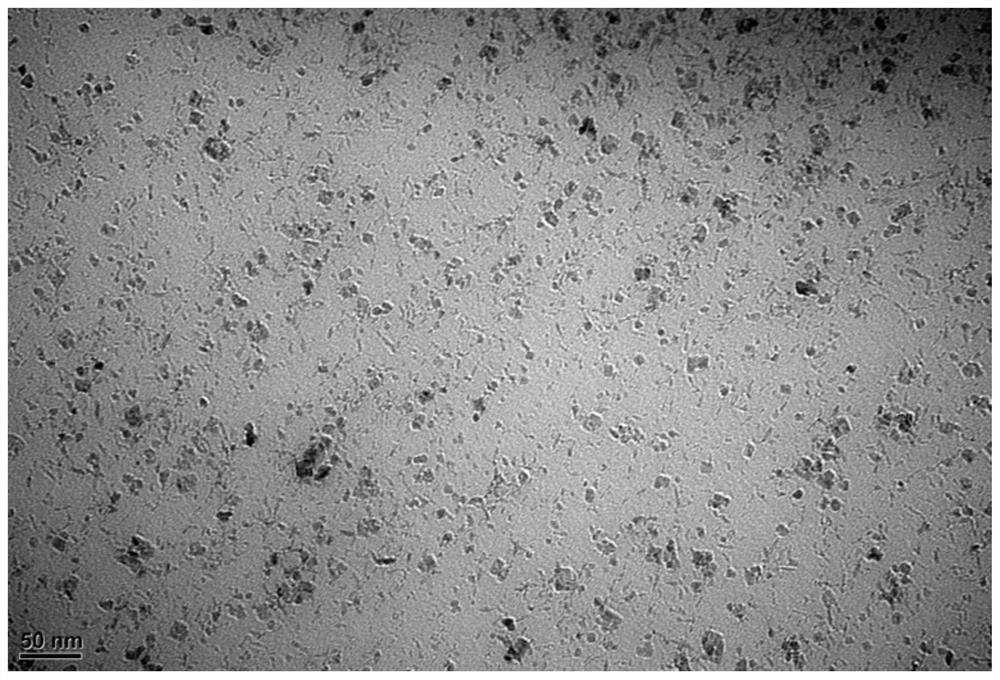

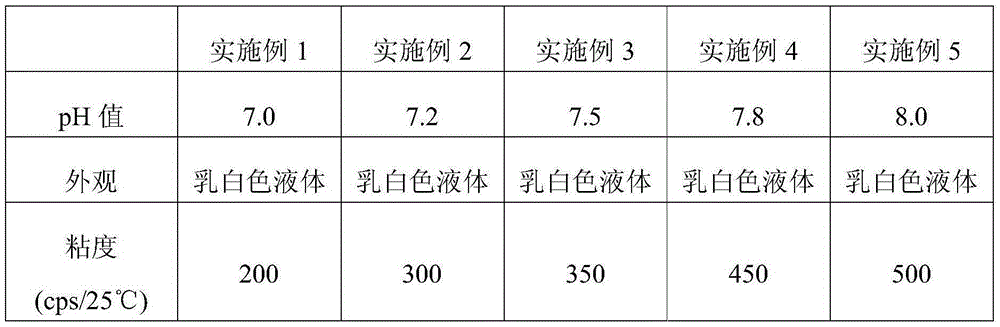

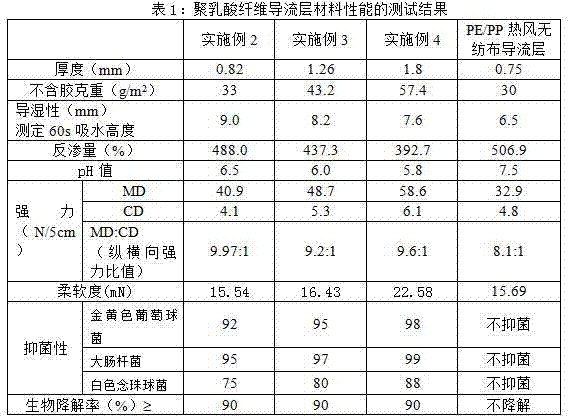

Multifunctional polyacrylate nano composite coating agent and preparation method thereof

InactiveCN112251097AImprove thermal stabilityGood solvent resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceNano al2o3

The invention relates to a multifunctional polyacrylate nano composite coating agent and a preparation method thereof. The multifunctional polyacrylate nano composite coating agent is prepared from the following raw materials: solid inorganic nanoparticles, a dispersing agent, deionized water, an olefine acid monomer, an olefine acid ester monomer, a vinyl imidazole ionic liquid monomer, an emulsifier and an initiator. The olefine acid monomer, the olefine acid ester monomer and the vinyl imidazole ionic liquid monomer are subjected to free radical emulsion polymerization under the action of the emulsifier and the initiator to form the composite coating agent. According to the composite coating agent, solid inorganic nanoparticles formed by nano aluminum oxide, nano zirconium hydroxide ornano hydroxyapatite are introduced into a polypropylene ester copolymer system, and the nanoparticles are used as a reinforcing material so that the tensile strength of a coating film is remarkably improved. Meanwhile, after the coating agent forms a film, a porous network structure can be formed on the surface of the leather so that the air permeability and the air permeability of the coated leather can be improved, and the leather is endowed with lasting antibacterial ability.

Owner:汤普勒新材料嘉兴有限公司

Biological protective covering

InactiveCN105879103AMicropores are small and denseImprove breathabilityAbsorbent padsBandagesIntestinal membraneImmunogenicity

The invention discloses a biological protective covering and a preparation method thereof. The biological protective covering is made of a substrate namely animal intestinal membranes, which have been crosslinked and fixed by a non-aldehyde fixing agent and subjected to an antigen removal treatment. An active modification layer, which contains fibronectin, laminin, or vitronectin that can adhere to cells, or an antibacterial sustained-release layer containing antibacterial drugs is arranged on the surface of the substrate. The biological protective covering is made of thin and tough animal intestinal membranes, and is light, soft, and user-friendly. The intestinal membranes are semi-permeable, gas and steam can penetrate the intestinal membranes, but bacteria cannot go through the intestinal membranes. Moreover, the intestinal membranes have been subjected to a multi-aspect antigen removal treatment to effectively remove the immunogenicity, the surface is subjected to active modification, the surface can aggregate epithelial cells and fibroblast to promote wound healing; the antibacterial drugs can be sustained-released, the anti-infection effect is enhanced, and the using performance and protective effect are better than those of dressing or protective covering made of pig skin.

Owner:CHONGQING BAFANGYUAN NETWORK TECH CO LTD

Water-based skin-feeling treating agent for synthetic leather and preparation method thereof

InactiveCN105316948ANo pollution in the processNo health hazardFibre treatmentLeather surface finishingMedicineSilicon dioxide

The invention relates to a water-based skin-feeling treating agent for synthetic leather, and the water-based skin-feeling treating agent is applied to a later period technology of the synthetic leather. The water-based skin-feeling treating agent is prepared from water-based skin-feeling resin, a water-based thickening agent, a defoaming agent, a levelling agent, water and a water-based skin-feeling hand feeling agent. The invention further relates to a preparation method of the water-based skin-feeling treating agent for the synthetic leather. According to the water-based skin-feeling treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent has the feeling of the baby skin and is clear in color and luster and excellent in comprehensive effect; meanwhile, a prepared spraying dilute solution has the very good storage stability, pigments are not prone to sedimentation, and the resin has the matting property and the better handfeel, so that gas-phase silicon dioxide matting powder does not need to be additionally added in the preparing process. The water-based skin-feeling treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

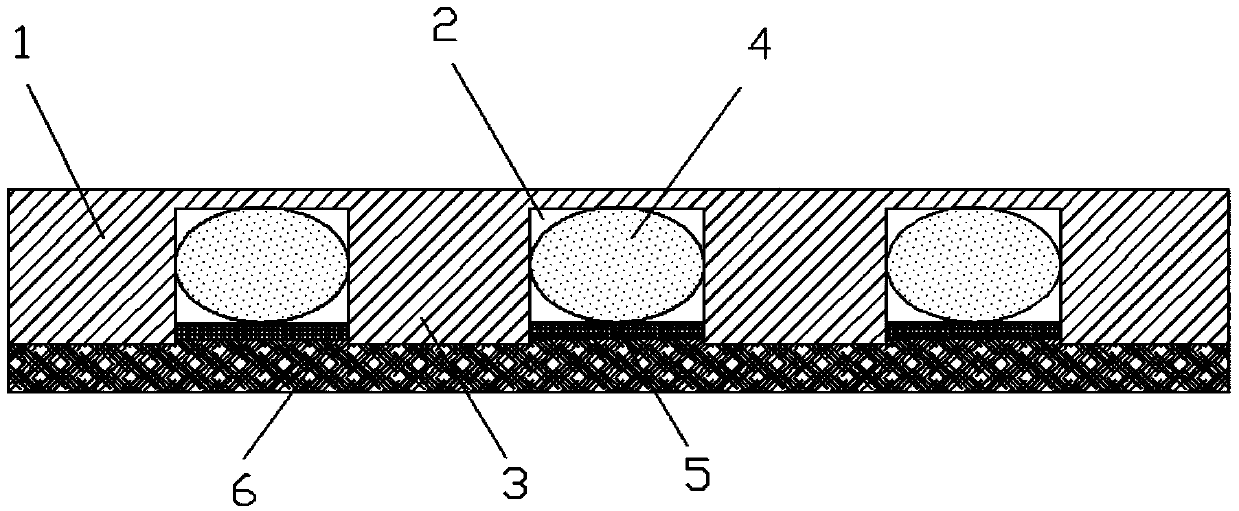

Aerogel filled structure for bedding and clothing and application of aerogel filled structure

