Polylactic acid fiber diversion layer material and preparing method thereof

The technology of polylactic acid fiber and guide layer is applied in the field of polylactic acid fiber guide layer material and its preparation, which can solve the problems of obstruction, poor guide effect and good instantaneous suction, so as to avoid liquid reverse osmosis backflow, increase The effect of flow conductivity and good stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

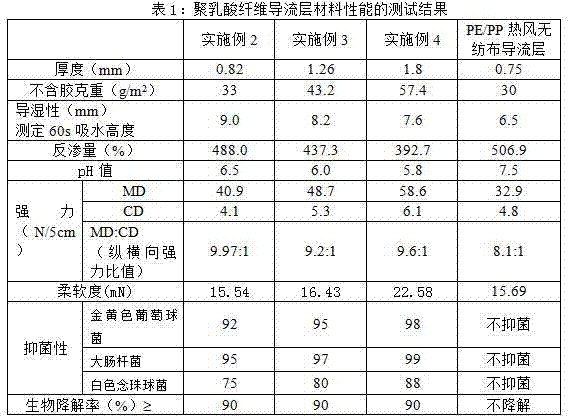

Examples

Embodiment 1

[0040] (1) According to the ratio of 4-8:92-96 of the antistatic agent and water, the antistatic agent solution is prepared, and the antistatic agent solution is used to compare two sizes of 3D×51mm and 6-9D×51-65mm. The two kinds of polylactic acid fibers are sprayed, the spraying amount of the antistatic agent solution is 10-16% of the weight of the two kinds of polylactic acid fibers, and the two kinds of polylactic acid fibers after spraying are stacked for 2-4 hours , So that the moisture regain of the two polylactic acid fibers can reach 8-12%.

[0041] (2) The two polylactic acid fibers are mixed according to the ratio of 20-35:65-80 between the polylactic acid fiber with a specification of 3D×51mm and the polylactic acid fiber with a specification of 6-9D×51-65mm. After the loosening process and the carding process, the gram weight is 33-57.4g / m 2 The opening process adopts three opening processes, and the main process parameters of the opening process are: one opening be...

Embodiment 2

[0056] 1. Selection of fiber raw materials and workshop temperature and humidity

[0057] Two kinds of hydrophilic polylactic acid fibers of different thickness specifications with 3D×51mm, crimp degree of 10 / 25mm and 6D×51mm, and crimp degree of 20 / 25mm are selected respectively. Among them, the two kinds of polylactic acid fibers have hydrophilic oil on the fiber surface The content of the agent is 0.5%, and the workshop temperature during the production of the two polylactic acid fiber guide layer materials is controlled at 25°C and the humidity is 65%.

[0058] 2. Preparation of polylactic acid fiber guide layer material

[0059] 1) Pretreatment of polylactic acid fiber

[0060] First, the antistatic agent solution was prepared according to the ratio of antistatic agent and water of 4:96, and then the antistatic agent solution was used to separately perform two kinds of polylactic acid fibers with specifications of 3D×51mm and 6-9D×51-65mm. Spraying treatment, the spraying amount...

Embodiment 3

[0072] 1. Selection of fiber raw materials and workshop temperature and humidity

[0073] Two kinds of hydrophilic polylactic acid fibers of different thickness specifications with 3D×51mm, crimp degree of 11 / 25mm and 7D×65mm, and crimp degree of 21 / 25mm are selected respectively. Among them, the two kinds of polylactic acid fibers have hydrophilic oil on the fiber surface The agent content is 1.2%, and the workshop temperature is controlled at 26°C and the humidity is 68% when producing the two polylactic acid fiber guide layers.

[0074] 2. Preparation of polylactic acid fiber guide layer material

[0075] 1) Pretreatment of polylactic acid fiber

[0076] First, the antistatic agent solution was prepared according to the ratio of antistatic agent and water of 6:94, and then the antistatic agent solution was used to separately perform two kinds of polylactic acid fibers with specifications of 3D×51mm and 6-9D×51-65mm. Spraying treatment, the spraying amount is 14% of the weight of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com