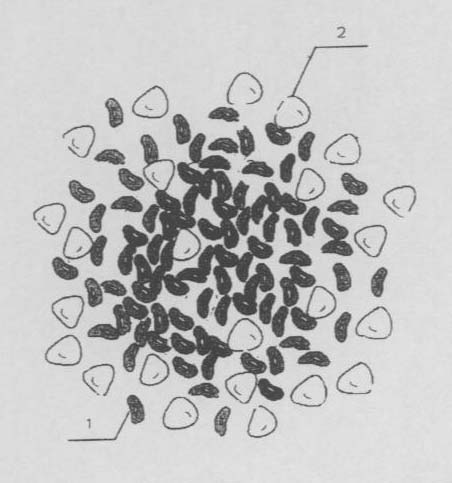

PendingCN109941952AWon't fall apart easilyNot easy to fall outUpholstery fillingFilling materialsPolymer chemistry

The invention discloses an aerogel filled structure for bedding and clothing. The aerogel filled structure comprises a breathable fabric and / or breathable film and aerogel large particle monomers and / or aerogel small particle aggregates; the aerogel large particle monomers comprise aerogel large particles and coating layers coating the aerogel large particles; the breathable fabric and / or breathable film completely coats a plurality of aerogel large particle monomers and / or the aerogel small particle aggregates; the sizes of the aerogel large particle monomers and / or the aerogel small particleaggregates are greater than that of breathable gaps and needle holes of the breathable fabric and / or breathable film. The aerogel filled material disclosed by the invention is prepared into clothingand bedding to realize the advantages that excellent heat insulation performance and high body fitness are achieved; a free air layer inside clothing is reduced or even eliminated and further the insulation performance is improved; the phenomenon that powder falls from aerogel is avoided and health hazard to a user is avoided; in addition, the phenomenon that the heat insulation performance gets poorer due to the reduction of the aerogel caused by powder falling is prevented; besides, the clothing and bedding have the characteristics of breathability, no stuffiness and high comfortableness.

Owner:翁文灏

Water-based fog-washing and brightening treating agent for synthetic leather and preparation method thereof

InactiveCN105316946ANo pollution in the processNo health hazardFibre treatmentProduction lineWater based

The invention relates to a water-based fog-washing and brightening treating agent for synthetic leather, and the water-based fog-washing and brightening treating agent is applied to a later period technology of the synthetic leather. The water-based fog-washing and brightening treating agent is prepared from water-based resin, a water-based thickening agent, a defoaming agent, silicon dioxide matting powder, a levelling agent, propylene glycol monomethyl ether and water. The invention further relates to a preparation method of the water-based fog-washing and brightening treating agent for the synthetic leather. According to the water-based fog-washing and brightening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster and excellent in comprehensive effect after being washed; meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based fog-washing and brightening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

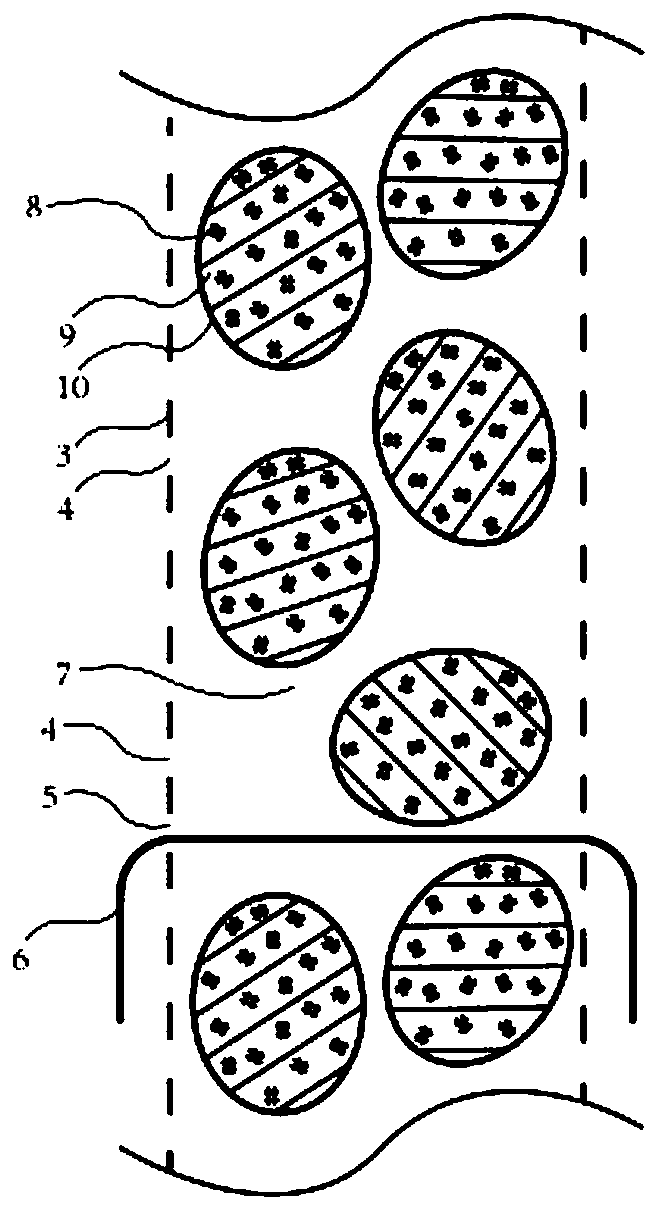

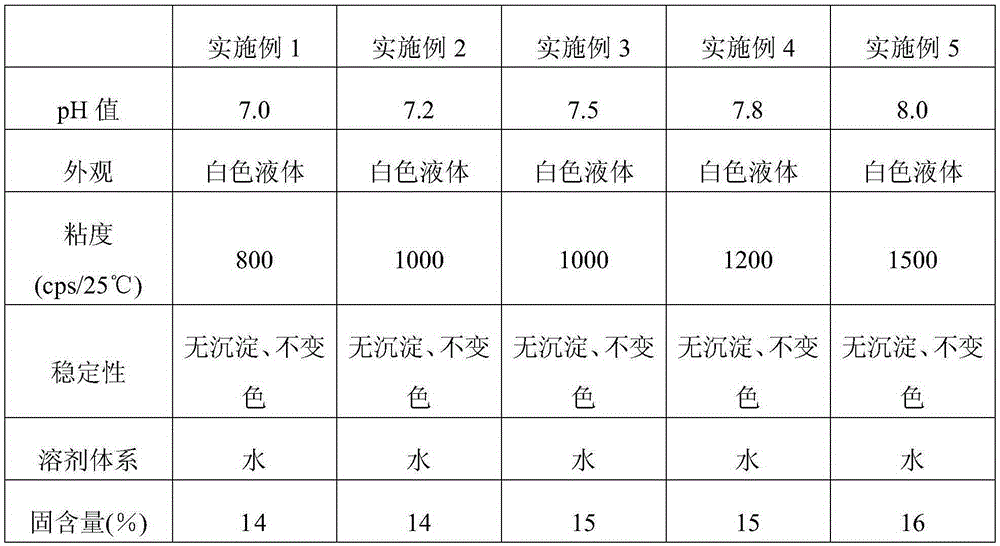

Polylactic acid fiber diversion layer material and preparing method thereof

ActiveCN106894160AAvoid the phenomenon of reverse osmosisImprove the diversion effectPersonal careNon-woven fabricsPolymer scienceAdhesive

The invention discloses a polylactic acid fiber diversion layer material and a preparing method thereof, and relates to the field of disposable hygienic products. The preparing method of the polylactic acid fiber diversion layer material comprises the steps of choosing polylactic acid fiber with different thicknesses and different crimpness, reasonably matching hydrophilic polylactic acid fiber and hydrophilic foam adhesive, reasonably exerting two technologies of hydrophilic foam adhesion and water repellency layer treatment, and well controlling fiber web hot air drying and contact type heat setting processing technological parameters. Therefore, the technical problems of the diversion layer material are solved that the diversion performance is poor, the liquid storage capability is low and the preparing technology is complicated, the effects are achieved that the prepared polylactic acid fiber diversion layer material has comprehensive performance of excellent diversion, moisture vapor transmission, instantaneous adsorption, good stiffness, an antibacterial activity, biodegradation and the like, and the functional requirements of the diversion layer material adopted by the disposable hygienic products for comprehensive diversion, instantaneous adsorption, obstruction and temporary storage for liquid are fully met.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

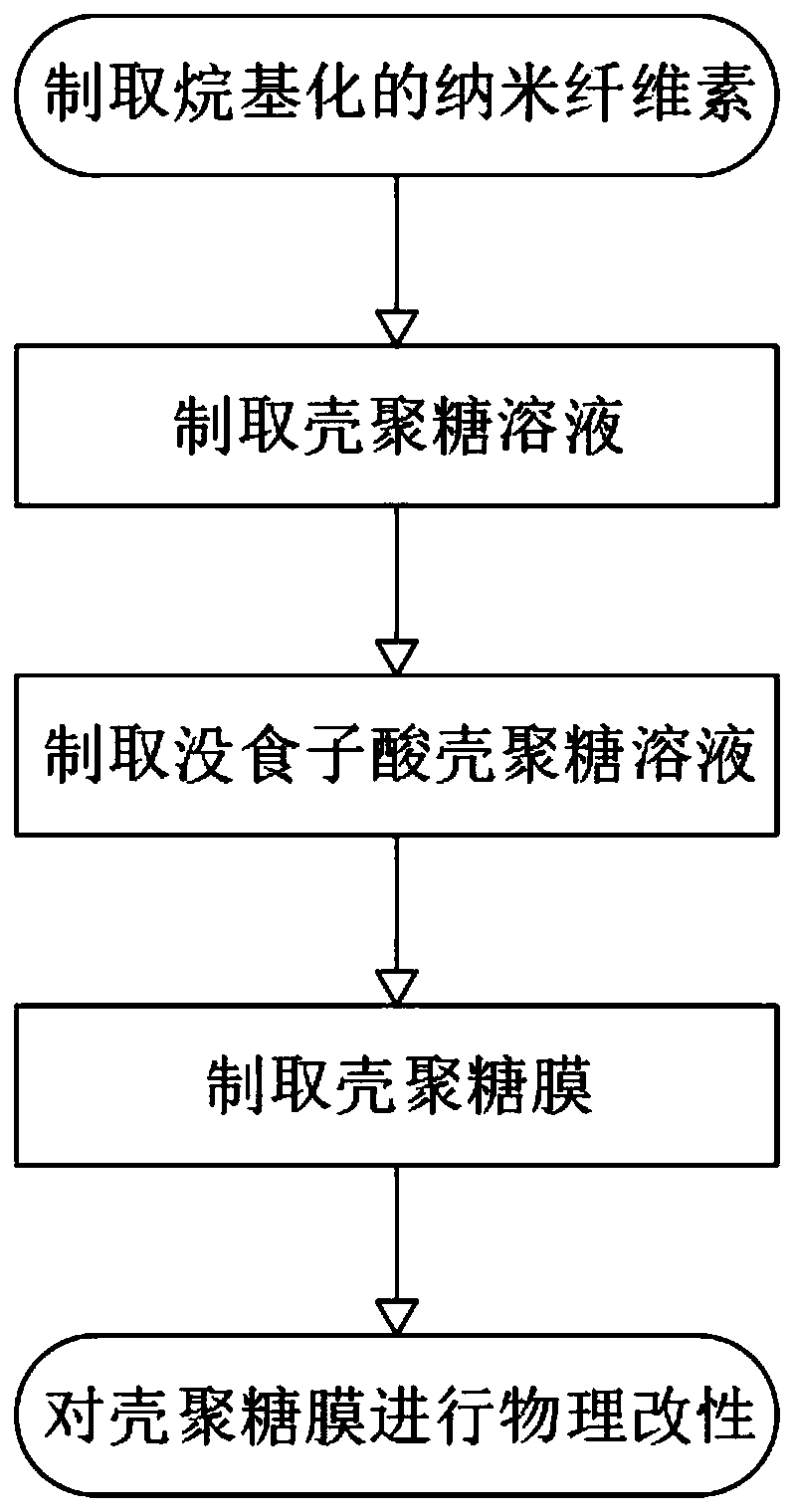

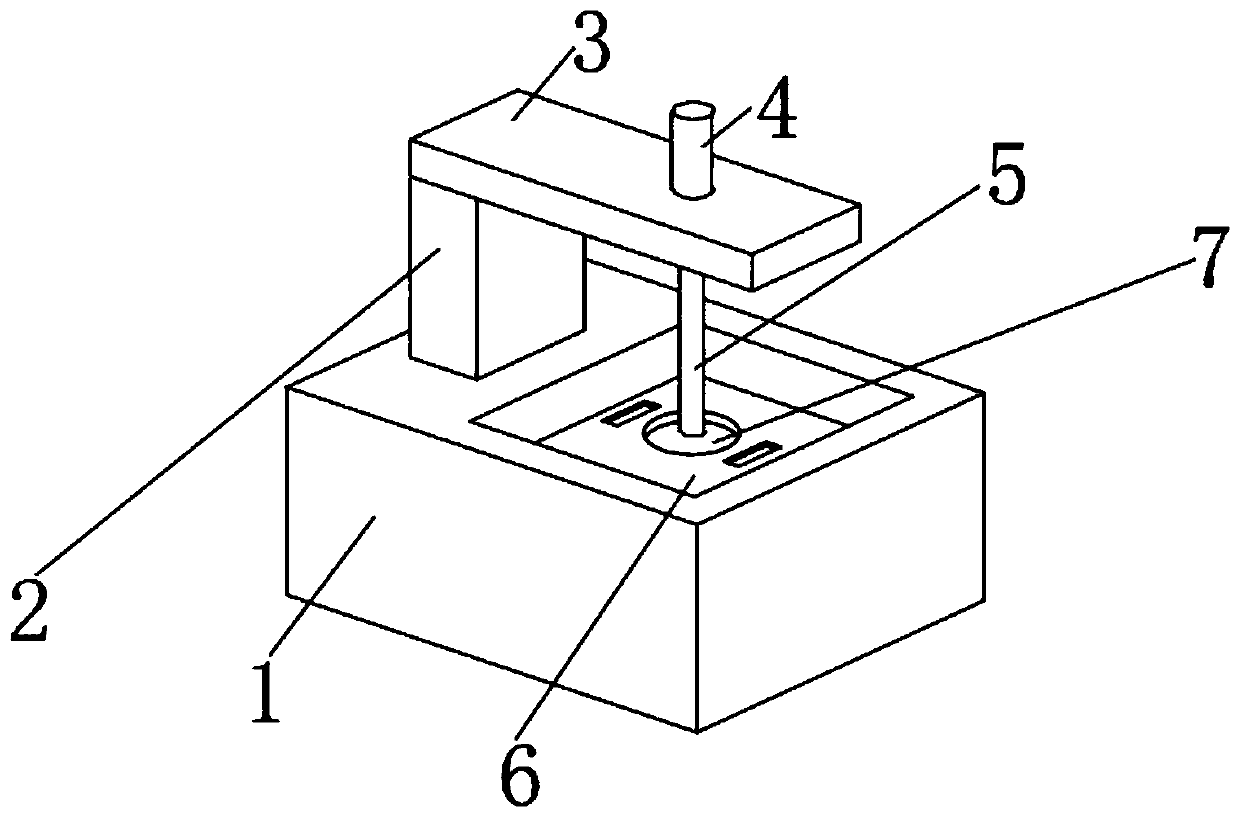

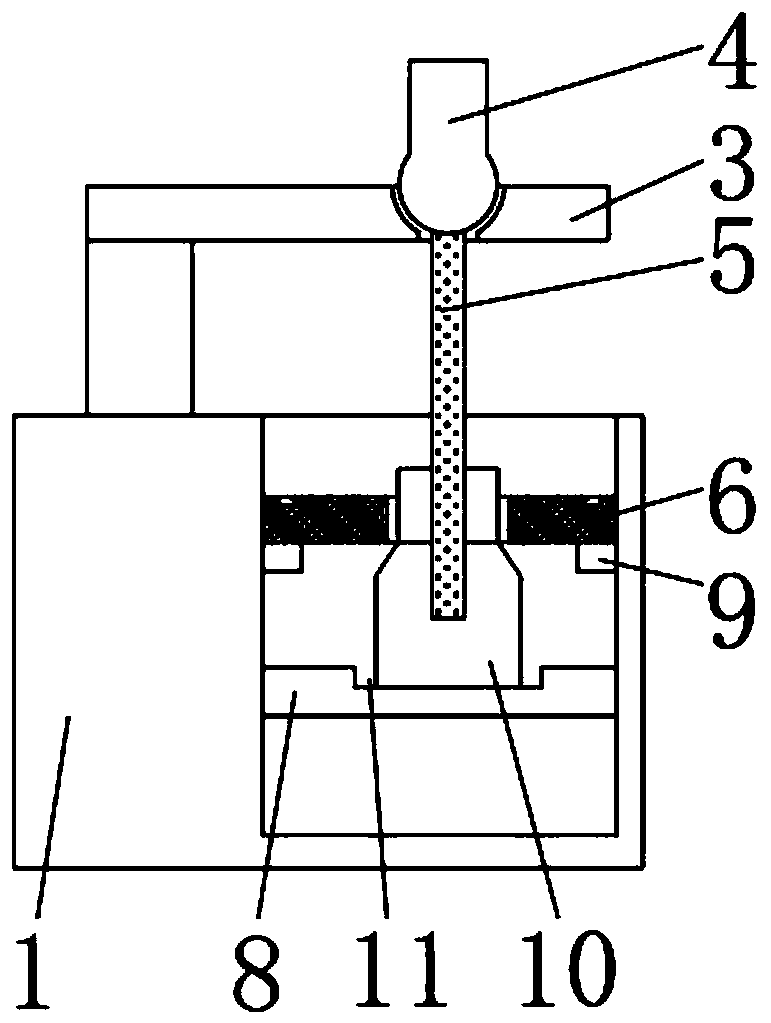

Preparation method and equipment of degradable environment-friendly packaging material for food contact

InactiveCN110951119AHigh degree of integrationSmall footprintFlexible coversWrappersPolymer scienceGallic acid ester

The invention discloses a preparation method and equipment of a degradable environment-friendly packaging material for food contact. The preparation method comprises the following steps: S1, preparingalkylated nanocellulose; S2, preparing a chitosan solution; S3, preparing a gallic acid chitosan solution; S4, preparing a chitosan film; and S5, carrying out physical modification on the chitosan film. The equipment comprises a stirrer body. A supporting rod is fixedly installed at the position, close to one end, of the outer surface of the upper end of the stirrer body. A transverse plate is fixedly installed on the outer surface of the top end of the supporting rod. A movable groove is formed in the outer surface of the end, away from the supporting rod, of the transverse plate. By improving the formula, process and equipment, production can be completed by adopting one piece of integrated equipment, the integration degree is high, the occupied area is small, the equipment investment is small, and the cost is low. According to the invention, the light transmittance, tensile strength, elongation at break and natural degradation rate of the chitosan film can be improved, the equilibrium moisture absorption rate of the chitosan film can be reduced, and the water resistance of the chitosan film can be improved.

Owner:QINGYUAN HUAYUAN INST OF SCI & TECH COLLABORATIVE INNOVATION CO LTD

Aqueous high-gloss gloss oil used for artificial leather and preparation method thereof

InactiveCN105421076ANo pollution in the processNo health hazardGrip property fibresEthylene diaminePolymer science

The invention provides aqueous high-gloss gloss oil used for artificial leather, which is used in after processes of the artificial leather and includes the following components: BG-AA diol being 1000 in molecular weight, DMPA, BDO, reactive dimethyl silicone oil, IPDI, acetone, triethylamine, ethyl diamine, water, an aqueous defoamer, a flatting agent and a thickening agent. The invention also provides a preparation method of the aqueous high-gloss gloss oil used for the artificial leather. The components in the aqueous high-gloss gloss oil cooperate and achieve synergistic effects, so that the aqueous high-gloss gloss oil can achieve a unique hand filling after treatment, is high in gloss and transparency, can form a clear color and has excellent comprehensive effects. A diluted solution for spray coating is excellent in storage stability and pigments are not liable to deposit. The aqueous high-gloss gloss oil is a novel material for after processes of the artificial leather, can be used in an artificial leather production line in the prior art, is simple in preparation process and is free of change on production equipment, and is free of increase on production cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

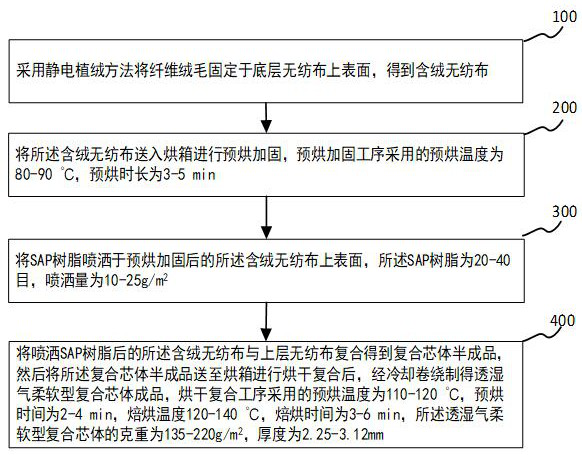

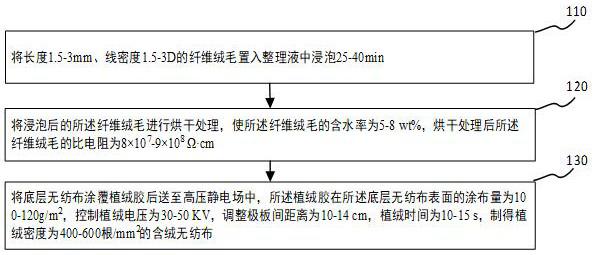

Moisture-permeable soft composite core and preparation method thereof

ActiveCN113116638AStrong absorption capacitySoft touchSanitary towelsBaby linensPolymer scienceNonwoven fabric

The invention discloses a moisture-permeable soft composite core and a preparation method thereof, and relates to the technical field of disposable hygienic products. According to the moisture-permeable soft composite core and the preparation method thereof, the moisture-permeable soft composite core is prepared from a bottom-layer non-woven fabric, fiber fluff, super absorbent resin and an upper-layer non-woven fabric together, wherein the fiber fluff is fixed on the bottom-layer non-woven fabric by an electrostatic flocking method, the super absorbent resin is uniformly distributed among the fiber fluff, and the upper-layer non-woven fabric is fixedly connected with the fiber fluff, so that the prepared moisture-permeable soft composite core is good in softness, and the super absorbent resin after absorbing water has enough space to swell, so that the utilization rate of the super absorbent resin in the composite core is increased; and the production cost is reduced while the use amount of the super absorbent resin in the composite core is reduced.

Owner:JIAXING UNIV

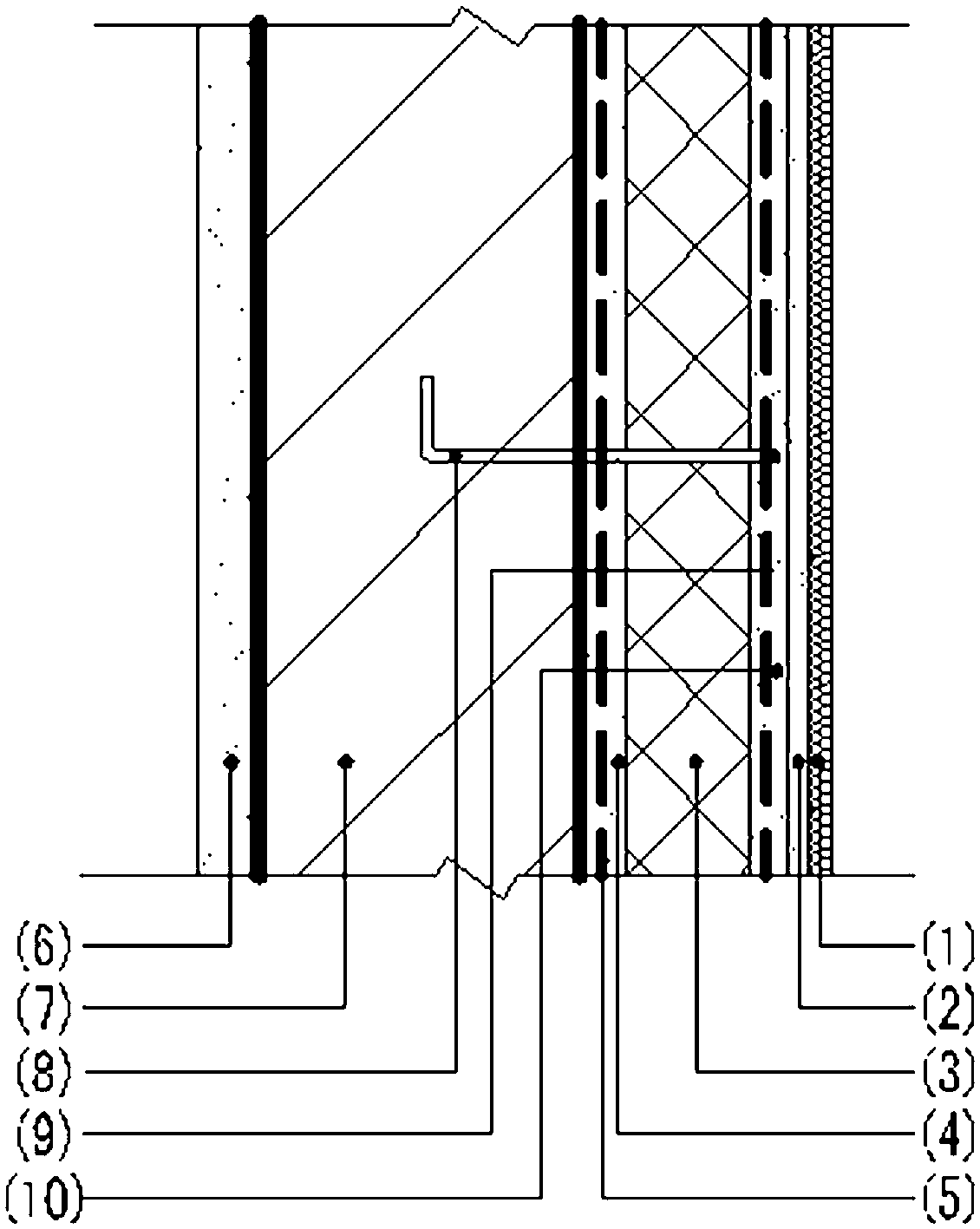

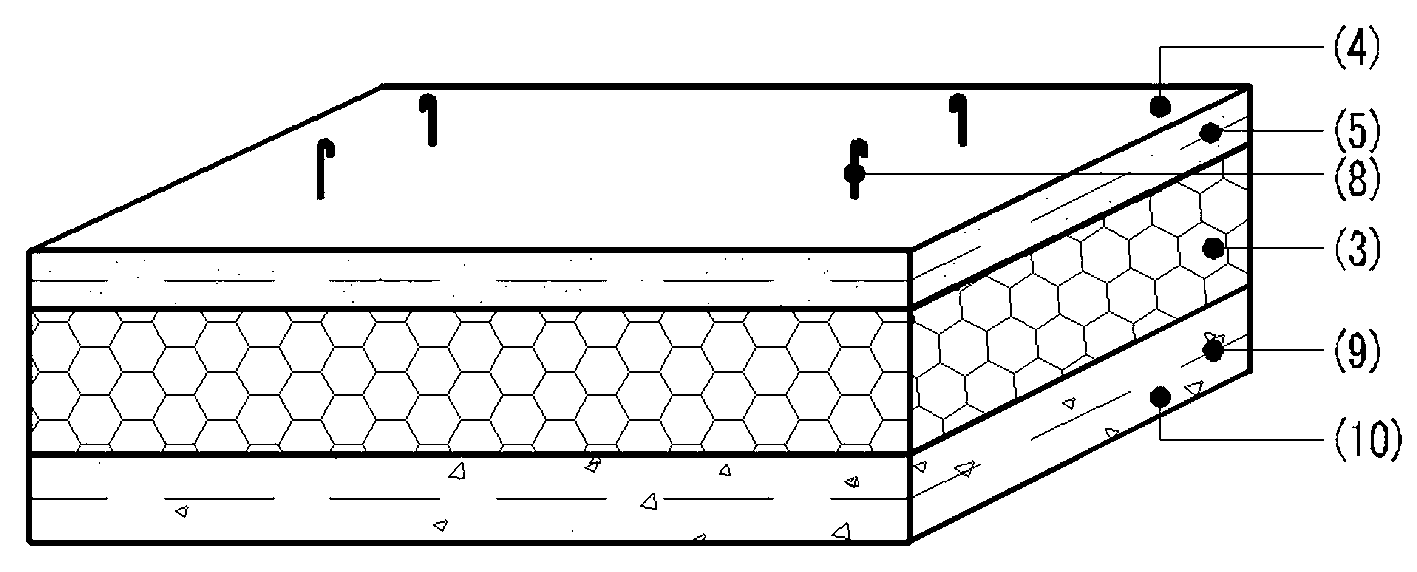

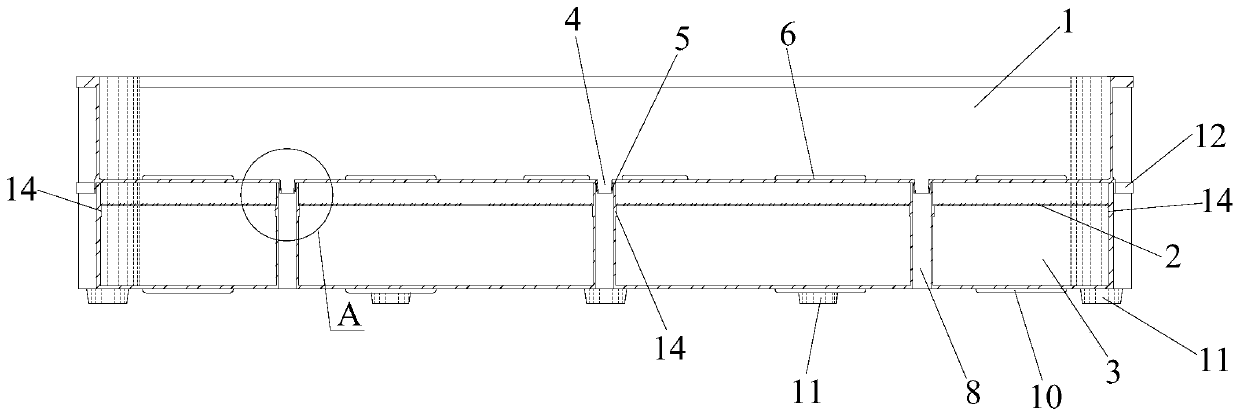

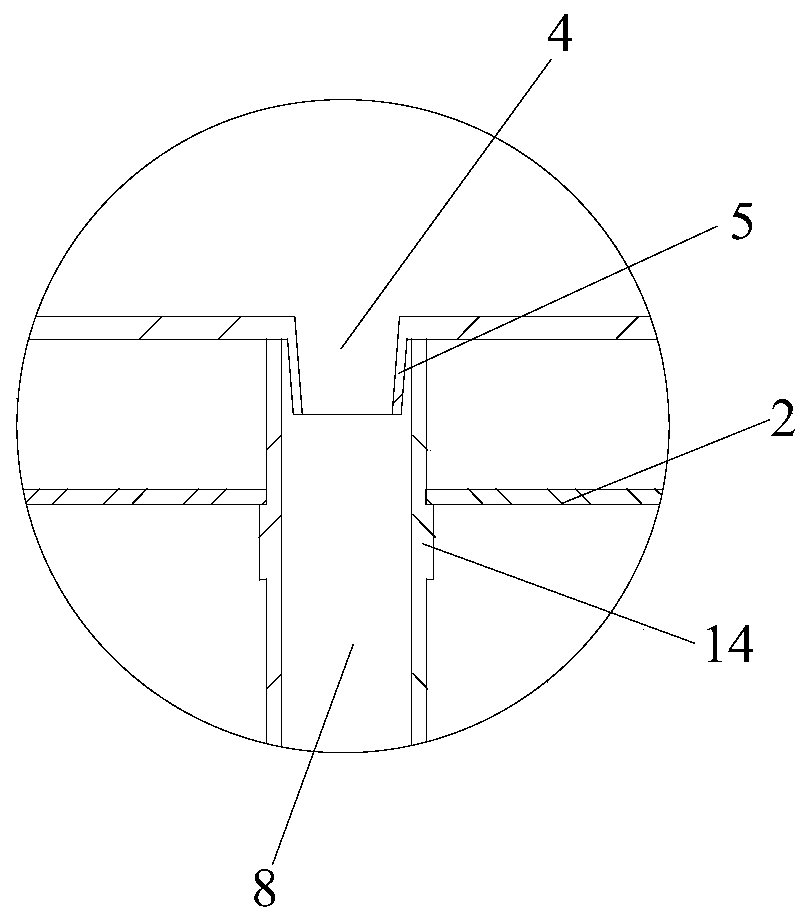

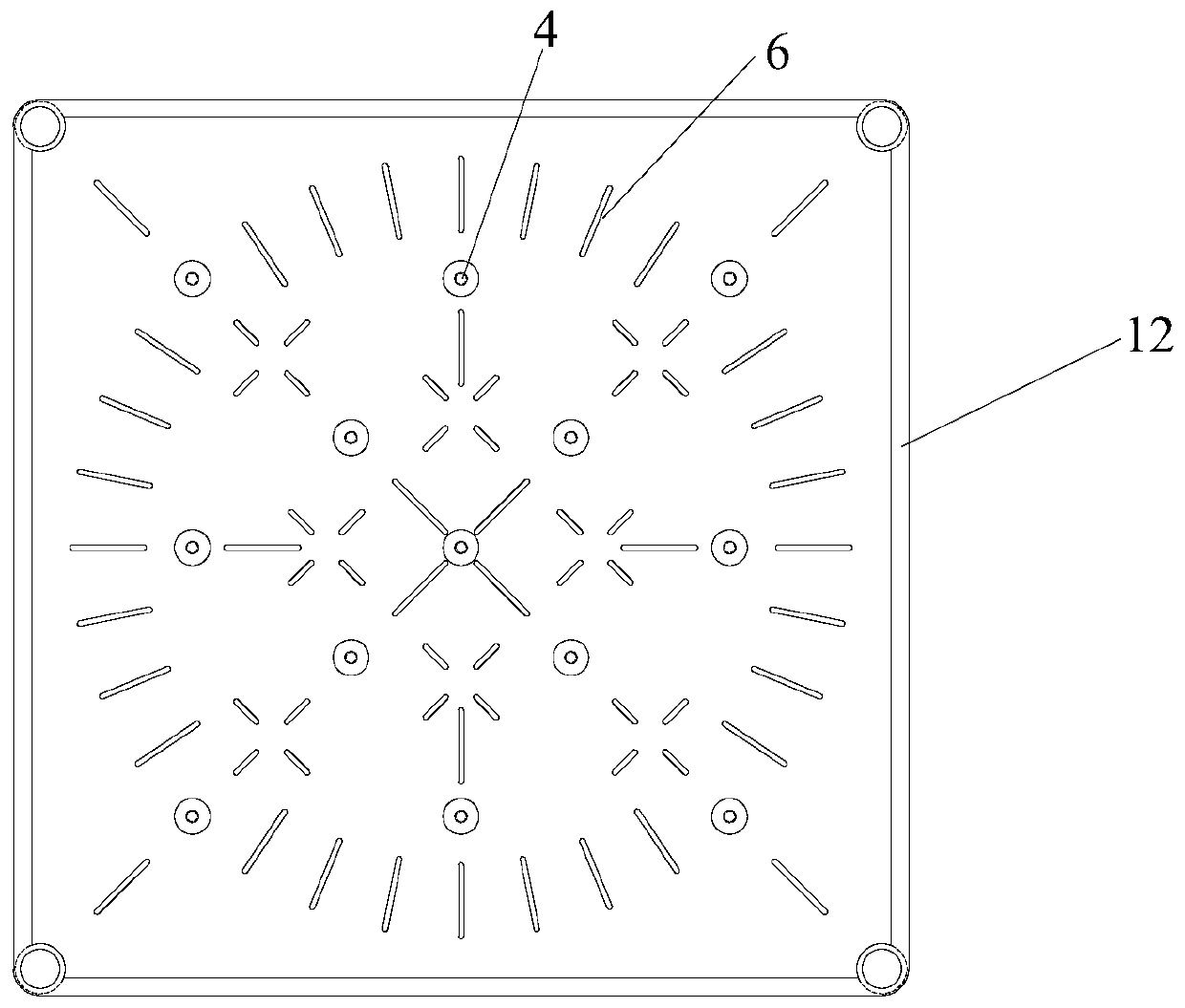

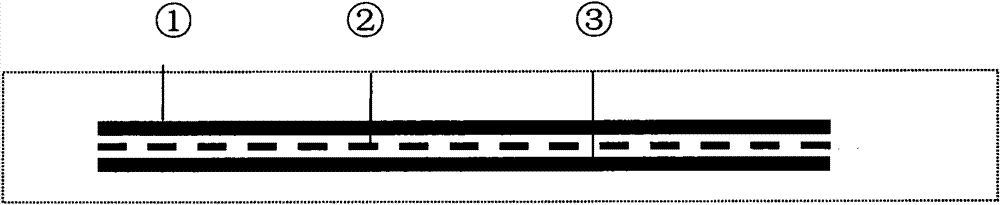

Progressive-temperature-control fireproof separation board

InactiveCN102758498AImprove comfortImprove securityCovering/liningsHeat proofingTemperature controlThermal insulation

The invention relates to a progressive-temperature-control fireproof separation board (NCB module). Thermal insulation and template functions are integrated in the board. With the board, an existing external thermal insulation system is changed, safety and shock resistance of the system are improved, and service life of a thermal insulation system is prolonged. The board is water-resisting and fire-resisting, and is not restricted by construction height and shape. The board can be used for replacing building external templates. Also, an over-coating layer can be manufactured according to a certain design, such that thermal insulation decoration and the template functions are integrated. The board is advantaged in good gas permeability, such that a mould multiplying environment is eliminated. The board is also advantaged in low temperature amplitude, high environment comfortableness, convenient construction, less processes, low labor intensity, short construction time, and the like.

Owner:HUAREN CONSTR GROUP

Waterborne light-curing oil treating agent for synthetic leather and preparation method of waterborne light-curing oil treating agent

The invention relates to a waterborne light-curing oil treating agent for synthetic leather and a preparation method of the waterborne light-curing oil treating agent. The waterborne light-curing oil treating agent for the synthetic leather comprises the following components: waterborne resin, a defoamer, a wetting agent, a Deqian thickening agent, BCS and water. Various components of the waterborne light-curing oil treating agent for the synthetic leather cooperate with one another and interact, and after being treated, the synthetic leather feels unique, and does not crack after being baked at high temperature. Meanwhile, a prepared spraying dilute solution has good storage stability, pigment cannot settle easily, and the leather manufactured by using the treating agent is natural in gloss, clear in color and luster, good in color developing and good in comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

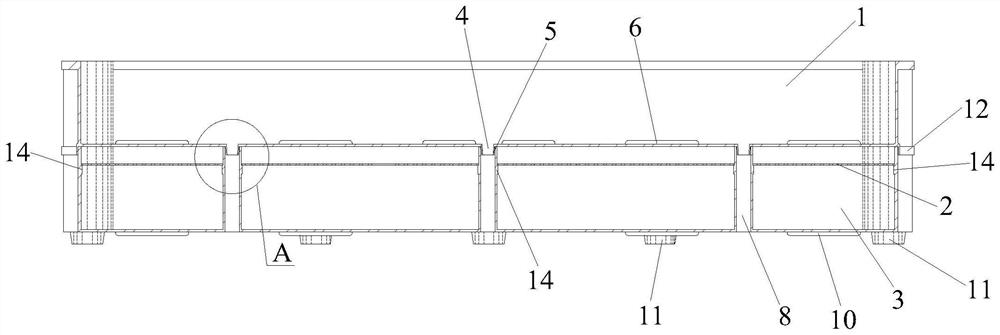

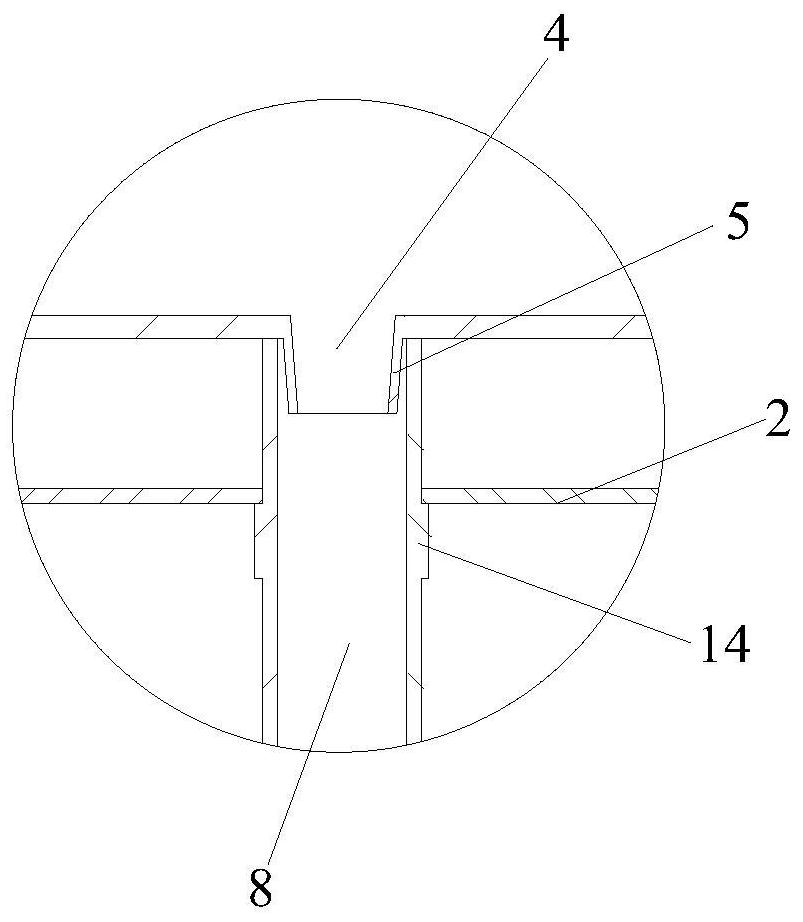

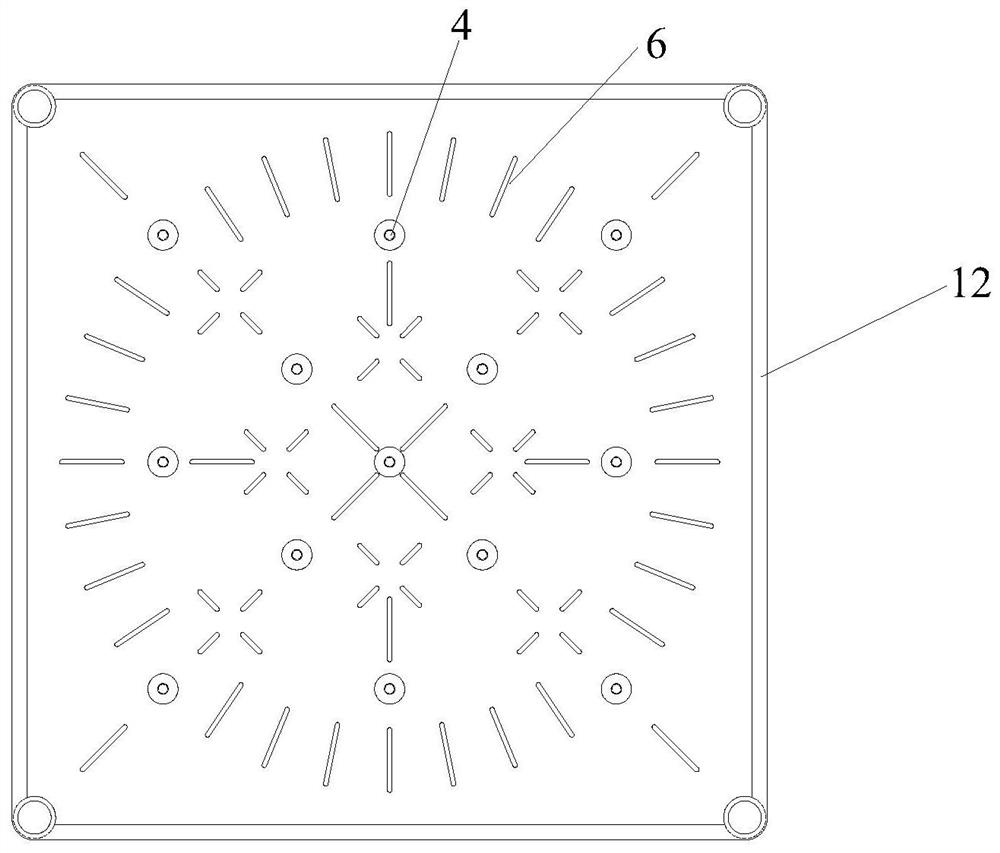

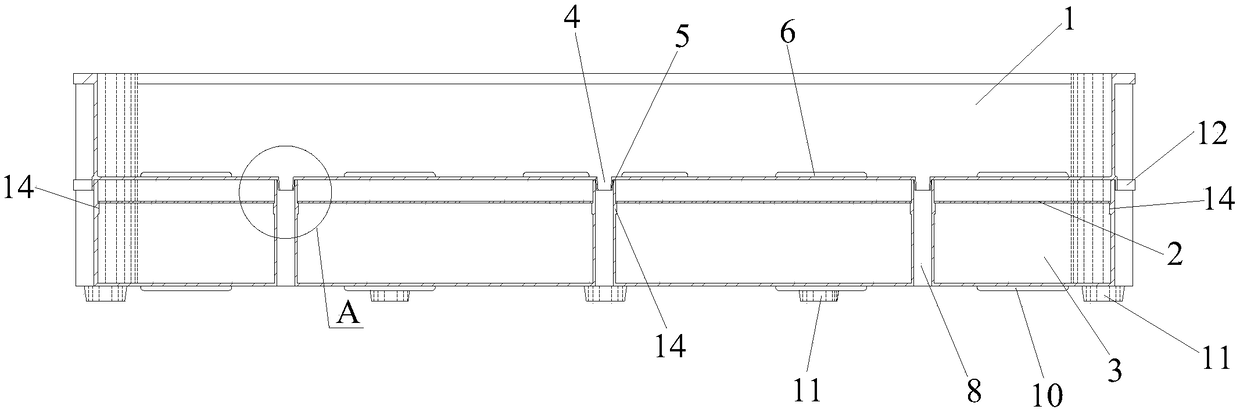

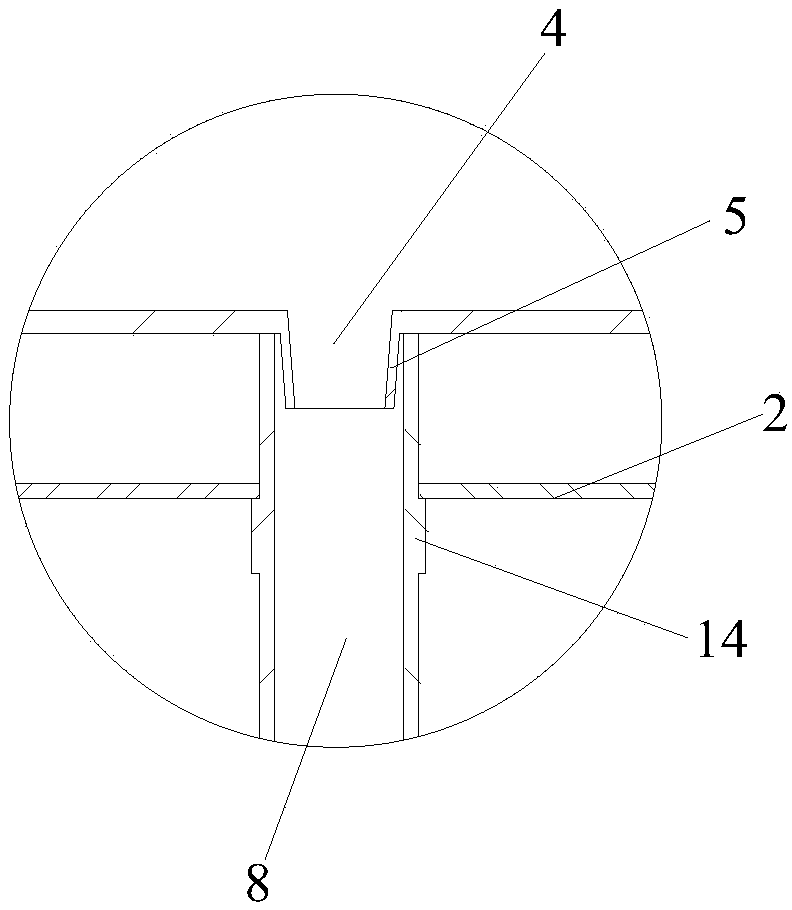

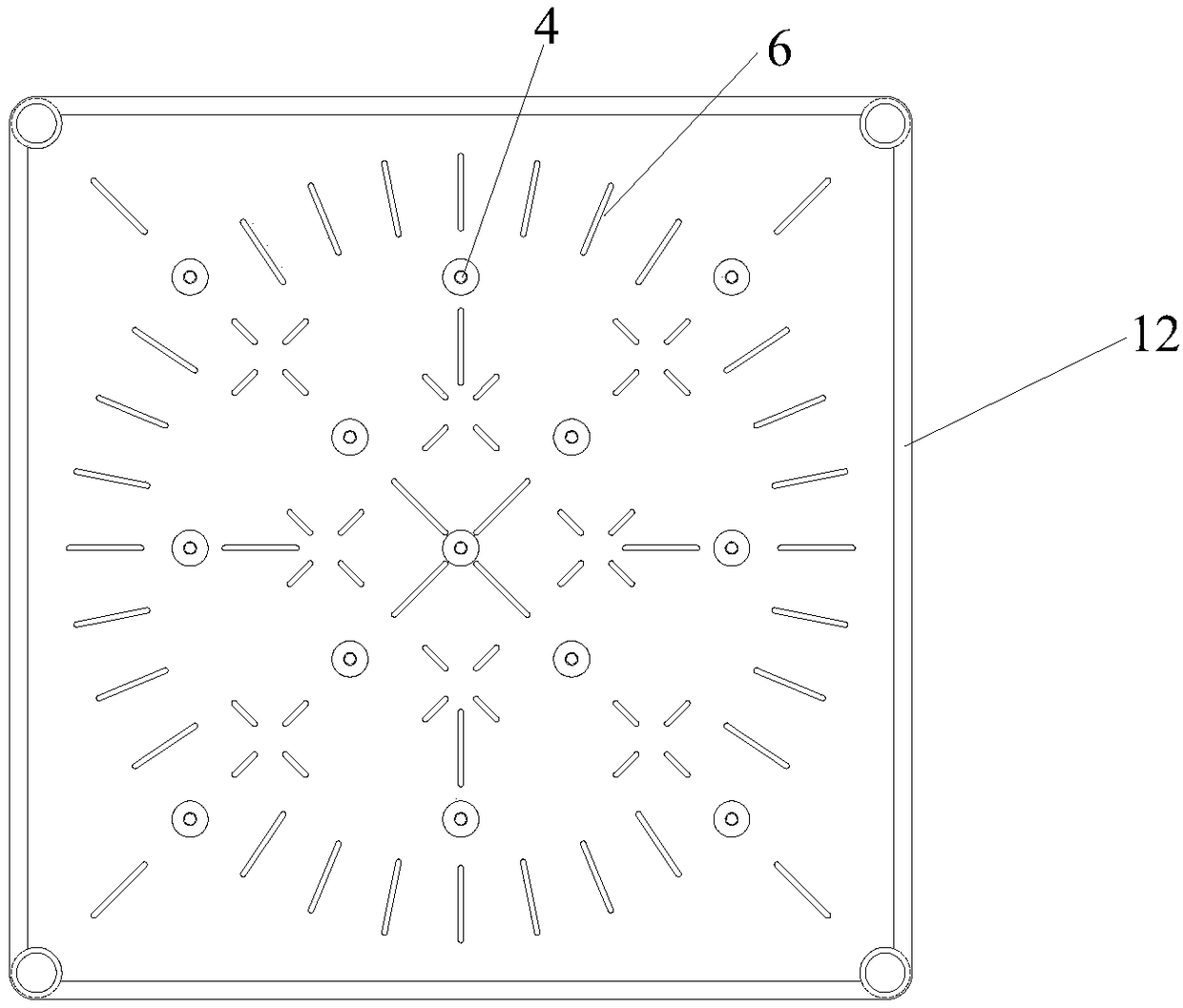

A green roof device

ActiveCN108842970BSimple structureSolving Thermal Bridge ConundrumsRoof coveringReceptacle cultivationBuilding energyArchitectural engineering

The invention belongs to the field of building energy conservation, and particularly relates to a greening phase-change box bridge. The greening phase-change box bridge is used for connecting greeningphase-change boxes and comprises a joint and connectors movably arranged inside the joint; the joint comprises four connecting ports; the connecting ports communicate with one another in the warp andweft directions of the joint; the connectors are inserted in the connecting ports and are made of plastic; cavities are formed inside the connectors; and IXPE foam is arranged inside the cavities. Each greening phase-change box comprises a flower disk, a tray and an energy storage disk which are assembled up and down; and phase-change materials are lid inside the flower disk, the tray and the energy storage disk. According to the bridge, the phase-change materials are lid inside the flower disks, the trays and the energy storage disks, and when the outside temperature changes, the phase-change materials absorb or release heat to play a role in heat insulation for a roof; and the multiple greening phase-change boxes are assembled and combined according to the roof design, so that the lightplanting roof heat insulation system can be formed.

Owner:JIANGNAN UNIV

Method for manufacturing silicone modified double-sided double-color flexible decorative brick

InactiveCN101947871BHigh mechanical strengthGood weather resistanceCovering/liningsSynthetic resin layered productsGlass fiberBrick

Owner:谈霄

A green phase change box

ActiveCN108966930BImprove protectionPromote growthRoof coveringReceptacle cultivationWater storageBuilding energy

Owner:JIANGNAN UNIV

White mulberry bark fiber cospinning fubric and its production technology

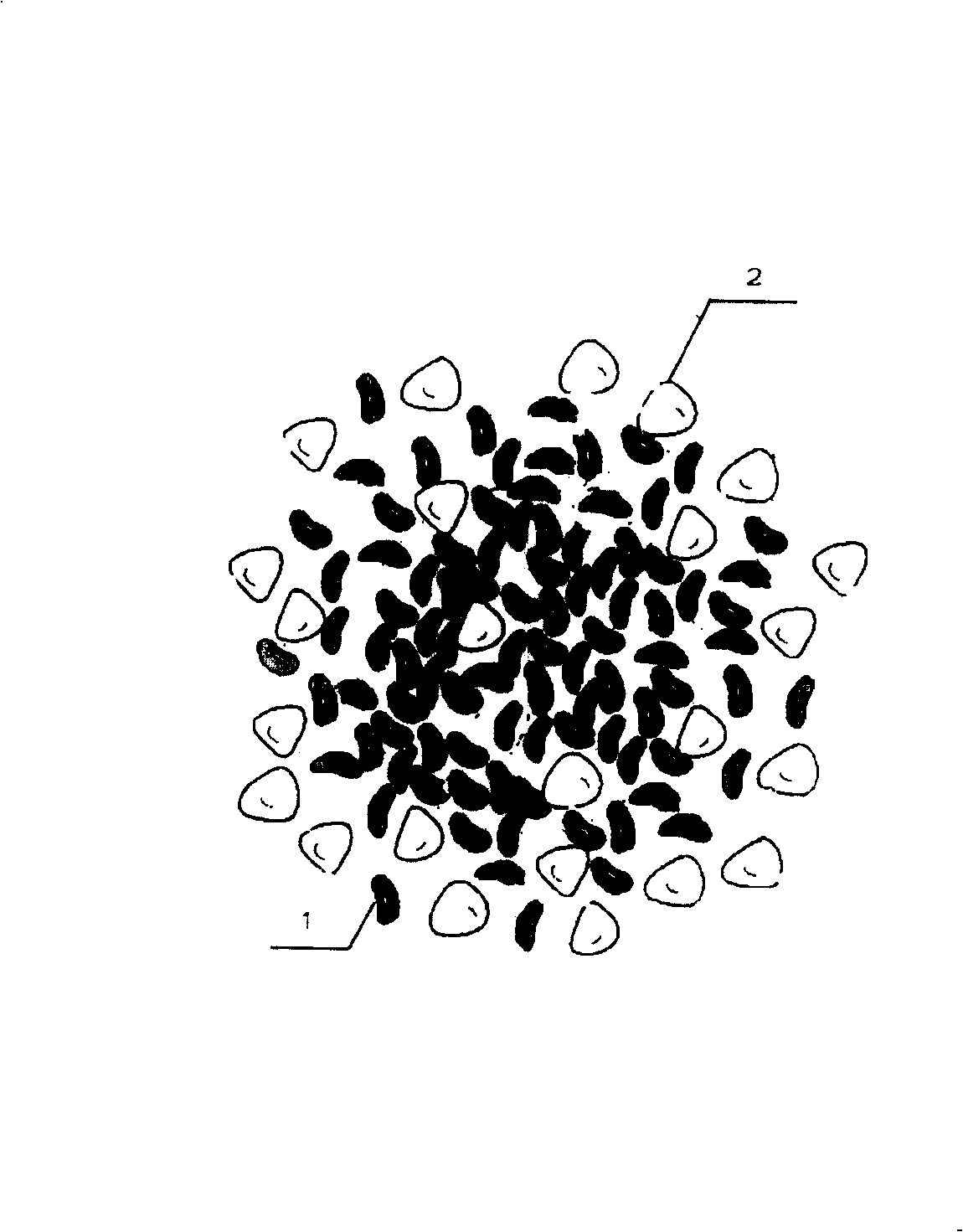

InactiveCN100443646CGood vapor permeabilityFeel cool but softWeft knittingWoven fabricsYarnPolymer science

The invention discloses a mulberry fiber blended fabric and a production process thereof. The yarn constituting the fabric is blended with 15-25% mulberry fiber and 75-85% long-staple cotton, and the yarn tex is 19.5-85%. 48Tex, the length of the mulberry fiber is 10-45mm when blending, the mulberry fiber is mainly distributed in the outer layer of the yarn, and the long-staple cotton fiber is mainly distributed in the inner layer of the yarn; the fabric design weight is: 80-400g / m2 . The fabric has good hygroscopicity and vapor permeability; it feels cool but soft, and has good cold feeling without itching; the fabric has a silky luster; it is a new type of green natural fiber textile.

Owner:四川省丝绸进出口集团有限公司 +1

Greening phase-change box

ActiveCN108966930AImprove protectionPromote growthRoof coveringReceptacle cultivationPhase-change materialEngineering

The invention belongs to the field of building energy conservation and particularly relates to a greening phase-change box. The greening phase-change box comprises a flowerpot, a tray and an energy storage plate, wherein the flowerpot, the tray and the energy storage plate are connectedly and vertically assembled and internally provided with a phase-change material by laying. By laying of the phase-change material in the flowerpot, the tray and the energy storage plate, when the external temperature changes, a roof heat insulation effect is achieved through the phase-change material which absorbs or releases heat. Special planting soil can be laid on the phase-change material of the flowerpot, crassulaceae such as sedum makinoi or araceae perennial herbaceous plants can be planted for greening a roof environment, the phase-change material in the flowerpot plays a role in water storage, and plant root growth is promoted. A lightweight planting roof heat insulation and preservation system can be formed by assembly of multiple greening phase-change boxes according to the roof design.

Owner:JIANGNAN UNIV

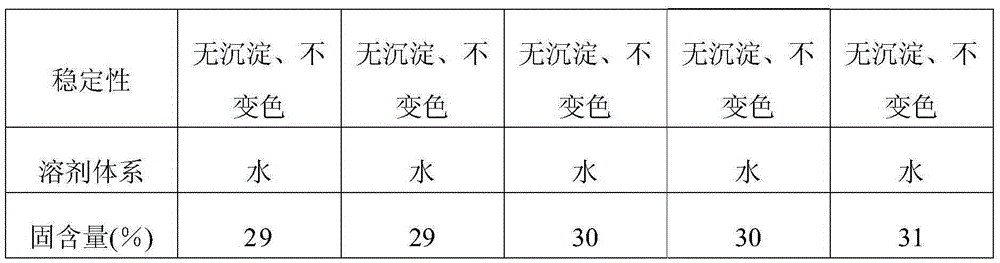

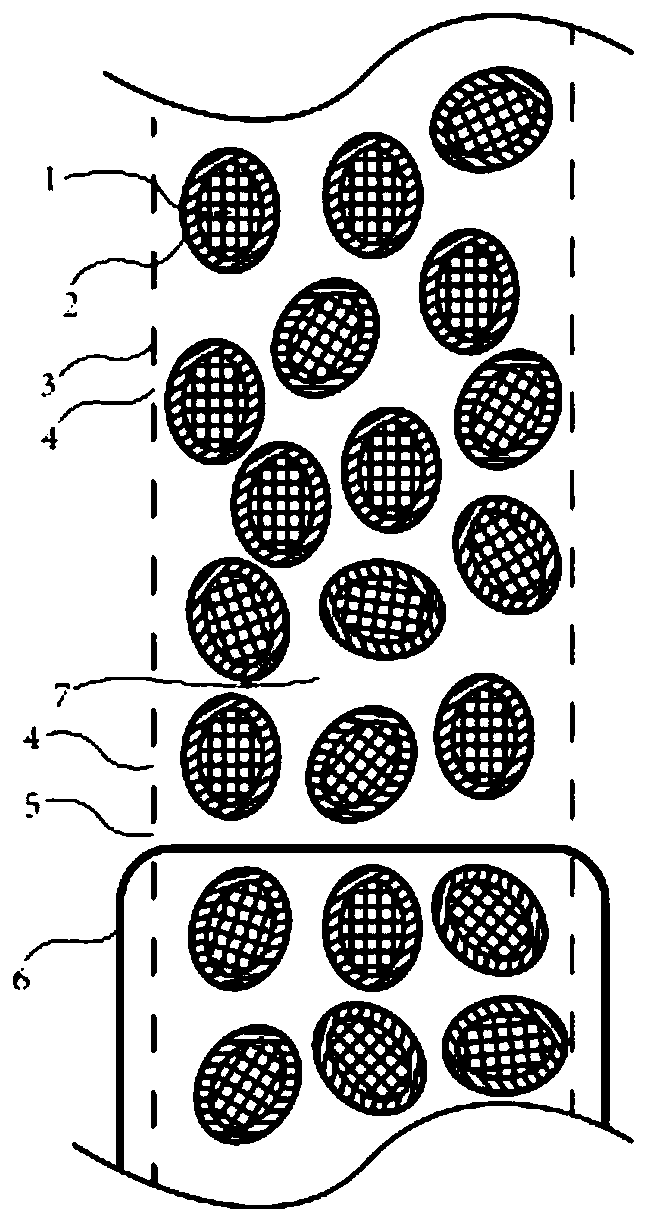

Preparation method of crease-free superfine fiber synthetic leather based on thermal expansion microspheres

InactiveCN112227076AGood vapor permeabilityGood moisture permeabilityTextiles and paperThermal dilatationMicrosphere

The invention discloses a preparation method of crease-free superfine fiber synthetic leather based on thermal expansion microspheres. The method is characterized in that the prepared thermal expansion microspheres are dispersed in water-borne polyurethane, fibers of superfine fiber non-woven fabric are filled with the thermal expansion microspheres through dipping, and after solidification and microsphere foaming, the superfine fiber synthetic leather is prepared through decrement and subsequent coating processing. The prepared superfine fiber synthetic leather has good pressing resilience, fullness and softness, base cloth and finished leather are free of creases, and compared with superfine fiber synthetic leather without thermal expansion microspheres, the leather has the advantages that thickness can be increased by 30%-70%, the softness can be increased by 30%-60%, and the water vapor permeability is increased by 100%-150%.

Owner:SICHUAN UNIV

Composite fabric and production process

The present invention relates to a composite fabric and its production method. The production method includes the following steps: spreading fabric base material, spreading pu film and preheating; selecting and heating hydrosolidification thermosol, coating the thermosol on the pu film, combining the fabric base material and pu film and binding them together, natural spreading and winding, solidifying and obtaining a certain binding strength so as to obtain the invented product.

Owner:SHANDONG YUNLONG EMBROIDERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com